Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Liu, Zengqian

Li, Ran

Wang, Gang

Wu, Sujun

Lu, Xuyang

and

Zhang, Tao

2011.

Quasi phase transition model of shear bands in metallic glasses.

Acta Materialia,

Vol. 59,

Issue. 19,

p.

7416.

Zhang, Tao

Yang, Qin

Ji, YunFei

Li, Ran

Pang, ShuJie

Wang, JianFeng

and

Xu, Tao

2011.

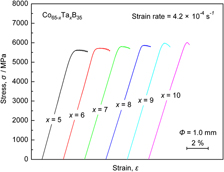

Centimeter-scale-diameter Co-based bulk metallic glasses with fracture strength exceeding 5000 MPa.

Chinese Science Bulletin,

Vol. 56,

Issue. 36,

p.

3972.

Wang, Jianfeng

Li, Ran

Xiao, Ruijuan

Xu, Tao

Li, Yan

Liu, Zengqian

Huang, Lu

Hua, Nengbin

Li, Gong

Li, Yanchun

and

Zhang, Tao

2011.

Compressibility and hardness of Co-based bulk metallic glass: A combined experimental and density functional theory study.

Applied Physics Letters,

Vol. 99,

Issue. 15,

Huang, Yongjiang

Zheng, Wei

He, Fulong

and

Shen, Jun

2012.

The temperature dependent dynamic mechanical response of a ZrCuNiAl bulk metallic glass.

Materials Science and Engineering: A,

Vol. 551,

Issue. ,

p.

100.

Wang, Wei Hua

2012.

The elastic properties, elastic models and elastic perspectives of metallic glasses.

Progress in Materials Science,

Vol. 57,

Issue. 3,

p.

487.

Qiao, J. W.

Zhang, Y.

Jia, H. L.

Yang, H. J.

Liaw, P. K.

and

Xu, B. S.

2012.

Tensile softening of metallic-glass-matrix composites in the supercooled liquid region.

Applied Physics Letters,

Vol. 100,

Issue. 12,

陈, 招娣

2012.

Curved Continuous Casting of Glassy Alloy Sheets.

Material Sciences,

Vol. 02,

Issue. 03,

p.

117.

Zhang, Huiyan

Li, Ran

Ji, Yunfei

Liu, Fanmao

Luo, Qiang

and

Zhang, Tao

2012.

Glass formation, magnetic properties and magnetocaloric effect of ternary Ho–Al–Co bulk metallic glass.

Journal of Magnetism and Magnetic Materials,

Vol. 324,

Issue. 23,

p.

4064.

Dun, Chaochao

Liu, Haishun

and

Shen, Baolong

2012.

Enhancement of plasticity in Co–Nb–B ternary bulk metallic glasses with ultrahigh strength.

Journal of Non-Crystalline Solids,

Vol. 358,

Issue. 23,

p.

3060.

Wang, H.

Hu, T.

Qin, J. Y.

and

Zhang, T.

2012.

Local structure origin of higher glass forming ability in Ta doped Co65B35 amorphous alloy.

Journal of Applied Physics,

Vol. 112,

Issue. 7,

Jiang, M.Q.

Jiang, F.

Keryvin, V.

Meng, J.X.

Sun, J.

and

Dai, L.H.

2012.

Relation between ideal and real strengths of metallic glasses.

Journal of Non-Crystalline Solids,

Vol. 358,

Issue. 23,

p.

3119.

Louzguine-Luzgin, Dmitri

Louzguina-Luzgina, Larissa

and

Churyumov, Alexander

2012.

Mechanical Properties and Deformation Behavior of Bulk Metallic Glasses.

Metals,

Vol. 3,

Issue. 1,

p.

1.

Hui, X.

Lin, D.Y.

Chen, X.H.

Wang, W.Y.

Wang, Y.

Shang, S.L.

and

Liu, Z.K.

2013.

Structural mechanism for ultrahigh-strength Co-based metallic glasses.

Scripta Materialia,

Vol. 68,

Issue. 5,

p.

257.

Zhang, Baoyu

Chen, Xiaohua

and

Hui, Xidong

2013.

Confined fracture behavior of bulk metallic glass-coated tungsten composite wires produced by continuously coating process.

Journal of Alloys and Compounds,

Vol. 553,

Issue. ,

p.

14.

Jia, Haoling

Muntele, Claudiu I.

Huang, Lu

Li, Xia

Li, Gong

Zhang, Tao

He, Wei

and

Liaw, Peter K.

2013.

A study on the surface structures and properties of Ni-free Zr-based bulk metallic glasses after Ar and Ca ion implantation.

Intermetallics,

Vol. 41,

Issue. ,

p.

35.

Zhang, Huiyan

Li, Ran

Xu, Tao

Liu, Fanmao

and

Zhang, Tao

2013.

Near room-temperature magnetocaloric effect in FeMnPBC metallic glasses with tunable Curie temperature.

Journal of Magnetism and Magnetic Materials,

Vol. 347,

Issue. ,

p.

131.

Gong, P.

Wang, X.

Shao, Y.

Chen, N.

Liu, X.

and

Yao, K.F.

2013.

A Ti–Zr–Be–Fe–Cu bulk metallic glass with superior glass-forming ability and high specific strength.

Intermetallics,

Vol. 43,

Issue. ,

p.

177.

Wang, Hui

Hu, Tao

and

Zhang, Tao

2013.

Local structure of Co55Ta10B35 amorphous alloy investigated by ab-initio molecular dynamics.

Science China Physics, Mechanics and Astronomy,

Vol. 56,

Issue. 5,

p.

904.

Zhang, S.G.

2013.

Signature of properties in elastic constants of no-metalloid bulk metallic glasses.

Intermetallics,

Vol. 35,

Issue. ,

p.

1.

Wang, Jianfeng

Huang, Lu

Zhu, Shijie

Li, Qingkui

Guan, Shaokang

and

Zhang, Tao

2013.

Glass-forming ability, fragility parameter, and mechanical properties of Co–Ir–Ta–B amorphous alloys.

Journal of Alloys and Compounds,

Vol. 576,

Issue. ,

p.

375.