Published online by Cambridge University Press: 04 March 2019

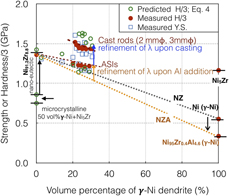

The effect of cooling rate on the microstructure evolution and the mechanical properties of ingots and rods of 2–5 mm diameter of (Ni0.92Zr0.08)100−xAlx (0 ≤ x ≤ 4 at.%) ultrafine eutectic composites have been investigated. The microstructure of the composites is comprised of micrometer size γ-Ni dendrites embedded in a nano/-ultrafine lamellar fcc γ-Ni and Ni5Zr matrix. The evolution of the microstructure at a wide range of cooling rates (10–104 K/s) has been analyzed in respect of volume fraction of the phases, lamellar spacing, and secondary dendritic arm spacing. All these composites exhibit high hardness up to 4.6 GPa and yield strength up to 1.6 GPa with large compressive plasticity up to 22% at room temperature. The effect of cooling rates on the strength and hardness, and the plasticity of the nanolamellar composites with wide range of alloy composition have been correlated.