Published online by Cambridge University Press: 06 June 2016

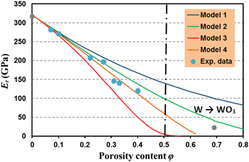

Density modulated tungsten (W) thin films with nanoscale porosity contents of 7% to 40% by volume were grown on Si substrates through magnetron sputter deposition. Process parameters were selected according to the structure zone model, which resulted in film thicknesses between 105 nm and 520 nm. Nanomechanical properties of samples were investigated by means of instrumented nanoindentation. Reduced-χ2 analysis was carried out to assess four models formulated through differential effective medium approach. The model that factored in both the crowding effect and the maximum random packing of pores successfully captured the experimental trends. Attempts to breach the auxetic barrier resulted in large-scale pulverization or spontaneous conversion into WO3. Porosity corrected yield strength calculations underlined the possibility of defining a porosity threshold beyond which the compressive yield strength of density modulated nanoporous metallic thin films would drop abruptly due to aggravated geometric slenderness effects in agreement with earlier hypotheses.

Present address: Materials Science and Engineering Department, Gebze Technical University, Kocaeli, 41400, Turkey.

Contributing Editor: Yang-T. Cheng