Article contents

Investigations on hot deformation behaviors and abnormal variation mechanisms of flow stress at elevated temperature for X45CrSi93 valve steel

Published online by Cambridge University Press: 04 May 2015

Abstract

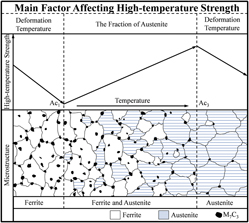

The hot deformation behavior of X45CrSi93 valve steel was investigated by a series of compression and tensile tests by means of the Gleeble-1500 simulator and microstructural analyses. The experimental results show that the flow stress decreases with the increasing temperature between 850 and 900 °C followed by an abnormal increase with the increasing temperature between 900 and 1000 °C under the compressive conditions. A normal decrease of the flow stress is continued with the increasing temperature above 1000 °C. Meantime, the tensile specimen conducted at 1000 °C shows double necking effect. Further microstructural analyses show that the phase transition from α-ferrite to austenite and the solution strengthening caused by carbide dissolution are the main reasons for abnormal variation of flow stress for X45CrSi93. The negative temperature gradient in the tensile specimen results in the symmetrical microstructure and then the double necking phenomenon.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 3

- Cited by