Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Bibhanshu, Nitish

Shankar, Gyan

and

Suwas, Satyam

2021.

Hot deformation and softening response in boronmodified two‐phase titanium aluminide Ti–48Al–2V–0.2B.

Journal of Materials Research,

Vol. 36,

Issue. 1,

p.

311.

Bibhanshu, Nitish

Shankar, Gyan

and

Suwas, Satyam

2021.

Hot deformation and softening response in boronmodified two‐phase titanium aluminide Ti–48Al–2V–0.2B.

Journal of Materials Research,

Vol. 36,

Issue. 1,

p.

311.

Bibhanshu, Nitish

Gussev, Maxim N.

and

Rosseel, Thomas M.

2021.

Complexity of deformation mechanism in neutron-irradiated 304L austenitic stainless steel at microstructural scale.

Materials Characterization,

Vol. 178,

Issue. ,

p.

111218.

Bibhanshu, Nitish

Gussev, Maxim N.

and

Rosseel, Thomas M.

2021.

Quantification of in-grain lattice gradient in neutron irradiated 304L SS during deformation using insitu EBSD.

Microscopy and Microanalysis,

Vol. 27,

Issue. S1,

p.

3366.

Bibhanshu, Nitish

Gussev, Maxim N.

Massey, Caleb P.

and

Field, Kevin G.

2022.

Investigation of deformation mechanisms in an advanced FeCrAl alloy using in-situ SEM-EBSD testing.

Materials Science and Engineering: A,

Vol. 832,

Issue. ,

p.

142373.

Lin, Xuejian

Huang, Hongjun

Yuan, Xiaoguang

Wang, Yinxiao

Zheng, Bowen

Zuo, Xiaojiao

and

Zhou, Ge

2022.

Study on microstructure evolution and deformation softening mechanism of a Ti–47.5Al–2.5V–1.0Cr–0.2Zr alloy.

Materials Science and Technology,

Vol. 38,

Issue. 18,

p.

1667.

Mandal, Mantosh

Aashranth, B.

Samantaray, Dipti

Davinci, M. Arvinth

Shankar, Vani

and

Vasudevan, M.

2023.

Microstructural manifestation and kinetics of dynamic transformation in a W-modified 9%Cr steel.

Materials Science and Technology,

Vol. 39,

Issue. 7,

p.

865.

Ghosh, Sumit

Bibhanshu, Nitish

Suwas, Satyam

and

Chatterjee, Kaushik

2023.

Micro-mechanisms underlying enhanced fatigue life of additively manufactured 316L stainless steel with a gradient heterogeneous microstructure.

Materials Science and Engineering: A,

Vol. 886,

Issue. ,

p.

145665.

Liu, X.

Song, L.

Stark, A.

Pyczak, F.

and

Zhang, T.B.

2023.

In-situ synchrotron high energy X-ray diffraction study on the internal strain evolution of D019-α2 phase during high-temperature compression and subsequent annealing in a TiAl alloy.

Journal of Materials Science & Technology,

Vol. 163,

Issue. ,

p.

212.

Zhang, Jin

Yang, Dian

Xiong, Wei

Shi, Dongfeng

Lei, Chenqi

Jiang, Zhen

and

Wang, Guoqing

2024.

Slip Activity and Precipitation Behaviors of Al-Cu-Li Alloy During High Temperature Tensile Deformation.

Metals and Materials International,

Tabassum, Aasma

Zhiqiang, Ren

Goel, Sunkulp

Hayat, Fateh

Muhammad, Amir

Hussain, Ahmad

Sardar, Maryam

Ullah, Zaka

Liu, Ying

and

Tao, Wang Jing

2024.

A systematic and precise study of deformed Zr52.5Cu17.9Ni14.6Al10Ti5 BMGs for notable shear bands towards better global plasticity.

Journal of Non-Crystalline Solids,

Vol. 635,

Issue. ,

p.

123009.

Yu, Yonghao

Kou, Hongchao

Zhang, Zilong

Xu, Xiaoxuan

Wang, Yarong

and

Li, Jinshan

2024.

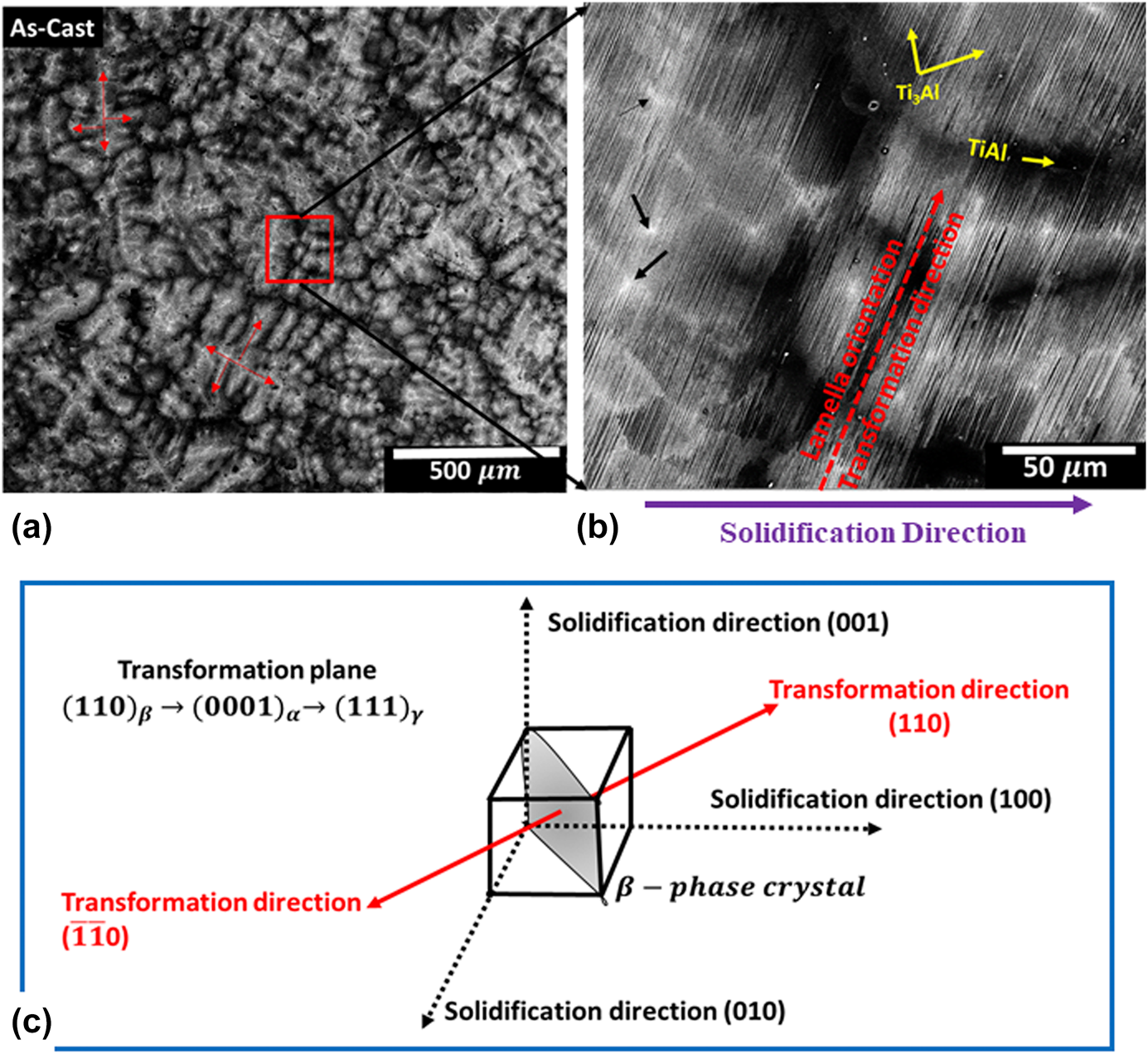

Deformation behavior of core–shell-like structure in β-solidified TiAl alloy during isothermal compression.

Materials Letters,

Vol. 357,

Issue. ,

p.

135637.