Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Mirzaali, Mohammad J.

Azarniya, Abolfazl

Sovizi, Saeed

Zhou, Jie

and

Zadpoor, Amir A.

2021.

Fundamentals of Laser Powder Bed Fusion of Metals.

p.

423.

Ossola, Enrico

Shapiro, Andrew A

Pate, Andre

Firdosy, Samad

Brusa, Eugenio

and

Sesana, Raffaella

2021.

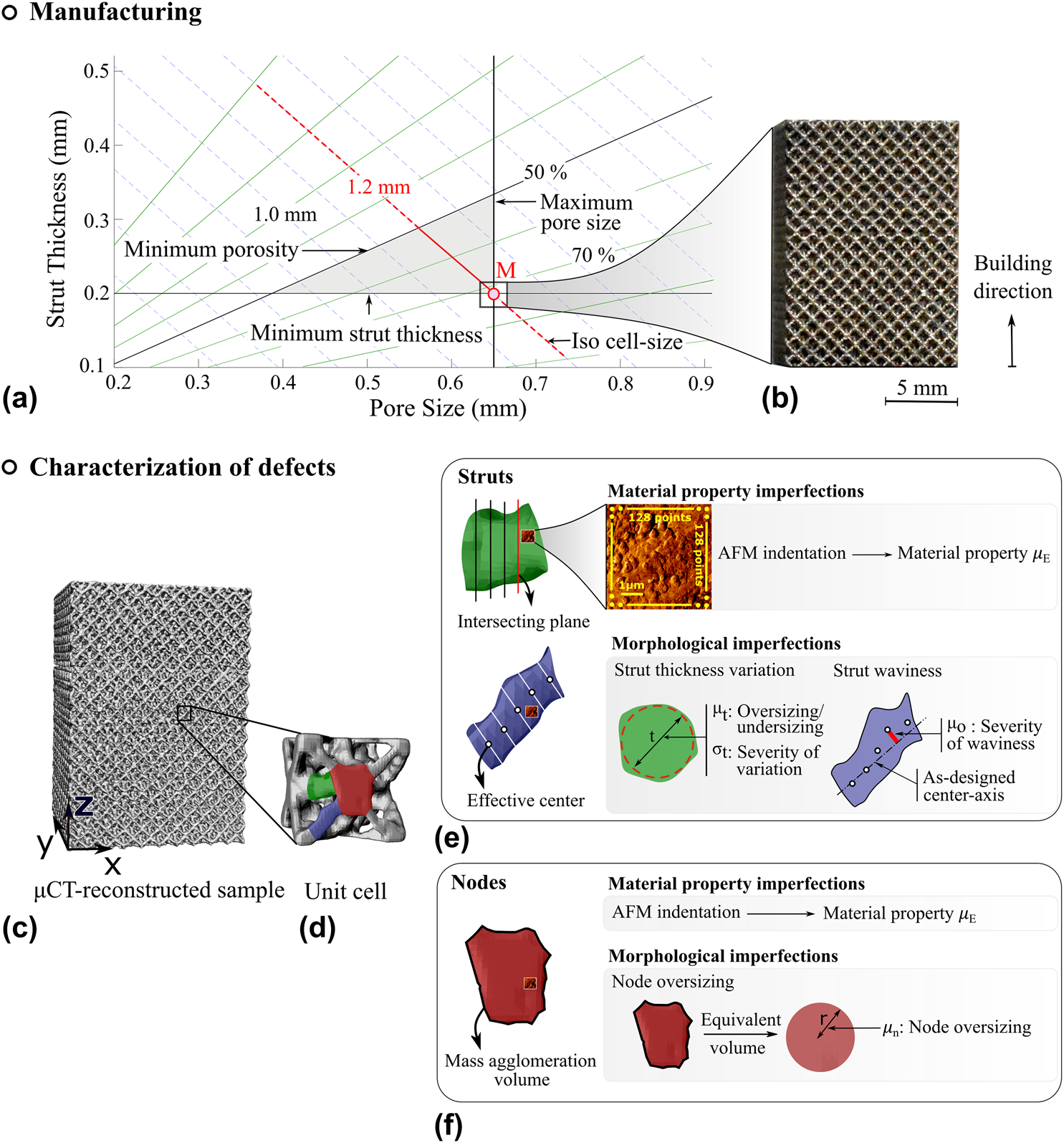

Fabrication defects and limitations of AlSi10Mg lattice structures manufactured by selective laser melting.

Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications,

Vol. 235,

Issue. 9,

p.

2071.

Hsieh, Meng-Ting

Ha, Chan Soo

Xu, Zhenpeng

Kim, Seokpum

Wu, H. Felix

Kunc, Vlastimil

and

Zheng, Xiaoyu

2021.

Stiff and strong, lightweight bi-material sandwich plate-lattices with enhanced energy absorption.

Journal of Materials Research,

Vol. 36,

Issue. 18,

p.

3628.

Li, Xiuhui

Ghasri-Khouzani, Morteza

Bogno, Abdoul-Aziz

Liu, Jing

Henein, Hani

Chen, Zengtao

and

Qureshi, Ahmed Jawad

2021.

Investigation of Compressive and Tensile Behavior of Stainless Steel/Dissolvable Aluminum Bimetallic Composites by Finite Element Modeling and Digital Image Correlation.

Materials,

Vol. 14,

Issue. 13,

p.

3654.

Szeto, Wing Hong

Wong, Francis Seung-Yin

Yau, Edmond Wing Fung

Mak, Sze Yi

and

Chuah, Kong Bieng

2021.

Kinematic Modelling of a Tri Robot Machining Cell.

p.

61.

Echeta, Ifeanyichukwu

Dutton, Ben

Leach, Richard K.

and

Piano, Samanta

2021.

Finite element modelling of defects in additively manufactured strut-based lattice structures.

Additive Manufacturing,

Vol. 47,

Issue. ,

p.

102301.

Davoodi, Elham

Montazerian, Hossein

Mirhakimi, Anooshe Sadat

Zhianmanesh, Masoud

Ibhadode, Osezua

Shahabad, Shahriar Imani

Esmaeilizadeh, Reza

Sarikhani, Einollah

Toorandaz, Sahar

Sarabi, Shima A.

Nasiri, Rohollah

Zhu, Yangzhi

Kadkhodapour, Javad

Li, Bingbing

Khademhosseini, Ali

and

Toyserkani, Ehsan

2022.

Additively manufactured metallic biomaterials.

Bioactive Materials,

Vol. 15,

Issue. ,

p.

214.

Neils, Andrew

Dong, Liang

and

Wadley, Haydn

2022.

The small-scale limits of electron beam melt additive manufactured Ti–6Al–4V octet-truss lattices.

AIP Advances,

Vol. 12,

Issue. 9,

Mostahsan, Amirhossein Jabbari

and

Farahmand, Farzam

2022.

Influence of cleaning process on mechanical properties and surface characteristics of selective laser melted Ti6Al4V parts prepared for medical implant applications.

Journal of Materials Research,

Vol. 37,

Issue. 16,

p.

2546.

Roth, Antonina

Ganzenmüller, Georg

Gutmann, Florian

Jakkula, Puneeth

Hild, François

Pfaff, Aron

Yin, Kaiyang

Eberl, Chris

and

Hiermaier, Stefan

2022.

2D Numerical Simulation of Auxetic Metamaterials Based on Force and Deformation Consistency.

Materials,

Vol. 15,

Issue. 13,

p.

4490.

Xue, Haowen

Bai, Haotian

Zhou, Rongqi

Wang, Jincheng

Zhou, Bin

Wang, Xiaonan

Luo, Wenbin

and

Zhao, Xin

2022.

Novel Design of the Compound Sleeve and Stem Prosthesis for Treatment of Proximal Femur Bone Defects Based on Topology Optimization.

Frontiers in Bioengineering and Biotechnology,

Vol. 10,

Issue. ,

Rahmat, N.

Kadkhodapour, J.

and

Arbabtafti, M.

2023.

Mechanical Characterization of Additively Manufactured Orthopedic Cellular Implants: Case Study on Different Cell Types and Effect of Defects.

Physical Mesomechanics,

Vol. 26,

Issue. 4,

p.

443.

Rezapourian, Mansoureh

Jasiuk, Iwona

Saarna, Mart

and

Hussainova, Irina

2023.

Selective laser melted Ti6Al4V split-P TPMS lattices for bone tissue engineering.

International Journal of Mechanical Sciences,

Vol. 251,

Issue. ,

p.

108353.

Iantaffi, Caterina

Bele, Eral

McArthur, David

Lee, Peter D.

and

Leung, Chu Lun Alex

2023.

Auxetic response of additive manufactured cubic chiral lattices at large plastic strains.

Materials & Design,

Vol. 233,

Issue. ,

p.

112207.

Montanari, Matteo

Brighenti, Roberto

and

Spagnoli, Andrea

2023.

Defect sensitivity mitigation in the compressive mechanical response of two-phase lattice metamaterials.

Composite Structures,

Vol. 323,

Issue. ,

p.

117501.

Mirzaali, M.J.

Shahriari, Nasim

Zhou, J.

and

Zadpoor, A.A.

2023.

Quality Analysis of Additively Manufactured Metals.

p.

689.

Zhang, Kevin

Hickey, Jean-Pierre

and

Vlasea, Mihaela

2023.

An Analysis Framework of Additively Manufactured Deterministic Porous Structures for Transpiration Cooling.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 20,

p.

9253.

O’Keeffe, C.

Taylor, D.

Lally, C.

and

Kelly, D.J.

2023.

Morphological induced improvements in the bulk mechanical properties of chemically etched additively manufactured Ti-6Al-4V micro-struts.

Additive Manufacturing,

Vol. 75,

Issue. ,

p.

103748.

Vyavahare, Swapnil

Mahesh, Vinyas

Mahesh, Vishwas

and

Harursampath, Dineshkumar

2023.

Additively manufactured meta-biomaterials: A state-of-the-art review.

Composite Structures,

Vol. 305,

Issue. ,

p.

116491.

Xu, Zhi

Li, Yuwan

Huang, Weijun

Wang, Ziru

Xu, Xing

and

Tian, Shoujin

2023.

Preliminary exploration of the biomechanical properties of three novel cervical porous fusion cages using a finite element study.

BMC Musculoskeletal Disorders,

Vol. 24,

Issue. 1,