Published online by Cambridge University Press: 14 December 2015

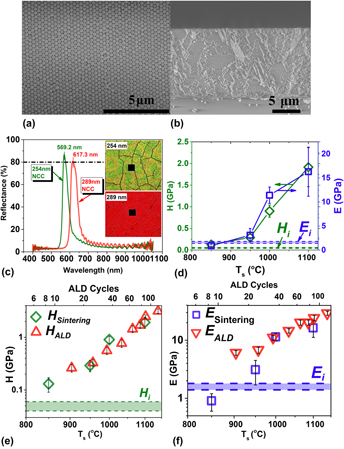

Nanocolloidal crystals (NCCs) have promising applications in optical and photonic devices. However, it is critical to mechanically reinforce NCCs for device reliability, since as-synthesized NCCs are fragile due to weak interparticle bonding. Thermal sintering is currently the most common reinforcement technique; however, this method could induce serious cracking and is not suitable for temperature-sensitive materials. In this study, by characterizing silica NCCs reinforced through sintering and alumina atomic layer deposition (ALD), we find that the ALD treatment is much more effective for hardening, stiffening, and more importantly toughening NCCs. Thermally sintered NCCs are prone to indentation-induced cracking due to large residual tensile stress, significantly impairing the toughness. In contrast, the ALD treatment toughens NCCs by much over 300%. Our finding provides insights for reinforcing and toughening various nanoparticle-based and nanoporous materials.