Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Hajiaboutalebi, Mohammad

Rajabi, Masoud

and

Khanali, Omid

2017.

Physical and mechanical properties of SiC-CNTs nano-composites produced by a rapid microwave process.

Journal of Materials Science: Materials in Electronics,

Vol. 28,

Issue. 12,

p.

8986.

Rahimi Pouyani, Millad

and

Rajabi, Masoud

2019.

Microwave-assisted synthesis of Cu–ZrB2 MM Nano-composite using double pressing double sintering method.

Journal of Materials Science: Materials in Electronics,

Vol. 30,

Issue. 1,

p.

266.

Alem, S.A.A.

Latifi, R.

Angizi, S.

Mohamadbeigi, N.

Rajabi, M.

Ghasali, E.

and

Orooji, Yasin

2020.

Development of Metal Matrix Composites and Nanocomposites Via Double-Pressing Double-Sintering (DPDS) Method.

Materials Today Communications,

Vol. 25,

Issue. ,

p.

101245.

Najafi, Alireza

Rajabi, Masoud

Baghshahi, Saeid

Mohammadi, Vahid

and

Esfahani, Fatemeh Parsi

2021.

Physical properties and microstructural characterization of copper–ZrO2/YSZ nano-composites produced via double-pressing double-sintering method (DPDS).

Journal of Materials Science: Materials in Electronics,

Vol. 32,

Issue. 24,

p.

28307.

Yarahmadi, Akbar

Mohammadian Semnani, Hamidreza

and

Abdoos, Hassan

2022.

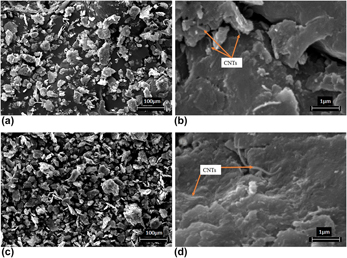

Simultaneous Effects of Carbon Nanotube Content and Diameter Size on Microstructure and Mechanical Properties of Double Pressed Double Sintered Al/Carbon Nanotube Nanocomposites.

Journal of Materials Engineering and Performance,

Vol. 31,

Issue. 9,

p.

7423.

Yarahmadi, Akbar

Mohammadian Semnani, Hamidreza

and

Abdoos, Hassan

2024.

Effect of Re-sintering Temperature and Carbon Nanotube Content on Mechanical Behavior Al-CNTs Nanocomposites.

Journal of Materials Engineering and Performance,

Yarahmadi, Akbar

Mohammadian Semnani, Hamidreza

and

Abdoos, Hassan

2025.

The response of double press double sintered (DPDS) Al/CNT nanocomposites against wear, impact, and bending.

Tribology - Materials, Surfaces & Interfaces,

Vol. 19,

Issue. 1,

p.

70.