Published online by Cambridge University Press: 06 August 2020

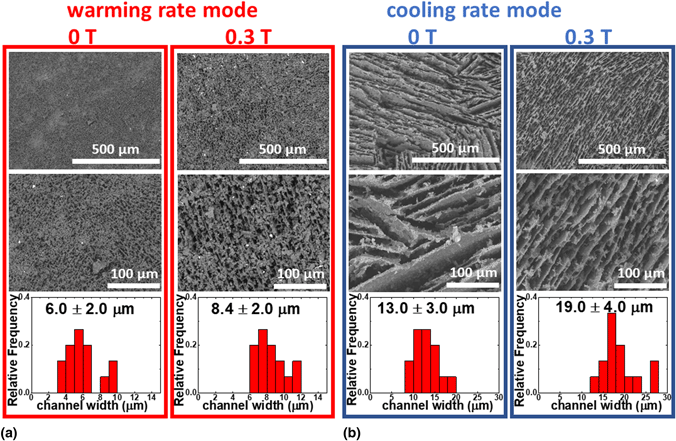

Magnetic field-assisted freeze-casting of porous alumina structures is reported. Different freeze-casting parameters were investigated and include the composition of the original slurry (Fe3O4 and PVA content) and the control of temperature during the free casting process. The optimum content of the additives in the slurry were 3 and 6 wt% for PVA and Fe3O4, respectively. These conditions provided the most unidirectional porous structures throughout the length of the sample. The sintering temperature was maintained at 1500 °C for 3 h. The application of a vertical magnetic field (parallel to ice growth direction) with using a cooling rate mode technique was found to enhance the homogeneity of the porous structure across the sample. The current study suggests that magnetic field-assisted freeze-casting is a viable method to create highly anisotropic porous ceramic structures.