Published online by Cambridge University Press: 30 September 2020

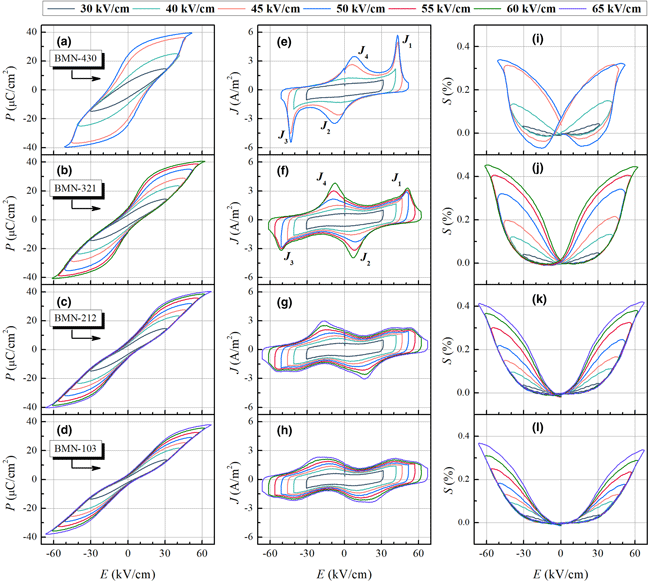

A new series of ternary perovskite 0.975(0.8Bi1/2Na1/2TiO3–0.2Bi1/2K1/2TiO3)–0.025Bix/3Mgy/3Nbz/3O3 (BNT–BKT–BMN, BMN-xyz) ceramics were designed and synthesized. The effect of the element ratio in the doping component BMN on the strain, ferroelectric, piezoelectric, and dielectric properties of the BNT–BKT matrix were studied. The BMN-430 composition without Nb element exhibits the typical features of non-ergodic relaxor, which is characterized by a higher piezoelectric coefficient d33 and a butterfly-shaped strain curve with negative strain. The introduction of trace Nb can significantly enhance the ergodicity of the system, reflecting in the high positive strain response and strain coefficient  $\lpar {d_{33}^\ast \gt 750\;{\rm pm/V}} \rpar$ of BMN-321 composition. In contrast, there is no significant difference in the properties between the presence and absence of Mg element. The temperature-dependent electrical behaviors of BMN-xyz ceramics were analyzed based on impedance spectroscopy. This study may be helpful to the design of the chemical modification strategy for the BNT-based relaxor ferroelectrics.

$\lpar {d_{33}^\ast \gt 750\;{\rm pm/V}} \rpar$ of BMN-321 composition. In contrast, there is no significant difference in the properties between the presence and absence of Mg element. The temperature-dependent electrical behaviors of BMN-xyz ceramics were analyzed based on impedance spectroscopy. This study may be helpful to the design of the chemical modification strategy for the BNT-based relaxor ferroelectrics.