Published online by Cambridge University Press: 08 November 2019

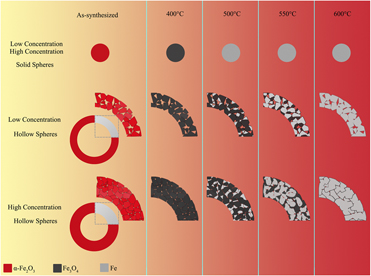

The global market requirement of ultra-fine iron powder (UFIP), with a range size of 0.1–1 μm, is more than 20,000 tons per annum. However, no low-cost nontoxic synthesis route of UFIP is known. In this study, we used the low-cost, rapid, and scalable flame aerosol synthesis (FAS) method to synthesize iron oxide nanoparticles with different size and morphology. Combining with a postreduction heat treatment process, a feasible synthesis route of UFIP which meets the commercial production criteria has been developed. By optimizing the precursor concentration and postreduction heat treatment parameters, the final particle size of UFIP can be controlled. The evolution of the microstructure, phase formation, and magnetic properties during the postreduction heat treatment are systematically investigated, and a feasible reaction model has been established. This work provides an important starting point for the facile commercial synthesis of UFIP and can be readily expanded to other pure metals.