Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Fé-Perdomo, Iván La

Ramos-Grez, Jorge Andres

Beruvides, Gerardo

and

Mujica, Rafael Alberto

2021.

Selective laser melting: lessons from medical devices industry and other applications.

Rapid Prototyping Journal,

Vol. 27,

Issue. 10,

p.

1801.

Huang, Renkai

Dai, Ning

Pan, ChunRong

Yang, Youwen

Jiang, Xiaotong

Tian, Sukun

and

Zhang, Zhe

2022.

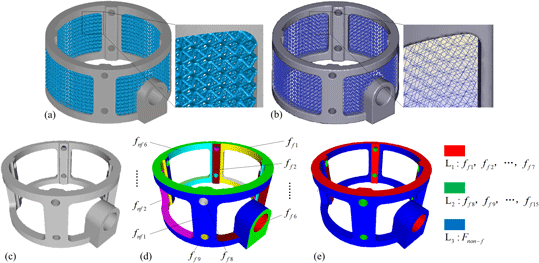

Grid-Tree Composite Support Structures for Lattice Parts in Selective Laser Melting.

SSRN Electronic Journal ,

Mele, Mattia

Campana, Giampaolo

and

Bergmann, André

2022.

Optimisation of part orientation and design of support structures in laser powder bed fusion.

International Journal on Interactive Design and Manufacturing (IJIDeM),

Vol. 16,

Issue. 2,

p.

597.

Huang, Renkai

Dai, Ning

Pan, Chunrong

Yang, Youwen

Jiang, Xiaotong

Tian, Sukun

and

Zhang, Zhe

2023.

Grid-tree composite support structures for lattice parts in selective laser melting.

Materials & Design,

Vol. 225,

Issue. ,

p.

111499.

Morvayova, Alexandra

Fabbiano, Laura

Contuzzi, Nicola

Caiazzo, Fabrizia

and

Casalino, Giuseppe

2023.

On the influence of building position on dimensional accuracy and surface quality of aluminum blocks manufactured by L-PBF.

Optics & Laser Technology,

Vol. 167,

Issue. ,

p.

109830.

Zhao, Hongjian

Yang, Binghua

Zhang, Rui

Tian, Yuxuan

Liu, Changsheng

and

Zhan, Yu

2024.

Study on the residual stress of simple cubic lattice structure produced by selective laser melting.

Journal of Sandwich Structures & Materials,

Vol. 26,

Issue. 7,

p.

1243.

Zou, Qiang

and

Luo, Guoyue

2025.

Geometric Modeling for Microstructure Design and Manufacturing: A Review of Representations and Modeling Algorithms.

Computer-Aided Design,

Vol. 180,

Issue. ,

p.

103834.

Wenger, Sebastian

Shevchenko, Iryna

zur Jacobsmühlen, Joschka

Krüger, Jörg

and

Uhlmann, Eckart

2025.

Learning automatic part orientation for powder bed fusion of metal from part data.

Progress in Additive Manufacturing,

Vol. 10,

Issue. 3,

p.

1713.

Uzun, Fatih

and

Korsunsky, Alexander M.

2025.

Reconstruction of residual stresses in additively manufactured Inconel 718 bridge structures using contour method.

The International Journal of Advanced Manufacturing Technology,