Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Chiu, Wan-Ting

Ishigaki, Takuya

Nohira, Naoki

Umise, Akira

Tahara, Masaki

Inamura, Tomonari

and

Hosoda, Hideki

2021.

Evaluations of mechanical properties and shape memory behaviors of the aging–treated Ti–Au–Mo alloys.

Materials Chemistry and Physics,

Vol. 269,

Issue. ,

p.

124775.

Akin, Erhan

Akgul, Ogulcan

Tugrul, Halil Onat

Dugan, Gunce

and

Kockar, Benat

2021.

Investigating the effect of hot extrusion and annealing to the functional fatigue behavior of Ni50Ti30Hf20 high temperature shape memory alloy.

Smart Materials and Structures,

Vol. 30,

Issue. 10,

p.

105017.

Kankanamge, Udesh M. H. U.

Reiner, Johannes

Ma, Xingjun

Gallo, Santiago Corujeira

and

Xu, Wei

2022.

Machine learning guided alloy design of high-temperature NiTiHf shape memory alloys.

Journal of Materials Science,

Vol. 57,

Issue. 41,

p.

19447.

Hasan, Md Mehedi

and

Baxevanis, Theocharis

2022.

Structural fatigue and fracture of shape memory alloy actuators: Current status and perspectives.

Journal of Intelligent Material Systems and Structures,

Vol. 33,

Issue. 12,

p.

1475.

Ekiciler, Meric

and

Kockar, Benat

2022.

Crack growth behavior during actuation cycling of hot extruded and annealed Ni50Ti30Hf20 high temperature shape memory alloys.

Smart Materials and Structures,

Vol. 31,

Issue. 9,

p.

095002.

Plummer, Gabriel

Mendelev, Mikhail I

Benafan, Othmane

and

Lawson, John W

2023.

Microstructural mechanisms of hysteresis and transformation width in NiTi alloy from molecular dynamics simulations.

Journal of Physics: Condensed Matter,

Vol. 35,

Issue. 49,

p.

495404.

Nicholson, D. E.

Benafan, O.

Bigelow, G. S.

Pick, D.

Demblon, A.

Mabe, J. H.

Karaman, I.

Van Doren, B.

Forbes, D.

Sczerzenie, F.

Fumagalli, L.

and

Wallner, C.

2023.

Standardization of Shape Memory Alloys from Material to Actuator.

Shape Memory and Superelasticity,

Vol. 9,

Issue. 2,

p.

353.

Demblon, A.

Mabe, J.H.

and

Karaman, I.

2023.

Order of magnitude increase in actuation fatigue lifetime through partial austenitic transformation of NiTiHf high-temperature shape memory alloys.

Materials Science and Engineering: A,

Vol. 887,

Issue. ,

p.

145717.

Karelin, Roman

Komarov, Victor

Cherkasov, Vladimir

Yusupov, Vladimir

Prokoshkin, Sergey

and

Andreev, Vladimir

2023.

Production, Mechanical and Functional Properties of Long-Length TiNiHf Rods with High-Temperature Shape Memory Effect.

Materials,

Vol. 16,

Issue. 2,

p.

615.

Demblon, A.

Mabe, J.H.

and

Karaman, I.

2024.

Compositional effects on strain-controlled actuation fatigue of NiTiHf high temperature shape memory alloys.

Scripta Materialia,

Vol. 242,

Issue. ,

p.

115904.

Kuś, Krzysztof

2024.

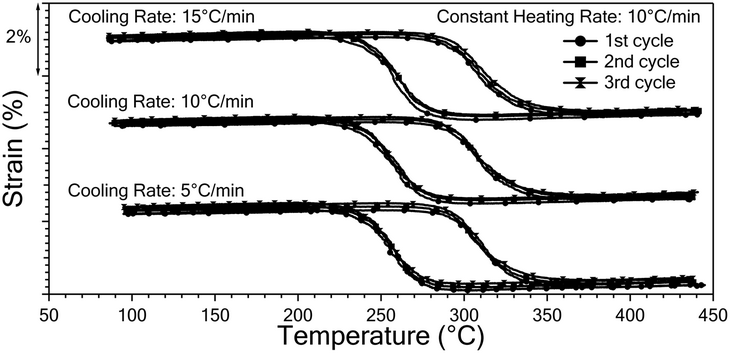

Study of the effect of cooling/heating rate on the thermal properties of ni-ti alloy (SMA) after annealing at different parameters.

Technical Sciences,

Young, Benjamin

Orrostieta, Roberto

Haghgouyan, Behrouz

Lagoudas, Dimitris C.

Baxevanis, T.

and

Karaman, Ibrahim

2024.

Fracture toughness and fatigue crack growth resistance of precipitate-free and precipitation hardened NiTiHf shape memory alloys.

Materials Science and Engineering: A,

Vol. 900,

Issue. ,

p.

146443.

Abedi, H.

Abdollahzadeh, M.J.

Bush, T.

Benafan, O.

Qattawi, A.

and

Elahinia, M.

2025.

Predicting actuation strain in quaternary shape memory alloy NiTiHfX using machine learning.

Computational Materials Science,

Vol. 246,

Issue. ,

p.

113345.

Huang, E-Wen

Lam, Tu-Ngoc

Aitken, Zachary H.

Luo, Mao-Yuan

Chiang, Nien-En

Sun, Yuh

Tseng, Jo-Chi

Chiang, Ching-Yu

Hsieh, Wan-Zhen

Lee, Wen-Jay

Zhang, Yong-Wei

Liaw, Peter K.

and

Tsai, Che-Wei

2025.

Mixing-enthalpy modulation on phase transformation in the gradient chemical core/shell high-entropy shape-memory alloys.

Materials & Design,

Vol. 251,

Issue. ,

p.

113623.