Article contents

Impurity stabilization of nanocrystalline grains in pulsed laser deposited tantalum

Published online by Cambridge University Press: 13 March 2017

Abstract

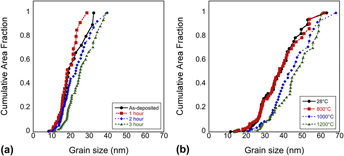

Thermal stability of pulsed laser deposited (PLD) nanocrystalline tantalum was explored through in situ transmission electron microscopy (TEM) annealing over the temperature range of 800–1200 °C. The evolution of the nanostructure was characterized using grain size distributions collectively with electron diffraction analysis and electron energy loss spectroscopy (EELS). Grain growth dynamics were further explored through molecular dynamics (MD) simulations of columnar tantalum nanostructures. The as-deposited grain size of 32 nm increased by only 18% at 1200 °C, i.e., 40% the melting point of tantalum, conflicting with the MD simulations that demonstrated extensive grain coalescence above 1000 °C. Furthermore, the grain size remained stable through the reversible α-to-β phase transition near 800 °C, which is often accompanied by grain growth in nanostructured tantalum. The EELS analysis confirmed the presence of oxygen impurities in the as-deposited films, indicating that impurity stabilization of grain boundaries was responsible for the exceptional thermal stability of PLD nanocrystalline tantalum.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 8

- Cited by