Published online by Cambridge University Press: 05 January 2017

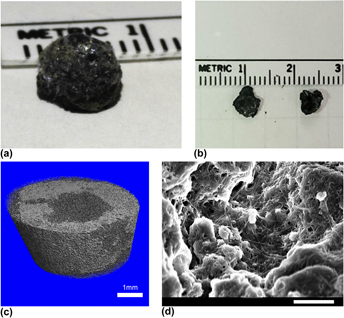

Two- and three-dimensional assemblies of carbon nanomaterials such as carbon nanotubes and graphene are necessary to harness their remarkable physicochemical properties in many clean energy, electronics, and biomedical applications. Herein we report a facile, economical, and versatile method for layer-by-layer fabrication of chemically-crosslinked carbon nanomaterial assemblies by ultrasonic spray coating combined with radical-initiated crosslinking reaction. The chemical, surface, and mechanical properties of the carbon nanomaterial coatings were characterized by Raman spectroscopy, atomic force microscopy, scanning- and transmission-electron microscopy, and nano-dynamic mechanical analysis. Our results indicate that the macroscopic 2D assemblies of crosslinked carbon nanotubes or graphene nanoparticles have surface uniformity, are chemically-crosslinked, and are mechanically robust. We further provide proof-of-concept demonstration of fabricating free-standing, porous, 3D single-walled carbon nanotube structures. Taken together, the results opens avenues toward adapting our method to enable 3D printing or additive manufacturing of all-carbon nanomaterial structures.