Published online by Cambridge University Press: 20 August 2020

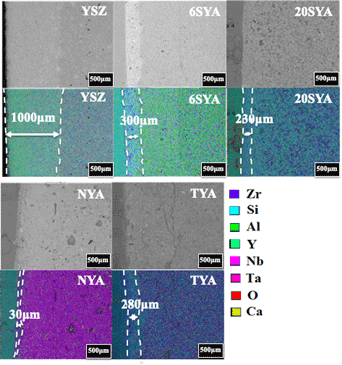

The mitigation of CMAS (calcium–magnesium–aluminum–silicon oxide) infiltration is a major requirement for the stability of thermal barrier coatings. In this study, yttria-stabilized zirconia (YSZ)–Al2O3–SiC, YSZ–Al2O3–Ta2O5, and YSZ–Al2O3–Nb2O5 self-healing composites produced by uniaxially pressing powders were investigated as an alternative to YSZ. CMAS infiltration in these materials was tested at 1250 °C for 10 h. Comparing the depth of CMAS infiltration using scanning electron microscope (SEM) in tandem with electron-dispersive X-ray spectroscopy (EDS), all self-healing materials were found to perform better than the reference materials. While standard YSZ shows massive CMAS infiltration, SEM micrographs and EDS maps revealed a 33-fold improvement in CMAS resistance for the YSZ–Al2O3–Nb2O5 system, which exhibited the best performance among the selected self-repairing materials. X-ray diffraction and high-resolution SEM micrographs taken 10 μm below the surface revealed that CMAS only infiltrated pores in the topmost region of the samples. Both YSZ–Al2O3–Ta2O5 and YSZ–Al2O3–Nb2O5 systems showed no signs of chemical reaction with CMAS.

Contributing Editor: Michael Walock.