Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Kaboli, Shirin

Goldbaum, Dina

Chromik, Richard R.

and

Gauvin, Raynald

2013.

Electron Channeling Contrast Imaging of Plastic Deformation Induced by Indentation in Polycrystalline Nickel.

Microscopy and Microanalysis,

Vol. 19,

Issue. 6,

p.

1620.

Kang, Seung-Kyun

Kim, Young-Cheon

Kim, Kug-Hwan

Kim, Ju-Young

and

Kwon, Dongil

2013.

Extended expanding cavity model for measurement of flow properties using instrumented spherical indentation.

International Journal of Plasticity,

Vol. 49,

Issue. ,

p.

1.

Nikas, George K.

2016.

Algebraic Equations for the Pile-Up Geometry in Debris Particle Indentation of Rolling Elastohydrodynamic Contacts.

Journal of Tribology,

Vol. 138,

Issue. 2,

Midawi, A.R.H.

Simha, C.H.M.

and

Gerlich, A.P.

2016.

Novel techniques for estimating yield strength from loads measured using nearly-flat instrumented indenters.

Materials Science and Engineering: A,

Vol. 675,

Issue. ,

p.

449.

Wang, Z.

Basu, S.

Murthy, T.G.

and

Saldana, C.

2016.

Modified cavity expansion formulation for circular indentation and experimental validation.

International Journal of Solids and Structures,

Vol. 97-98,

Issue. ,

p.

129.

Budnitzki, M.

and

Kuna, M.

2016.

Stress induced phase transitions in silicon.

Journal of the Mechanics and Physics of Solids,

Vol. 95,

Issue. ,

p.

64.

Yuan, Zhanwei

Wang, Yu

Tian, Wenbin

Wang, Yingying

Wang, Kai

Li, Fuguo

Guo, Yajie

Hu, Yongbiao

and

Wang, Xingang

2018.

The relationship between plastic zone and contact radius during indentation experiment for strain-hardened materials.

Philosophical Magazine Letters,

Vol. 98,

Issue. 5,

p.

209.

Zhan, Xuepeng

Wu, Jianjun

Wu, Hongfei

Wang, Mingzhi

Hui, Yu

Shang, Qi

and

Ren, Yinxiang

2018.

A new modified ECM approach on the identification of plastic anisotropic properties by spherical indentation.

Materials & Design,

Vol. 139,

Issue. ,

p.

392.

Wang, Zhiyu

Murthy, Tejas G.

and

Saldana, Christopher

2019.

Deformation field interaction in sequential circular indentation of a strain hardening material.

Philosophical Magazine,

Vol. 99,

Issue. 10,

p.

1259.

An, Lu

Zhang, Di

Zhang, Lin

and

Feng, Gang

2019.

Effect of nanoparticle size on the mechanical properties of nanoparticle assemblies.

Nanoscale,

Vol. 11,

Issue. 19,

p.

9563.

Nikas, George K.

2022.

Approximate analytical solution for the pile-up (lip) profile in normal, quasi-static, elastoplastic, spherical and conical indentation of ductile materials.

International Journal of Solids and Structures,

Vol. 234-235,

Issue. ,

p.

111240.

Yang, Liu

Yang, Duo

Li, Yuxue

Cai, Jiawei

and

Jiang, Xiaoyu

2024.

Nanoindentation study on microscopic mineral mechanics and bedding characteristics of continental shales.

Energy,

Vol. 312,

Issue. ,

p.

133614.

Kim, Jong-hyoung

Kwon, Oh Min

Lee, Junsang

Son, Hae-Jin

Kim, Young-Cheon

and

Kang, Seung-Kyun

2024.

Equivalent-Volume Model: Estimating Contact Morphology of Spherical Indentation for Metallic Materials.

Metals and Materials International,

Vol. 30,

Issue. 3,

p.

714.

Sevastyanov, Georgiy M.

2024.

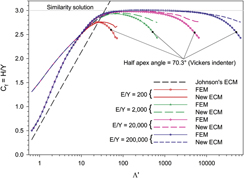

New expanding cavity model for conical indentation and its application to determine an intrinsic length scale of polymeric materials.

Acta Mechanica,

Vol. 235,

Issue. 7,

p.

4229.

Kim, Jong-hyoung

Lee, Kyungyul

Kwon, Dongil

and

Schajer, Gary S.

2025.

Evaluation of Non-equi-biaxial Residual Stresses from the Surface Displacements Around a Single Indentation.

Metals and Materials International,