Article contents

Characterization of polymer materials using magnetic levitation

Published online by Cambridge University Press: 06 April 2020

Abstract

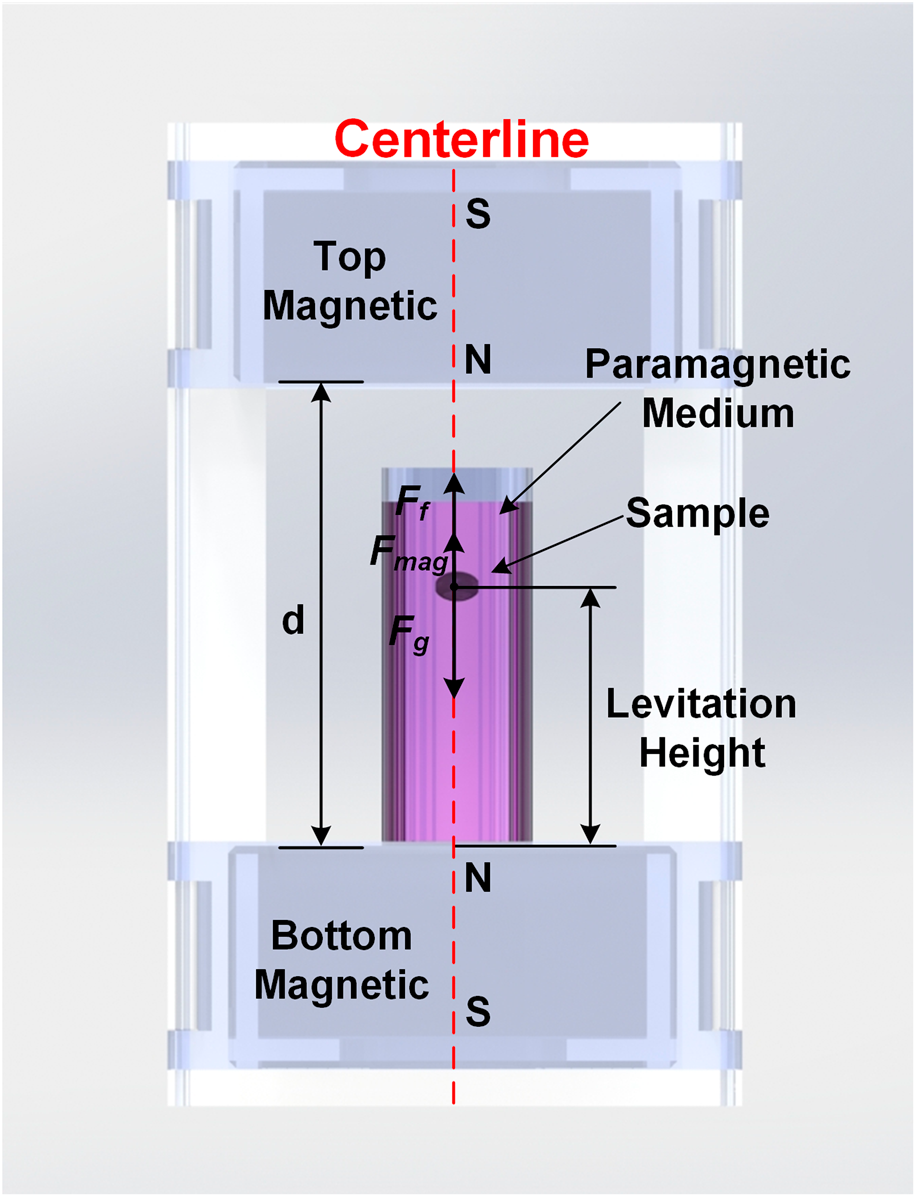

The quality of the polymer raw material used in plastic processing methods is an important characteristic because it is one of the main factors in producing quality products. Therefore, the characterization of polymeric pellets in the polymer processing industry is very important to avoid using inferior materials. In general, differences in the interiors of polymeric pellets reflect differences in their densities. In this study, a high-sensitivity magnetic levitation method was used to characterize the polymeric pellets in four different occasions. The device used has a high sensitivity that can distinguish minute differences as small as of 0.0041 g/cm3 in density between different samples. In addition, the method can obtain a sample's density without knowing the weight and volume of the sample. This method can be used to characterize materials by testing only a single pellet, which is very useful for polymeric pellet characterization.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 8

- Cited by