Published online by Cambridge University Press: 04 August 2020

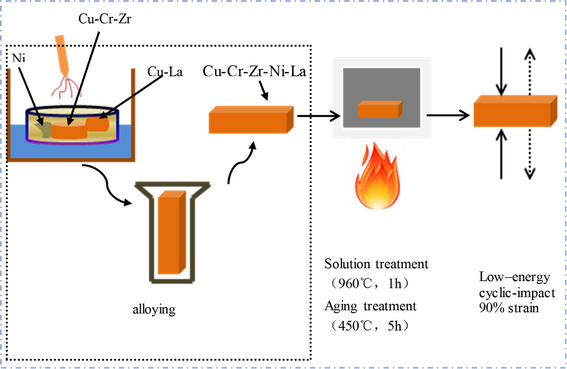

In this paper, CuCr–Zr alloys prepared by vacuum melting with adding La and Ni elementswere heat-treated and aged, followed by plastic deformation using low-energy cyclic impact tests, to simultaneously improve their mechanical and electrical properties. Results showed that the grain size of the casted Cu–Cr–Zr alloys was significantly reduced after the solid-solution aging and plastic deformation process. There were a lot of dispersed Cr and Cu5Zr precipitates formed in the alloys, and the numbers of dislocations were significantly increased. Accordingly, the hardness was increased from 78 to 232 HV, and the tensile strength was increased from 225 to 691 MPa. Electrical conductivity has not been significantly affected after these processes. The enhancement of overall performance is mainly attributed to the combined effects of solid-solution hardening, fine grain hardening, and precipitation/dislocation strengthening.