No CrossRef data available.

Article contents

Controlled synthesis of polystyrene-assisted tin-doped indium oxide nanowire networks

Published online by Cambridge University Press: 03 April 2017

Abstract

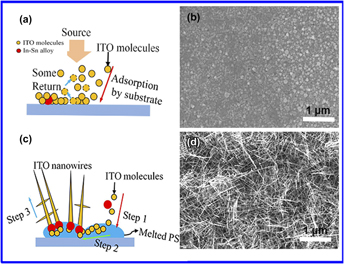

Polystyrene spheres were found to be an effective assisted material in the growth of indium-tin-oxide (ITO) nanowire networks, bearing low temperature, high purity, and good control of size. The temperature and time of growth were studied to achieve ITO nanowire networks with high transmission and low resistivity. When prepared by PS spheres of 670 nm dia. for 15 min at 300 °C, the transmittance is above 90% after the wave length of 400 nm, and the sheet resistance is ∼200 Ω/□. Polystyrene-assisted ITO nanowires showed the high degree of crystallinity with lattice fringes, and well coincided cubic phase of In2O3. The density of ITO nanowire networks were controlled by polystyrene spheres and the residual polystyrene was removed by thermal annealing. ITO nanowire networks open new opportunities for optoelectronic devices needing special morphology for the improvement of light extraction efficiency, and as a new type of conductive film, which have an even broad application arena.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Winston V. Schoenfeld