1. Introduction

High-amplitude vibrations of an elastic sheet in a fluid flow provide a novel mechanical approach for harvesting fluid kinetic energy. Diverse configurations of a flapping flag with one fixed end and one free end have been suggested for applications to piezoelectric energy harvesters. These are mostly based on the deformation of single or multiple flags (Doaré & Michelin Reference Doaré and Michelin2011; Tosi, Dorschner & Colonius Reference Tosi, Dorschner and Colonius2021), a flag with an upstream bluff body (Allen & Smits Reference Allen and Smits2001; Akaydin, Elvin & Andreopoulos Reference Akaydin, Elvin and Andreopoulos2010; Mittal & Sharma Reference Mittal and Sharma2022), single or multiple inverted flags (Kim et al. Reference Kim, Cossé, Cerdeira and Gharib2013; Shoele & Mittal Reference Shoele and Mittal2016; Ryu, Park & Sung Reference Ryu, Park and Sung2018; Mazharmanesh et al. Reference Mazharmanesh, Young, Tian and Lai2020; Tavallaeinejad et al. Reference Tavallaeinejad, Païdoussis, Salinas, Legrand, Kheiri and Botez2020) and an inverted flag with an upstream bluff body (Kim, Kang & Kim Reference Kim, Kang and Kim2017). Furthermore, for triboelectric energy generation, the contact and separation of a flag with a nearby rigid wall (Bae et al. Reference Bae2014; Meng, Zhu & Wang Reference Meng, Zhu and Wang2014; Zhang et al. Reference Zhang, Meng, Xia, Deng, Dai, Hagedorn, Peng and Wang2020; Lee, Kim & Kim Reference Lee, Kim and Kim2021) or bluff body (Zhang et al. Reference Zhang, Meng, Xia, Deng, Dai, Hagedorn, Peng and Wang2020) and the mutual contact and separation of two side-by-side flags (Chen et al. Reference Chen2020) have been investigated.

A buckled elastic sheet with two clamped ends, which is initially bi-stable, rapidly snaps to the other side if the external force exerted on the sheet satisfies a certain criterion. This snap-through motion can be initiated by various external inputs, including a point force (Chen & Hung Reference Chen and Hung2011; Pandey et al. Reference Pandey, Moulton, Vella and Holmes2014), a change in the supporting angle of the sheet (Beharic, Lucas & Harnett Reference Beharic, Lucas and Harnett2014; Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017a), the capillary force of a droplet deposited on the sheet (Fargette, Neukirch & Antkowiak Reference Fargette, Neukirch and Antkowiak2014) and a midpoint magnetic force (Boisseau et al. Reference Boisseau, Despesse, Monfray, Puscasu and Skotnicki2013). Fluid flow has also been used to trigger one-off snap through in applications to on/off switches, valves or flow regulators. Gomez, Moulton & Vella (Reference Gomez, Moulton and Vella2017b) used a small-scale low-Reynolds-number channel flow to study the one-off snap-through of a buckled sheet embedded at the bottom of a channel, whereas Arena et al. (Reference Arena, Groh, Brinkmeyer, Theunissen, Weaver and Pirrera2017) devised a shape-adapted air inlet with a buckled sheet in which the flow is regulated by the snap-through and snap-back motions at the inlet. Peretz et al. (Reference Peretz, Mishra, Shepherd and Gat2020) proposed a slender elastic membrane to make a continuous multi-stable structure in which two different equilibrium states coexist, with a transition region between them.

A buckled sheet undergoes periodic snap-through oscillations under a uniform external flow at high Reynolds numbers. For a single buckled sheet, Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b) identified the conditions for transition between the static equilibrium and snap-through oscillations, and revealed several salient features of the snap-through oscillations such as divergence instability and high bending-energy generation. Furthermore, the snapping motions of tandem buckled sheets under fluid flow have been examined to determine the effects of the upstream buckled sheet on the critical condition and post-critical dynamics of the downstream buckled sheet (Kim, Kim & Kim Reference Kim, Kim and Kim2021a). For triboelectric energy harvesting, Kim et al. (Reference Kim, Zhou, Kim and Oh2020) introduced a buckled elastic sheet of a finite height between two parallel confining walls, where the snap-through oscillations of the sheet by uniform fluid flow in three-dimensional space induce periodic contact and separation with the walls, and showed that this configuration had several regular contact modes depending on the flow speed and gap distance between the walls.

The snap-through phenomenon has only recently been introduced as a method for triboelectric energy harvesting. The aforementioned previous studies approached the problem with experimental measurements, which lack detailed information about flow characteristics around the sheet, contact force and vortex dynamics in the wake. These aspects are essential to comprehensively understand the fluid–structure interaction principles of triboelectric energy harvesting applications, and can be unravelled using numerical simulations. Therefore, in this study, we numerically investigate the snap-through dynamics of a buckled sheet between two confining walls to elucidate the complicated contact and separation process of the sheet and confining walls. The simulations of snap-through oscillations and periodic contacts with the walls are conducted for the first time to the best of our knowledge. A two-dimensional sheet model and fluid domain are adopted to simplify the problem. The streamwise distance between the two clamped ends of the sheet, the cross-wise distance between the two confining walls, the bending stiffness of the sheet and the free-stream velocity are varied.

Details of the model configuration and input parameters, as well as the governing equations for numerical simulations, are provided in § 2. The coupling of the fluid and structure solvers and contact algorithm are described in § 3. The shape of the sheet in equilibrium state and the critical condition for the onset of snap-through are discussed in § 4.1. In § 4.2, the post-critical dynamics of the sheet is analysed, with a particular focus on the contact force and oscillation frequency of the sheet. The effects of the confining walls on flow structures in the post-equilibrium state are then addressed in § 4.3. Finally, our findings are summarised in § 5.

2. Problem description

2.1. Model and parameters

An elastic sheet of length ![]() $L$, thickness

$L$, thickness ![]() $h$, density

$h$, density ![]() $\rho _s$, Young's modulus E and bending stiffness per unit depth

$\rho _s$, Young's modulus E and bending stiffness per unit depth ![]() $EI(=Eh^3/12)$ is located between two horizontal walls of gap distance

$EI(=Eh^3/12)$ is located between two horizontal walls of gap distance ![]() $d$ (figure 1). The distance

$d$ (figure 1). The distance ![]() $L_0$ between the two clamped ends of the sheet is identical to the length of the walls, being smaller than

$L_0$ between the two clamped ends of the sheet is identical to the length of the walls, being smaller than ![]() $L$; a bi-stable buckled sheet is formed in the absence of fluid flow. The sheet is exposed to a uniform fluid flow of velocity

$L$; a bi-stable buckled sheet is formed in the absence of fluid flow. The sheet is exposed to a uniform fluid flow of velocity ![]() $U$, density

$U$, density ![]() $\rho _f$ and kinematic viscosity

$\rho _f$ and kinematic viscosity ![]() $\nu$. The sheet is initially at equilibrium without the fluid flow, and the geometric parameters determine whether the sheet is in contact with the confining wall or not. Although two up–down symmetric shapes of the buckled sheet are possible in the equilibrium state without the fluid flow, only one configuration is considered as an initial condition (figure 1). When the free-stream velocity

$\nu$. The sheet is initially at equilibrium without the fluid flow, and the geometric parameters determine whether the sheet is in contact with the confining wall or not. Although two up–down symmetric shapes of the buckled sheet are possible in the equilibrium state without the fluid flow, only one configuration is considered as an initial condition (figure 1). When the free-stream velocity ![]() $U$ surpasses a certain critical value

$U$ surpasses a certain critical value ![]() $U_c$, the buckled sheet becomes unstable and snaps to the other side, leading to periodic oscillations (Kim et al. Reference Kim, Zhou, Kim and Oh2020, Reference Kim, Lahooti, Kim and Kim2021b).

$U_c$, the buckled sheet becomes unstable and snaps to the other side, leading to periodic oscillations (Kim et al. Reference Kim, Zhou, Kim and Oh2020, Reference Kim, Lahooti, Kim and Kim2021b).

Figure 1. Schematic of a buckled sheet between two horizontal confining walls and a fluid domain. The inner dotted rectangle and outer dashed rectangle indicate the region with fine grid resolution and the entire fluid domain, respectively.

Instead of finite walls with length ![]() $L_0$, infinite walls along the

$L_0$, infinite walls along the ![]() $x$-direction could be considered alternatively: that is, a buckled sheet inside an infinitely long channel of Poiseuille flow. In such a configuration, the incoming flow cannot be diverted at the inlet of the channel, which leads to the significant increase in the pressure force acting on the sheet and the consequent reduction in the critical velocity

$x$-direction could be considered alternatively: that is, a buckled sheet inside an infinitely long channel of Poiseuille flow. In such a configuration, the incoming flow cannot be diverted at the inlet of the channel, which leads to the significant increase in the pressure force acting on the sheet and the consequent reduction in the critical velocity ![]() $U_c$, particularly for cases with large blockage by the sheet inside the channel. The configuration with finite walls is more realistic for actual applications to fluid kinetic energy harvesting from wind and ocean. Hence, the present study adopts the finite walls although the configuration with infinite walls is expected to have some distinct characteristics.

$U_c$, particularly for cases with large blockage by the sheet inside the channel. The configuration with finite walls is more realistic for actual applications to fluid kinetic energy harvesting from wind and ocean. Hence, the present study adopts the finite walls although the configuration with infinite walls is expected to have some distinct characteristics.

The response of the sheet is affected by several dimensionless parameters: the dimensionless flow velocity (![]() $U^*=U(\rho _f w_0L^2/EI)^{1/2}$), sheet length ratio (

$U^*=U(\rho _f w_0L^2/EI)^{1/2}$), sheet length ratio (![]() $L^*=L_0/L$), gap distance ratio (

$L^*=L_0/L$), gap distance ratio (![]() $d^*=d/L$), blockage ratio (

$d^*=d/L$), blockage ratio (![]() $w_0^*=w_0/d$), mass ratio (

$w_0^*=w_0/d$), mass ratio (![]() $m^*=\rho _s h/\rho _f L$) and Reynolds number (

$m^*=\rho _s h/\rho _f L$) and Reynolds number (![]() $Re=UL/\nu$). The maximum transverse deflection of the initial buckled sheet along the

$Re=UL/\nu$). The maximum transverse deflection of the initial buckled sheet along the ![]() $y$ direction at

$y$ direction at ![]() $U = 0$ when no wall is present is

$U = 0$ when no wall is present is ![]() $w_0$, which varies with changes in

$w_0$, which varies with changes in ![]() $L$ or

$L$ or ![]() $L_0$. Although

$L_0$. Although ![]() $w_0$ is the maximum transverse deflection of the sheet without the walls, it is also used to define the blockage ratio for the cases in contact with the wall. It is because, when the sheet is in contact with the wall, the peak-to-peak transverse distance of the deformed sheet at

$w_0$ is the maximum transverse deflection of the sheet without the walls, it is also used to define the blockage ratio for the cases in contact with the wall. It is because, when the sheet is in contact with the wall, the peak-to-peak transverse distance of the deformed sheet at ![]() $U=0$ is similar to

$U=0$ is similar to ![]() $w_0$. The choice of the dimensionless parameters, except for gap distance ratio, follows the work of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), in which detailed reasoning on non-dimensionalisation is provided;

$w_0$. The choice of the dimensionless parameters, except for gap distance ratio, follows the work of Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), in which detailed reasoning on non-dimensionalisation is provided; ![]() $U^*$ is a particular dimensionless parameter introduced by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b) for a snap-through model, and is different from the dimensionless flow velocity commonly used for fluttering sheet models (Kim et al. Reference Kim, Cossé, Cerdeira and Gharib2013; Shoele & Mittal Reference Shoele and Mittal2016; Kim & Kim Reference Kim and Kim2019).

$U^*$ is a particular dimensionless parameter introduced by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b) for a snap-through model, and is different from the dimensionless flow velocity commonly used for fluttering sheet models (Kim et al. Reference Kim, Cossé, Cerdeira and Gharib2013; Shoele & Mittal Reference Shoele and Mittal2016; Kim & Kim Reference Kim and Kim2019).

The dimensionless flow velocity ![]() $U^*$ ranges from 5.0 to 28.0;

$U^*$ ranges from 5.0 to 28.0; ![]() $L^*$ ranges between 0.6 and 0.9, and is varied by changing

$L^*$ ranges between 0.6 and 0.9, and is varied by changing ![]() $L_0$ while maintaining

$L_0$ while maintaining ![]() $L=1$. The parameter

$L=1$. The parameter ![]() $d^*(=0.40$–1.00) is considered to include both contact and non-contact conditions, and the cases without confining walls (

$d^*(=0.40$–1.00) is considered to include both contact and non-contact conditions, and the cases without confining walls (![]() $d^*=\infty$) are also considered. The parameter

$d^*=\infty$) are also considered. The parameter ![]() $w_0^*$ was originally introduced by Gomez et al. (Reference Gomez, Moulton and Vella2017b) to indicate how much the cross-section of the channel is blocked by the buckled sheet. Because

$w_0^*$ was originally introduced by Gomez et al. (Reference Gomez, Moulton and Vella2017b) to indicate how much the cross-section of the channel is blocked by the buckled sheet. Because ![]() $w_0$ is a function of

$w_0$ is a function of ![]() $L$ and

$L$ and ![]() $L_0$,

$L_0$, ![]() $w_0^*$ is not an independent dimensionless parameter, but is determined by

$w_0^*$ is not an independent dimensionless parameter, but is determined by ![]() $L^*$ and

$L^*$ and ![]() $d^*$. Here,

$d^*$. Here, ![]() $m^* (=0.75)$ and

$m^* (=0.75)$ and ![]() $Re (=200)$ are fixed, following Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), who showed that the snap-through instability is of divergence type rather than flutter type and these parameters are of relatively less importance in determining the critical conditions, compared with

$Re (=200)$ are fixed, following Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), who showed that the snap-through instability is of divergence type rather than flutter type and these parameters are of relatively less importance in determining the critical conditions, compared with ![]() $U^*$ and

$U^*$ and ![]() $L^*$. For this reason, although

$L^*$. For this reason, although ![]() $m^*$ and

$m^*$ and ![]() $Re$ affect the post-critical dynamics of the sheet, only

$Re$ affect the post-critical dynamics of the sheet, only ![]() $U^*$,

$U^*$, ![]() $L^*$ and

$L^*$ and ![]() $d^*$ are considered as dimensionless variables in this study. The input parameters of this study are summarised in table 1.

$d^*$ are considered as dimensionless variables in this study. The input parameters of this study are summarised in table 1.

Table 1. Dimensionless input parameters.

2.2. Governing equations

For numerical simulations, the nonlinear elastic model with an inextensibility constraint, which is commonly used for elastic sheets (Zhu & Peskin Reference Zhu and Peskin2002; Connel & Yue Reference Connel and Yue2007; Tian et al. Reference Tian, Luo, Zhu, Liao and Lu2011; Mazharmanesh et al. Reference Mazharmanesh, Young, Tian and Lai2020), is adopted along with the direct-forcing immersed boundary method (IBM) (Uhlmann Reference Uhlmann2005). The numerical method is implemented in the OpenFOAM framework by developing a new library for the elastic sheet model and IBM. The flow is two-dimensional, incompressible and laminar, and is governed by the following dimensionless continuity and momentum equations:

where ![]() $\boldsymbol {u}=(u,v)$ and

$\boldsymbol {u}=(u,v)$ and ![]() $p$ are the velocity vector and pressure. In (2.1b),

$p$ are the velocity vector and pressure. In (2.1b), ![]() $\boldsymbol {f}$ is a source term that enforces the continuity of the flow passing the immersed boundary (Uhlmann Reference Uhlmann2005). The entire fluid domain extends

$\boldsymbol {f}$ is a source term that enforces the continuity of the flow passing the immersed boundary (Uhlmann Reference Uhlmann2005). The entire fluid domain extends ![]() $23 L_0$ and

$23 L_0$ and ![]() $16 L_0$ in the streamwise and cross-wise directions, to minimise the effect of artificial boundary conditions (figure 1). A uniform flow is applied to the inlet on the left side of the domain. Symmetric conditions are assigned on the top and bottom boundaries, and a zero velocity gradient and constant pressure are imposed at the outlet on the right, with the no-slip condition enforced on the two confining walls.

$16 L_0$ in the streamwise and cross-wise directions, to minimise the effect of artificial boundary conditions (figure 1). A uniform flow is applied to the inlet on the left side of the domain. Symmetric conditions are assigned on the top and bottom boundaries, and a zero velocity gradient and constant pressure are imposed at the outlet on the right, with the no-slip condition enforced on the two confining walls.

The two-dimensional equation for the elastic sheet is written in dimensionless form as (Connel & Yue Reference Connel and Yue2007)

where ![]() $m^*(=\rho _s h/\rho _f L)$ is the mass ratio,

$m^*(=\rho _s h/\rho _f L)$ is the mass ratio, ![]() $\boldsymbol {X}=(x,y)$ is the position vector,

$\boldsymbol {X}=(x,y)$ is the position vector, ![]() $s$ is the curvilinear coordinate starting from the left end of the sheet and

$s$ is the curvilinear coordinate starting from the left end of the sheet and ![]() $k_b=EI/(\rho _fU^2 L^3)$ is the bending coefficient. Here,

$k_b=EI/(\rho _fU^2 L^3)$ is the bending coefficient. Here, ![]() $\boldsymbol {F}_f$ is the fluid force exerted on the sheet, which is calculated by extrapolating the pressure and stress on the structure surface,

$\boldsymbol {F}_f$ is the fluid force exerted on the sheet, which is calculated by extrapolating the pressure and stress on the structure surface, ![]() $\boldsymbol {F}_c$ is the force exerted by the wall contact and

$\boldsymbol {F}_c$ is the force exerted by the wall contact and ![]() $Fr=gL/U^2$ is the Froude number. Also,

$Fr=gL/U^2$ is the Froude number. Also, ![]() $T$ is the tension force, defined as

$T$ is the tension force, defined as

\begin{equation} T(s)=k_s \left[ \left( \frac{\partial\boldsymbol{X}}{\partial s} \boldsymbol{\cdot} \frac{\partial\boldsymbol{X}}{\partial s} \right)^{1/2}-1 \right], \end{equation}

\begin{equation} T(s)=k_s \left[ \left( \frac{\partial\boldsymbol{X}}{\partial s} \boldsymbol{\cdot} \frac{\partial\boldsymbol{X}}{\partial s} \right)^{1/2}-1 \right], \end{equation}

where ![]() $k_s=200$ is a sufficiently large coefficient chosen to ensure the inextensibility of the sheet; we confirmed that our simulations were insensitive to the value of this parameter. The last term in (2.2) for the gravitational effect is only considered for validation cases in § 3.2. At both clamped ends of the sheet, the boundary conditions are

$k_s=200$ is a sufficiently large coefficient chosen to ensure the inextensibility of the sheet; we confirmed that our simulations were insensitive to the value of this parameter. The last term in (2.2) for the gravitational effect is only considered for validation cases in § 3.2. At both clamped ends of the sheet, the boundary conditions are

The equilibrium shape of the sheet in the absence of flow is acquired by numerically solving (2.2). Depending on the sheet length ratio ![]() $L^*$ and the gap distance ratio

$L^*$ and the gap distance ratio ![]() $d^*$, the sheet can be in contact with the wall or separated from the wall. For non-contact cases, the exact solution for the equilibrium shape at zero flow velocity is obtained from the solution in Beharic et al. (Reference Beharic, Lucas and Harnett2014). To find the equilibrium shape at zero flow velocity for all contact cases, first, we place the walls at

$d^*$, the sheet can be in contact with the wall or separated from the wall. For non-contact cases, the exact solution for the equilibrium shape at zero flow velocity is obtained from the solution in Beharic et al. (Reference Beharic, Lucas and Harnett2014). To find the equilibrium shape at zero flow velocity for all contact cases, first, we place the walls at ![]() $d^{*}=0.7$ where contact does not occur, so that we can use the exact solution of a sheet with no contact. The walls are then gradually moved closer together until a specified

$d^{*}=0.7$ where contact does not occur, so that we can use the exact solution of a sheet with no contact. The walls are then gradually moved closer together until a specified ![]() $d^*$ is reached.

$d^*$ is reached.

3. Numerical method

3.1. Fluid and structure solvers

Equations (2.1a) and (2.1b) are solved using the PISO algorithm (Pressure-Implicit with Splitting of Operators) as described by Jasak (Reference Jasak1996), with some modifications to consider the forcing term ![]() $\boldsymbol {f}$. All terms are discretised by second-order Gauss finite-volume integration, except for the convection term, which is discretised by the second-order upwind scheme. The implicit first-order Euler method is used for time marching. To find

$\boldsymbol {f}$. All terms are discretised by second-order Gauss finite-volume integration, except for the convection term, which is discretised by the second-order upwind scheme. The implicit first-order Euler method is used for time marching. To find ![]() $\boldsymbol {f}$, a momentum equation without

$\boldsymbol {f}$, a momentum equation without ![]() $\boldsymbol {f}$ is first solved to obtain

$\boldsymbol {f}$ is first solved to obtain ![]() $\tilde {\boldsymbol {u}}$

$\tilde {\boldsymbol {u}}$

Here, ![]() $\tilde {u}$ is an intermediate velocity, which is different from the solution of the previous time step, and it is not the exact solution of the current time step;

$\tilde {u}$ is an intermediate velocity, which is different from the solution of the previous time step, and it is not the exact solution of the current time step; ![]() $\tilde {u}$ is then interpolated to the Lagrangian grid for the sheet

$\tilde {u}$ is then interpolated to the Lagrangian grid for the sheet

where ![]() $\delta$ is a function defined by Roma, Peskin & Berger (Reference Roma, Peskin and Berger1999) as

$\delta$ is a function defined by Roma, Peskin & Berger (Reference Roma, Peskin and Berger1999) as

where ![]() $\Delta x_r$ is the size of uniform grids in the fluid region around the sheet in both the

$\Delta x_r$ is the size of uniform grids in the fluid region around the sheet in both the ![]() $x$ and

$x$ and ![]() $y$ directions. The parameter

$y$ directions. The parameter ![]() $\phi (r)$ is a continuous function defined as

$\phi (r)$ is a continuous function defined as

\begin{equation} \phi(r)=\left\{ \begin{array}{@{}ll} \dfrac{1}{6}(5-3|r|-\sqrt{-3(1-|r|)^2+1}) & 0.5\leq|r|\leq 1.5,\\ \dfrac{1}{3}(1+\sqrt{-3r^2+1}) & |r|\leq0.5,\\ 0\quad & \text{otherwise.} \end{array} \right.\end{equation}

\begin{equation} \phi(r)=\left\{ \begin{array}{@{}ll} \dfrac{1}{6}(5-3|r|-\sqrt{-3(1-|r|)^2+1}) & 0.5\leq|r|\leq 1.5,\\ \dfrac{1}{3}(1+\sqrt{-3r^2+1}) & |r|\leq0.5,\\ 0\quad & \text{otherwise.} \end{array} \right.\end{equation}

The difference between the intermediate velocity ![]() $\tilde {\boldsymbol {U}}$ of the sheet, which is interpolated from the fluid, and the velocity

$\tilde {\boldsymbol {U}}$ of the sheet, which is interpolated from the fluid, and the velocity ![]() $\boldsymbol {U}$ of the sheet at the previous time step, which is provided by the structure solver, is used to define a forcing term on the Lagrangian points (Uhlmann Reference Uhlmann2005)

$\boldsymbol {U}$ of the sheet at the previous time step, which is provided by the structure solver, is used to define a forcing term on the Lagrangian points (Uhlmann Reference Uhlmann2005)

Then, ![]() $\boldsymbol {f}$ is determined by transferring

$\boldsymbol {f}$ is determined by transferring ![]() $\boldsymbol {F}$ to the Eulerian domain for the flow field

$\boldsymbol {F}$ to the Eulerian domain for the flow field

The divergence-free velocity is then given by solving for the pressure.

The inextensibility condition of the elastic sheet is a well-known issue in the coupling of a fluid and an elastic sheet (Huang, Shin & Sung Reference Huang, Shin and Sung2007). To avoid instability in the numerical simulations and large errors in the length change, the time step must be much smaller than the value specified by the Courant–Friedrichs–Lewy condition (Huang et al. Reference Huang, Shin and Sung2007; Shoele & Mittal Reference Shoele and Mittal2016; Ryu et al. Reference Ryu, Park and Sung2018; Mazharmanesh et al. Reference Mazharmanesh, Young, Tian and Lai2020).Here, sub-cycling is suggested to solve (2.2), as this considerably reduces the computation time while accurately preserving the sheet length. Equation (2.2) for the sheet is solved implicitly at the end of the PISO algorithm with the fluid pressure and velocity at time ![]() $t = (n+1)\Delta t$. For

$t = (n+1)\Delta t$. For ![]() $N$ sub-cycles of the structure solver with the sub-cycle time step

$N$ sub-cycles of the structure solver with the sub-cycle time step ![]() $\Delta \tau =\Delta t/N$

$\Delta \tau =\Delta t/N$

where the superscript ![]() $m$ indicates the

$m$ indicates the ![]() $m$th sub-cycle time step. After sub-cycling, the location of the sheet is obtained at time

$m$th sub-cycle time step. After sub-cycling, the location of the sheet is obtained at time ![]() $t = (n+1)\Delta t$. The spatial discretisation of (3.7) is performed using the central differencing method and on staggered grids of the same size as the uniform fluid grids around the sheet.

$t = (n+1)\Delta t$. The spatial discretisation of (3.7) is performed using the central differencing method and on staggered grids of the same size as the uniform fluid grids around the sheet.

The collision of the sheet with a confining wall is implemented using an artificial repulsive force ![]() $\boldsymbol {F}_c$, which prevents the sheet from penetrating the wall. The total repulsive force applied on each element

$\boldsymbol {F}_c$, which prevents the sheet from penetrating the wall. The total repulsive force applied on each element ![]() $i$ of the sheet is calculated as a summation over the forces exerted by all elements of the wall (Glowinski et al. Reference Glowinski, Pan, Hesla, Joseph and Périaux2001)

$i$ of the sheet is calculated as a summation over the forces exerted by all elements of the wall (Glowinski et al. Reference Glowinski, Pan, Hesla, Joseph and Périaux2001)

\begin{align} \boldsymbol{F}_{c,i}=\begin{cases} \displaystyle \sum_{j=1}^{k} \frac{1}{\epsilon}\boldsymbol{d}_{ij} \delta(\boldsymbol{d}_{ij})(\xi-|\boldsymbol{d}_{ij}|)^2 & \text{if } |\boldsymbol{d}_{ij}| \leq \xi,\\ 0 & \text{otherwise}, \end{cases} \end{align}

\begin{align} \boldsymbol{F}_{c,i}=\begin{cases} \displaystyle \sum_{j=1}^{k} \frac{1}{\epsilon}\boldsymbol{d}_{ij} \delta(\boldsymbol{d}_{ij})(\xi-|\boldsymbol{d}_{ij}|)^2 & \text{if } |\boldsymbol{d}_{ij}| \leq \xi,\\ 0 & \text{otherwise}, \end{cases} \end{align}

where ![]() $\boldsymbol {d}_{ij}=\boldsymbol {X}_i-\boldsymbol {X}_j$ is the distance vector between the centres of element

$\boldsymbol {d}_{ij}=\boldsymbol {X}_i-\boldsymbol {X}_j$ is the distance vector between the centres of element ![]() $i$ of the sheet and element

$i$ of the sheet and element ![]() $j$ of the wall;

$j$ of the wall; ![]() $\xi =2 \Delta x_r$ is the reference distance within which the force is active;

$\xi =2 \Delta x_r$ is the reference distance within which the force is active; ![]() $\Delta x_r$ is the grid size of the fluid around the sheet;

$\Delta x_r$ is the grid size of the fluid around the sheet; ![]() $\epsilon$ is a parameter that regulates the force to prevent penetration through boundaries. In all simulations,

$\epsilon$ is a parameter that regulates the force to prevent penetration through boundaries. In all simulations, ![]() $\epsilon =\Delta x_r$ was found to be small enough to avoid penetration.

$\epsilon =\Delta x_r$ was found to be small enough to avoid penetration.

The numerical procedure for coupling of the fluid and structure solvers is as follows:

(i) Solve (3.1) for the intermediate flow velocity

$\tilde {\boldsymbol {u}}$.

$\tilde {\boldsymbol {u}}$.(iii) Solve with the PISO algorithm to obtain

$p^{n+1}$ and

$p^{n+1}$ and  $\boldsymbol {u}^{n+1}$.

$\boldsymbol {u}^{n+1}$.(iv) Calculate the fluid force on the sheet

$\boldsymbol {F}_f^{n+1}$.

$\boldsymbol {F}_f^{n+1}$.(v) Solve (3.7) for

$N$ sub-cycles to obtain the sheet location

$N$ sub-cycles to obtain the sheet location  $\boldsymbol {X}^{n+1}$ and velocity

$\boldsymbol {X}^{n+1}$ and velocity  $\boldsymbol {U}^{n+1}$.

$\boldsymbol {U}^{n+1}$.

Snap through is accompanied by the rapid and complex shape morphing that may cause instability in both the flow field and the structure, and sometimes the failure of the simulation. In our model, the instability occurs as the saw shape of the sheet and the checkered pressure field around the sheet. To overcome these numerical issues, a small time step of ![]() $\Delta t=0.0005$ is chosen for the fluid solver in all cases, and a time step for the structure solver is set to be

$\Delta t=0.0005$ is chosen for the fluid solver in all cases, and a time step for the structure solver is set to be ![]() $25$ times smaller (

$25$ times smaller (![]() $N=25$). We confirmed that these time steps were sufficiently small to ensure convergence. Larger time steps for the fluid solver cause checkered pressure fields and the saw shape of the sheet, while fewer iterations for the structure solver leads to its failure.

$N=25$). We confirmed that these time steps were sufficiently small to ensure convergence. Larger time steps for the fluid solver cause checkered pressure fields and the saw shape of the sheet, while fewer iterations for the structure solver leads to its failure.

3.2. Grid convergence test and validation

For the fluid domain, uniform grids of size ![]() $\Delta x_r=L/150$ are used around the sheet and confining walls inside the dotted rectangular region in figure 1. Outside this region, the grids gradually coarsen so that the largest spacing at the domain boundaries is

$\Delta x_r=L/150$ are used around the sheet and confining walls inside the dotted rectangular region in figure 1. Outside this region, the grids gradually coarsen so that the largest spacing at the domain boundaries is ![]() $\Delta x=\Delta x_r/4$. A value of

$\Delta x=\Delta x_r/4$. A value of ![]() $\Delta x_r=L/150$ was chosen after conducting extensive grid convergence tests for four grid layouts with

$\Delta x_r=L/150$ was chosen after conducting extensive grid convergence tests for four grid layouts with ![]() $\Delta x_r=L/60$,

$\Delta x_r=L/60$, ![]() $L/100$,

$L/100$, ![]() $L/150$ and

$L/150$ and ![]() $L/225$, with particular focus on the contact force averaged over the time span of

$L/225$, with particular focus on the contact force averaged over the time span of ![]() $t=20.0$–60.0 and the oscillation frequency as they are important parameters in this study. Cases with no contact or weak contact are hardly affected by the gird size. The general response of the sheet and the flow field are the same for

$t=20.0$–60.0 and the oscillation frequency as they are important parameters in this study. Cases with no contact or weak contact are hardly affected by the gird size. The general response of the sheet and the flow field are the same for ![]() $L/100$ and finer grid layouts. However, in a few cases, we observed large variations in contact force, which also causes considerable errors in oscillation frequency. Such variations are negligible between the selected grid layout of

$L/100$ and finer grid layouts. However, in a few cases, we observed large variations in contact force, which also causes considerable errors in oscillation frequency. Such variations are negligible between the selected grid layout of ![]() $\Delta x_r=L/150$ and the smaller grid layout of

$\Delta x_r=L/150$ and the smaller grid layout of ![]() $\Delta x_r=L/225$. For example, in the case of

$\Delta x_r=L/225$. For example, in the case of ![]() $L^*=0.6$,

$L^*=0.6$, ![]() $d^*=0.40$ and

$d^*=0.40$ and ![]() $U^*=22.0$, the variations in the averaged contact force are 4.3 %, 2.4 % and 0.5 % for

$U^*=22.0$, the variations in the averaged contact force are 4.3 %, 2.4 % and 0.5 % for ![]() $\Delta x_r=L/60$,

$\Delta x_r=L/60$, ![]() $L/100$ and

$L/100$ and ![]() $L/150$, respectively, compared with the finest grid layout of

$L/150$, respectively, compared with the finest grid layout of ![]() $\Delta x_r=L/225$.

$\Delta x_r=L/225$.

The validation of the structure solver is first performed using an elastic sheet in the absence of fluid. For the validation, the right end of the sheet is assigned to be free with the following boundary conditions:

The sheet is initially straight with an initial inclination angle of ![]() $\theta =1.8^\circ$ with respect to the

$\theta =1.8^\circ$ with respect to the ![]() $x$-axis, and is then exposed to the gravitational force (figure 2ai). For

$x$-axis, and is then exposed to the gravitational force (figure 2ai). For ![]() $L=1$,

$L=1$, ![]() $Fr=10$,

$Fr=10$, ![]() $k_b=0$,

$k_b=0$, ![]() $k_s=1000$ and

$k_s=1000$ and ![]() $50$ Lagrangian cells along the sheet, the time history of the tip displacement in our simulation is in excellent agreement with that of the analytical solution given by Huang et al. (Reference Huang, Shin and Sung2007) (figure 2aii).

$50$ Lagrangian cells along the sheet, the time history of the tip displacement in our simulation is in excellent agreement with that of the analytical solution given by Huang et al. (Reference Huang, Shin and Sung2007) (figure 2aii).

Figure 2. (ai) Schematic of a single inclined sheet exposed to the gravitational force and (aii) comparison of tip displacement of the sheet between our numerical solution (solid line) and analytical solution (dotted line). (bi) Schematic of two side-by-side sheets exposed to an inflow of velocity ![]() $U$ and gravity and (bii) comparison of tip displacements of the upper (black) and lower (blue) sheets between our numerical solution (solid lines) and Huang et al. (Reference Huang, Shin and Sung2007) (dotted lines).

$U$ and gravity and (bii) comparison of tip displacements of the upper (black) and lower (blue) sheets between our numerical solution (solid lines) and Huang et al. (Reference Huang, Shin and Sung2007) (dotted lines).

To validate the coupling of the fluid and structure solvers and the contact algorithm, two side-by-side sheets with a pole-to-pole distance of ![]() $D=0.3L$ along the

$D=0.3L$ along the ![]() $y$-axis are considered (figure 2bi). Both sheets have the same properties of

$y$-axis are considered (figure 2bi). Both sheets have the same properties of ![]() $L =1$,

$L =1$, ![]() $m^*=1.5$,

$m^*=1.5$, ![]() $Fr=0.5$,

$Fr=0.5$, ![]() $k_b=0.0015$ and

$k_b=0.0015$ and ![]() $k_s=100$ with an initial inclination angle of

$k_s=100$ with an initial inclination angle of ![]() $\theta =18.0^\circ$. They are immersed inside a fluid domain extending over

$\theta =18.0^\circ$. They are immersed inside a fluid domain extending over ![]() $-2\leq x \leq 6$ and

$-2\leq x \leq 6$ and ![]() $-4\leq y \leq 4$ and are subjected to a uniform fluid flow at

$-4\leq y \leq 4$ and are subjected to a uniform fluid flow at ![]() $Re=200$. A grid spacing of

$Re=200$. A grid spacing of ![]() $L/64$ is used for both the structure and fluid domains. The two sheets start in-phase oscillations, and at a certain time they commence out-of-phase oscillations, causing multiple collisions between them. The contact force between the two sheets is modelled in the same way as that between the sheet and the wall in our snap-through model, using (3.8). The displacements of the free right ends of both sheets are in good agreement with those of Huang et al. (Reference Huang, Shin and Sung2007) (figure 2bii). Slight discrepancies are observed during

$L/64$ is used for both the structure and fluid domains. The two sheets start in-phase oscillations, and at a certain time they commence out-of-phase oscillations, causing multiple collisions between them. The contact force between the two sheets is modelled in the same way as that between the sheet and the wall in our snap-through model, using (3.8). The displacements of the free right ends of both sheets are in good agreement with those of Huang et al. (Reference Huang, Shin and Sung2007) (figure 2bii). Slight discrepancies are observed during ![]() $t=15$–35 when a transition from in-phase to out-of-phase oscillations occurs, because the process of transition to out-of-phase oscillations may differ by the numerical method employed. In out-of-phase oscillations after

$t=15$–35 when a transition from in-phase to out-of-phase oscillations occurs, because the process of transition to out-of-phase oscillations may differ by the numerical method employed. In out-of-phase oscillations after ![]() $t = 35$, the results of the two methods become similar again.

$t = 35$, the results of the two methods become similar again.

3.3. Dynamic mode decomposition

Dynamic mode decomposition (DMD) is a method for extracting the dominant and coherent modes of a dynamical system (Schmid Reference Schmid2010). The nonlinear behaviour of the dynamical system can be examined through a linear approximation if a sufficiently short time interval is considered:

where ![]() $\boldsymbol {\varPhi }(t)\in \mathbb {R}^n$ is an

$\boldsymbol {\varPhi }(t)\in \mathbb {R}^n$ is an ![]() $n$-dimensional vector representing the state of the system at time

$n$-dimensional vector representing the state of the system at time ![]() $t$. From a total of

$t$. From a total of ![]() $m$ measurements of states

$m$ measurements of states ![]() $\boldsymbol {\varPhi }_k$ at equally spaced time intervals

$\boldsymbol {\varPhi }_k$ at equally spaced time intervals ![]() $\delta t$, with the initial state of

$\delta t$, with the initial state of ![]() $\boldsymbol {\varPhi }(0)$, the solution of (3.10) can be expressed as (Kutz et al. Reference Kutz, Brunton, Brunton and Proctor2016)

$\boldsymbol {\varPhi }(0)$, the solution of (3.10) can be expressed as (Kutz et al. Reference Kutz, Brunton, Brunton and Proctor2016)

\begin{equation} \boldsymbol{\varPhi}(t)=\sum_{k=1}^{n} \boldsymbol{\psi}_k \exp(\omega_k t)b_k. \end{equation}

\begin{equation} \boldsymbol{\varPhi}(t)=\sum_{k=1}^{n} \boldsymbol{\psi}_k \exp(\omega_k t)b_k. \end{equation}

The solution of ![]() $\boldsymbol {\varPhi }(t)$ requires the eigenvectors

$\boldsymbol {\varPhi }(t)$ requires the eigenvectors ![]() $\boldsymbol {\psi }_k$ and eigenvalues

$\boldsymbol {\psi }_k$ and eigenvalues ![]() $\omega _k$ of the matrix

$\omega _k$ of the matrix ![]() $\mathcal {A}$ and the coefficients

$\mathcal {A}$ and the coefficients ![]() $b_k$. These terms are extracted by considering a discretised representation of (3.10) as

$b_k$. These terms are extracted by considering a discretised representation of (3.10) as

with ![]() $\boldsymbol {A}=\exp (\mathcal {A}\delta t)$. We follow the DMD algorithm explained in Kutz et al. (Reference Kutz, Brunton, Brunton and Proctor2016) to solve (3.12) using a low-rank eigendecomposition of

$\boldsymbol {A}=\exp (\mathcal {A}\delta t)$. We follow the DMD algorithm explained in Kutz et al. (Reference Kutz, Brunton, Brunton and Proctor2016) to solve (3.12) using a low-rank eigendecomposition of ![]() $\boldsymbol {A}$ and find the parameters in (3.11).

$\boldsymbol {A}$ and find the parameters in (3.11).

The real and imaginary parts of ![]() $\omega _k=2{\rm \pi} f_k+\mathrm {i}\zeta _k$ indicate the oscillation frequency

$\omega _k=2{\rm \pi} f_k+\mathrm {i}\zeta _k$ indicate the oscillation frequency ![]() $f_k$ and growth/decay rate

$f_k$ and growth/decay rate ![]() $\zeta _k$ of each mode, respectively. For the snap-through oscillations of the sheet, we make this parameter dimensionless using twice the maximum transverse deflection of the unbounded buckled sheet without flow (

$\zeta _k$ of each mode, respectively. For the snap-through oscillations of the sheet, we make this parameter dimensionless using twice the maximum transverse deflection of the unbounded buckled sheet without flow (![]() $2w_0$) as the characteristic amplitude (Kim et al. Reference Kim, Lahooti, Kim and Kim2021b):

$2w_0$) as the characteristic amplitude (Kim et al. Reference Kim, Lahooti, Kim and Kim2021b): ![]() $\omega _k^*=\omega _k(2w_0)/U$. The snap-through frequency is then defined to be equal to the frequency of the first dominant oscillatory DMD mode (

$\omega _k^*=\omega _k(2w_0)/U$. The snap-through frequency is then defined to be equal to the frequency of the first dominant oscillatory DMD mode (![]() $\,f^*=f_d(2w_0)/U$). The DMD is applied to snapshots of the sheet over the time span

$\,f^*=f_d(2w_0)/U$). The DMD is applied to snapshots of the sheet over the time span ![]() $t=20.0$–60.0 at intervals of

$t=20.0$–60.0 at intervals of ![]() $\delta t=0.008$, which is sufficient to accurately capture the dominant frequency. The same time span is used to extract the DMD modes of the vorticity field. The DMD modes of the vorticity field are obtained from snapshots of the rectangular fluid domain

$\delta t=0.008$, which is sufficient to accurately capture the dominant frequency. The same time span is used to extract the DMD modes of the vorticity field. The DMD modes of the vorticity field are obtained from snapshots of the rectangular fluid domain ![]() $[-0.2,8.0]\times [-1.0,1.0]$.

$[-0.2,8.0]\times [-1.0,1.0]$.

4. Results and discussion

4.1. Shape in equilibrium state and critical flow velocity

When the dimensionless flow velocity ![]() $U^*$ increases from zero, the buckled sheet maintains a quasi-static equilibrium shape up to a certain critical condition. Even at the pre-critical condition, the sheet may snap a few times due to the sudden rise of the fluid force at the beginning of the simulation. However, the snapping motion does not persist and the sheet reaches a stable equilibrium on either the upper or lower side of the channel centreline (the horizontal line that connects the two ends of the sheet). In this section, if the equilibrium state of the sheet is on the lower side, it is mirrored to the upper side for ease of comparison. The equilibrium shapes of the sheet differ between contact and non-contact cases (figure 3). The smallest sheet length ratio

$U^*$ increases from zero, the buckled sheet maintains a quasi-static equilibrium shape up to a certain critical condition. Even at the pre-critical condition, the sheet may snap a few times due to the sudden rise of the fluid force at the beginning of the simulation. However, the snapping motion does not persist and the sheet reaches a stable equilibrium on either the upper or lower side of the channel centreline (the horizontal line that connects the two ends of the sheet). In this section, if the equilibrium state of the sheet is on the lower side, it is mirrored to the upper side for ease of comparison. The equilibrium shapes of the sheet differ between contact and non-contact cases (figure 3). The smallest sheet length ratio ![]() $L^*(=0.6)$, which initially has the largest transverse deflection in the absence of the confining walls, and the smallest gap distance ratio

$L^*(=0.6)$, which initially has the largest transverse deflection in the absence of the confining walls, and the smallest gap distance ratio ![]() $d^*(=0.40)$ are shown in figure 3 to illustrate the dramatic effects of sheet–wall interactions. As

$d^*(=0.40)$ are shown in figure 3 to illustrate the dramatic effects of sheet–wall interactions. As ![]() $U^*$ increases, the stable sheet gradually leans along the streamwise direction until the sheet can no longer maintain the equilibrium and snaps to the other side of the channel at the critical velocity

$U^*$ increases, the stable sheet gradually leans along the streamwise direction until the sheet can no longer maintain the equilibrium and snaps to the other side of the channel at the critical velocity ![]() $U^* = U^*_c$.

$U^* = U^*_c$.

Figure 3. Equilibrium shapes of the sheet for several dimensionless flow velocities ![]() $U^*$. The horizontal black solid bars on the right end of the panel denote the positions of the confining walls for

$U^*$. The horizontal black solid bars on the right end of the panel denote the positions of the confining walls for ![]() $d^* = 0.40$. The critical flow velocity

$d^* = 0.40$. The critical flow velocity ![]() $U^*_c$ is 11.6 for

$U^*_c$ is 11.6 for ![]() $d^* = \infty$ and 18.3 for

$d^* = \infty$ and 18.3 for ![]() $d^*=0.40$.

$d^*=0.40$.

The unbounded case without the confining walls has one apex above the centreline near the midpoint (![]() $x=0.3$), which gradually shifts backwards (along the

$x=0.3$), which gradually shifts backwards (along the ![]() $x$-axis) with increasing

$x$-axis) with increasing ![]() $U^*$. When

$U^*$. When ![]() $U^*$ is close to

$U^*$ is close to ![]() $U^*_c$, the front (left) part of the sheet crosses the centreline slightly, having a negative

$U^*_c$, the front (left) part of the sheet crosses the centreline slightly, having a negative ![]() $y$ value in figure 3. By contrast, for

$y$ value in figure 3. By contrast, for ![]() $d^* =0.40$ in figure 3, the sheet is highly deformed, making contact with the upper wall. It has one nadir below the centreline on the rear (right) part of the sheet and one apex above the centreline on the left of the nadir. Thus, the sheet blocks a significant portion of the channel, which hinders the fluid from passing through the channel and delays the onset of periodic snap through. Compared with a channel of the same gap distance (

$d^* =0.40$ in figure 3, the sheet is highly deformed, making contact with the upper wall. It has one nadir below the centreline on the rear (right) part of the sheet and one apex above the centreline on the left of the nadir. Thus, the sheet blocks a significant portion of the channel, which hinders the fluid from passing through the channel and delays the onset of periodic snap through. Compared with a channel of the same gap distance (![]() $d^* =0.40$) without the sheet, the flow rate inside the channel is reduced approximately 10 times from 0.310 to 0.036 at

$d^* =0.40$) without the sheet, the flow rate inside the channel is reduced approximately 10 times from 0.310 to 0.036 at ![]() $U^* = 10.0$ when a sheet of

$U^* = 10.0$ when a sheet of ![]() $L^* =0.6$ is located inside the channel. By gradual morphing of the sheet, the flow rate through the channel becomes greater with increasing

$L^* =0.6$ is located inside the channel. By gradual morphing of the sheet, the flow rate through the channel becomes greater with increasing ![]() $U^*$, and it amounts to 0.065 at

$U^*$, and it amounts to 0.065 at ![]() $U^*=18.0$ before the occurrence of instability, which is still much lower than the flow rate without the sheet.

$U^*=18.0$ before the occurrence of instability, which is still much lower than the flow rate without the sheet.

Figure 4(a) presents the equilibrium shapes of the sheet with ![]() $L^*=0.6$ when

$L^*=0.6$ when ![]() $U^*$ is slightly less than the critical value for five gap distances,

$U^*$ is slightly less than the critical value for five gap distances, ![]() $d^*=0.40$–0.60 and

$d^*=0.40$–0.60 and ![]() $d^* = \infty$ (no confining walls); note that the

$d^* = \infty$ (no confining walls); note that the ![]() $U^*$ values differ in the five cases. The corresponding pressure fields around the sheet, which are normalised by

$U^*$ values differ in the five cases. The corresponding pressure fields around the sheet, which are normalised by ![]() $\rho _f U^2$ (figure 4b), and the net pressure

$\rho _f U^2$ (figure 4b), and the net pressure ![]() $\Delta p$ acting on the sheet (figure 4c) are also depicted for the five gap distances.

$\Delta p$ acting on the sheet (figure 4c) are also depicted for the five gap distances. ![]() $\Delta p(=p_{u}-p_{l})$ is the difference in the normalised pressure between the upper and lower surfaces of the sheet.

$\Delta p(=p_{u}-p_{l})$ is the difference in the normalised pressure between the upper and lower surfaces of the sheet.

Figure 4. (a) Equilibrium shapes of the sheet just before the transition to periodic snap-through for five confining wall distances (![]() $L^*=0.6$). The horizontal colour bars on the right end of the panel denote the positions of the confining walls for each colour. (b) Contours of normalised fluid pressure

$L^*=0.6$). The horizontal colour bars on the right end of the panel denote the positions of the confining walls for each colour. (b) Contours of normalised fluid pressure ![]() $p$. (c) Distribution of net pressure

$p$. (c) Distribution of net pressure ![]() $\varDelta _p(=p_{u}-p_{l})$ acting on the sheet. The colour on the sheet indicates the value of net pressure.

$\varDelta _p(=p_{u}-p_{l})$ acting on the sheet. The colour on the sheet indicates the value of net pressure.

For the case of ![]() $d^*=0.60$, the apex height is slightly lower because the sheet is constricted by the wall, and the front part of the sheet crosses farther below the centreline compared with the unbounded case of

$d^*=0.60$, the apex height is slightly lower because the sheet is constricted by the wall, and the front part of the sheet crosses farther below the centreline compared with the unbounded case of ![]() $d^* = \infty$. Although the net pressure force on the front part of the sheet for

$d^* = \infty$. Although the net pressure force on the front part of the sheet for ![]() $d^*= 0.60$ is lower than for

$d^*= 0.60$ is lower than for ![]() $d^* = \infty$ (figure 4ci,cii), the instability can occur at a lower dimensionless velocity:

$d^* = \infty$ (figure 4ci,cii), the instability can occur at a lower dimensionless velocity: ![]() $U^*_c = 11.5$ for

$U^*_c = 11.5$ for ![]() $d^* = \infty$ and 10.8 for

$d^* = \infty$ and 10.8 for ![]() $d^* = 0.60$. When the confining walls are placed more closely together at

$d^* = 0.60$. When the confining walls are placed more closely together at ![]() $d^*=0.55$,

$d^*=0.55$, ![]() $U^*_c$ drops dramatically to 8.7. Despite minor changes in the pressure field of the flow and the pressure force on the sheet (figure 4biii,ciii), there are distinct differences in the shape of the sheet between

$U^*_c$ drops dramatically to 8.7. Despite minor changes in the pressure field of the flow and the pressure force on the sheet (figure 4biii,ciii), there are distinct differences in the shape of the sheet between ![]() $d^*=0.60$ and 0.55. Therefore, the reduction in the critical velocity is attributed to the shape change of the sheet resulting from stronger contact with the confining wall. While the front part of the sheet slightly crosses the centreline for

$d^*=0.60$ and 0.55. Therefore, the reduction in the critical velocity is attributed to the shape change of the sheet resulting from stronger contact with the confining wall. While the front part of the sheet slightly crosses the centreline for ![]() $d^* = \infty$, it notably passes the centreline and forms a nadir for

$d^* = \infty$, it notably passes the centreline and forms a nadir for ![]() $d^*=0.55$ (figure 4a). Because of this particular configuration, the sheet is most susceptible to instability when

$d^*=0.55$ (figure 4a). Because of this particular configuration, the sheet is most susceptible to instability when ![]() $d^*=0.55$, and the transition to periodic snap-through occurs at lower

$d^*=0.55$, and the transition to periodic snap-through occurs at lower ![]() $U^*$ than for the other cases. For contact cases, the initial shape of the sheet has a nadir on its left and an apex on its right at

$U^*$ than for the other cases. For contact cases, the initial shape of the sheet has a nadir on its left and an apex on its right at ![]() $U^* = 0$. For

$U^* = 0$. For ![]() $L^* = 0.6$, the smallest gap distance ratio at which the sheet is able to preserve this configuration under the fluid flow before the transition to the post-equilibrium state is

$L^* = 0.6$, the smallest gap distance ratio at which the sheet is able to preserve this configuration under the fluid flow before the transition to the post-equilibrium state is ![]() $d^*=0.55$. Further reducing the gap distance ratio from

$d^*=0.55$. Further reducing the gap distance ratio from ![]() $d^*=0.55$ causes the sheet to become temporarily unstable at a certain flow velocity and snap to the other side due to the forces imposed by the flow and wall contact, accompanied by a dramatic shift in the equilibrium shape. The new equilibrium shape, which is mirrored in figure 4(a) for ease of comparison, is slanted in the streamwise direction, yielding a deep nadir and the highly curved deformation of an S-shape on the right of the sheet. Such a shift in the equilibrium shape was also observed in the experimental study of Kim et al. (Reference Kim, Zhou, Kim and Oh2020) for the length ratio of

$d^*=0.55$ causes the sheet to become temporarily unstable at a certain flow velocity and snap to the other side due to the forces imposed by the flow and wall contact, accompanied by a dramatic shift in the equilibrium shape. The new equilibrium shape, which is mirrored in figure 4(a) for ease of comparison, is slanted in the streamwise direction, yielding a deep nadir and the highly curved deformation of an S-shape on the right of the sheet. Such a shift in the equilibrium shape was also observed in the experimental study of Kim et al. (Reference Kim, Zhou, Kim and Oh2020) for the length ratio of ![]() $L^*=0.75$. They reported that the apex occurred at the front of the sheet for

$L^*=0.75$. They reported that the apex occurred at the front of the sheet for ![]() $d^*<0.42$ and at the rear for

$d^*<0.42$ and at the rear for ![]() $d^*>0.42$. For

$d^*>0.42$. For ![]() $d^*=0.42$, the sheet had two equilibrium shapes with different

$d^*=0.42$, the sheet had two equilibrium shapes with different ![]() $U^*_c$ values, one with the nadir on the rear (higher

$U^*_c$ values, one with the nadir on the rear (higher ![]() $U^*_c$) and the other on the front (lower

$U^*_c$) and the other on the front (lower ![]() $U^*_c$). The multiple (two) equilibrium shapes at a specific

$U^*_c$). The multiple (two) equilibrium shapes at a specific ![]() $d^*$ are not observed in our numerical simulations for several

$d^*$ are not observed in our numerical simulations for several ![]() $d^*$ values considered in the present study. This indicates that

$d^*$ values considered in the present study. This indicates that ![]() $d^*=0.55$ is not the exact threshold for the shift in shape and two equilibrium shapes may exist at a specific

$d^*=0.55$ is not the exact threshold for the shift in shape and two equilibrium shapes may exist at a specific ![]() $d^*$ which is not covered in the current simulations. Except for

$d^*$ which is not covered in the current simulations. Except for ![]() $L^*=0.9$, which produces no contact with the confining wall, a shift in the equilibrium shape is also observed for

$L^*=0.9$, which produces no contact with the confining wall, a shift in the equilibrium shape is also observed for ![]() $L^*=0.7$ and

$L^*=0.7$ and ![]() $0.8$ at a certain flow velocity by reducing

$0.8$ at a certain flow velocity by reducing ![]() $d^*$ from 0.50 to 0.45 and from 0.45 to 0.40, respectively (table 2). Interestingly, the shape shift arises consistently when the blockage ratio

$d^*$ from 0.50 to 0.45 and from 0.45 to 0.40, respectively (table 2). Interestingly, the shape shift arises consistently when the blockage ratio ![]() $w_0^*$ exceeds a threshold value in the narrow range of 0.66–0.70. This suggests that the blockage ratio is the dominant geometric parameter in determining the shift in the equilibrium shape.

$w_0^*$ exceeds a threshold value in the narrow range of 0.66–0.70. This suggests that the blockage ratio is the dominant geometric parameter in determining the shift in the equilibrium shape.

Table 2. Gap distance ratio ![]() $d^*$ and blockage ratio

$d^*$ and blockage ratio ![]() $w_0^*$ at which the shift in equilibrium shape occurs at a certain flow velocity, moving the nadir from the left part to the right part of the sheet.

$w_0^*$ at which the shift in equilibrium shape occurs at a certain flow velocity, moving the nadir from the left part to the right part of the sheet.

The shifted equilibrium shapes of ![]() $d^*=0.50$ and

$d^*=0.50$ and ![]() $0.40$ (

$0.40$ (![]() $L^*=0.6$) alter the surrounding flow field remarkably and cause an increase in the pressure of the fluid entrained below the apex (figure 4biv,bv). Because a large portion of the channel is blocked (

$L^*=0.6$) alter the surrounding flow field remarkably and cause an increase in the pressure of the fluid entrained below the apex (figure 4biv,bv). Because a large portion of the channel is blocked (![]() $w_0^*=0.69$ and 0.87 for

$w_0^*=0.69$ and 0.87 for ![]() $d^*=0.50$ and

$d^*=0.50$ and ![]() $0.40$, respectively), the fluid flow is hindered from passing through the gap between the sheet and the confining wall, which raises the pressure of the entrained flow below the apex. The inclination of the sheet along the streamwise direction due to confinement by the confining walls also contribute to greater pressure in the entrained flow. The pressure increase below the apex weakens the net pressure

$0.40$, respectively), the fluid flow is hindered from passing through the gap between the sheet and the confining wall, which raises the pressure of the entrained flow below the apex. The inclination of the sheet along the streamwise direction due to confinement by the confining walls also contribute to greater pressure in the entrained flow. The pressure increase below the apex weakens the net pressure ![]() $\Delta p (= p_{u}-p_{l})$ imposed on the front part of the sheet, but strengthens the net pressure on its rear part (figure 4civ,cv). Along with the formation of the nadir on the rear part of the sheet, this change in the distribution of the net pressure force makes it difficult for the sheet to snap, leading to an increase in the critical velocity from

$\Delta p (= p_{u}-p_{l})$ imposed on the front part of the sheet, but strengthens the net pressure on its rear part (figure 4civ,cv). Along with the formation of the nadir on the rear part of the sheet, this change in the distribution of the net pressure force makes it difficult for the sheet to snap, leading to an increase in the critical velocity from ![]() $U^*_c = 8.7$ for

$U^*_c = 8.7$ for ![]() $d^*=0.55$ to 11.3 for

$d^*=0.55$ to 11.3 for ![]() $d^*=0.50$. The change in pressure distribution is more pronounced for

$d^*=0.50$. The change in pressure distribution is more pronounced for ![]() $d^*=0.40$. Compared with

$d^*=0.40$. Compared with ![]() $d^*=0.50$, the greater magnitude of net pressure

$d^*=0.50$, the greater magnitude of net pressure ![]() $\Delta p$ and the formation of the deeper nadir on the rear of the sheet result in a significant increase in

$\Delta p$ and the formation of the deeper nadir on the rear of the sheet result in a significant increase in ![]() $U^*_c$ to 18.3. That is, after the occurrence of the shape shift, the net pressure force on the sheet, which itself is strongly affected by the blockage of the channel, becomes an important factor in determining the critical flow velocity.

$U^*_c$ to 18.3. That is, after the occurrence of the shape shift, the net pressure force on the sheet, which itself is strongly affected by the blockage of the channel, becomes an important factor in determining the critical flow velocity.

As mentioned above, when the sheet is in contact with the confining wall for a given sheet length ratio ![]() $L^*$ (except for

$L^*$ (except for ![]() $L^*=0.9$), the dimensionless critical flow velocity

$L^*=0.9$), the dimensionless critical flow velocity ![]() $U^*_c$ decreases with the gap distance ratio

$U^*_c$ decreases with the gap distance ratio ![]() $d^*$ up to a certain value, and then increases beyond this threshold. This trend is observed more distinctly for

$d^*$ up to a certain value, and then increases beyond this threshold. This trend is observed more distinctly for ![]() $L^*=0.6$ than for

$L^*=0.6$ than for ![]() $L^* = 0.7$ and 0.8 (figure 5a). Moreover, according to figure 5(a),

$L^* = 0.7$ and 0.8 (figure 5a). Moreover, according to figure 5(a), ![]() $U^*_c$ tends to decrease with

$U^*_c$ tends to decrease with ![]() $L^*$ for a given gap distance ratio

$L^*$ for a given gap distance ratio ![]() $d^*$, including

$d^*$, including ![]() $d^* = \infty$. The smallest gap distance ratio

$d^* = \infty$. The smallest gap distance ratio ![]() $d^*=0.40$ produces the largest drop in

$d^*=0.40$ produces the largest drop in ![]() $U^*_c$, from

$U^*_c$, from ![]() $18.0$ for

$18.0$ for ![]() $L^*=0.6$ to

$L^*=0.6$ to ![]() $6.2$ for

$6.2$ for ![]() $L^*=0.9$. A similar drop in

$L^*=0.9$. A similar drop in ![]() $U^*_c$ is also observed for

$U^*_c$ is also observed for ![]() $d^*=0.45$, but for the other cases, the drop in

$d^*=0.45$, but for the other cases, the drop in ![]() $U^*$ is much smaller.

$U^*$ is much smaller.

Figure 5. (a) Dimensionless critical flow velocity ![]() $U^*_c$ for the onset of periodic snap-through with respect to gap distance ratio

$U^*_c$ for the onset of periodic snap-through with respect to gap distance ratio ![]() $d^*$ for different length ratios

$d^*$ for different length ratios ![]() $L^*$; (b)

$L^*$; (b) ![]() $U^*_cL^*$ with respect to blockage ratio

$U^*_cL^*$ with respect to blockage ratio ![]() $w_0^*$. In (a,b), the colours of the markers denote

$w_0^*$. In (a,b), the colours of the markers denote ![]() $d^*$, and their shapes denote

$d^*$, and their shapes denote ![]() $L^*$.

$L^*$.

In figure 5(b), ![]() $U^*_c L^*$ is plotted with respect to the blockage ratio

$U^*_c L^*$ is plotted with respect to the blockage ratio ![]() $w_0^*$. Evidently, for

$w_0^*$. Evidently, for ![]() $w_0^*<0.66$,

$w_0^*<0.66$, ![]() $U^*_c L^*$ is between 5.2 and 7.0, implying that

$U^*_c L^*$ is between 5.2 and 7.0, implying that ![]() $U_c^*$ scales inversely with

$U_c^*$ scales inversely with ![]() $L^*$ and is relatively unaffected by

$L^*$ and is relatively unaffected by ![]() $w_0^*$. However, beyond

$w_0^*$. However, beyond ![]() $w_0^*=0.66$, the effect of channel blockage on the critical velocity becomes significant. Earlier, we reported that all cases with

$w_0^*=0.66$, the effect of channel blockage on the critical velocity becomes significant. Earlier, we reported that all cases with ![]() $w_0^*\geq 0.66$ undergo a shift in the equilibrium shape and form a deep nadir on the right of the sheet (table 2). After the shape shift that occurs beyond

$w_0^*\geq 0.66$ undergo a shift in the equilibrium shape and form a deep nadir on the right of the sheet (table 2). After the shape shift that occurs beyond ![]() $w_0^*=0.66$,

$w_0^*=0.66$, ![]() $L^*U_c^*$ increases almost linearly with

$L^*U_c^*$ increases almost linearly with ![]() $w_0^*$ and reaches a peak value of 10.7 for

$w_0^*$ and reaches a peak value of 10.7 for ![]() $w_0^*=0.87$ with the strongest blockage effect.

$w_0^*=0.87$ with the strongest blockage effect.

4.2. Dynamics in post-equilibrium state

When the free-stream velocity ![]() $U^*$ exceeds the critical value of

$U^*$ exceeds the critical value of ![]() $U^*_c$, the sheet no longer persists quasi-static deformation, but exhibits repeated snap-through oscillations, periodically contacting the confining walls. Snap-through in each cycle could be characterised by rapid release of stored bending energy. This change is accompanied by complex shape morphing that could occur in a time interval as small as 10 % of a cycle or in an interval as large as half of a cycle, depending on the dimensionless velocity, gap distance ratio and length ratio. The characteristics of bending energy for a snapping sheet were discussed by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), and will not be examined further in the current study. Here, we primarily focus on the contact force between the sheet and the wall and the oscillation frequency, which are the parameters of interest for triboelectric energy harvesting applications.

$U^*_c$, the sheet no longer persists quasi-static deformation, but exhibits repeated snap-through oscillations, periodically contacting the confining walls. Snap-through in each cycle could be characterised by rapid release of stored bending energy. This change is accompanied by complex shape morphing that could occur in a time interval as small as 10 % of a cycle or in an interval as large as half of a cycle, depending on the dimensionless velocity, gap distance ratio and length ratio. The characteristics of bending energy for a snapping sheet were discussed by Kim et al. (Reference Kim, Lahooti, Kim and Kim2021b), and will not be examined further in the current study. Here, we primarily focus on the contact force between the sheet and the wall and the oscillation frequency, which are the parameters of interest for triboelectric energy harvesting applications.

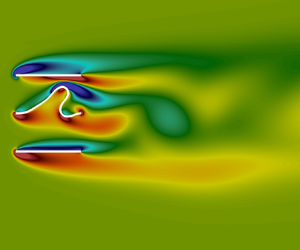

4.2.1. Symmetric and asymmetric oscillations

Before discussing the contact mode and force, we report a particular behaviour of the oscillating sheet that can be attributed to its strict confinement within the channel. Generally, the shape of the oscillating sheet is almost symmetric between the upper and lower sides of the channel centreline. However, by strengthening the sheet–wall interaction (reducing ![]() $L^*$ and

$L^*$ and ![]() $d^*$), it is possible to break the symmetry of the oscillations. Snapshots of the pressure field and the magnitudes of the contact force integrated over the sheet (

$d^*$), it is possible to break the symmetry of the oscillations. Snapshots of the pressure field and the magnitudes of the contact force integrated over the sheet (![]() $F_c=|\sum _{i}\boldsymbol {F}_{c,i}|$) are compared between symmetric and asymmetric cases in figure 6 and supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.894; see (3.8) for the definition of

$F_c=|\sum _{i}\boldsymbol {F}_{c,i}|$) are compared between symmetric and asymmetric cases in figure 6 and supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.894; see (3.8) for the definition of ![]() $\boldsymbol {F}_{c,i}$. Here,

$\boldsymbol {F}_{c,i}$. Here, ![]() $F_c$ is the dimensionless contact force normalised by

$F_c$ is the dimensionless contact force normalised by ![]() $\rho _f U^2 L$. The case of

$\rho _f U^2 L$. The case of ![]() $L^* = 0.6$,

$L^* = 0.6$, ![]() $d^* = 0.50$ and

$d^* = 0.50$ and ![]() $U^*=24.0$ exemplifies the symmetric behaviour of the sheet, which is evident in the time history of the contact force (figure 6ai). While the sheet approaches a confining wall and first impacts the confining wall with the generation of a peak in

$U^*=24.0$ exemplifies the symmetric behaviour of the sheet, which is evident in the time history of the contact force (figure 6ai). While the sheet approaches a confining wall and first impacts the confining wall with the generation of a peak in ![]() $F_c$, the fluid pressure in front of the contact region increases (figure 6aii,aiii). Sequentially, the apex separates from the wall slightly while moving along the streamwise direction, and hits the wall again, while the front part of the sheet moves closer to the centreline (figure 6aiv–avi), which is followed by the next snap through to the opposite side.

$F_c$, the fluid pressure in front of the contact region increases (figure 6aii,aiii). Sequentially, the apex separates from the wall slightly while moving along the streamwise direction, and hits the wall again, while the front part of the sheet moves closer to the centreline (figure 6aiv–avi), which is followed by the next snap through to the opposite side.

Figure 6. (ai, bi) Temporal variations in contact force ![]() $F_c$. In (ai) and (bi), Roman numbers on the horizontal axis correspond to the sequential snapshots of pressure contours in (aii–avi) and (bii–bxi), respectively. For the symmetric case (a), only half of the cycle for shape morphing on the upper side of the centreline is illustrated. See supplementary movie 1. Panels show (a)

$F_c$. In (ai) and (bi), Roman numbers on the horizontal axis correspond to the sequential snapshots of pressure contours in (aii–avi) and (bii–bxi), respectively. For the symmetric case (a), only half of the cycle for shape morphing on the upper side of the centreline is illustrated. See supplementary movie 1. Panels show (a) ![]() $U^* = 24.0$,

$U^* = 24.0$, ![]() $L^* = 0.6$,

$L^* = 0.6$, ![]() $d^* = 0.50$ and (b)

$d^* = 0.50$ and (b) ![]() $U^* = 24.0$,

$U^* = 24.0$, ![]() $L^* = 0.6$,

$L^* = 0.6$, ![]() $d^* = 0.40$.

$d^* = 0.40$.

By decreasing ![]() $d^*$, the apex of the sheet becomes more displaced in the streamwise direction before snapping to the other side, eventually resulting in the contact force and shape changing substantially from those of the symmetric case. The asymmetric deformation of the sheet near the upper and lower walls is specific to cases with the extreme confinement of

$d^*$, the apex of the sheet becomes more displaced in the streamwise direction before snapping to the other side, eventually resulting in the contact force and shape changing substantially from those of the symmetric case. The asymmetric deformation of the sheet near the upper and lower walls is specific to cases with the extreme confinement of ![]() $L^*=0.6$ and

$L^*=0.6$ and ![]() $d^*=0.40$ and a high velocity range of

$d^*=0.40$ and a high velocity range of ![]() $U^*=19.0$–28.0, which is exemplified in figure 6(b) for

$U^*=19.0$–28.0, which is exemplified in figure 6(b) for ![]() $U^*=24.0$. After contact with the upper wall, the apex of the sheet moves along the streamwise direction, and may even pass the clamped right end at the centreline, yielding a very high curvature on the rear part of the sheet (figure 6bv,bvi). This excessive streamwise displacement of the sheet enables an increase in flow velocity on the left of the apex and above the sheet, which leads to a reduction in the fluid pressure above the sheet (figure 6bv). The subsequent deceleration and stagnation of sheet movement in the streamwise direction induces a notable pressure increase above the sheet (figure 6bvi,bvii).

$U^*=24.0$. After contact with the upper wall, the apex of the sheet moves along the streamwise direction, and may even pass the clamped right end at the centreline, yielding a very high curvature on the rear part of the sheet (figure 6bv,bvi). This excessive streamwise displacement of the sheet enables an increase in flow velocity on the left of the apex and above the sheet, which leads to a reduction in the fluid pressure above the sheet (figure 6bv). The subsequent deceleration and stagnation of sheet movement in the streamwise direction induces a notable pressure increase above the sheet (figure 6bvi,bvii).

The sheet then moves toward the lower wall with a shape clearly different from that of the instant before impacting the upper wall (compare figures 6bii and 6bvii). According to figure 6(bi), the sheet slides along the upper wall during the contact process with short separation. By contrast, the sheet undergoes a long separation from the lower wall and a subsequent bouncing behaviour. Several bounces near the lower wall in the transverse direction while moving to the right (figure 6bix–bxi) prevent the fast streamwise sliding that occurs on the upper side of the channel. Consequently, the temporal characteristics of the contact force differ starkly between the contact phases of the upper wall and the lower wall in figure 6(b).

4.2.2. Contact force

The possibility of periodic contact with the confining walls and the intensity of the sheet–wall interaction depend on the sheet length ratio ![]() $L^*$, gap distance ratio

$L^*$, gap distance ratio ![]() $d^*$ and dimensionless flow velocity

$d^*$ and dimensionless flow velocity ![]() $U^*$. For given

$U^*$. For given ![]() $L^*$ and

$L^*$ and ![]() $d^*$, a necessary condition for the occurrence of contact in the absence of flow is that the maximum transverse deflection

$d^*$, a necessary condition for the occurrence of contact in the absence of flow is that the maximum transverse deflection ![]() $w_0$ of a sheet without confining walls is greater than

$w_0$ of a sheet without confining walls is greater than ![]() $d/2$, corresponding to

$d/2$, corresponding to ![]() $w_0^*>0.50$. However, in the presence of flow, the behaviour of the oscillating sheet is influenced by

$w_0^*>0.50$. However, in the presence of flow, the behaviour of the oscillating sheet is influenced by ![]() $U^*$, causing substantial changes in the contact process. In some cases, the contact can be eliminated by increasing the flow velocity. Throughout this section, we discuss only those cases with small

$U^*$, causing substantial changes in the contact process. In some cases, the contact can be eliminated by increasing the flow velocity. Throughout this section, we discuss only those cases with small ![]() $L^*=[0.6, 0.7]$ and

$L^*=[0.6, 0.7]$ and ![]() $d^*=0.40$–0.55, which produce stronger sheet–wall interactions than other cases.

$d^*=0.40$–0.55, which produce stronger sheet–wall interactions than other cases.

Kim et al. (Reference Kim, Zhou, Kim and Oh2020) categorised the wall contact mode of a three-dimensional sheet for ![]() $L^*=0.75$,

$L^*=0.75$, ![]() $d^*=0.43$–0.60 and

$d^*=0.43$–0.60 and ![]() $U^*=9.4$–13.0 into three regimes of rolling, head-on and touch/sliding contact, based on the position of the contact point on the sheet and the temporal variation in the contact force. Although these three regimes are also observed in our simulations, it is hard to determine the regime in some cases. Moreover, this categorisation is inappropriate for our two-dimensional sheet at relatively low Reynolds number and does not cover the wide ranges of parameters considered in our study. Instead, we propose four contact-mode regimes suitable for our model, which are more general and easier to identify: sliding/rolling (type I), combination of sliding/rolling and bouncing (type II), bouncing (type III) and short touch (type IV), which embrace the regimes used by Kim et al. (Reference Kim, Zhou, Kim and Oh2020). To identify the regime for each case, the morphing sequence of the sheet near contact and the time history of contact force are examined. The sheet is in contact with the wall if it has a non-zero contact force. A bounce is assumed to occur in two circumstances; first, if the sheet is contact with the wall for a time interval shorter than 0.5, and second, if the sheet loses contact (zero contact force) and contacts again with the same wall. Furthermore, if the sheet stays in contact with the wall for an interval greater than 0.5, the contact type is identified as rolling/sliding.