Published online by Cambridge University Press: 08 July 2020

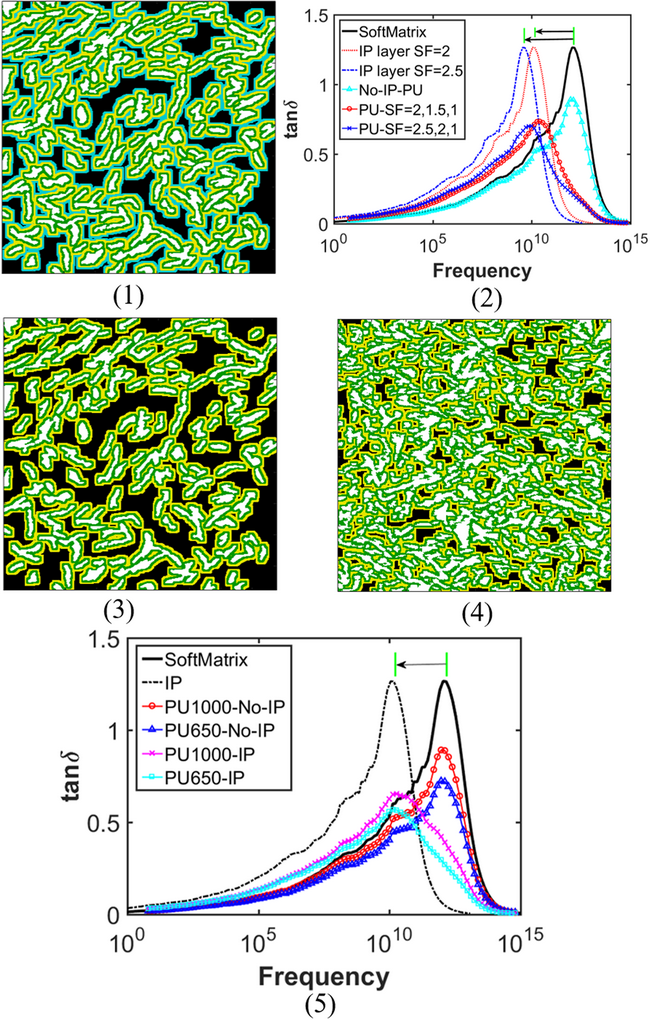

In this paper, we use finite element analysis (FEA) to study the linear viscoelastic response of polyurea, a type of hard–soft block copolymer. A Niblack's algorithm-based technique employed on atomic force microscopy images provides geometry inputs for the FEA model, while the viscoelastic master curves of the soft matrix are obtained via a combination of dynamic mechanical analysis data and molecular dynamic (MD) estimations. In this microstructural image-based FEA framework, we introduce an interphase area of altered properties between the hard and soft domains. Both spatial and property distributions of this interphase area affect the viscoelastic response of the copolymer system. To quantitatively investigate the impact of structural and property features of the interphase on the energy storage and dissipation of a system during linear perturbation, we develop a statistical descriptor representation of the interphase region related to physical parameters. Utilizing decision-tree and random forest concepts from machine learning, we apply a ranking algorithm to identify the most significant features for four different mechanical response descriptors. Results show that the total interphase volume fraction and shifting factor distributions in the interphase area dominate the magnitude of the tan δ peak, whereas the magnitudes of the shifting factors primarily affect the tan δ peak location in frequency space. This method allows us to readily identify the dominant features impacting individual properties and paves the way for material design of hard–soft block copolymer systems.