Published online by Cambridge University Press: 23 June 2015

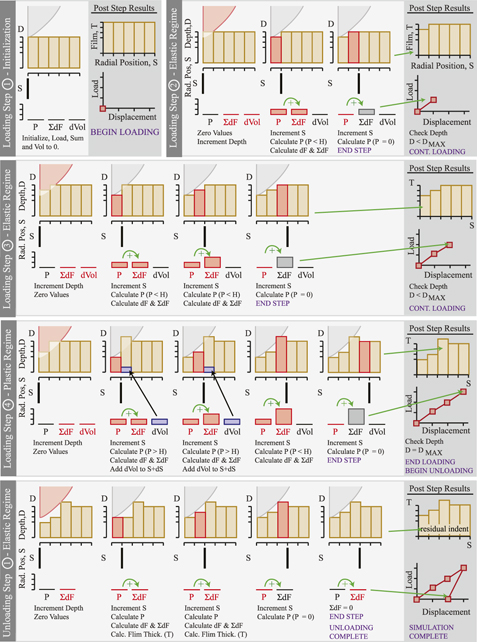

A novel method for the analysis of the mechanical properties of thin films is presented and uses a modified Winkler (bed of springs) approach to estimate indentation hardness and reduced modulus using nanoindentation data. This method is especially useful in situations where significant plastic deformation occurs in the thin film resulting in pileup of material and a divergence from accepted tip area calculations. The model has been adapted into a MATLAB® script and its derivation is presented. A proof of concept study was completed using Au thin films over a range of thickness and deposition methods. Results are compared with traditional nanoindentation analysis methods and validated against the Hall–Petch relationship. It can be seen that this modified Winkler approach accurately predicts material pile-up as well as contact area for films up to 500 nm in thickness.