Article contents

Effect of the pouring temperature by novel synchronous rolling-casting for metal on microstructure and properties of ZLl04 alloy

Published online by Cambridge University Press: 01 July 2016

Abstract

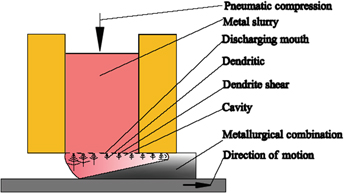

A novel synchronous rolling-casting for metal (SRCM) process for producing metal components is developed. In this paper, the microstructure evolution and mechanical property of ZLl04 alloy with different pouring temperatures by SRCM are investigated. In the process, the pouring temperature has great effects on the microstructure and mechanical property primarily through the crystal change in the rolling-casting area. Temperature of liquids and solids of ZL104 alloy is measured by differential scanning calorimetry. Distribution and characteristics of the microstructure of samples are examined by optical microscopy, scanning electron microscopy equipped with energy dispersive spectrometer. The results show that the samples fabricated by SRCM present uniform structure and good performance with the pouring temperature at 620 °C when the velocity of the substrate is at 10 cm/s. The tensile strength of ZLl04 alloy reaches 211.89 Mpa, while the average vickers hardness is 81.5 HV.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 7

- Cited by