Published online by Cambridge University Press: 22 December 2016

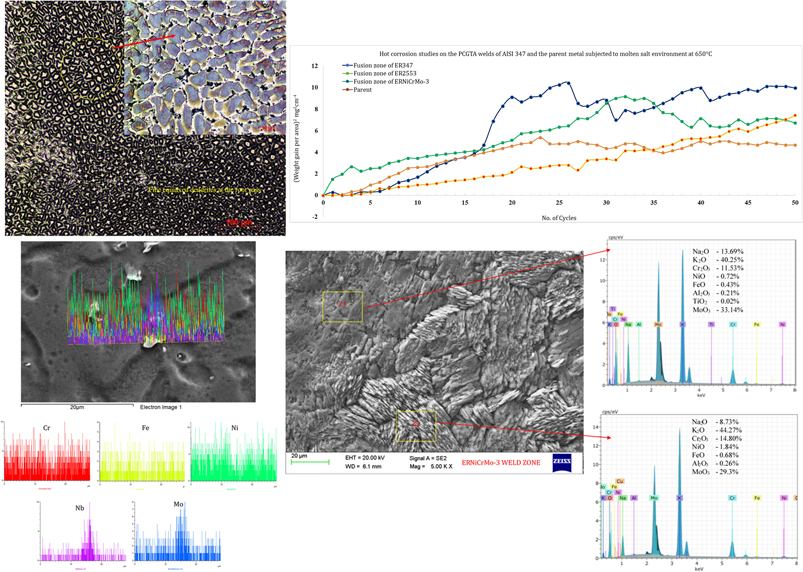

This research article addresses the effect of fillers on the high-temperature corrosion behavior of AISI 347 weld joints. Multi-pass pulsed current gas tungsten arc welding was carried out on 6.67 mm thick plates of AISI 347 using three different fillers namely ER347, ER2553, and ERNiCrMo-3. The fusion zone microstructures of AISI 347 employing ER2553 and ERNiCrMo-3 exhibited columnar and dendritic grain growth; whereas vermicular delta ferrite was observed at the fusion zone of ER347 welds. Tensile studies showed that the weld employing ERNiCrMo-3 exhibited better tensile strength than the parent metal. High-temperature corrosion studies were carried out on the fusion zones by exposing the coupons to an aggressive, synthetic molten-salt incinerator environment containing 40% Na2SO4–40% K2SO4–10% NaCl–10% KCl at 650 °C for 50 cycles. The studies attested that the fusion zone employing ERNiCrMo-3 exhibited better corrosion resistance than the other two fillers used in the study. Spallation of oxides was witnessed due to the dissolution of Cr2O3 in the ER347 and ER2553 fusion zones. The hot corroded samples were characterized using surface analytical techniques.