Published online by Cambridge University Press: 16 April 2015

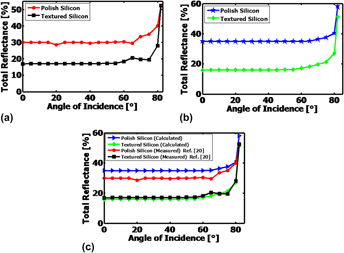

This study presents an analytical model of the reflectance of flat and textured silicon substrates. The model was used to study the reflection behavior of textured silicon surfaces under non-normal incidence. By characterizing the incident light and facets of the silicon wafer with vector geometry, dot products and Phong's reflection model (https://cs.oberlin.edu/∼bob/cs357.08/VectorGeometry/VectorGeometry.pdf) were used to determine the reflection angles between incident light rays and pyramidal facets. The possible optical interactions are considered for a wide range of pyramidal geometries and light incidence angles that are relevant to the exposure of textured silicon surfaces to incident sunlight. Furthermore, the model was used to investigate the possibility of secondary reflection, for the full range of incidence angles to the substrate. The textured silicon surfaces were found to reduce the reflection angles more effectively than flat substrates at lower angles of incidence. Secondary reflection was also found to be experienced or guaranteed, for all pyramid heights, when the angle of incidence to the substrate was less than 19.4°. The predictions are validated with experimental measurements of reflectance from (001)-textured silicon surfaces. The implications of the results are then discussed for the development of micropyramids for improved photoconversion in silicon solar cells.