Article contents

Correlation of wear characteristics with hardness of recycled carbon fiber prepreg reinforced polypropylene composites

Published online by Cambridge University Press: 26 February 2016

Abstract

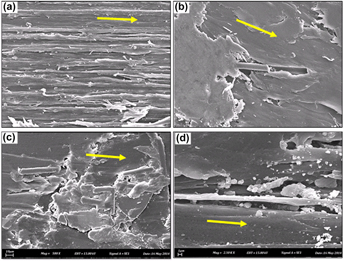

Incineration or disposal of carbon fiber waste from the aircraft industry leads to serious energy consumption and environmental pollution. The use of this waste as reinforcement is a wise approach to appreciate the high performance of the carbon fiber. In this study, the sliding wear and frictional behavior of recycled carbon fiber prepreg (rCFP) reinforced polypropylene (PP) prepared via melt compounding method using an internal mixer were studied. The samples were categorized into PP reinforced by carbon fiber with resin (A) and carbon fiber without resin (B). Pin-on-disc method was utilized to evaluate the effect of rCFP content and physical condition of fibers on tribological performance of the composites. The results were supported by morphological analyses using scanning electron microscopy. It was found that polymer composites B for rCFP without resin exhibited better tribological performance than composites category-A. The addition of rCFP into PP was observed to increase its wear resistance with minimum coefficient of friction achieved at 3 wt% of rCFP content for both polymer composites.

- Type

- Invited Articles

- Information

- Journal of Materials Research , Volume 31 , Issue 13: Focus Issue: Advances and Challenges in Carbon-based Tribomaterials , 14 July 2016 , pp. 1908 - 1913

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 10

- Cited by