Article contents

Dramatically enhanced impact toughness in welded ultra-ferritic stainless steel by additional nitrogen gas in Ar-based shielding gas

Published online by Cambridge University Press: 02 November 2016

Abstract

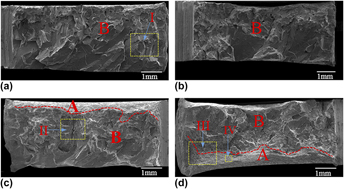

The effect of nitrogen gas addition in Ar-based double-layer shielding gas on the impact toughness of welded ultra-ferritic stainless steel during an autogenous gas tungsten arc welding (GTAW) process was investigated. The nitrogen behavior was proposed. The microstructure, mechanical properties, and fracture surface morphology of the weld metals have been evaluated. More equiaxed crystals, refined grain, narrow HAZ width, and increased microhardness were produced with nitrogen addition. Experimental findings indicated that nitrogen diffused into HAZ and dissolved into weld pool. The solute distribution was changed thus bringing significant constitutional supercooling and decreased temperature gradient of weld pool, which contributed to fine microstructure. Impact toughness at room temperature was enhanced from 2J to 9J (welds), 5J–13J (HAZ). Ductile fracture zone was produced about 0.3–0.5 mm thickness distance from the weld surface. A significant increased impact toughness of weld metal was due to the refinement of microstructure and element addition.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 9

- Cited by