Published online by Cambridge University Press: 14 May 2019

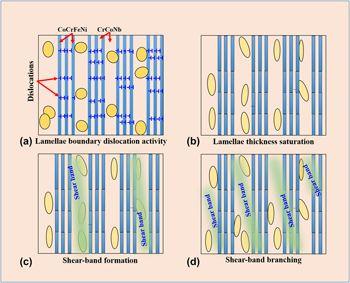

High-entropy composites (HECs) were subjected to severe straining by high-pressure torsion (HPT) to evaluate their influence on the evolution of microstructure and deformation behavior. Severe straining leads to a homogeneously strained microstructure and inhomogeneous micro-shear bands in these HECs. Nb addition in HECs varies the microstructure from single phase to eutectic, and the Vickers microhardness in HPT HECs increases to 7.45 GPa. Nb addition up to x = 0.80 in as-cast HECs improves the strength of these materials at the expense of its plasticity. Nevertheless, severe straining provides a better combination of strength and ductility without sacrificing its plasticity. Such improvement in properties is attributed to the evolved microstructural features, formation of “transformation-shear bands (T-SBs)” and “deformation-shear bands (D-SBs)” at severe straining. This assures the homogeneous deformation by shear banding and suggests that shear banding is the dominant deformation mechanism when the lamellar spacing becomes saturated upon severe straining.

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.