Published online by Cambridge University Press: 12 March 2020

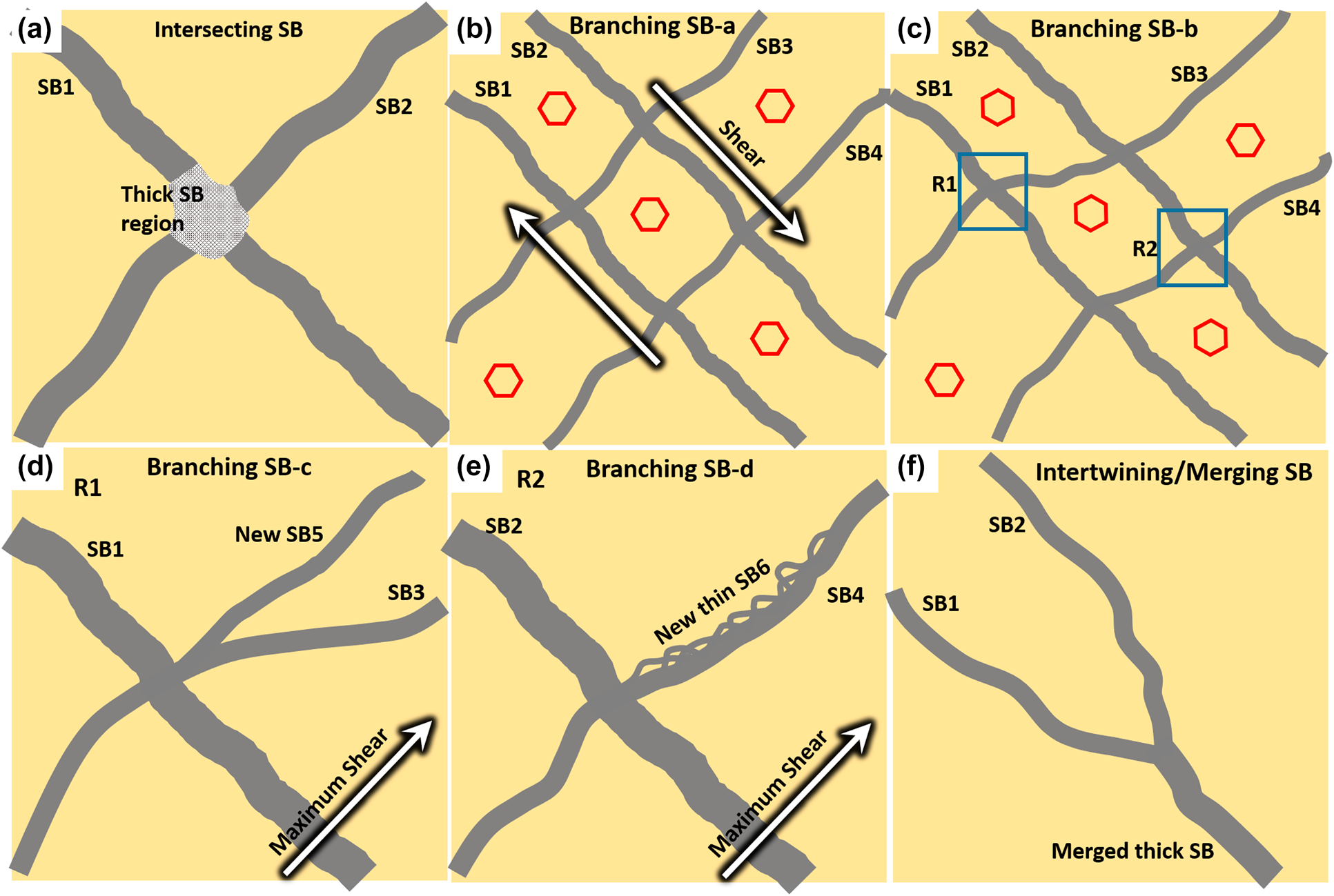

In this study, mechanical properties and microstructural investigation of Ti64 at high strain rate are studied using a split-Hopkinson pressure bar method under compression for temperatures up to 800 °C. Flow softening in the mechanical response of material to such loading conditions hints at instability in compression, which increases with an increase in temperature. Microstructural characterization of the deformed material is characterized using the electron-backscattered diffraction technique. It reveals the presence of instabilities in Ti64 in the form of a fine network of shear bands. The shear band width grows with an increase in temperature along with the area fraction of shear band in the material, displaying its improved capacity to contain microstructural instabilities at higher temperature. After a detailed microstructural investigation, a mechanism for shear band widening is proposed. Based on this mechanism, a path generating nuclei within shear bands is discussed.