No CrossRef data available.

Article contents

A low-cost processing of CuIn(SexS1−x)2 films: Using sulfides nanoparticle precursors

Published online by Cambridge University Press: 05 December 2012

Abstract

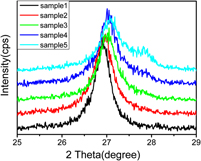

Most CuIn(SexS1−x)2 (CISS) thin films are deposited via conventional two-stage process. However, a significant problem related to the conventional two-stage process is the separation of CuInSe2 and CuInS2 phases. In this article, single-phase CISS thin films have been successfully prepared by selenizing sulfides of copper and indium. The mixed sulfides of Cu–In precursors were synthesized by coprecipitation method and then partly reduced. The inks containing partly reduced powders and organic binders were deposited onto glass substrate using a spin-coating technique. After coating, the precursor films were selenized to get CISS. X-ray diffraction and energy dispersive x-ray spectroscopy data show that the single (112) peak position changed with the variation of Se/S ratio. The absorption energy Egchanges linearly with Se/(Se + S) calculated by ultraviolet–vis absorption spectra. Those results confirm the formation of single-phase CISS with homogenous composition.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2012