Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Yan, Jiawei

Li, Wei

Liu, Haiting

and

Shen, Yao

2019.

Reversion of sub-boundaries into dense dislocations in aluminum by electric pulsing treatment.

Scripta Materialia,

Vol. 167,

Issue. ,

p.

86.

Ba, Xin

Zhou, Mengcheng

Zhang, Xinfang

and

Wang, Hui

2020.

Manipulating Dislocations Using Electric Field to Repair Embrittlement Damage.

ISIJ International,

Vol. 60,

Issue. 8,

p.

1803.

Orallo, Ana

Trinidad, Javier

Galdos, Lander

de Argandoña, Eneko Sáenz

and

Mendiguren, Joseba

2020.

Aluminum Springback Reduction by Post-forming Electric Pulses.

Procedia Manufacturing,

Vol. 47,

Issue. ,

p.

1387.

Yan, Jiawei

Liu, Guisen

Zhao, Xiaofeng

and

Shen, Yao

2021.

Rapid homogeneous precipitation of nano-sized Si in Al–1%Si alloy by electric pulses.

Materials Science and Technology,

Vol. 37,

Issue. 2,

p.

144.

Jiang, Bo

Zhang, Dongdong

Xu, Hong

Liu, Yongbing

Cao, Zhanyi

and

Yang, Xiaohong

2021.

Excellent Ductility in the Extruded AZ61 Magnesium Alloy Tube Induced by Electropulsing Treatment during Tension.

Metals,

Vol. 11,

Issue. 5,

p.

813.

Xu, Hong

Zou, Yu-Jie

Huang, Yu

Ma, Pin-Kui

Guo, Zhi-Peng

Zhou, You

and

Wang, Yu-Peng

2021.

Enhanced Electroplasticity through Room-Temperature Dynamic Recrystallization in a Mg-3Al-1Sn-1Zn Alloy.

Materials,

Vol. 14,

Issue. 13,

p.

3739.

Zhao, Shiteng

Zhang, Ruopeng

Chong, Yan

Li, Xiaoqing

Abu-Odeh, Anas

Rothchild, Eric

Chrzan, Daryl C.

Asta, Mark

Morris, J. W.

and

Minor, Andrew M.

2021.

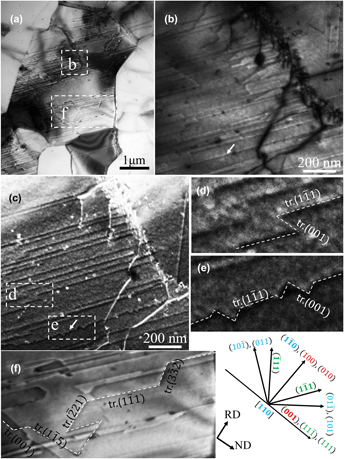

Defect reconfiguration in a Ti–Al alloy via electroplasticity.

Nature Materials,

Vol. 20,

Issue. 4,

p.

468.

Liu, Wenqi

Otegi, Nagore

Orallo, Ana

Barrenetxea, Manex

Aizpuru, Iosu

Lian, Junhe

and

Mendiguren, Joseba

2022.

Post-forming, electro-plastic effect internal stress reduction in AA5754 aluminium alloy.

Materials Science and Engineering: A,

Vol. 852,

Issue. ,

p.

143686.

Jeong, Kyeongjae

Jin, Sung-Woo

Kang, Sung-Gyu

Park, Ju-Won

Jeong, Hye-Jin

Hong, Sung-Tae

Cho, Seung Hyun

Kim, Moon-Jo

and

Han, Heung Nam

2022.

Athermally enhanced recrystallization kinetics of ultra-low carbon steel via electric current treatment.

Acta Materialia,

Vol. 232,

Issue. ,

p.

117925.

He, Guangyu

Liu, Zhiyi

and

Liu, Fei

2022.

Effects of dislocation slip behaviour and second-phase particles on hot rolled texture of an Al-Cu-Mg alloy with a high Cu/Mg ratio.

Journal of Alloys and Compounds,

Vol. 911,

Issue. ,

p.

165085.

Deng, Zhike

Li, Xiaopei

Wang, Shengzhan

Li, Xiaohui

Chen, Dexin

and

Xiao, Xiufeng

2022.

Texture tailoring of a cold-rolled Mg-Zn-Gd alloy by electropulse treatment: The effect of electropulse and Gd element.

Materials Characterization,

Vol. 190,

Issue. ,

p.

112046.

Zhou, Yicheng

Yang, Bing

and

Zhang, Guodong

2022.

Microstructure and Mechanical Properties of Cocrfemnni/Wc Plasma Deposited Layer after the Synergistic Treatment of Pulsed Current and Joule Heat.

SSRN Electronic Journal ,

Liu, Fei

Liu, Zhiyi

and

He, Guangyu

2022.

Effect of cold rolling on microstructure and hardness of annealed Al–Cu–Mg alloy.

Archives of Civil and Mechanical Engineering,

Vol. 22,

Issue. 2,

Chen, Wanji

Xu, Jie

Ding, Chaogang

Shan, Debin

Guo, Bin

and

Langdon, T.G.

2022.

Fracture Mechanism of Electrically-Assisted Micro-Tension in Nanostructured Titanium Using Synchrotron Radiation X-Ray Tomography.

SSRN Electronic Journal ,

Chen, Wanji

Xu, Jie

Ding, Chaogang

Shan, Debin

Guo, Bin

and

Langdon, Terence G.

2023.

Fracture mechanism of electrically-assisted micro-tension in nanostructured titanium using synchrotron radiation X-ray tomography.

Scripta Materialia,

Vol. 222,

Issue. ,

p.

114997.

Wang, Kuizhao

Zhang, Cunsheng

Cheng, Zinan

Meng, Zijie

Chen, Liang

and

Zhao, Guoqun

2023.

Deformation mechanism of as-extruded Al–Cu–Li alloy with heterogeneous fiber structure.

Materials & Design,

Vol. 229,

Issue. ,

p.

111872.

Song, Yanli

Wu, Yuhang

Lu, Jue

Mei, Manlin

Xie, Lechun

and

Hao, Chuanchuan

2023.

Promoting Dynamic Recrystallization of Al-Zn-Mg-Cu Alloy via Electroshock Treatment.

Metals,

Vol. 13,

Issue. 5,

p.

944.

Xue, Ling

Jiang, Junda

Yang, Yi

Xu, Gaolei

Liao, Chengzhi

Liu, Jian

and

Wu, Mingxia

2023.

An eco-friendly electric pulse treatment process for improving the microstructure and properties of cold-rolled pure copper sheet.

Materials Research Express,

Vol. 10,

Issue. 6,

p.

066513.

Wang, Xiang

Zhou, Baoxue

Huang, Hua

Niu, Jialin

Guan, Shaokang

and

Yuan, Guangyin

2024.

Extraordinary ductility enhancement of Mg-Nd-Zn-Zr alloy achieved by electropulsing treatment.

Journal of Magnesium and Alloys,

Vol. 12,

Issue. 11,

p.

4481.

Kim, Moon-Jo

Bui-Thi, Tu-Anh

Kang, Sung-Gyu

Hong, Sung-Tae

and

Nam Han, Heung

2024.

Electric current-induced phenomena in metallic materials.

Current Opinion in Solid State and Materials Science,

Vol. 32,

Issue. ,

p.

101190.