Published online by Cambridge University Press: 11 February 2019

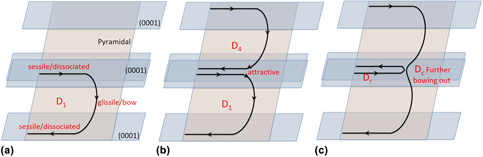

Recent molecular dynamics simulations revealed that 〈c + a〉 dislocations in Mg were prone to dissociation on the basal plane, thus becoming sessile. Basal dissociation of 〈c + a〉 dislocations is significant because it is a major factor in the limited ductility and high work-hardening in Mg. We report an in situ transmission electron microscopy study of the deformation process using an H-bar-shaped thin foil of Mg single crystal designed to facilitate 〈c + a〉 slip, observe 〈c + a〉 dislocation activity, and establish the validity of the largely immobile 〈c + a〉 dislocations caused by the predicted basal dissociation. In addition, through detailed observations on the fine movement of some 〈c + a〉 dislocations, it was revealed that limited bowing out movement for some non-basal portions of 〈c + a〉 dislocations was possible; under certain circumstances, i.e., through attraction and reaction between two 〈c + a〉 dislocations on the same pyramidal plane, at least portions of the sessile configuration were observed to be reversed into a glissile one.

Now at Pacific Northwest National Laboratory.

Now at Materials & Structural Analysis, Thermo Fisher Scientific, Hillsboro, OR, 97124.