Published online by Cambridge University Press: 06 June 2013

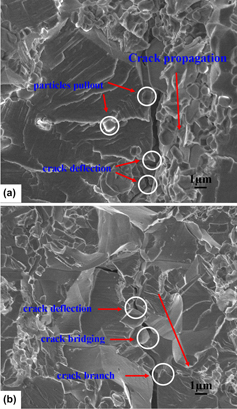

(Ti,Mn)Al/Al2O3 composites were successfully synthesized by reactive hot pressing from Ti–Al–TiO2–MnO2 system. The effect of Mn coming from the Al–MnO2 reaction on the microstructure and mechanical properties of (Ti,Mn)Al/Al2O3 in situ composites was investigated in detail. The results show that the as-prepared products are mainly composed of (Ti,Mn)Al matrix (including a little of Ti3Al) and Al2O3 particles, together with a few amount of Al77.5Mn22.5 phases. The (Ti,Mn)Al matrix is refined and the in situ generated Al2O3 particles distribute uniformly on the boundaries of (Ti,Mn)Al by incorporation of Mn. The (Ti,Mn)Al/Al2O3 composite with 1.92 wt% Mn possesses the best mechanical properties. Compared with Mn-free samples obtained from Ti–Al–TiO2 system, the hardness, flexural strength, and fracture toughness are enhanced by 53.46%, 76.49%, and 64.21%, respectively. The strengthening and toughening mechanisms were also discussed specifically.