Published online by Cambridge University Press: 27 September 2016

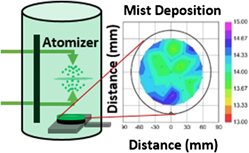

A new lab-based aerosol jet fog (ajFOG) deposition system with an atomizer consisting of two opposing jets located within the deposition chamber is introduced and its capabilities are examined. The unique opposing configuration of the atomizer enables the formation of a highly uniform fog even from low volatility precursors. Aluminum oxide phosphate (AlPO) thin films were deposited onto Si wafers at room temperature and sub-atmospheric pressure by using an aqueous precursor. Films were characterized by spectroscopic ellipsometry, x-ray diffraction and reflectivity, scanning electron microscopy, and metal/oxide/semiconductor (MOS) capacitor electrical measurements. Film thickness uniformity, density, surface roughness, and charge transport mechanisms were found to be comparable to spin-coated thin films deposited using the same precursor, demonstrating the effectiveness of this aerosol technique. A process model was developed to predict film thickness as a function of precursor concentration, exposure time, fog settling time, and number of exposures.

Contributing Editor: Gary L. Messing