Article contents

Thickness effect on fracture behavior of columnar-grained Cu with preferentially oriented nanoscale twins

Published online by Cambridge University Press: 22 August 2017

Abstract

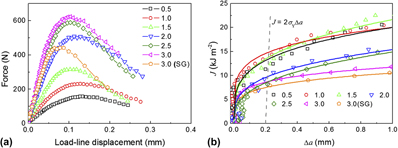

The effect of specimen thickness on fracture toughness and fracture mechanism was investigated in bulk columnar-grained Cu with preferentially oriented nanoscale growth twins. Below a critical specimen thickness of ∼1.0 mm, plane stress state prevailed ahead of the crack tip and the fracture initiation toughness J C decreased with decreasing thickness. Above the critical thickness, J C decreased with increasing thickness until approaching an intrinsic thickness-independent value when the crack front was mainly under plane strain condition. Under plane strain condition, threading dislocations were majorly activated to glide along the nanotwin channels and to produce severe stress concentrations when they piled-up against grain boundaries (GBs). As a result, intergranular cracking mediated the failure of the nanotwinned Cu. On the contrary, under plane stress condition, dislocations slipping-transfer across twin boundaries (TBs) or partial dislocations gliding at TBs were activated to accommodate the plastic deformation. Consequently, stress intensification at GBs was plastically relaxed through enhanced detwinning and shear banding, which suppressed the intergranular fracture and promoted transgranular shear fracture.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 24: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART B , 28 December 2017 , pp. 4554 - 4562

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Yuntian Zhu

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

References

REFERENCES

- 10

- Cited by