Article contents

Hardening and crystallization in monatomic metallic glass during elastic cycling

Published online by Cambridge University Press: 19 May 2015

Abstract

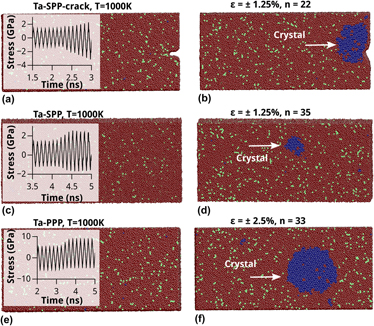

While conventional metallic glass (MG) is usually an alloy that contains at least two types of different elements, monatomic metallic glass (MMG) in body-centered cubic metals has recently been vitrified experimentally through ultrafast quenching. In this research, MMG in Ta was vitrified by molecular dynamics simulations and used as a model system to explore the atomistic mechanism of hardening in MG under cyclic loading well below the yield point. It was found that significant structural ordering was caused during the elastic cycling without accumulating apparent plastic strain, which ultimately led to the crystallization of MG that has been long conjectured but rarely directly proved before. It was also revealed that tensile stresses were more likely to induce structural ordering and crystallization in MG than compressive stresses.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

Footnotes

Contributing Editor: Franz Faupel

References

REFERENCES

- 8

- Cited by