Published online by Cambridge University Press: 16 July 2019

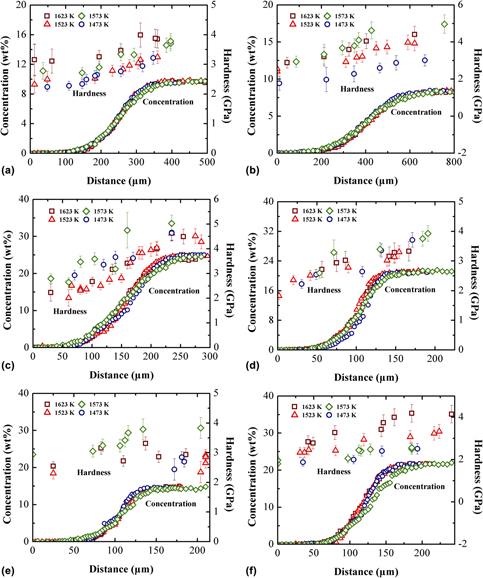

In this paper, the hardness and Young’s moduli along the diffusion paths in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) binary diffusion couples were measured by using the nanoindentation technique. Hardness increases gradually from the pure Ni to the fcc Ni–X alloys, except for the Ni–Os system. While the Young’ moduli in fcc Ni–X alloys scatter much larger and do not show noticeable variation with the addition of element X. After that, the CALPHAD models for description of the composition-dependent hardness and Young’s modulus were proposed, and an in-house code was developed. Based on the present experimental data, the CALPHAD-type descriptions for hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) systems were obtained. The model-predicted hardness and Young’s moduli of composition dependence agree with the experimental data in general. It is anticipated that the presently obtained CALPHAD-type hardness and Young’s modulus descriptions, together with the previous thermodynamic and atomic mobility databases, can be used for the future alloy design of novel Ni-based superalloys.