1. Introduction

The elasticity of a polymer solution can be probed by stretching a drop between one's thumb and index finger, resulting in the formation of a filament with a persistence time that is linked to the relaxation time of the solution. Such filaments are observable in many industrial free-surface flows such as spraying (Keshavarz et al. Reference Keshavarz, Sharma, Houze, Koerner, Moore, Cotts, Threlfall-Holmes and McKinley2015, Reference Keshavarz, Houze, Moore, Koerner and McKinley2016; Gaillard, Sijs & Bonn Reference Gaillard, Sijs and Bonn2022) and inkjet printing (Christanti & Walker Reference Christanti and Walker2002; Sen et al. Reference Sen, Datt, Segers, Wijshoff, Snoeijer, Versluis and Lohse2021), where long polymer molecules can be added to a Newtonian solvent to achieve a specific flow property, as well as in ejecta produced when coughing and sneezing (Scharfman et al. Reference Scharfman, Techet, Bush and Bourouiba2016; Gidreta & Kim Reference Gidreta and Kim2023). The capillary-driven thinning dynamics of these filaments is the basis of numerous rheometry techniques dedicated to low-viscosity fluids, for which other techniques such as rheometric melt elongation (Meissner's RME) and filament stretching extensional rheometry (FiSER) are not applicable. These techniques include capillary breakup extensional rheometry (CaBER), where a droplet is confined between two plates that are separated beyond the range of stable liquid bridges (Bazilevsky et al. Reference Bazilevsky, Entov, Lerner and Rozhkov1997; Stelter et al. Reference Stelter, Brenn, Yarin, Singh and Durst2000; Anna & McKinley Reference Anna and McKinley2001), the dripping technique where a droplet detaches from a nozzle (Amarouchene et al. Reference Amarouchene, Bonn, Meunier and Kellay2001; Tirtaatmadja, McKinley & Cooper-White Reference Tirtaatmadja, McKinley and Cooper-White2006; Rajesh, Thiévenaz & Sauret Reference Rajesh, Thiévenaz and Sauret2022), and dripping-onto-substrate (DoS), where a solid substrate is brought into contact with a drop hanging steadily from a nozzle (Dinic, Jimenez & Sharma Reference Dinic, Jimenez and Sharma2017). All these techniques aim to creae a viscoelastic filament by triggering the pinching of a liquid column via the Rayleigh–Plateau instability.

Viscoelastic filaments are found to thin exponentially over time for a wide range of polymer-solvent systems and polymer concentrations (dilute and semi-dilute), consistent with the Oldroyd-B model, which predicts

where ![]() $h$ is the (minimum) filament radius, and

$h$ is the (minimum) filament radius, and ![]() $\tau$ is the relaxation time of the polymer solution, the longest one for a multimode model (Entov & Hinch Reference Entov and Hinch1997; Anna & McKinley Reference Anna and McKinley2001). This regime corresponds to an elasto-capillary balance where the elastic stress arising from the stretching of polymer chains balances the driving capillary pressure. Experimentally, starting from an equilibrium situation where polymers are relaxed (no pre-stress), this elastic regime can be observed only once polymers have been sufficiently stretched to overcome inertia and/or viscosity, which occurs at a time

$\tau$ is the relaxation time of the polymer solution, the longest one for a multimode model (Entov & Hinch Reference Entov and Hinch1997; Anna & McKinley Reference Anna and McKinley2001). This regime corresponds to an elasto-capillary balance where the elastic stress arising from the stretching of polymer chains balances the driving capillary pressure. Experimentally, starting from an equilibrium situation where polymers are relaxed (no pre-stress), this elastic regime can be observed only once polymers have been sufficiently stretched to overcome inertia and/or viscosity, which occurs at a time ![]() $t_1$ and at a filament radius

$t_1$ and at a filament radius ![]() $h_1 = h(t_1)$ marked by a sudden deceleration of the thinning dynamics.

$h_1 = h(t_1)$ marked by a sudden deceleration of the thinning dynamics.

The amount of stretching of polymer chains at times ![]() $t< t_1$ is set by the strength of the extensional flow in the pinching region. In the limit case where the thinning dynamics at times

$t< t_1$ is set by the strength of the extensional flow in the pinching region. In the limit case where the thinning dynamics at times ![]() $t< t_1$ (before elasticity balances capillarity) is much faster than the solution's relaxation time – i.e. where polymer chains deform by the same amount as the surrounding solvent itself without relaxing – Clasen et al. (Reference Clasen, Eggers, Fontelos, Li and McKinley2006a) showed that the Oldroyd-B model leads to

$t< t_1$ (before elasticity balances capillarity) is much faster than the solution's relaxation time – i.e. where polymer chains deform by the same amount as the surrounding solvent itself without relaxing – Clasen et al. (Reference Clasen, Eggers, Fontelos, Li and McKinley2006a) showed that the Oldroyd-B model leads to

\begin{equation} h_1 = \left( \frac{G h_0^4}{2 \gamma} \right)^{1/3}, \end{equation}

\begin{equation} h_1 = \left( \frac{G h_0^4}{2 \gamma} \right)^{1/3}, \end{equation}

where ![]() $\gamma$ is the surface tension,

$\gamma$ is the surface tension, ![]() $G$ is the elastic modulus and

$G$ is the elastic modulus and ![]() $h_0$ is the radius of the ‘initial’ liquid column before the onset of thinning, i.e. when the fluid is still at rest. This formula was first derived by Bazilevsky et al. (Reference Bazilevsky, Entov, Lerner and Rozhkov1997) and differs by a factor

$h_0$ is the radius of the ‘initial’ liquid column before the onset of thinning, i.e. when the fluid is still at rest. This formula was first derived by Bazilevsky et al. (Reference Bazilevsky, Entov, Lerner and Rozhkov1997) and differs by a factor ![]() $2^{1/3}$ from the formula proposed by Entov & Hinch (Reference Entov and Hinch1997), who did not treat the tension in the filament properly.

$2^{1/3}$ from the formula proposed by Entov & Hinch (Reference Entov and Hinch1997), who did not treat the tension in the filament properly.

This ‘relaxation-free’ scenario leading to (1.2) corresponds to the step-strain CaBER protocol where the plates are separated so fast that polymer chains stretch without having time to relax as the liquid bridge, connecting the two plates, stretches axially. In this step-strain protocol, the plates are separated exponentially over time to create an extensional flow with a constant extension rate ![]() $\dot {\epsilon }_0$ that, to ensure that polymer relaxation is negligible, must be larger that the coil–stretch transition value

$\dot {\epsilon }_0$ that, to ensure that polymer relaxation is negligible, must be larger that the coil–stretch transition value ![]() $1/2\tau$ (Miller, Clasen & Rothstein Reference Miller, Clasen and Rothstein2009). This corresponds to Weissenberg number

$1/2\tau$ (Miller, Clasen & Rothstein Reference Miller, Clasen and Rothstein2009). This corresponds to Weissenberg number ![]() ${Wi}_0 = \dot {\epsilon }_0 \tau > 1/2$. Once the plates have reached their final separation distance

${Wi}_0 = \dot {\epsilon }_0 \tau > 1/2$. Once the plates have reached their final separation distance ![]() $L_F$, the unstable liquid bridge between the two plates continues to thin, this time under the action of capillarity, until the elastic regime starts at a bridge/filament (minimum) radius

$L_F$, the unstable liquid bridge between the two plates continues to thin, this time under the action of capillarity, until the elastic regime starts at a bridge/filament (minimum) radius ![]() $h_1$. Miller et al. (Reference Miller, Clasen and Rothstein2009) showed that, consistent with (1.2),

$h_1$. Miller et al. (Reference Miller, Clasen and Rothstein2009) showed that, consistent with (1.2), ![]() $h_1$ does not depend on

$h_1$ does not depend on ![]() $L_F$ for polymer solutions. However, we could not find experimental studies where

$L_F$ for polymer solutions. However, we could not find experimental studies where ![]() $h_1$ was reported and tested against (1.2) for different plate diameters and initial gaps, which set the radius

$h_1$ was reported and tested against (1.2) for different plate diameters and initial gaps, which set the radius ![]() $h_0$ of the initial (unloaded) fluid sample, or for different polymer solutions.

$h_0$ of the initial (unloaded) fluid sample, or for different polymer solutions.

This step-strain CaBER protocol is, however, not recommended for low-viscosity polymer solutions since a fast plate separation leads to inertio-capillary oscillations of the end drops that hinder the measurement of the relaxation time (Rodd et al. Reference Rodd, Scott, Cooper-White and McKinley2005). Alternative protocols consist in reaching the threshold of the Rayleigh–Plateau instability slowly, e.g. by separating the plates at a constant low velocity in CaBER (slow retraction method or SRM) (Campo-Deano & Clasen Reference Campo-Deano and Clasen2010). In that case, the initially stable liquid bridge connecting the two end-plates becomes unstable at a critical plate separation distance, corresponding to a minimum bridge radius ![]() $h_0$, and thins further under the action of capillarity. This is similar to the dripping method where the bridge connecting a droplet to a nozzle, from which liquid is infused at a low flow rate, becomes unstable at a critical droplet weight (Rajesh et al. Reference Rajesh, Thiévenaz and Sauret2022).

$h_0$, and thins further under the action of capillarity. This is similar to the dripping method where the bridge connecting a droplet to a nozzle, from which liquid is infused at a low flow rate, becomes unstable at a critical droplet weight (Rajesh et al. Reference Rajesh, Thiévenaz and Sauret2022).

In such slow protocols, (1.2) may not be valid if the time taken by the bridge to thin from its initial (minimum) radius ![]() $h_0$ to the radius

$h_0$ to the radius ![]() $h_1$ (marking the onset of the elastic regime) is longer than the liquid's relaxation time

$h_1$ (marking the onset of the elastic regime) is longer than the liquid's relaxation time ![]() $\tau$, as was already noticed by Bazilevsky et al. (Reference Bazilevsky, Entov, Lerner and Rozhkov1997). In that case, polymer chains may indeed remain in a coiled state for a significant time, starting to stretch only when the bridge's thinning rate becomes comparable to

$\tau$, as was already noticed by Bazilevsky et al. (Reference Bazilevsky, Entov, Lerner and Rozhkov1997). In that case, polymer chains may indeed remain in a coiled state for a significant time, starting to stretch only when the bridge's thinning rate becomes comparable to ![]() $1/\tau$. This led Campo-Deano & Clasen (Reference Campo-Deano and Clasen2010) to derive an alternative formula for

$1/\tau$. This led Campo-Deano & Clasen (Reference Campo-Deano and Clasen2010) to derive an alternative formula for ![]() $h_1$ for their slow retraction CaBER method that, to the best of our knowledge, has never been tested experimentally. In this formula,

$h_1$ for their slow retraction CaBER method that, to the best of our knowledge, has never been tested experimentally. In this formula, ![]() $h_1$ is independent of

$h_1$ is independent of ![]() $h_0$, in sharp contrast with (1.2), which predicts

$h_0$, in sharp contrast with (1.2), which predicts ![]() $h_1 \propto h_0^{4/3}$. In a more recent experimental work from Rajesh et al. (Reference Rajesh, Thiévenaz and Sauret2022), the authors proposed an empirical scaling

$h_1 \propto h_0^{4/3}$. In a more recent experimental work from Rajesh et al. (Reference Rajesh, Thiévenaz and Sauret2022), the authors proposed an empirical scaling ![]() $h_1 \propto R_n^{0.66}$ in dripping experiments with low-viscosity polymer solutions, where

$h_1 \propto R_n^{0.66}$ in dripping experiments with low-viscosity polymer solutions, where ![]() $R_n$ is the nozzle radius, but they did not provide a theoretical explanation for their findings.

$R_n$ is the nozzle radius, but they did not provide a theoretical explanation for their findings.

In such slow protocols, (1.2) is expected to be valid only if the time taken by the liquid bridge to thin from ![]() $h_0$ to

$h_0$ to ![]() $h_1$ is much shorter than the liquid's relaxation time, in which case polymer chains stretch without having time to relax. This time is expected to scale as the characteristic time scale of the capillary-driven bridge thinning dynamics derived from linear stability theory, namely, the Rayleigh (inertio-capillary) time scale (Wagner et al. Reference Wagner, Amarouchene, Bonn and Eggers2005)

$h_1$ is much shorter than the liquid's relaxation time, in which case polymer chains stretch without having time to relax. This time is expected to scale as the characteristic time scale of the capillary-driven bridge thinning dynamics derived from linear stability theory, namely, the Rayleigh (inertio-capillary) time scale (Wagner et al. Reference Wagner, Amarouchene, Bonn and Eggers2005)

or the visco-capillary time scale

depending on the Ohnesorge number

where ![]() $\rho$ and

$\rho$ and ![]() $\eta _0$ are the liquid density and total (zero-shear) viscosity, respectively. In other words, if we define a Deborah number

$\eta _0$ are the liquid density and total (zero-shear) viscosity, respectively. In other words, if we define a Deborah number

based on the Rayleigh time scale, then (1.2) is expected to be valid for ![]() ${De} \gg 1$ in the inviscid case (

${De} \gg 1$ in the inviscid case (![]() ${Oh} \ll 1$), and for

${Oh} \ll 1$), and for ![]() ${De} / {Oh} = \tau / \tau _{{visc}} \gg 1$ in the viscous case (

${De} / {Oh} = \tau / \tau _{{visc}} \gg 1$ in the viscous case (![]() ${Oh} \gg 1$), which is the limit considered in most analytical studies (Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006a).

${Oh} \gg 1$), which is the limit considered in most analytical studies (Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006a).

In this study, we aim to expand our current understanding of the transition radius ![]() $h_1$ (marking the onset of the elastic regime) to cases where polymer relaxation is not negligible during the capillary-driven thinning of the liquid bridge. This discussion follows up on our previous paper, where

$h_1$ (marking the onset of the elastic regime) to cases where polymer relaxation is not negligible during the capillary-driven thinning of the liquid bridge. This discussion follows up on our previous paper, where ![]() $h_1$ was observed to increase linearly with

$h_1$ was observed to increase linearly with ![]() $h_0$ for different liquids for a slow plate separation CaBER protocol (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), a scaling that differs from the

$h_0$ for different liquids for a slow plate separation CaBER protocol (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), a scaling that differs from the ![]() $h_1 \propto h_0^{4/3}$ prediction of (1.2). Materials and methods are presented in § 2, and experimental results are presented in § 3. Theoretical expressions for

$h_1 \propto h_0^{4/3}$ prediction of (1.2). Materials and methods are presented in § 2, and experimental results are presented in § 3. Theoretical expressions for ![]() $h_1$ are derived and tested experimentally and numerically using the Oldroyd-B model in § 4, and the FENE-P model in § 5.

$h_1$ are derived and tested experimentally and numerically using the Oldroyd-B model in § 4, and the FENE-P model in § 5.

2. Materials and methods

The liquids, their shear rheology and the experimental set-up and protocol are presented in §§ 2.1, 2.2 and 2.3, respectively. The equations and numerical methods are presented in § 2.4.

2.1. Liquids

Three of the polymer solutions used in the present study are the same as in our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024) and have comparable ‘relaxation times’ or, more precisely, comparable filament thinning rates. Two of them are solutions of poly(ethylene oxide) (PEO) of molecular weight ![]() $M_w = 4 \times 10^{6}\,{\rm g}\,{\rm mol}^{-1}$ (PEO-4M), one in water with concentration

$M_w = 4 \times 10^{6}\,{\rm g}\,{\rm mol}^{-1}$ (PEO-4M), one in water with concentration ![]() $500\,{\rm ppm}$, referred to as

$500\,{\rm ppm}$, referred to as ![]() ${\rm PEO}_{{aq}}$, and one in a

${\rm PEO}_{{aq}}$, and one in a ![]() ${\sim }260$ times more viscous solvent with concentration

${\sim }260$ times more viscous solvent with concentration ![]() $25\,{\rm ppm}$, referred to as

$25\,{\rm ppm}$, referred to as ![]() ${\rm PEO}_{{visc}}$. The third solution is a

${\rm PEO}_{{visc}}$. The third solution is a ![]() $1000\,{\rm ppm}$ solution of poly(acrylamide/sodium acrylate) (HPAM)

$1000\,{\rm ppm}$ solution of poly(acrylamide/sodium acrylate) (HPAM) ![]() $[70\,:\,30]$ of molecular weight

$[70\,:\,30]$ of molecular weight ![]() $M_w = 18 \times 10^{6}\,{\rm g}\,{\rm mol}^{-1}$ in water with 1 wt% NaCl to screen electrostatic interactions and make polymer chains flexible instead of semi-rigid. Both polymers were provided by Polysciences (ref. 04030 for PEO and 18522 for HPAM). The solvent of the

$M_w = 18 \times 10^{6}\,{\rm g}\,{\rm mol}^{-1}$ in water with 1 wt% NaCl to screen electrostatic interactions and make polymer chains flexible instead of semi-rigid. Both polymers were provided by Polysciences (ref. 04030 for PEO and 18522 for HPAM). The solvent of the ![]() ${\rm PEO}_{visc}$ solution is a Newtonian 30 wt% aqueous solution of poly(ethylene glycol) (PEG) with molecular weight

${\rm PEO}_{visc}$ solution is a Newtonian 30 wt% aqueous solution of poly(ethylene glycol) (PEG) with molecular weight ![]() $20\,000\,{\rm g}\,{\rm mol}^{-1}$ (PEG-20K). After slowly injecting the polymer powder into a vortex generated by a magnetic stirrer, solutions were homogenised using a mechanical stirrer at low rotation speed for approximately 16 h. For the

$20\,000\,{\rm g}\,{\rm mol}^{-1}$ (PEG-20K). After slowly injecting the polymer powder into a vortex generated by a magnetic stirrer, solutions were homogenised using a mechanical stirrer at low rotation speed for approximately 16 h. For the ![]() ${\rm PEO}_{{visc}}$ solution, PEG was added after mixing PEO with water. Additional solutions of PEO-4M in water were prepared from dilution of a

${\rm PEO}_{{visc}}$ solution, PEG was added after mixing PEO with water. Additional solutions of PEO-4M in water were prepared from dilution of a ![]() $10\,000\,{\rm ppm}$ stock solution with concentrations ranging between

$10\,000\,{\rm ppm}$ stock solution with concentrations ranging between ![]() $5$ and

$5$ and ![]() $10\,000\,{\rm ppm}$ to investigate the influence of polymer concentration.

$10\,000\,{\rm ppm}$ to investigate the influence of polymer concentration.

2.2. Shear rheology

The shear viscosity ![]() $\eta$ and first normal stress difference

$\eta$ and first normal stress difference ![]() $N_1$ of polymer solutions were measured at the temperature of CaBER experiments, typically

$N_1$ of polymer solutions were measured at the temperature of CaBER experiments, typically ![]() $20\,^{\circ }{\rm C}$, with an MRC-302 rheometer from Anton Paar equipped with a cone plate geometry (diameter

$20\,^{\circ }{\rm C}$, with an MRC-302 rheometer from Anton Paar equipped with a cone plate geometry (diameter ![]() $50\,{\rm mm}$, angle

$50\,{\rm mm}$, angle ![]() $1^{\circ }$, and truncation gap

$1^{\circ }$, and truncation gap ![]() $53\,\mathrm {\mu }{\rm m}$) and are shown in figure 1. To measure

$53\,\mathrm {\mu }{\rm m}$) and are shown in figure 1. To measure ![]() $N_1$, we follow a step-by-step protocol similar to Casanellas et al. (Reference Casanellas, Alves, Poole, Lerouge and Lindner2016) in order to circumvent the instrumental drift of the normal force. This protocol consists of applying steps of constant shear rate followed by steps of zero shear, and subtracting the two raw

$N_1$, we follow a step-by-step protocol similar to Casanellas et al. (Reference Casanellas, Alves, Poole, Lerouge and Lindner2016) in order to circumvent the instrumental drift of the normal force. This protocol consists of applying steps of constant shear rate followed by steps of zero shear, and subtracting the two raw ![]() $N_1$ plateau values. The contribution of inertia to the normal force is corrected for by the rheometer (Macosko Reference Macosko1994). We find that the

$N_1$ plateau values. The contribution of inertia to the normal force is corrected for by the rheometer (Macosko Reference Macosko1994). We find that the ![]() ${\rm PEO}_{{visc}}$ solution is a Boger fluid with a constant shear viscosity, while the HPAM solution is shear-thinning, as well as the aqueous PEO solutions when concentrations are larger than

${\rm PEO}_{{visc}}$ solution is a Boger fluid with a constant shear viscosity, while the HPAM solution is shear-thinning, as well as the aqueous PEO solutions when concentrations are larger than ![]() $250\,{\rm ppm}$. For shear-thinning solutions, the shear viscosity is fitted with the Carreau–Yasuda formula

$250\,{\rm ppm}$. For shear-thinning solutions, the shear viscosity is fitted with the Carreau–Yasuda formula

where ![]() $\eta _0$ is the zero-shear viscosity,

$\eta _0$ is the zero-shear viscosity, ![]() $n$ is the shear-thinning exponent, and

$n$ is the shear-thinning exponent, and ![]() $\dot {\gamma }_c$ is the shear rate marking the onset of shear thinning, with

$\dot {\gamma }_c$ is the shear rate marking the onset of shear thinning, with ![]() $a_1$ (typically

$a_1$ (typically ![]() $2$) encoding the sharpness of the transition towards the shear-thinning regime. The polymer contribution to the shear viscosity

$2$) encoding the sharpness of the transition towards the shear-thinning regime. The polymer contribution to the shear viscosity ![]() $\eta _p = \eta _0 - \eta _s$ increases linearly with polymer concentration

$\eta _p = \eta _0 - \eta _s$ increases linearly with polymer concentration ![]() $c$ in the dilute regime, and follows

$c$ in the dilute regime, and follows ![]() $\eta _p = \eta _s [\eta ] c$, where, for the PEO solutions in water, we find an intrinsic viscosity

$\eta _p = \eta _s [\eta ] c$, where, for the PEO solutions in water, we find an intrinsic viscosity ![]() $[\eta ] = 2.87\,{\rm m}^3\,{\rm kg}^{-1}$. Using the expression of Graessley (Reference Graessley1980) gives a critical overlap concentration

$[\eta ] = 2.87\,{\rm m}^3\,{\rm kg}^{-1}$. Using the expression of Graessley (Reference Graessley1980) gives a critical overlap concentration ![]() $c^* = 0.77/[\eta ] = 0.268\,{\rm kg}\,{\rm m}^{-3}$ (

$c^* = 0.77/[\eta ] = 0.268\,{\rm kg}\,{\rm m}^{-3}$ (![]() $268\,{\rm ppm}$), consistent with the onset of shear thinning expected at

$268\,{\rm ppm}$), consistent with the onset of shear thinning expected at ![]() $c>c^*$. For the

$c>c^*$. For the ![]() ${\rm PEO}_{{visc}}$ solution, where only one concentration (

${\rm PEO}_{{visc}}$ solution, where only one concentration (![]() $25\,{\rm ppm}$) was tested, assuming that the solution is dilute to calculate

$25\,{\rm ppm}$) was tested, assuming that the solution is dilute to calculate ![]() $[\eta ]$ and

$[\eta ]$ and ![]() $c^*$ using the same formulas leads to a larger critical overlap concentration

$c^*$ using the same formulas leads to a larger critical overlap concentration ![]() $c^* = 1400\,{\rm ppm}$, probably due to differences in polymer–solvent interactions (PEO in water versus PEO in PEG solution). The first normal stress difference is fitted by a power law

$c^* = 1400\,{\rm ppm}$, probably due to differences in polymer–solvent interactions (PEO in water versus PEO in PEG solution). The first normal stress difference is fitted by a power law

where we find ![]() $\alpha _1 = 2$ below

$\alpha _1 = 2$ below ![]() $c^*$, and

$c^*$, and ![]() $\alpha _1 < 2$ above

$\alpha _1 < 2$ above ![]() $c^*$, for aqueous PEO solutions, and

$c^*$, for aqueous PEO solutions, and ![]() $\alpha _1 < 2$ for the

$\alpha _1 < 2$ for the ![]() ${\rm PEO}_{{visc}}$ and HPAM solutions. All fitting parameters are reported in table 1 for the PEO solutions of different concentrations in water, and in table 2 for the

${\rm PEO}_{{visc}}$ and HPAM solutions. All fitting parameters are reported in table 1 for the PEO solutions of different concentrations in water, and in table 2 for the ![]() ${\rm PEO}_{{aq}}$,

${\rm PEO}_{{aq}}$, ![]() ${\rm PEO}_{{visc}}$ and HPAM solutions. We also report the density

${\rm PEO}_{{visc}}$ and HPAM solutions. We also report the density ![]() $\rho$ and surface tension

$\rho$ and surface tension ![]() $\gamma$ measured with a pendant drop method and, when known, the ratio

$\gamma$ measured with a pendant drop method and, when known, the ratio ![]() $c/c^*$. Note that PEO addition reduces the surface tension of water since PEO is known to adsorb at the air/water interface (Gilányi et al. Reference Gilányi, Varga, Gilányi and Mészáros2006). Surface tensions reported in tables 1 and 2 are the equilibrium ones.

$c/c^*$. Note that PEO addition reduces the surface tension of water since PEO is known to adsorb at the air/water interface (Gilányi et al. Reference Gilányi, Varga, Gilányi and Mészáros2006). Surface tensions reported in tables 1 and 2 are the equilibrium ones.

Table 1. Concentration ![]() $c$, reduced concentration

$c$, reduced concentration ![]() $c/c^*$, surface tension

$c/c^*$, surface tension ![]() $\gamma$ and shear rheological properties (from (2.1) and (2.2)) of aqueous PEO-4M solutions prepared from dilution of the same

$\gamma$ and shear rheological properties (from (2.1) and (2.2)) of aqueous PEO-4M solutions prepared from dilution of the same ![]() $10\,000\,{\rm ppm}$ stock solution. Here,

$10\,000\,{\rm ppm}$ stock solution. Here, ![]() $\eta _p = \eta _0-\eta _s$ is the polymer contribution to the shear viscosity. The density and solvent viscosity are

$\eta _p = \eta _0-\eta _s$ is the polymer contribution to the shear viscosity. The density and solvent viscosity are ![]() $\rho = 998\,{\rm kg}\,{\rm m}^{-3}$ and

$\rho = 998\,{\rm kg}\,{\rm m}^{-3}$ and ![]() $\eta _s = 0.92\,{\rm mPa}\,{\rm s}$. The 500 ppm solution in this table is referred to as

$\eta _s = 0.92\,{\rm mPa}\,{\rm s}$. The 500 ppm solution in this table is referred to as ![]() ${\rm PEO}_{{aq,1}}$ in the text. For the

${\rm PEO}_{{aq,1}}$ in the text. For the ![]() $5\,{\rm ppm}$ solution,

$5\,{\rm ppm}$ solution, ![]() $\eta _0$ is too close to

$\eta _0$ is too close to ![]() $\eta _s$ to estimate

$\eta _s$ to estimate ![]() $\eta _p$, and we therefore use

$\eta _p$, and we therefore use ![]() $\eta _p = \eta _s [\eta ] c$ with the intrinsic viscosity

$\eta _p = \eta _s [\eta ] c$ with the intrinsic viscosity ![]() $[\eta ]$ extracted from the linear fit of

$[\eta ]$ extracted from the linear fit of ![]() $\eta _p (c)$ for

$\eta _p (c)$ for ![]() $c< c^*$.

$c< c^*$.

Table 2. Properties of the polymer solutions used for plate diameters ![]() $2R_0$ up to 25 mm in CaBER measurements. Here,

$2R_0$ up to 25 mm in CaBER measurements. Here, ![]() $\rho$ is the density, and

$\rho$ is the density, and ![]() $\gamma$ is the surface tension. See the caption of table 1 for the definition of the shear properties. Also,

$\gamma$ is the surface tension. See the caption of table 1 for the definition of the shear properties. Also, ![]() $\tau _{m}$ is the maximum CaBER relaxation time measured for the largest plates; see figure 4(a). The

$\tau _{m}$ is the maximum CaBER relaxation time measured for the largest plates; see figure 4(a). The ![]() ${\rm PEO}_{{visc,1}}$ and

${\rm PEO}_{{visc,1}}$ and ![]() ${\rm PEO}_{{visc,2}}$ solutions have the same shear viscosity to within less than

${\rm PEO}_{{visc,2}}$ solutions have the same shear viscosity to within less than ![]() $5\,\%$.

$5\,\%$.

Figure 1. (a) Shear viscosity ![]() $\eta$ and (b) first normal stress difference

$\eta$ and (b) first normal stress difference ![]() $N_1$ of the different polymer solutions against the shear rate

$N_1$ of the different polymer solutions against the shear rate ![]() $\dot {\gamma }$.

$\dot {\gamma }$.

We must mention here that two different ![]() ${\rm PEO}_{{aq}}$ solutions and two different

${\rm PEO}_{{aq}}$ solutions and two different ![]() ${\rm PEO}_{{visc}}$ solutions have been used in this study, with differences in rheological properties in each case, caused by slightly different preparation protocols for a given recipe (e.g. a slightly different agitation time). The

${\rm PEO}_{{visc}}$ solutions have been used in this study, with differences in rheological properties in each case, caused by slightly different preparation protocols for a given recipe (e.g. a slightly different agitation time). The ![]() ${\rm PEO}_{{aq,1}}$ solution is prepared from dilution of the same stock solution as the other aqueous PEO solutions in table 1. The

${\rm PEO}_{{aq,1}}$ solution is prepared from dilution of the same stock solution as the other aqueous PEO solutions in table 1. The ![]() ${\rm PEO}_{{aq,2}}$ solution featured in table 2 exhibits a

${\rm PEO}_{{aq,2}}$ solution featured in table 2 exhibits a ![]() $10\,\%$ larger shear viscosity and approximately

$10\,\%$ larger shear viscosity and approximately ![]() $2.5$ times larger values of

$2.5$ times larger values of ![]() $N_1$, as shown in figure 1. The

$N_1$, as shown in figure 1. The ![]() ${\rm PEO}_{{visc,1}}$ and

${\rm PEO}_{{visc,1}}$ and ![]() ${\rm PEO}_{{visc,2}}$ solutions have the same shear viscosity to within less than

${\rm PEO}_{{visc,2}}$ solutions have the same shear viscosity to within less than ![]() $5\,\%$, and only the latter one is presented in figure 1 and in table 2. As explained in § 2.3, the

$5\,\%$, and only the latter one is presented in figure 1 and in table 2. As explained in § 2.3, the ![]() ${\rm PEO}_{{aq,1}}$ and

${\rm PEO}_{{aq,1}}$ and ![]() ${\rm PEO}_{{visc,1}}$ solutions were tested with (CaBER) plate diameters less than 7 mm, varying the (non-dimensional) drop volume for each plate, whereas the

${\rm PEO}_{{visc,1}}$ solutions were tested with (CaBER) plate diameters less than 7 mm, varying the (non-dimensional) drop volume for each plate, whereas the ![]() ${\rm PEO}_{{aq,2}}$ and

${\rm PEO}_{{aq,2}}$ and ![]() ${\rm PEO}_{{visc,2}}$ solutions were used for plate diameters up to 25 mm with a single (non-dimensional) drop volume for each plate.

${\rm PEO}_{{visc,2}}$ solutions were used for plate diameters up to 25 mm with a single (non-dimensional) drop volume for each plate.

2.3. Experimental set-up and slow stepwise CaBER protocol

The CaBER set-up and slow stepwise plate separation protocol described here are the same as in our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024). A droplet of volume ![]() $V$ is placed on a horizontal plate of radius

$V$ is placed on a horizontal plate of radius ![]() $R_0$, and the motor-controlled top plate of same radius is first moved down until it is fully wetted by the liquid, i.e. until the liquid bridge between the plates has a quasi-cylindrical shape. The top plate is then moved up slowly (at approximately

$R_0$, and the motor-controlled top plate of same radius is first moved down until it is fully wetted by the liquid, i.e. until the liquid bridge between the plates has a quasi-cylindrical shape. The top plate is then moved up slowly (at approximately ![]() $0.5\,{\rm mm}\,{\rm s}^{-1}$) and stopped at a plate separation distance

$0.5\,{\rm mm}\,{\rm s}^{-1}$) and stopped at a plate separation distance ![]() $L_p$ where the liquid bridge is still stable, as in the left-hand inset image of figure 2(a), but close to the bridge instability threshold. Then, instead of moving the top plate at a constant (lower) velocity, i.e. as in the SRM (Campo-Deano & Clasen Reference Campo-Deano and Clasen2010), we move it by

$L_p$ where the liquid bridge is still stable, as in the left-hand inset image of figure 2(a), but close to the bridge instability threshold. Then, instead of moving the top plate at a constant (lower) velocity, i.e. as in the SRM (Campo-Deano & Clasen Reference Campo-Deano and Clasen2010), we move it by ![]() $10\,\mathrm {\mu }{\rm m}$

$10\,\mathrm {\mu }{\rm m}$ ![]() $L_p$-increment steps, waiting approximately one second between each step (longer than the solution's relaxation time), which is long enough to ensure that polymers are at equilibrium (no pre-stress) before each new step. At a certain step, the bridge becomes unstable (due to the Rayleigh–Plateau instability) and collapses under the action of surface tension, transiently leading to the formation of a nearly cylindrical filament that is the signature of viscoelastic pinch-off, as shown in the right-hand inset image of figure 2(a). We stop moving the top plate once we reach the step at which the bride collapses. The plate separation distance hence remains constant during the capillary thinning of the bridge/filament.

$L_p$-increment steps, waiting approximately one second between each step (longer than the solution's relaxation time), which is long enough to ensure that polymers are at equilibrium (no pre-stress) before each new step. At a certain step, the bridge becomes unstable (due to the Rayleigh–Plateau instability) and collapses under the action of surface tension, transiently leading to the formation of a nearly cylindrical filament that is the signature of viscoelastic pinch-off, as shown in the right-hand inset image of figure 2(a). We stop moving the top plate once we reach the step at which the bride collapses. The plate separation distance hence remains constant during the capillary thinning of the bridge/filament.

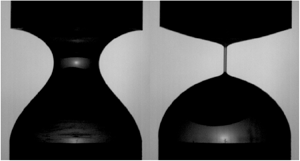

Figure 2. (a) Time evolution of the minimum bridge/filament radius ![]() $h$ in our slow stepwise plate separation protocol for the

$h$ in our slow stepwise plate separation protocol for the ![]() ${\rm PEO}_{{aq,1}}$ solution for plate diameter

${\rm PEO}_{{aq,1}}$ solution for plate diameter ![]() $2R_0 = 3.5\,{\rm mm}$ and a sample volume

$2R_0 = 3.5\,{\rm mm}$ and a sample volume ![]() $V^* = V/R_0^3 \approx 2.4$. Inset images correspond to a stable liquid bridge (left) and a thinning filament (right) of the same liquid, with

$V^* = V/R_0^3 \approx 2.4$. Inset images correspond to a stable liquid bridge (left) and a thinning filament (right) of the same liquid, with ![]() $2R_0 = 7\,{\rm mm}$ and

$2R_0 = 7\,{\rm mm}$ and ![]() $V^* \approx 2.4$. (b) Last stable bridge radius

$V^* \approx 2.4$. (b) Last stable bridge radius ![]() $h_0$ against the plate radius

$h_0$ against the plate radius ![]() $R_0$: for

$R_0$: for ![]() $2R_0$ between

$2R_0$ between ![]() $2$ and

$2$ and ![]() $7\,{\rm mm}$, and for each plate,

$7\,{\rm mm}$, and for each plate, ![]() $V^* \approx 1.3$,

$V^* \approx 1.3$, ![]() $2.4$ and

$2.4$ and ![]() $3.2$ for the

$3.2$ for the ![]() ${\rm PEO}_{{aq,1}}$ and

${\rm PEO}_{{aq,1}}$ and ![]() ${\rm PEO}_{{visc,1}}$ solutions; and for

${\rm PEO}_{{visc,1}}$ solutions; and for ![]() $2R_0$ between

$2R_0$ between ![]() $2$ and

$2$ and ![]() $25\,{\rm mm}$, and a single volume (

$25\,{\rm mm}$, and a single volume (![]() $V^* \approx 2.4$ for the smallest plates, and

$V^* \approx 2.4$ for the smallest plates, and ![]() $V^*\approx 0.88$ for the largest plates) for the

$V^*\approx 0.88$ for the largest plates) for the ![]() ${\rm PEO}_{{aq,2}}$,

${\rm PEO}_{{aq,2}}$, ![]() ${\rm PEO}_{{visc,2}}$ and HPAM solutions. Inset images correspond to stable liquid bridges (

${\rm PEO}_{{visc,2}}$ and HPAM solutions. Inset images correspond to stable liquid bridges (![]() $h \ge h_0$) for

$h \ge h_0$) for ![]() $2R_0 = 2\,{\rm mm}$ (left,

$2R_0 = 2\,{\rm mm}$ (left, ![]() ${\rm PEO}_{{aq,1}}$ solution with

${\rm PEO}_{{aq,1}}$ solution with ![]() $V^* \approx 2.4$) and

$V^* \approx 2.4$) and ![]() $2R_0 = 20\,{\rm mm}$ (right, HPAM solution with

$2R_0 = 20\,{\rm mm}$ (right, HPAM solution with ![]() $V^* \approx 1.0$), the right-hand inset being taken from a phone camera because the lens of the set-up camera (used to take the other inset pictures) did not have a large enough field of view.

$V^* \approx 1.0$), the right-hand inset being taken from a phone camera because the lens of the set-up camera (used to take the other inset pictures) did not have a large enough field of view.

The process is recorded by a high-magnification objective mounted on a high-speed camera (Phantom TMX 7510), and images are analysed by a Python code. A typical time evolution of the minimum bridge/filament radius is shown in figure 2(a). Throughout the paper, we use the term ‘bridge’ for times ![]() $t< t_1$ before the onset of the elastic regime, and the term ‘filament’ during the elastic regime (

$t< t_1$ before the onset of the elastic regime, and the term ‘filament’ during the elastic regime (![]() $t \ge t_1$). This radius, measured at the thinnest point along the bridge/filament profile (see left-hand inset image in figure 2a) and labelled ‘

$t \ge t_1$). This radius, measured at the thinnest point along the bridge/filament profile (see left-hand inset image in figure 2a) and labelled ‘![]() $h_{{min}}$’ by many authors, is simply referred to as

$h_{{min}}$’ by many authors, is simply referred to as ![]() $h$ in the rest of the paper. Note that each step can trigger small inertio-capillary oscillations that increase in intensity as the Rayleigh–Plateau instability threshold is approached; see figure 2(a), where oscillations vanish after approximately

$h$ in the rest of the paper. Note that each step can trigger small inertio-capillary oscillations that increase in intensity as the Rayleigh–Plateau instability threshold is approached; see figure 2(a), where oscillations vanish after approximately ![]() $0.2$ s for the

$0.2$ s for the ![]() ${\rm PEO}_{{aq,1}}$ solution. The purpose of this step-by-step plate separation protocol is to identify the last stable liquid bridge configuration and to extract the value of its (minimum) radius

${\rm PEO}_{{aq,1}}$ solution. The purpose of this step-by-step plate separation protocol is to identify the last stable liquid bridge configuration and to extract the value of its (minimum) radius ![]() $h_0$. Since steps are small,

$h_0$. Since steps are small, ![]() $h_0$ can be considered to be the initial bridge radius at the onset of capillary thinning. Our image resolution is up to 1 pixel per micrometre for the smallest drops, corresponding to the smallest plates, and our time resolution is

$h_0$ can be considered to be the initial bridge radius at the onset of capillary thinning. Our image resolution is up to 1 pixel per micrometre for the smallest drops, corresponding to the smallest plates, and our time resolution is ![]() $15\,000$ images per second to capture the fast bridge collapse from radius

$15\,000$ images per second to capture the fast bridge collapse from radius ![]() $h_0$ to the radius

$h_0$ to the radius ![]() $h_1$ marking the onset of the elastic regime; see figure 2(a).

$h_1$ marking the onset of the elastic regime; see figure 2(a).

The liquid bridge becomes unstable at a critical plate separation distance ![]() $L_p = L_p^*$ marking the Rayleigh–Plateau instability threshold. The critical aspect ratio

$L_p = L_p^*$ marking the Rayleigh–Plateau instability threshold. The critical aspect ratio ![]() $\varLambda ^* = L_p^*/(2 R_0)$ depends on the liquid volume

$\varLambda ^* = L_p^*/(2 R_0)$ depends on the liquid volume ![]() $V$ and on the Bond number

$V$ and on the Bond number ![]() ${Bo} = \rho g R_0^2 / \gamma$, where

${Bo} = \rho g R_0^2 / \gamma$, where ![]() $g$ is the gravitational acceleration (Slobozhanin & Perales Reference Slobozhanin and Perales1993; Montanero & Ponce-Torres Reference Montanero and Ponce-Torres2020). In our experiments, we vary the plate diameter

$g$ is the gravitational acceleration (Slobozhanin & Perales Reference Slobozhanin and Perales1993; Montanero & Ponce-Torres Reference Montanero and Ponce-Torres2020). In our experiments, we vary the plate diameter ![]() $2R_0$ between

$2R_0$ between ![]() $2$ and

$2$ and ![]() $25\,{\rm mm}$, as well as the non-dimensional sample volume

$25\,{\rm mm}$, as well as the non-dimensional sample volume

Note that using ![]() $R_0^3$ as a reference volume is an arbitrary choice. Other authors often use the volume

$R_0^3$ as a reference volume is an arbitrary choice. Other authors often use the volume ![]() ${\rm \pi} R_0^2 L_p^*$ between the plates. As shown in figure 2(b), the last stable bridge radius increases approximately linearly with the plate radius, i.e.

${\rm \pi} R_0^2 L_p^*$ between the plates. As shown in figure 2(b), the last stable bridge radius increases approximately linearly with the plate radius, i.e. ![]() $h_0 \propto R_0$ with a prefactor that increases with

$h_0 \propto R_0$ with a prefactor that increases with ![]() $V^*$, with no strong dependence on the liquid used since they all have comparable surface tensions. Typically,

$V^*$, with no strong dependence on the liquid used since they all have comparable surface tensions. Typically, ![]() $h_0/R_0$ ranges between

$h_0/R_0$ ranges between ![]() $0.24$ and

$0.24$ and ![]() $0.35$ for

$0.35$ for ![]() $V^* \approx 1.3$ and

$V^* \approx 1.3$ and ![]() $3.2$, respectively.

$3.2$, respectively.

The size difference between the top and bottom end drops, visible in the inset images of figures 2(a,b), stems from Bond numbers ![]() ${Bo} = \rho g R_0^2 / \gamma$ increasing from

${Bo} = \rho g R_0^2 / \gamma$ increasing from ![]() $0.16$ to

$0.16$ to ![]() $25$ as the plate size increases (Pingulkar, Peixinho & Crumeyrolle Reference Pingulkar, Peixinho and Crumeyrolle2021). The ‘filament’ Bond number

$25$ as the plate size increases (Pingulkar, Peixinho & Crumeyrolle Reference Pingulkar, Peixinho and Crumeyrolle2021). The ‘filament’ Bond number ![]() ${Bo}_f = \rho g L_f h_1 / \gamma$, however, comparing the typical capillary pressure

${Bo}_f = \rho g L_f h_1 / \gamma$, however, comparing the typical capillary pressure ![]() $\gamma / h_1$ in the filament to the hydrostatic pressure

$\gamma / h_1$ in the filament to the hydrostatic pressure ![]() $\rho g L_f$ over the filament length

$\rho g L_f$ over the filament length ![]() $L_f$, is only up to

$L_f$, is only up to ![]() $0.1$ for the largest plate, indicating that the thinning dynamics is not driven by gravity. The filament length

$0.1$ for the largest plate, indicating that the thinning dynamics is not driven by gravity. The filament length ![]() $L_f$, shown in the right-hand inset image of figure 2(a), is discussed in the Appendix.

$L_f$, shown in the right-hand inset image of figure 2(a), is discussed in the Appendix.

The aluminium plates are plasma-treated before each measurement to increase their hydrophilicity and hence prevent dewetting of the top plate. However, dewetting could not be avoided for plate diameters ![]() $2R_0 \ge 10\,{\rm mm}$, as shown in the right-hand inset image of figure 2(b), featuring a stable liquid bridge (

$2R_0 \ge 10\,{\rm mm}$, as shown in the right-hand inset image of figure 2(b), featuring a stable liquid bridge (![]() $h \ge h_0$) where the top end drop does not fully cover the top plate for

$h \ge h_0$) where the top end drop does not fully cover the top plate for ![]() $2R_0 = 20\,{\rm mm}$. Perhaps surprisingly,

$2R_0 = 20\,{\rm mm}$. Perhaps surprisingly, ![]() $h_0$ does not saturate at

$h_0$ does not saturate at ![]() $2R_0 \ge 10\,{\rm mm}$ in spite of this lack of full coverage; see figure 2(b). For such large plates, the top end drop is not necessarily at the centre of the top plate since the two plates are not perfectly parallel. Note that because of the plasma treatment, there is always a thin film covering the top plate.

$2R_0 \ge 10\,{\rm mm}$ in spite of this lack of full coverage; see figure 2(b). For such large plates, the top end drop is not necessarily at the centre of the top plate since the two plates are not perfectly parallel. Note that because of the plasma treatment, there is always a thin film covering the top plate.

All experiments are carried out at a high relative humidity (![]() ${>}80\,\%$) ensured by placing the CaBER set-up in a box with wet paper tissues. We checked that repeating an experiment several times over the course of

${>}80\,\%$) ensured by placing the CaBER set-up in a box with wet paper tissues. We checked that repeating an experiment several times over the course of ![]() $10$ min does not lead to any monotonic increase or decrease of the filament thinning rate (defined as

$10$ min does not lead to any monotonic increase or decrease of the filament thinning rate (defined as ![]() $1/3\tau _e$; see § 3) over time, beyond small variations of less than

$1/3\tau _e$; see § 3) over time, beyond small variations of less than ![]() $5\,\%$, suggesting that both evaporation and polymer degradation (which may occur during bridge/filament thinning) are negligible.

$5\,\%$, suggesting that both evaporation and polymer degradation (which may occur during bridge/filament thinning) are negligible.

2.4. Equations and numerical methods

The numerical simulations discussed in §§ 4 and 5 are performed using the FENE-P model, which aims to describe the stretching and finite extensibility of polymer chains. We consider a cylindrical axisymmetric ![]() $(r,z)$ coordinate system aligned with the vertical axis of the liquid bridge. In the simulations, we integrate the mass and momentum conservation equations of general form

$(r,z)$ coordinate system aligned with the vertical axis of the liquid bridge. In the simulations, we integrate the mass and momentum conservation equations of general form

where ![]() $\rho$,

$\rho$, ![]() ${\boldsymbol v}=v_r({ r,z},t)\,{\boldsymbol e}_r+v_z(r,z,t)\,{\boldsymbol e}_z$ and

${\boldsymbol v}=v_r({ r,z},t)\,{\boldsymbol e}_r+v_z(r,z,t)\,{\boldsymbol e}_z$ and ![]() $p({ r,z},t)$ are the density, velocity and (reduced) pressure fields (accounting for gravity), respectively, and

$p({ r,z},t)$ are the density, velocity and (reduced) pressure fields (accounting for gravity), respectively, and ![]() ${\rm D}/{\rm D}t$ is the material derivative. These equations are completed with the constitutive relationships for the stress tensor

${\rm D}/{\rm D}t$ is the material derivative. These equations are completed with the constitutive relationships for the stress tensor ![]() $\boldsymbol \sigma = \boldsymbol \sigma _s+\boldsymbol \sigma _p$, where

$\boldsymbol \sigma = \boldsymbol \sigma _s+\boldsymbol \sigma _p$, where

is the contribution of the solvent of viscosity ![]() $\eta _s$, and

$\eta _s$, and ![]() $\boldsymbol \sigma _p$ is the polymer contribution. In the FENE-P model (Snoeijer et al. Reference Snoeijer, Pandey, Herrada and Eggers2020), this contribution is calculated as

$\boldsymbol \sigma _p$ is the polymer contribution. In the FENE-P model (Snoeijer et al. Reference Snoeijer, Pandey, Herrada and Eggers2020), this contribution is calculated as

where ![]() $\eta _p$ is the polymer contribution to the zero-shear viscosity

$\eta _p$ is the polymer contribution to the zero-shear viscosity ![]() $\eta _0 = \eta _s + \eta _p$,

$\eta _0 = \eta _s + \eta _p$, ![]() $\tau$ represents the relaxation time, and

$\tau$ represents the relaxation time, and ![]() $L^2$ denotes the finite extensibility limit, with

$L^2$ denotes the finite extensibility limit, with ![]() $\boldsymbol{\mathsf{I}}$ the identity matrix. The conformation tensor

$\boldsymbol{\mathsf{I}}$ the identity matrix. The conformation tensor ![]() $\boldsymbol{\mathsf{A}}$ is calculated from the nonlinear relaxation law

$\boldsymbol{\mathsf{A}}$ is calculated from the nonlinear relaxation law

The free-surface location is defined by the equation ![]() $r=h(z,t)$. The boundary conditions at that surface are

$r=h(z,t)$. The boundary conditions at that surface are

where ![]() $h_z \equiv \partial h/\partial z$,

$h_z \equiv \partial h/\partial z$, ![]() $h_{zz} \equiv \partial ^2h/\partial z^2$,

$h_{zz} \equiv \partial ^2h/\partial z^2$, ![]() $g$ is the gravitational acceleration,

$g$ is the gravitational acceleration, ![]() ${\boldsymbol n}$ is the unit outward normal vector, and

${\boldsymbol n}$ is the unit outward normal vector, and ![]() ${\boldsymbol t}$ is the unit vector tangential to the free-surface meridians. Equation (2.9) is the kinematic compatibility condition, while (2.10) and (2.11) express the balance of normal and tangential stresses, respectively. The anchorage condition

${\boldsymbol t}$ is the unit vector tangential to the free-surface meridians. Equation (2.9) is the kinematic compatibility condition, while (2.10) and (2.11) express the balance of normal and tangential stresses, respectively. The anchorage condition ![]() $h=R_0$ is set at

$h=R_0$ is set at ![]() $z=0$ and

$z=0$ and ![]() $z=L_p$, where

$z=L_p$, where ![]() $L_p$ is the plate separation distance. The no-slip boundary condition is imposed at the solid surfaces in contact with the liquid. The liquid volume

$L_p$ is the plate separation distance. The no-slip boundary condition is imposed at the solid surfaces in contact with the liquid. The liquid volume ![]() $V$ of the initial configuration is prescribed (and conserved), namely,

$V$ of the initial configuration is prescribed (and conserved), namely,

We start the simulation from a liquid bridge at equilibrium with a plate separation distance ![]() $L_p$ just below (very close to) the critical one. The breakup process is triggered by applying a very small gravitational force perturbation. We refer to the minimum radius of the (stable) liquid bridge just before the perturbation is applied as

$L_p$ just below (very close to) the critical one. The breakup process is triggered by applying a very small gravitational force perturbation. We refer to the minimum radius of the (stable) liquid bridge just before the perturbation is applied as ![]() $h_0$ due to the similarities with the experimental stepwise plate separation protocol described in § 2.3.

$h_0$ due to the similarities with the experimental stepwise plate separation protocol described in § 2.3.

A numerical simulation is fully determined by five quantities: the Ohnesorge number, the Deborah number, the non-dimensional sample volume ![]() $V^* = V/R_0^3$, the finite extensibility parameter

$V^* = V/R_0^3$, the finite extensibility parameter ![]() $L^2$, and the viscosity ratio

$L^2$, and the viscosity ratio

While equations are non-dimensionalised using ![]() $R_0$ and

$R_0$ and ![]() $(\rho R_0^3 / \gamma )^{1/2}$ as the characteristic length and time scales, in §§ 4 and 5 we refer only to values involving

$(\rho R_0^3 / \gamma )^{1/2}$ as the characteristic length and time scales, in §§ 4 and 5 we refer only to values involving ![]() $h_0$ since, as we will show in § 3.1, it is

$h_0$ since, as we will show in § 3.1, it is ![]() $h_0$ (not

$h_0$ (not ![]() $R_0$) that is the most relevant length scale of the problem. In particular, we refer to the Rayleigh and viscous time scales, and Ohnesorge and Deborah numbers defined in (1.3)–(1.6).

$R_0$) that is the most relevant length scale of the problem. In particular, we refer to the Rayleigh and viscous time scales, and Ohnesorge and Deborah numbers defined in (1.3)–(1.6).

Simulations are performed in the absence of gravity where the threshold of the Rayleigh–Plateau instability – and therefore the shape of the initial bridge of minimum radius ![]() $h_0$ from which simulations start – is determined solely by

$h_0$ from which simulations start – is determined solely by ![]() $V^*$. In §§ 4 and 5, instead of referring to

$V^*$. In §§ 4 and 5, instead of referring to ![]() $V^*$, we refer to the value of

$V^*$, we refer to the value of ![]() $h_0/R_0$, since in experiments

$h_0/R_0$, since in experiments ![]() $h_0/R_0$ is set not only by

$h_0/R_0$ is set not only by ![]() $V^*$ but also by the Bond number. We recall that in experiments,

$V^*$ but also by the Bond number. We recall that in experiments, ![]() $h_0/R_0$ ranges between

$h_0/R_0$ ranges between ![]() $0.24$ and

$0.24$ and ![]() $0.35$ for

$0.35$ for ![]() $V^* \approx 1.3$ and

$V^* \approx 1.3$ and ![]() $3.2$, respectively; see figure 2(b).

$3.2$, respectively; see figure 2(b).

The model was solved with a variation of the method described in Herrada & Montanero (Reference Herrada and Montanero2016). The physical domain occupied by the liquid is mapped onto a rectangular domain through a coordinate transformation. Each variable, and its spatial and temporal derivatives appearing in the transformed equations, was written as a single symbolic vector. Then we used a symbolic toolbox to calculate the analytical Jacobians of all the equations with respect to the symbolic vector. Using these analytical Jacobians, we generated functions that could be evaluated in the iterations at each point of the discretised numerical domains.

The transformed spatial domain is discretised using ![]() $n_\eta =11$ Chebyshev spectral collocation points in the transformed radial direction

$n_\eta =11$ Chebyshev spectral collocation points in the transformed radial direction ![]() $\eta$ of the domain. We used

$\eta$ of the domain. We used ![]() $n_\xi =501$ equally spaced collocation points in the transformed axial direction

$n_\xi =501$ equally spaced collocation points in the transformed axial direction ![]() $\xi$. The axial direction was discretised using second finite differences. Second-order backward finite differences were used to discretise the time domain. We used an automatic variable time step based on the norm of the difference between the solution calculated with a first-order approximation and that obtained from the second-order procedure. The nonlinear system of discretised equations was solved at each time step using the Newton method. The method is fully implicit.

$\xi$. The axial direction was discretised using second finite differences. Second-order backward finite differences were used to discretise the time domain. We used an automatic variable time step based on the norm of the difference between the solution calculated with a first-order approximation and that obtained from the second-order procedure. The nonlinear system of discretised equations was solved at each time step using the Newton method. The method is fully implicit.

3. Experimental results

In this experimental section, we investigate the roles of the plate radius and sample volume in § 3.1, and of the polymer concentration in § 3.2 on the pinch-off dynamics.

3.1. Influence of the plate radius and sample volume

Image sequences of the pinch-off dynamics are shown in figures 3(a) and 3(b) for the ![]() ${\rm PEO}_{{aq,1}}$ solution (

${\rm PEO}_{{aq,1}}$ solution (![]() $500\,{\rm ppm}$ PEO-4M in water) and the

$500\,{\rm ppm}$ PEO-4M in water) and the ![]() ${\rm PEO}_{{visc,1}}$ solution (

${\rm PEO}_{{visc,1}}$ solution (![]() $25\,{\rm ppm}$ PEO-4M in a

$25\,{\rm ppm}$ PEO-4M in a ![]() $\sim 260$ more viscous solvent), respectively, illustrating the transition from a bridge shape in the Newtonian regime to a filament shape in the elastic regime. For the

$\sim 260$ more viscous solvent), respectively, illustrating the transition from a bridge shape in the Newtonian regime to a filament shape in the elastic regime. For the ![]() ${\rm PEO}_{{aq,1}}$ solution, the filament is initially cylindrical until localised pinching is observed near one of the end drops (see frame 6 in figure 3a), followed by its destabilisation into a succession of beads connected by thin filaments (which are below our spatial resolution), a phenomenon usually referred to as ‘blistering’ instability (Sattler, Wagner & Eggers Reference Sattler, Wagner and Eggers2008; Sattler et al. Reference Sattler, Gier, Eggers and Wagner2012; Eggers Reference Eggers2014; Semakov et al. Reference Semakov, Kulichikhin, Tereshin, Antonov and Malkin2015) (see frames 7 and 8). For the

${\rm PEO}_{{aq,1}}$ solution, the filament is initially cylindrical until localised pinching is observed near one of the end drops (see frame 6 in figure 3a), followed by its destabilisation into a succession of beads connected by thin filaments (which are below our spatial resolution), a phenomenon usually referred to as ‘blistering’ instability (Sattler, Wagner & Eggers Reference Sattler, Wagner and Eggers2008; Sattler et al. Reference Sattler, Gier, Eggers and Wagner2012; Eggers Reference Eggers2014; Semakov et al. Reference Semakov, Kulichikhin, Tereshin, Antonov and Malkin2015) (see frames 7 and 8). For the ![]() ${\rm PEO}_{{visc,1}}$ solution, local pinching occurs very close to breakup, and no blistering is observed. In this paper, we refer to the minimum bridge/filament radius

${\rm PEO}_{{visc,1}}$ solution, local pinching occurs very close to breakup, and no blistering is observed. In this paper, we refer to the minimum bridge/filament radius ![]() $h$, which therefore corresponds to the pinched region if localised pinching occurs. On another note, inertio-capillary oscillations of the top and bottom end drops lead to oscillations of the filament length for the

$h$, which therefore corresponds to the pinched region if localised pinching occurs. On another note, inertio-capillary oscillations of the top and bottom end drops lead to oscillations of the filament length for the ![]() ${\rm PEO}_{{aq,1}}$ solution (see frames 3–6 in figure 3a). These oscillations are absent for the

${\rm PEO}_{{aq,1}}$ solution (see frames 3–6 in figure 3a). These oscillations are absent for the ![]() ${\rm PEO}_{{visc,1}}$ solution due to viscous damping. Note that oscillations do not lead to significant oscillations of the filament radius, implying that when the length of the filament increases, new filament is being created from the liquid in the end drops.

${\rm PEO}_{{visc,1}}$ solution due to viscous damping. Note that oscillations do not lead to significant oscillations of the filament radius, implying that when the length of the filament increases, new filament is being created from the liquid in the end drops.

Figure 3. (a,b) Image sequences of the bridge/filament for the (a) ![]() ${\rm PEO}_{{aq,1}}$ and (b)

${\rm PEO}_{{aq,1}}$ and (b) ![]() ${\rm PEO}_{{visc,1}}$ solutions tested with plate diameter

${\rm PEO}_{{visc,1}}$ solutions tested with plate diameter ![]() $2R_0 = 5\,{\rm mm}$ and sample volume

$2R_0 = 5\,{\rm mm}$ and sample volume ![]() $V^* \approx 2.4$. (c–f) Time evolution of the minimum bridge/filament radius

$V^* \approx 2.4$. (c–f) Time evolution of the minimum bridge/filament radius ![]() $h$ in (c,e) semi-log and (d, f) lin–lin, for plate diameters

$h$ in (c,e) semi-log and (d, f) lin–lin, for plate diameters ![]() $2R_0$ between

$2R_0$ between ![]() $2$ and

$2$ and ![]() $7\,{\rm mm}$, and fixed

$7\,{\rm mm}$, and fixed ![]() $V^* \approx 2.4$, for the (c,d)

$V^* \approx 2.4$, for the (c,d) ![]() ${\rm PEO}_{{aq,1}}$ and (e, f)

${\rm PEO}_{{aq,1}}$ and (e, f) ![]() ${\rm PEO}_{{visc,1}}$ solutions, and for their respective solvents (smaller data points), compared with (3.1) and (3.2), where

${\rm PEO}_{{visc,1}}$ solutions, and for their respective solvents (smaller data points), compared with (3.1) and (3.2), where ![]() $t_c$ is the solvent breakup time. Times with labels 1–7 and 2–5 in (c,e), respectively, for

$t_c$ is the solvent breakup time. Times with labels 1–7 and 2–5 in (c,e), respectively, for ![]() $2R_0=5\,{\rm mm}$, correspond to the snapshots in (a,b).

$2R_0=5\,{\rm mm}$, correspond to the snapshots in (a,b).

Time evolutions of the minimum bridge/filament radius ![]() $h$ are shown in figures 3(c–f) for four plate diameters between

$h$ are shown in figures 3(c–f) for four plate diameters between ![]() $2$ and

$2$ and ![]() $7\,{\rm mm}$, and a fixed non-dimensional sample volume

$7\,{\rm mm}$, and a fixed non-dimensional sample volume ![]() $V^* \approx 2.4$ for the

$V^* \approx 2.4$ for the ![]() ${\rm PEO}_{{aq,1}}$ solution (figures 3c,d) and the

${\rm PEO}_{{aq,1}}$ solution (figures 3c,d) and the ![]() ${\rm PEO}_{{visc,1}}$ solution (figures 3e, f) in semi-log (figures 3c,e) and lin–lin (figures 3d, f), the latter focusing on the transition to the elastic regime. The smaller data points correspond to the solvent alone for three of the same plate diameters, and in each case, the same

${\rm PEO}_{{visc,1}}$ solution (figures 3e, f) in semi-log (figures 3c,e) and lin–lin (figures 3d, f), the latter focusing on the transition to the elastic regime. The smaller data points correspond to the solvent alone for three of the same plate diameters, and in each case, the same ![]() $V^*$ (to within experimental reproducibility). The time reference

$V^*$ (to within experimental reproducibility). The time reference ![]() $t_c$ corresponds to the critical time at which the bridge of solvent alone breaks up. For polymer solutions, since

$t_c$ corresponds to the critical time at which the bridge of solvent alone breaks up. For polymer solutions, since ![]() $t_c$ cannot be determined, curves are shifted along the time axis until overlapping their corresponding solvent curves. The good overlap between polymer solutions and their solvent at all times

$t_c$ cannot be determined, curves are shifted along the time axis until overlapping their corresponding solvent curves. The good overlap between polymer solutions and their solvent at all times ![]() $t< t_1$ (before the transition to the elastic regime) confirms that polymers do not affect the pinch-off dynamics in the (hence rightfully called) Newtonian regime. For the

$t< t_1$ (before the transition to the elastic regime) confirms that polymers do not affect the pinch-off dynamics in the (hence rightfully called) Newtonian regime. For the ![]() ${\rm PEO}_{{visc,1}}$ solution, where, as is about to be discussed, capillarity is balanced by viscosity in the Newtonian regime, this solution–solvent overlap is consistent with the low polymer contribution to the total shear viscosity (

${\rm PEO}_{{visc,1}}$ solution, where, as is about to be discussed, capillarity is balanced by viscosity in the Newtonian regime, this solution–solvent overlap is consistent with the low polymer contribution to the total shear viscosity (![]() $\eta _p / \eta _0 = 0.013$). The least good solution–solvent overlaps are explained by experimental differences in

$\eta _p / \eta _0 = 0.013$). The least good solution–solvent overlaps are explained by experimental differences in ![]() $V^*$.

$V^*$.

All curves corresponding to Newtonian solvents in figures 3(d, f) overlap close to breakup, indicating a self-similar thinning regime where the initial condition, set by ![]() $R_0$ and

$R_0$ and ![]() $V^*$, is forgotten. Such overlap is also observed for droplets of different volumes for a given plate radius. For the water solvent in figure 3(d), the self-similar regime is well captured by the inertio-capillary thinning law

$V^*$, is forgotten. Such overlap is also observed for droplets of different volumes for a given plate radius. For the water solvent in figure 3(d), the self-similar regime is well captured by the inertio-capillary thinning law

\begin{equation} h = A \left( \frac{\gamma}{\rho} \right)^{1/3} (t_c-t)^{2/3}, \end{equation}

\begin{equation} h = A \left( \frac{\gamma}{\rho} \right)^{1/3} (t_c-t)^{2/3}, \end{equation}

with a prefactor ![]() $A = 0.47$ that is consistent with the experimental and numerical results of Deblais et al. (Reference Deblais, Herrada, Hauner, Velikov, Van Roon, Kellay, Eggers and Bonn2018). For the

$A = 0.47$ that is consistent with the experimental and numerical results of Deblais et al. (Reference Deblais, Herrada, Hauner, Velikov, Van Roon, Kellay, Eggers and Bonn2018). For the ![]() $\sim 260$ times more viscous solvent in figure 3( f), the self-similar regime is well captured by the visco-capillary thinning law (Papageorgiou Reference Papageorgiou1995; McKinley & Tripathi Reference McKinley and Tripathi2000)

$\sim 260$ times more viscous solvent in figure 3( f), the self-similar regime is well captured by the visco-capillary thinning law (Papageorgiou Reference Papageorgiou1995; McKinley & Tripathi Reference McKinley and Tripathi2000)

This is consistent with the fact that the Ohnesorge number ![]() ${Oh} = \eta _0/\sqrt {\rho \gamma h_0}$ (see (1.5)) is up to

${Oh} = \eta _0/\sqrt {\rho \gamma h_0}$ (see (1.5)) is up to ![]() $0.02$ for

$0.02$ for ![]() ${\rm PEO}_{{aq}}$, and up to

${\rm PEO}_{{aq}}$, and up to ![]() $0.1$ for HPAM (for the smallest plate diameter where

$0.1$ for HPAM (for the smallest plate diameter where ![]() $h_0$ is lowest), i.e.

$h_0$ is lowest), i.e. ![]() ${Oh} \ll 1$, and ranges between

${Oh} \ll 1$, and ranges between ![]() $1.0$ and

$1.0$ and ![]() $2.0$ for the

$2.0$ for the ![]() ${\rm PEO}_{{visc,1}}$ solution in the range of plate diameters considered in figure 3. In spite of the moderate Ohnesorge numbers in the latter case, we do not observe a clear transition to the inertio-visco-capillary thinning law

${\rm PEO}_{{visc,1}}$ solution in the range of plate diameters considered in figure 3. In spite of the moderate Ohnesorge numbers in the latter case, we do not observe a clear transition to the inertio-visco-capillary thinning law ![]() $h = 0.0304 (\gamma /\eta _0) (t_c-t)$ (Eggers Reference Eggers1993, Reference Eggers1997; Li & Sprittles Reference Li and Sprittles2016; Verbeke et al. Reference Verbeke, Formenti, Vangosa, Mitrias, Reddy, Anderson and Clasen2020) that describes the behaviour of Newtonian fluids close to breakup; see figure 3(d).

$h = 0.0304 (\gamma /\eta _0) (t_c-t)$ (Eggers Reference Eggers1993, Reference Eggers1997; Li & Sprittles Reference Li and Sprittles2016; Verbeke et al. Reference Verbeke, Formenti, Vangosa, Mitrias, Reddy, Anderson and Clasen2020) that describes the behaviour of Newtonian fluids close to breakup; see figure 3(d).

Interestingly, the transition to the elastic regime occurs at approximately the time at which the self-similar Newtonian regime is reached in figures 3(d, f) – slightly after for the ![]() ${\rm PEO}_{{aq,1}}$ solution, and slightly before for the

${\rm PEO}_{{aq,1}}$ solution, and slightly before for the ![]() ${\rm PEO}_{{visc,1}}$ solution. However, in both cases, the transition radius

${\rm PEO}_{{visc,1}}$ solution. However, in both cases, the transition radius ![]() $h_1 = h(t_1)$ increases with the plate diameter

$h_1 = h(t_1)$ increases with the plate diameter ![]() $2R_0$, which indicates that polymers already started to deform significantly before the self-similar regime. Indeed, if polymers started to deform only within the self-similar regime where the thinning dynamics no longer depends on

$2R_0$, which indicates that polymers already started to deform significantly before the self-similar regime. Indeed, if polymers started to deform only within the self-similar regime where the thinning dynamics no longer depends on ![]() $R_0$ or

$R_0$ or ![]() $V^*$, then the amount of polymer deformation would be independent of the initial condition, leading to a transition radius

$V^*$, then the amount of polymer deformation would be independent of the initial condition, leading to a transition radius ![]() $h_1$ that would not depend on

$h_1$ that would not depend on ![]() $R_0$ or

$R_0$ or ![]() $V^*$, as we discuss further in § 4.3.

$V^*$, as we discuss further in § 4.3.

After the filament formation, the thinning rate ![]() $\vert \dot {h}/h \vert$ is initially fairly constant, indicating an exponential decay, and increases close to breakup in a so-called ‘terminal regime’ where authors argue that polymer chains approach full extension and a Newtonian-like high-viscosity dynamics is recovered (Anna & McKinley Reference Anna and McKinley2001; Stelter et al. Reference Stelter, Brenn, Yarin, Singh and Durst2002; Campo-Deano & Clasen Reference Campo-Deano and Clasen2010; Dinic & Sharma Reference Dinic and Sharma2019). The (constant) filament thinning rate measured during the exponential part of the elastic regime is found to decrease with increasing plate diameter; see figures 3(c,e). This is inconsistent with the Oldroyd-B model, which predicts

$\vert \dot {h}/h \vert$ is initially fairly constant, indicating an exponential decay, and increases close to breakup in a so-called ‘terminal regime’ where authors argue that polymer chains approach full extension and a Newtonian-like high-viscosity dynamics is recovered (Anna & McKinley Reference Anna and McKinley2001; Stelter et al. Reference Stelter, Brenn, Yarin, Singh and Durst2002; Campo-Deano & Clasen Reference Campo-Deano and Clasen2010; Dinic & Sharma Reference Dinic and Sharma2019). The (constant) filament thinning rate measured during the exponential part of the elastic regime is found to decrease with increasing plate diameter; see figures 3(c,e). This is inconsistent with the Oldroyd-B model, which predicts ![]() $\vert \dot {h}/h \vert = 1/3\tau$ (see (1.1)), where

$\vert \dot {h}/h \vert = 1/3\tau$ (see (1.1)), where ![]() $\tau$ is the (longest) relaxation time of the polymer solution, which is a fluid property, independent of the size of the system. As we show in our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), this surprising dependence on the system size is also observed for the classical step-strain plate separation protocol of a commercial CaBER rheometer as well as for DoS and dripping (Rajesh et al. Reference Rajesh, Thiévenaz and Sauret2022) experiments. We show that this is not caused by artefacts such as solvent evaporation or polymer degradation, suggesting that the liquid does not change when being tested with different plate diameters. To discuss this geometry-dependent filament thinning rate, we define an apparent (or effective) relaxation time

$\tau$ is the (longest) relaxation time of the polymer solution, which is a fluid property, independent of the size of the system. As we show in our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), this surprising dependence on the system size is also observed for the classical step-strain plate separation protocol of a commercial CaBER rheometer as well as for DoS and dripping (Rajesh et al. Reference Rajesh, Thiévenaz and Sauret2022) experiments. We show that this is not caused by artefacts such as solvent evaporation or polymer degradation, suggesting that the liquid does not change when being tested with different plate diameters. To discuss this geometry-dependent filament thinning rate, we define an apparent (or effective) relaxation time ![]() $\tau _e$ such that

$\tau _e$ such that ![]() $\vert \dot {h}/h \vert = 1/3\tau _e$ during the exponential part of the elastic regime.

$\vert \dot {h}/h \vert = 1/3\tau _e$ during the exponential part of the elastic regime.

The apparent relaxation time ![]() $\tau _e$ and the transition radius

$\tau _e$ and the transition radius ![]() $h_1$ are plotted against

$h_1$ are plotted against ![]() $h_0$ in figure 4 for different polymer solutions, plate diameters

$h_0$ in figure 4 for different polymer solutions, plate diameters ![]() $2R_0$ and non-dimensional sample volumes

$2R_0$ and non-dimensional sample volumes ![]() $V^*$. The fact that data corresponding to different values of

$V^*$. The fact that data corresponding to different values of ![]() $R_0$ and

$R_0$ and ![]() $V^*$ collapse on a single curve for both the

$V^*$ collapse on a single curve for both the ![]() ${\rm PEO}_{{aq,1}}$ and

${\rm PEO}_{{aq,1}}$ and ![]() ${\rm PEO}_{{visc,1}}$ solutions suggests that

${\rm PEO}_{{visc,1}}$ solutions suggests that ![]() $h_0$, which is an increasing function of both

$h_0$, which is an increasing function of both ![]() $R_0$ and

$R_0$ and ![]() $V^*$ (see figure 2b), is the only relevant geometrical parameter of the problem. This is the reason why we chose

$V^*$ (see figure 2b), is the only relevant geometrical parameter of the problem. This is the reason why we chose ![]() $h_0$ at the relevant length scale for non-dimensional numbers such as the Ohnesorge and Deborah numbers in (1.5) and (1.6). This is in agreement with the idea that the thinning dynamics is influenced only by extensional flow in the bridge/filament, while the top and bottom end droplets act as passive liquid reservoirs.

$h_0$ at the relevant length scale for non-dimensional numbers such as the Ohnesorge and Deborah numbers in (1.5) and (1.6). This is in agreement with the idea that the thinning dynamics is influenced only by extensional flow in the bridge/filament, while the top and bottom end droplets act as passive liquid reservoirs.

Figure 4. (a) Effective extensional relaxation time ![]() $\tau _e$ and (b) transition radius

$\tau _e$ and (b) transition radius ![]() $h_1$ against the last stable bridge radius

$h_1$ against the last stable bridge radius ![]() $h_0$ for different plate radii

$h_0$ for different plate radii ![]() $R_0$ and sample volumes

$R_0$ and sample volumes ![]() $V^*$ for all polymer solutions. For the

$V^*$ for all polymer solutions. For the ![]() ${\rm PEO}_{{aq,1}}$ and

${\rm PEO}_{{aq,1}}$ and ![]() ${\rm PEO}_{{visc,1}}$ solutions, three points of the same colour correspond to the same

${\rm PEO}_{{visc,1}}$ solutions, three points of the same colour correspond to the same ![]() $R_0$ and three different

$R_0$ and three different ![]() $V^* \approx 1.3$,

$V^* \approx 1.3$, ![]() $2.4$ and

$2.4$ and ![]() $3.2$.

$3.2$.

We find that ![]() $\tau _e$ seems to saturate towards a maximum value

$\tau _e$ seems to saturate towards a maximum value ![]() $\tau _m$ at large

$\tau _m$ at large ![]() $h_0$; see figure 4(a). The estimated values of

$h_0$; see figure 4(a). The estimated values of ![]() $\tau _m$ are reported in table 2 for the

$\tau _m$ are reported in table 2 for the ![]() ${\rm PEO}_{{aq,2}}$,

${\rm PEO}_{{aq,2}}$, ![]() ${\rm PEO}_{{visc,2}}$ and HPAM solutions for which plate diameters up to

${\rm PEO}_{{visc,2}}$ and HPAM solutions for which plate diameters up to ![]() $25\,{\rm mm}$ were used, well beyond typical CaBER plate sizes, which was needed to observe the saturation of

$25\,{\rm mm}$ were used, well beyond typical CaBER plate sizes, which was needed to observe the saturation of ![]() $\tau _e$. In our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), we explored the possibility that

$\tau _e$. In our previous paper (Gaillard et al. Reference Gaillard, Herrada, Deblais, Eggers and Bonn2024), we explored the possibility that ![]() $\tau _m$ could be the ‘real’ relaxation time of the solution, invoking finite extensibility effects described by the FENE-P model to explain thinning rates larger than

$\tau _m$ could be the ‘real’ relaxation time of the solution, invoking finite extensibility effects described by the FENE-P model to explain thinning rates larger than ![]() $1/3\tau _m$ for low

$1/3\tau _m$ for low ![]() $h_0$. We concluded that this was a possible explanation only for the

$h_0$. We concluded that this was a possible explanation only for the ![]() ${\rm PEO}_{{visc,2}}$ solution, not for the

${\rm PEO}_{{visc,2}}$ solution, not for the ![]() ${\rm PEO}_{{aq,2}}$ and HPAM solutions, suggesting that the FENE-P model misses some important features of polymer dynamics in extensional flows.

${\rm PEO}_{{aq,2}}$ and HPAM solutions, suggesting that the FENE-P model misses some important features of polymer dynamics in extensional flows.

The first transition radius ![]() $h_1$ increases approximately linearly with

$h_1$ increases approximately linearly with ![]() $h_0$ for all liquids; see figure 4(b). This is in contradiction with the scaling

$h_0$ for all liquids; see figure 4(b). This is in contradiction with the scaling ![]() $h_1 \propto h_0^{4/3}$ expected from the Oldroyd-B model when assuming that polymer relaxation is negligible during the time needed for the bridge to thin from

$h_1 \propto h_0^{4/3}$ expected from the Oldroyd-B model when assuming that polymer relaxation is negligible during the time needed for the bridge to thin from ![]() $h_0$ to

$h_0$ to ![]() $h_1$; see (1.2). Since

$h_1$; see (1.2). Since ![]() $h_0 \propto R_0$ for a fixed

$h_0 \propto R_0$ for a fixed ![]() $V^*$ (see figure 2b), this implies that

$V^*$ (see figure 2b), this implies that ![]() $h_1 \propto R_0$, different from the scaling

$h_1 \propto R_0$, different from the scaling ![]() $h_1 \propto R_{n}^{0.66}$ observed experimentally by Rajesh et al. (Reference Rajesh, Thiévenaz and Sauret2022) in the analogous problem of a drop falling from a nozzle of radius

$h_1 \propto R_{n}^{0.66}$ observed experimentally by Rajesh et al. (Reference Rajesh, Thiévenaz and Sauret2022) in the analogous problem of a drop falling from a nozzle of radius ![]() $R_n$. This is surprising since

$R_n$. This is surprising since ![]() $R_n$ should play the same role as the plate radius

$R_n$ should play the same role as the plate radius ![]() $R_0$ in CaBER.

$R_0$ in CaBER.

Note that the ![]() ${\rm PEO}_{{aq,2}}$ and