Published online by Cambridge University Press: 13 June 2017

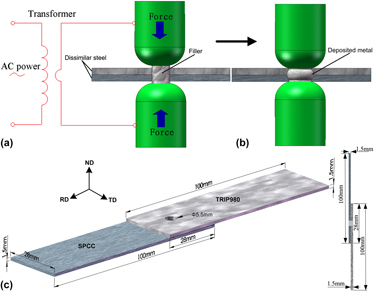

A well-designed hybrid welding process for resistance plug welding (RPW) was conducted based on TRIP980 high-strength steel and SPCC low-carbon steel. The effects of welding current, welding duration time, electrode pressure and filler diameter on the shear tensile failure loading of the joint were systematically investigated and the related optimal welding parameters were accordingly obtained. The microstructure and mechanical properties of the joint were subsequently analyzed. The experimental results indicated that the welding parameters of welding current, filler diameter, and welding duration time and electrode pressure influencing the shear tensile failure loading of the joint are quite vital. This kind of joint possesses a rounded rectangular nugget and transition region. The atomic diffusion results in the firm joint, the metallurgical bonding between filler and base material is realized through the RPW technique.

Contributing Editor: Jürgen Eckert