No CrossRef data available.

Published online by Cambridge University Press: 20 November 2020

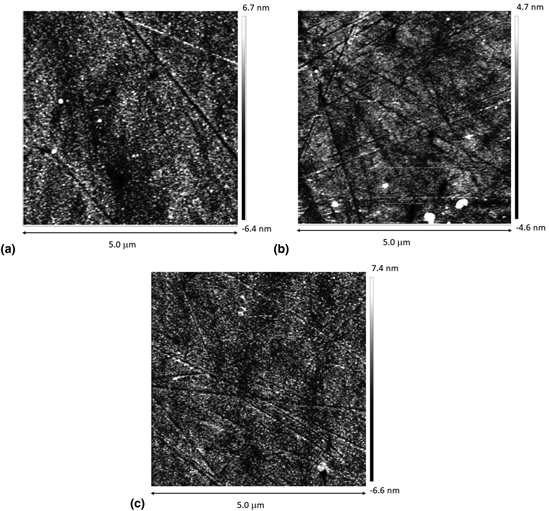

Austenitic stainless steel is used in several industrial branches due to its mechanical and thermal properties, and to its good corrosion resistance. With low cost and biocompatibility, it is used to manufacture prostheses and devices for bone fixation. However, direct contact with body fluids may cause corrosion. Thin films of FeAlCr intermetallic alloy can be used to increase service life of prostheses and avoid replacement surgeries. The aim of this work was to cover the austenitic stainless steel to study the effect of target–substrate distance on the film characteristics. Coatings were performed using the magnetron sputtering technique with the substrate positioned at different distances from the target. The influence on film thickness, morphology, roughness, and adhesion to the substrate was investigated. The thin films of FeAlCr (160 nm thick deposited at 100 mm far from the substrate) were formed by smaller particles (11.2 nm long), densely packed (551,000 particles/mm2), with flat and regular appearance, and greater adherence to the substrate.