1. Introduction

Global climate change is taking place at an unprecedented pace and is expected to have dramatic consequences on humankind from both health and economic perspectives (Babar et al. Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021; Zhao et al. Reference Zhao, Yuan, Zhao, Chang, Li, Lin and Li2022). There is a consensus among researchers that the growing anthropogenic ![]() $\text {CO}_2$ emissions are mainly to blame (Farcas & Woods Reference Farcas and Woods2009; Mac Dowell et al. Reference Mac Dowell, Fennell, Shah and Maitland2017; Hepburn et al. Reference Hepburn, Adlen, Beddington, Carter, Fuss, Mac Dowell, Minx, Smith and Williams2019; Gilmore et al. Reference Gilmore, Sahu, Benham, Neufeld and Bickle2022). To mitigate

$\text {CO}_2$ emissions are mainly to blame (Farcas & Woods Reference Farcas and Woods2009; Mac Dowell et al. Reference Mac Dowell, Fennell, Shah and Maitland2017; Hepburn et al. Reference Hepburn, Adlen, Beddington, Carter, Fuss, Mac Dowell, Minx, Smith and Williams2019; Gilmore et al. Reference Gilmore, Sahu, Benham, Neufeld and Bickle2022). To mitigate ![]() $\text {CO}_2$ emissions, it is necessary to introduce carbon capture technologies to separate

$\text {CO}_2$ emissions, it is necessary to introduce carbon capture technologies to separate ![]() $\text {CO}_2$ from the flue gas of power plants. Several

$\text {CO}_2$ from the flue gas of power plants. Several ![]() $\text {CO}_2$ capture technologies are under development, such as chemical absorption, physical adsorption, membrane separation and cryogenic capture (Song et al. Reference Song, Liu, Deng, Li and Kitamura2019; Nocito & Dibenedetto Reference Nocito and Dibenedetto2020; Gomez-Rueda et al. Reference Gomez-Rueda, Verougstraete, Ranga, Perez-Botella, Reniers and Denayer2022; Naquash et al. Reference Naquash, Qyyum, Haider, Bokhari, Lim and Lee2022). One of the cryogenic carbon capture (CCC) technologies is to desublimate

$\text {CO}_2$ capture technologies are under development, such as chemical absorption, physical adsorption, membrane separation and cryogenic capture (Song et al. Reference Song, Liu, Deng, Li and Kitamura2019; Nocito & Dibenedetto Reference Nocito and Dibenedetto2020; Gomez-Rueda et al. Reference Gomez-Rueda, Verougstraete, Ranga, Perez-Botella, Reniers and Denayer2022; Naquash et al. Reference Naquash, Qyyum, Haider, Bokhari, Lim and Lee2022). One of the cryogenic carbon capture (CCC) technologies is to desublimate ![]() $\text {CO}_2$ on the cooled surface of heat exchangers, achieving the separation of

$\text {CO}_2$ on the cooled surface of heat exchangers, achieving the separation of ![]() $\text {CO}_2$ in pure from the flue gas (bin Ab Halim Reference bin Ab Halim2013; Maqsood et al. Reference Maqsood, Mullick, Ali, Kargupta and Ganguly2014; Shen et al. Reference Shen, Tong, Yin, Liu, Wang, Feng and Ding2022). This desublimation-based CCC technology offers attractive advantages, such as easy operation, high efficiency, no chemical reaction, and pure separation. With these advantages, CCC is considered to hold significant application perspectives and research interests (Babar et al. Reference Babar, Bustam, Ali and Maulud2018, Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021; Font-Palma, Cann & Udemu Reference Font-Palma, Cann and Udemu2021). Nevertheless, compared with the other mature technologies, the development of desublimation-based CCC is still in a nascent stage due to some operational concerns (Pan, Clodic & Toubassy Reference Pan, Clodic and Toubassy2013; Gallucci & van Sint Annaland Reference Gallucci and van Sint Annaland2015). For example, a proper cooling temperature is required to guarantee the efficient desublimation rate and avoid the high cooling duty and cost. Meanwhile, the flue gas should be fed at a suitable rate so that the heat transfer surface can be fully utilized before the flue gas breakthrough. Furthermore, the desublimated solid

$\text {CO}_2$ in pure from the flue gas (bin Ab Halim Reference bin Ab Halim2013; Maqsood et al. Reference Maqsood, Mullick, Ali, Kargupta and Ganguly2014; Shen et al. Reference Shen, Tong, Yin, Liu, Wang, Feng and Ding2022). This desublimation-based CCC technology offers attractive advantages, such as easy operation, high efficiency, no chemical reaction, and pure separation. With these advantages, CCC is considered to hold significant application perspectives and research interests (Babar et al. Reference Babar, Bustam, Ali and Maulud2018, Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021; Font-Palma, Cann & Udemu Reference Font-Palma, Cann and Udemu2021). Nevertheless, compared with the other mature technologies, the development of desublimation-based CCC is still in a nascent stage due to some operational concerns (Pan, Clodic & Toubassy Reference Pan, Clodic and Toubassy2013; Gallucci & van Sint Annaland Reference Gallucci and van Sint Annaland2015). For example, a proper cooling temperature is required to guarantee the efficient desublimation rate and avoid the high cooling duty and cost. Meanwhile, the flue gas should be fed at a suitable rate so that the heat transfer surface can be fully utilized before the flue gas breakthrough. Furthermore, the desublimated solid ![]() $\text {CO}_2$ layer (SCL) needs to be controlled in a suitable pattern, otherwise it may adversely affect heat and mass transfer and even plug flow paths. These concerns demand a deep investigation of

$\text {CO}_2$ layer (SCL) needs to be controlled in a suitable pattern, otherwise it may adversely affect heat and mass transfer and even plug flow paths. These concerns demand a deep investigation of ![]() $\text {CO}_2$ desublimation in the CCC process.

$\text {CO}_2$ desublimation in the CCC process.

During the desublimation-based CCC process, the flue gas containing multiple components flows unsteadily in void channels (or flow paths). Meanwhile, the component ![]() $\text {CO}_2$ desublimates on the cooled surface of solid heat exchangers, which introduces two important physical processes: the evolution of channel structures, and the conjugate heat transfer between the solid and the gas phases. These two processes, in turn, can significantly affect the flue gas flow and the

$\text {CO}_2$ desublimates on the cooled surface of solid heat exchangers, which introduces two important physical processes: the evolution of channel structures, and the conjugate heat transfer between the solid and the gas phases. These two processes, in turn, can significantly affect the flue gas flow and the ![]() $\text {CO}_2$ desublimation rate (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). Therefore,

$\text {CO}_2$ desublimation rate (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). Therefore, ![]() $\text {CO}_2$ desublimation in the CCC process is a complex problem with fully coupled multiphysics. To study such a problem, some experiments were designed and conducted. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010) proposed a post-combustion CCC system based on packed beds. This novel system used packing materials to act as the heat transfer surface for

$\text {CO}_2$ desublimation in the CCC process is a complex problem with fully coupled multiphysics. To study such a problem, some experiments were designed and conducted. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010) proposed a post-combustion CCC system based on packed beds. This novel system used packing materials to act as the heat transfer surface for ![]() $\text {CO}_2$ desublimation, which operated in three consecutive steps: cooling, capture and recovery. In order to obtain a pseudo-continuous capture of

$\text {CO}_2$ desublimation, which operated in three consecutive steps: cooling, capture and recovery. In order to obtain a pseudo-continuous capture of ![]() $\text {CO}_2$, Tuinier, Hamers & van Sint Annaland (Reference Tuinier, Hamers and van Sint Annaland2011a) and Tuinier & van Sint Annaland (Reference Tuinier and van Sint Annaland2012) operated three packed beds in parallel, following three different cycles of capture, recovery and cooling. They also changed the system design to use the evaporation of liquid natural gas for cooling, which would be a preferred option if the liquid natural gas was available at low cost (Tuinier et al. Reference Tuinier, Hamers and van Sint Annaland2011a). By using such dynamically operated beds at atmospheric pressure,

$\text {CO}_2$, Tuinier, Hamers & van Sint Annaland (Reference Tuinier, Hamers and van Sint Annaland2011a) and Tuinier & van Sint Annaland (Reference Tuinier and van Sint Annaland2012) operated three packed beds in parallel, following three different cycles of capture, recovery and cooling. They also changed the system design to use the evaporation of liquid natural gas for cooling, which would be a preferred option if the liquid natural gas was available at low cost (Tuinier et al. Reference Tuinier, Hamers and van Sint Annaland2011a). By using such dynamically operated beds at atmospheric pressure, ![]() $\text {CO}_2$ was effectively separated from the flue gas or biogas. But this CCC system was not tested for gas mixtures with high

$\text {CO}_2$ was effectively separated from the flue gas or biogas. But this CCC system was not tested for gas mixtures with high ![]() $\text {CO}_2$ content and high pressure. To fill this gap, cryogenic packed beds with different flow configurations were exploited to purify the natural gas with high

$\text {CO}_2$ content and high pressure. To fill this gap, cryogenic packed beds with different flow configurations were exploited to purify the natural gas with high ![]() $\text {CO}_2$ content (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014, Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016). Through experimental observations, the countercurrent flow configuration was found to provide optimal separation and energy efficiencies, which was superior to the cocurrent flow bed.

$\text {CO}_2$ content (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014, Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016). Through experimental observations, the countercurrent flow configuration was found to provide optimal separation and energy efficiencies, which was superior to the cocurrent flow bed.

Later, another CCC system was developed to introduce Stirling coolers as the heat transfer surface (Song, Kitamura & Li Reference Song, Kitamura and Li2012a; Song et al. Reference Song, Kitamura, Li and Ogasawara2012b, Reference Song, Kitamura, Li and Jiang2013). Similar to the above CCC systems with packed beds, this one included three Stirling coolers for gas cooling, ![]() $\text {CO}_2$ desublimation, and

$\text {CO}_2$ desublimation, and ![]() $\text {CO}_2$ capture. From experiments,

$\text {CO}_2$ capture. From experiments, ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {H}_2\text {O}$ were separated at different Stirling coolers, without introducing large pressure drops and plugging problems. In addition, by adjusting operation parameters (i.e. the gas flow rate and the Stirling cooler temperature), the optimal performance with high

$\text {H}_2\text {O}$ were separated at different Stirling coolers, without introducing large pressure drops and plugging problems. In addition, by adjusting operation parameters (i.e. the gas flow rate and the Stirling cooler temperature), the optimal performance with high ![]() $\text {CO}_2$ recovery and low energy consumption was obtained. More recently, in order to avoid the use of multiple packed beds or Stirling coolers, a new CCC system based on a packed bed of moving packing materials was built (Willson et al. Reference Willson, Lychnos, Clements, Michailos, Font-Palma, Diego, Pourkashanian and Howe2019; Cann, Font-Palma & Willson Reference Cann, Font-Palma and Willson2021). Experimental results showed that this system had a modest life cost for large-scale applications, but a substantially low cost for small-scale applications. Besides, no excessive accumulation of desublimated

$\text {CO}_2$ recovery and low energy consumption was obtained. More recently, in order to avoid the use of multiple packed beds or Stirling coolers, a new CCC system based on a packed bed of moving packing materials was built (Willson et al. Reference Willson, Lychnos, Clements, Michailos, Font-Palma, Diego, Pourkashanian and Howe2019; Cann, Font-Palma & Willson Reference Cann, Font-Palma and Willson2021). Experimental results showed that this system had a modest life cost for large-scale applications, but a substantially low cost for small-scale applications. Besides, no excessive accumulation of desublimated ![]() $\text {CO}_2$ was observed in the capture step, suggesting the ability to capture

$\text {CO}_2$ was observed in the capture step, suggesting the ability to capture ![]() $\text {CO}_2$ continuously. Subsequently, Wang et al. (Reference Wang, Pfotenhauer, Qiu, Zhi and Jiang2020) carried out experiments to visualize the growth of the SCL on a cooled surface. They demonstrated that under the low-temperature condition,

$\text {CO}_2$ continuously. Subsequently, Wang et al. (Reference Wang, Pfotenhauer, Qiu, Zhi and Jiang2020) carried out experiments to visualize the growth of the SCL on a cooled surface. They demonstrated that under the low-temperature condition, ![]() $\text {CO}_2$ desublimated quickly to generate a loose SCL, which sublimated easily in the recovery step.

$\text {CO}_2$ desublimated quickly to generate a loose SCL, which sublimated easily in the recovery step.

The above experiments were conducted to implement various cryogenic capture concepts and investigate the ![]() $\text {CO}_2$ capture performance. Due to the operational complexity and the experimental cost, however, limited system designs and operation conditions could be tested by experiments. For such reasons, the numerical simulation was applied as a powerful and economic approach to investigate the desublimation-based CCC technology. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010) proposed a one-dimensional (1-D) pseudo-homogeneous model to describe evolutions of axial temperature, desublimated

$\text {CO}_2$ capture performance. Due to the operational complexity and the experimental cost, however, limited system designs and operation conditions could be tested by experiments. For such reasons, the numerical simulation was applied as a powerful and economic approach to investigate the desublimation-based CCC technology. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010) proposed a one-dimensional (1-D) pseudo-homogeneous model to describe evolutions of axial temperature, desublimated ![]() $\text {CO}_2$, and concentration profiles during the CCC process within packed beds. This 1-D model was validated by their experiments, and the

$\text {CO}_2$, and concentration profiles during the CCC process within packed beds. This 1-D model was validated by their experiments, and the ![]() $\text {CO}_2$ capture performance was evaluated for different parameters. The lower inlet

$\text {CO}_2$ capture performance was evaluated for different parameters. The lower inlet ![]() $\text {CO}_2$ content and the higher bed temperature were found to cause the larger cooling duty per mass of

$\text {CO}_2$ content and the higher bed temperature were found to cause the larger cooling duty per mass of ![]() $\text {CO}_2$ captured (Tuinier, van Sint Annaland & Kuipers Reference Tuinier, van Sint Annaland and Kuipers2011b). Moreover, compared with other competing

$\text {CO}_2$ captured (Tuinier, van Sint Annaland & Kuipers Reference Tuinier, van Sint Annaland and Kuipers2011b). Moreover, compared with other competing ![]() $\text {CO}_2$ capture technologies (i.e. chemical absorption and membrane separation), the packed-bed-based CCC was shown to be favourable in cases with the decreased pressure drop and the incorporated impurity removal (Tuinier et al. Reference Tuinier, Hamers and van Sint Annaland2011a). By introducing a multiple equilibrium temperature scheme, this 1-D model was extended to investigate the

$\text {CO}_2$ capture technologies (i.e. chemical absorption and membrane separation), the packed-bed-based CCC was shown to be favourable in cases with the decreased pressure drop and the incorporated impurity removal (Tuinier et al. Reference Tuinier, Hamers and van Sint Annaland2011a). By introducing a multiple equilibrium temperature scheme, this 1-D model was extended to investigate the ![]() $\text {CO}_2$ capture performance of a desublimation-based cryogenic pipeline network consisting of three packed beds (Ali et al. Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016). The modelled

$\text {CO}_2$ capture performance of a desublimation-based cryogenic pipeline network consisting of three packed beds (Ali et al. Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016). The modelled ![]() $\text {CO}_2$ content at the outlet showed a promising agreement with experimental measurements. This 1-D pseudo-homogeneous model was modified further to consider the desublimation of

$\text {CO}_2$ content at the outlet showed a promising agreement with experimental measurements. This 1-D pseudo-homogeneous model was modified further to consider the desublimation of ![]() $\text {CO}_2$ both on the gas–solid interface and in the gas area (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). The spatio-temporal evolution of an SCL in a cryogenic packed bed was simulated under different operation conditions. The results suggested that the desublimation rate increased with the decreasing bed temperature, the increasing pressure, and the ascending

$\text {CO}_2$ both on the gas–solid interface and in the gas area (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). The spatio-temporal evolution of an SCL in a cryogenic packed bed was simulated under different operation conditions. The results suggested that the desublimation rate increased with the decreasing bed temperature, the increasing pressure, and the ascending ![]() $\text {CO}_2$ content. In order to enhance the understanding of CCC using Stirling coolers, Song et al. (Reference Song, Kitamura, Li and Jiang2013, Reference Song, Kitamura and Li2014, Reference Song, Liu, Ji, Deng, Zhao and Kitamura2017a,Reference Song, Liu, Ji, Deng, Zhao, Li and Kitamurab) developed a two-dimensional (2-D) model to simulate the formation of an SCL during the CCC process. By synthesizing the heat integration and the membrane capture units, their simulations demonstrated that the energy requirement of the improved CCC system was reduced. Besides, with the growth of the SCL on Stirling coolers, the temperature of the SCL increased and the desublimation rate of

$\text {CO}_2$ content. In order to enhance the understanding of CCC using Stirling coolers, Song et al. (Reference Song, Kitamura, Li and Jiang2013, Reference Song, Kitamura and Li2014, Reference Song, Liu, Ji, Deng, Zhao and Kitamura2017a,Reference Song, Liu, Ji, Deng, Zhao, Li and Kitamurab) developed a two-dimensional (2-D) model to simulate the formation of an SCL during the CCC process. By synthesizing the heat integration and the membrane capture units, their simulations demonstrated that the energy requirement of the improved CCC system was reduced. Besides, with the growth of the SCL on Stirling coolers, the temperature of the SCL increased and the desublimation rate of ![]() $\text {CO}_2$ decreased. This indicated that an advanced knowledge base of the SCL could hep to improve the

$\text {CO}_2$ decreased. This indicated that an advanced knowledge base of the SCL could hep to improve the ![]() $\text {CO}_2$ capture performance. By comparing with experiments, Wang et al. (Reference Wang, Pfotenhauer, Zhi, Qiu and Li2018a) also demonstrated that numerical models considering heat transfer in the SCL could produce more accurate results.

$\text {CO}_2$ capture performance. By comparing with experiments, Wang et al. (Reference Wang, Pfotenhauer, Zhi, Qiu and Li2018a) also demonstrated that numerical models considering heat transfer in the SCL could produce more accurate results.

The existing numerical studies have improved the understanding of ![]() $\text {CO}_2$ desublimation during the CCC process. However, they applied volumetric models to describe the desublimation of

$\text {CO}_2$ desublimation during the CCC process. However, they applied volumetric models to describe the desublimation of ![]() $\text {CO}_2$ on the cooled heat transfer surface, which simplified the intricate pore structure of the SCL as homogeneous. Consequently, these models focused on averaged desublimation properties at macroscopic scales and ignored pore-scale details. Furthermore, these numerical studies adopted empirical correlations to determine the effective transport and desublimation properties. But the formulation of empirical correlations requires a prior understanding of pore-scale desublimation properties (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a,Reference Xu, Long, Jiang, Zan, Huang, Chen and Shib, Reference Xu, Dai, Yang, Liu and Shi2022). As can be seen, models that can investigate

$\text {CO}_2$ on the cooled heat transfer surface, which simplified the intricate pore structure of the SCL as homogeneous. Consequently, these models focused on averaged desublimation properties at macroscopic scales and ignored pore-scale details. Furthermore, these numerical studies adopted empirical correlations to determine the effective transport and desublimation properties. But the formulation of empirical correlations requires a prior understanding of pore-scale desublimation properties (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a,Reference Xu, Long, Jiang, Zan, Huang, Chen and Shib, Reference Xu, Dai, Yang, Liu and Shi2022). As can be seen, models that can investigate ![]() $\text {CO}_2$ desublimation in the CCC process at the pore scale are essential.

$\text {CO}_2$ desublimation in the CCC process at the pore scale are essential.

As a powerful pore-scale solver, the lattice Boltzmann (LB) method has been applied widely to study complex fluid flows in porous structures over the past three decades (Li et al. Reference Li, Luo, Kang, He, Chen and Liu2016; Lei, Luo & Wu Reference Lei, Luo and Wu2019; Lei & Luo Reference Lei and Luo2021a; Chen et al. Reference Chen, He, Zhao, Kang, Li, Carmeliet, Shikazono and Tao2022). Accordingly, LB simulations were reported to investigate separately the physical processes that are encountered in ![]() $\text {CO}_2$ desublimation, including the unsteady fluid flow, the heat and mass transfer, and the active gas–solid interface for desublimation. On the one hand, for simulating the incompressible fluid flow and component transport in porous structures, LB models with a single relaxation time or multiple relaxation times were developed (Dorschner et al. Reference Dorschner, Bösch, Chikatamarla, Boulouchos and Karlin2016; Wang et al. Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018b; Lei & Luo Reference Lei and Luo2020). Compared with traditional solvers, these LB models offered attractive advantages, such as simple implementation, high parallelism, easy treatment of complex porous structures, and the ability to extend from two to three dimensions. On the other hand,

$\text {CO}_2$ desublimation, including the unsteady fluid flow, the heat and mass transfer, and the active gas–solid interface for desublimation. On the one hand, for simulating the incompressible fluid flow and component transport in porous structures, LB models with a single relaxation time or multiple relaxation times were developed (Dorschner et al. Reference Dorschner, Bösch, Chikatamarla, Boulouchos and Karlin2016; Wang et al. Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018b; Lei & Luo Reference Lei and Luo2020). Compared with traditional solvers, these LB models offered attractive advantages, such as simple implementation, high parallelism, easy treatment of complex porous structures, and the ability to extend from two to three dimensions. On the other hand, ![]() $\text {CO}_2$ desublimation on the active gas–solid interface can be modelled by tracking the porous structure evolution and solving the boundary conditions for mass conservation and conjugate heat transfer. To model the mass conservation condition at the active fluid–solid boundary, Zhang et al. (Reference Zhang, Shi, Guo, Chai and Lu2012) developed a general bounce-back LB boundary scheme. This scheme was easy to implement and suitable for boundaries with or without curvature and velocity, but the update of porous structures was not considered. In the meantime, Kang, Lichtner & Zhang (Reference Kang, Lichtner and Zhang2006) and Chen et al. (Reference Chen, Kang, Carey and Tao2014) proposed an LB boundary scheme to solve the active fluid–solid interface, with both the dissolution of solid matrix and the precipitation of solid products being considered. Under effects of these two interfacial reactions, porous structures evolved with time and were tracked by the volume of pixel (VOP) method. Their model was applied extensively to investigate the active fluid–solid boundary in applications such as geological

$\text {CO}_2$ desublimation on the active gas–solid interface can be modelled by tracking the porous structure evolution and solving the boundary conditions for mass conservation and conjugate heat transfer. To model the mass conservation condition at the active fluid–solid boundary, Zhang et al. (Reference Zhang, Shi, Guo, Chai and Lu2012) developed a general bounce-back LB boundary scheme. This scheme was easy to implement and suitable for boundaries with or without curvature and velocity, but the update of porous structures was not considered. In the meantime, Kang, Lichtner & Zhang (Reference Kang, Lichtner and Zhang2006) and Chen et al. (Reference Chen, Kang, Carey and Tao2014) proposed an LB boundary scheme to solve the active fluid–solid interface, with both the dissolution of solid matrix and the precipitation of solid products being considered. Under effects of these two interfacial reactions, porous structures evolved with time and were tracked by the volume of pixel (VOP) method. Their model was applied extensively to investigate the active fluid–solid boundary in applications such as geological ![]() $\text {CO}_2$ sequestration and fuel cells (Chen et al. Reference Chen, Zhang, He, Kang, He and Tao2018a,Reference Chen, Zhang, Min, Kang and Taob; Chen, Kang & Tao Reference Chen, Kang and Tao2019; Lei & Luo Reference Lei and Luo2021b). To solve the conjugate heat transfer boundary conditions, several efforts were made in the LB community without involving conventional extrapolations or iterations (He et al. Reference He, Liu, Li and Tao2019). A half-lattice division scheme was proposed to model the conjugate heat transfer between the solid and fluid phases. The reliability of this scheme was limited to cases with steady-state solutions or unified heat capacities between the two phases (Wang, Wang & Li Reference Wang, Wang and Li2007; Wang & Pan Reference Wang and Pan2008). Later, by recasting the energy conservation equation, a new source term was introduced into LB equations to guarantee the conjugate heat transfer (Karani & Huber Reference Karani and Huber2015). Due to the easy implementation, this treatment was applied to consider the conjugate heat transfer during coke combustion and methane hydrate dissolution (Zhang et al. Reference Zhang, Zhang, Zhang, Zhang, Yao, Sun and Yang2019; Lei, Wang & Luo Reference Lei, Wang and Luo2021).

$\text {CO}_2$ sequestration and fuel cells (Chen et al. Reference Chen, Zhang, He, Kang, He and Tao2018a,Reference Chen, Zhang, Min, Kang and Taob; Chen, Kang & Tao Reference Chen, Kang and Tao2019; Lei & Luo Reference Lei and Luo2021b). To solve the conjugate heat transfer boundary conditions, several efforts were made in the LB community without involving conventional extrapolations or iterations (He et al. Reference He, Liu, Li and Tao2019). A half-lattice division scheme was proposed to model the conjugate heat transfer between the solid and fluid phases. The reliability of this scheme was limited to cases with steady-state solutions or unified heat capacities between the two phases (Wang, Wang & Li Reference Wang, Wang and Li2007; Wang & Pan Reference Wang and Pan2008). Later, by recasting the energy conservation equation, a new source term was introduced into LB equations to guarantee the conjugate heat transfer (Karani & Huber Reference Karani and Huber2015). Due to the easy implementation, this treatment was applied to consider the conjugate heat transfer during coke combustion and methane hydrate dissolution (Zhang et al. Reference Zhang, Zhang, Zhang, Zhang, Yao, Sun and Yang2019; Lei, Wang & Luo Reference Lei, Wang and Luo2021).

From the above literature review, it is concluded that the LB method can be applied to model separately various aspects of the multiphysics behind ![]() $\text {CO}_2$ desublimation in the CCC process. However, modelling the interaction of all these complex and coupled physics at the pore scale remains challenging and has not been achieved by a single LB model. To advance the predictive capability of the LB method and improve the current understanding of the CCC process, this work aims to develop an LB model for studying

$\text {CO}_2$ desublimation in the CCC process. However, modelling the interaction of all these complex and coupled physics at the pore scale remains challenging and has not been achieved by a single LB model. To advance the predictive capability of the LB method and improve the current understanding of the CCC process, this work aims to develop an LB model for studying ![]() $\text {CO}_2$ desublimation during the CCC process at the pore scale. The main goal of the pore-scale simulations is to elucidate the

$\text {CO}_2$ desublimation during the CCC process at the pore scale. The main goal of the pore-scale simulations is to elucidate the ![]() $\text {CO}_2$ desublimation properties and evaluate the

$\text {CO}_2$ desublimation properties and evaluate the ![]() $\text {CO}_2$ capture performance under various operation conditions.

$\text {CO}_2$ capture performance under various operation conditions.

2. Mathematical and physical models

This study focuses on the multiphysical processes behind ![]() $\text {CO}_2$ desublimation during the CCC process within a packed bed. The simplified schematic of a sample cryogenic packed bed is depicted in figure 1, where the bed is jacked by stainless steel and packed with solid materials (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014). Before constructing governing equations for describing the desublimation of

$\text {CO}_2$ desublimation during the CCC process within a packed bed. The simplified schematic of a sample cryogenic packed bed is depicted in figure 1, where the bed is jacked by stainless steel and packed with solid materials (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014). Before constructing governing equations for describing the desublimation of ![]() $\text {CO}_2$ at the pore scale, some simplifications and assumptions are made as follows.

$\text {CO}_2$ at the pore scale, some simplifications and assumptions are made as follows.

(i) This work investigates the capture of

$\text {CO}_2$ without detailing the cooling of packing materials and the recovery of desublimated

$\text {CO}_2$ without detailing the cooling of packing materials and the recovery of desublimated  $\text {CO}_2$.

$\text {CO}_2$.(ii) The temperature of packing materials is fixed as

$T_w$.

$T_w$.(iii) The incompressible flue gas is neutrally buoyant and obeys the ideal gas law.

(iv) The flue gas is represented as a mixture of

$\text {CO}_2$ and

$\text {CO}_2$ and  $\text {N}_2$.

$\text {N}_2$.(v) Fick's law is applied to describe the mass diffusion of gas components.

(vi) The desublimation rate of the gaseous component

$\text {CO}_2$ is proportional to the local deviation from the gas–solid equilibrium.

$\text {CO}_2$ is proportional to the local deviation from the gas–solid equilibrium.(vii) Physical properties of the gas and the solid phases are set as constants in relation to the initial condition.

(viii) To allow for a wide-range parametric study, the computational domain is reduced to a small-size one that can both decrease the computational cost and hold the

$\text {CO}_2$ desublimation characteristics.

$\text {CO}_2$ desublimation characteristics.(ix) To compare 2-D and three-dimensional (3-D) simulations, the shape of packing materials is considered cylindrical.

Figure 1. The schematic diagram of the problem: desublimation of ![]() $\text {CO}_2$ in the CCC process.

$\text {CO}_2$ in the CCC process.

Under these premises, a small computational domain encompassing a single solid packing cylinder is selected from the cryogenic packed bed as depicted in figure 1. The computational domain is ![]() $0 \leqslant x \leqslant l_x$,

$0 \leqslant x \leqslant l_x$, ![]() $0 \leqslant y \leqslant l_y$ and

$0 \leqslant y \leqslant l_y$ and ![]() $0 \leqslant z \leqslant l_z$. From the inlet of the selected domain, the incompressible flue gas at temperature

$0 \leqslant z \leqslant l_z$. From the inlet of the selected domain, the incompressible flue gas at temperature ![]() $T_0$, pressure

$T_0$, pressure ![]() $p_0$ and velocity

$p_0$ and velocity ![]() $\boldsymbol {u}_0$ is injected in. Such a flue gas initially consists of

$\boldsymbol {u}_0$ is injected in. Such a flue gas initially consists of ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {N}_2$ with mass fractions

$\text {N}_2$ with mass fractions ![]() $Y_0$ and

$Y_0$ and ![]() $(1-Y_0)$, respectively. The temperature of the packing cylinder (

$(1-Y_0)$, respectively. The temperature of the packing cylinder (![]() $T_{w}$) is above the freezing point of

$T_{w}$) is above the freezing point of ![]() $\text {N}_2$ but below that of

$\text {N}_2$ but below that of ![]() $\text {CO}_2$. Thus once the flue gas is sufficiently cooled by the cylinder,

$\text {CO}_2$. Thus once the flue gas is sufficiently cooled by the cylinder, ![]() $\text {N}_2$ continues passing the cylinder and leaving the domain without phase change, while the gaseous

$\text {N}_2$ continues passing the cylinder and leaving the domain without phase change, while the gaseous ![]() $\text {CO}_2$ starts to deposit as solid on the cylinder surface:

$\text {CO}_2$ starts to deposit as solid on the cylinder surface:

Here, ![]() $Q$ is the released heat from

$Q$ is the released heat from ![]() $\text {CO}_2$ desublimation, and the gaseous and solid phases of

$\text {CO}_2$ desublimation, and the gaseous and solid phases of ![]() $\text {CO}_2$ are denoted by g and s, respectively. During such a desublimation process, the mass transfer rate from the gaseous

$\text {CO}_2$ are denoted by g and s, respectively. During such a desublimation process, the mass transfer rate from the gaseous ![]() $\text {CO}_2$ to the solid

$\text {CO}_2$ to the solid ![]() $\text {CO}_2$ is estimated as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010; Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019)

$\text {CO}_2$ is estimated as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010; Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019)

In the above calculation, ![]() $k_r$ is the mass desublimation rate constant,

$k_r$ is the mass desublimation rate constant, ![]() $p$ is the flue gas pressure, and

$p$ is the flue gas pressure, and ![]() $y_i$ is the mole fraction of

$y_i$ is the mole fraction of ![]() $\text {CO}_2$. The value of

$\text {CO}_2$. The value of ![]() $y_i$ is calculated based on the mass fraction

$y_i$ is calculated based on the mass fraction ![]() $Y$ of

$Y$ of ![]() $\text {CO}_2$:

$\text {CO}_2$:

where ![]() $M$,

$M$, ![]() $M_{\text {CO}_2}$ and

$M_{\text {CO}_2}$ and ![]() $M_{\text {N}_2}$ are the molecular weights of the flue gas,

$M_{\text {N}_2}$ are the molecular weights of the flue gas, ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {N}_2$, respectively. The equilibrium pressure between the gas and the solid phases corresponding to the local temperature

$\text {N}_2$, respectively. The equilibrium pressure between the gas and the solid phases corresponding to the local temperature ![]() $T$ is determined by an empirical correlation as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010)

$T$ is determined by an empirical correlation as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010)

The units of ![]() $p_e$ and

$p_e$ and ![]() $T$ are pascal (Pa) and kelvin (K), respectively. Note that

$T$ are pascal (Pa) and kelvin (K), respectively. Note that ![]() $\text {CO}_2$ desublimates continuously on the cylinder surface until the equilibrium pressure is reached. That is, (2.2) is valid when the partial pressure of

$\text {CO}_2$ desublimates continuously on the cylinder surface until the equilibrium pressure is reached. That is, (2.2) is valid when the partial pressure of ![]() $\text {CO}_2$ is larger than the equilibrium pressure (i.e.

$\text {CO}_2$ is larger than the equilibrium pressure (i.e. ![]() $y_i p > p_e$), otherwise the mass transfer rate becomes zero under conditions with

$y_i p > p_e$), otherwise the mass transfer rate becomes zero under conditions with ![]() $y_i p\leqslant p_e$. From the desublimation process, the released heat

$y_i p\leqslant p_e$. From the desublimation process, the released heat ![]() $Q$ is calculated as

$Q$ is calculated as

with ![]() $h_r$ being the enthalpy change of

$h_r$ being the enthalpy change of ![]() $\text {CO}_2$ desublimation, and

$\text {CO}_2$ desublimation, and ![]() $a_r$ being the specific surface area per unit volume. During the

$a_r$ being the specific surface area per unit volume. During the ![]() $\text {CO}_2$ desublimation process, the pore structure of the SCL changes with the deposition of solid

$\text {CO}_2$ desublimation process, the pore structure of the SCL changes with the deposition of solid ![]() $\text {CO}_2$ on the cylinder surface. This structure evolution is tracked by the mass conservation equation for the solid

$\text {CO}_2$ on the cylinder surface. This structure evolution is tracked by the mass conservation equation for the solid ![]() $\text {CO}_2$ as (Kang et al. Reference Kang, Chen, Valocchi and Viswanathan2014)

$\text {CO}_2$ as (Kang et al. Reference Kang, Chen, Valocchi and Viswanathan2014)

where ![]() $V_s$ and

$V_s$ and ![]() $\rho _s$ represent the volume and density of solid

$\rho _s$ represent the volume and density of solid ![]() $\text {CO}_2$, respectively, and

$\text {CO}_2$, respectively, and ![]() $V_r$ is the active volume for desublimation.

$V_r$ is the active volume for desublimation.

To model ![]() ${\text {CO}_2}$ desublimation at the pore scale, a set of governing equations is built, including the continuity equation (2.7) and the incompressible Navier–Stokes equation (2.8) for the flue gas flow, the species conservation equation (2.9) for the transport of

${\text {CO}_2}$ desublimation at the pore scale, a set of governing equations is built, including the continuity equation (2.7) and the incompressible Navier–Stokes equation (2.8) for the flue gas flow, the species conservation equation (2.9) for the transport of ![]() ${\text {CO}_2}$ in flow paths, and the energy conservation equation (2.10) for heat transfer in both flow paths and solid phases (i.e. solid cylinder and solid

${\text {CO}_2}$ in flow paths, and the energy conservation equation (2.10) for heat transfer in both flow paths and solid phases (i.e. solid cylinder and solid ![]() ${\text {CO}_2}$):

${\text {CO}_2}$):

Here, ![]() $\boldsymbol {u}=(u, v, w)$,

$\boldsymbol {u}=(u, v, w)$, ![]() $\rho _g$ and

$\rho _g$ and ![]() $\nu$ are the gas velocity, density and kinematic viscosity, respectively;

$\nu$ are the gas velocity, density and kinematic viscosity, respectively; ![]() $t$ is the time, and

$t$ is the time, and ![]() $D$ is the diffusion coefficient of the gaseous component

$D$ is the diffusion coefficient of the gaseous component ![]() $\text {CO}_2$;

$\text {CO}_2$; ![]() $\rho$,

$\rho$, ![]() $c_p$ and

$c_p$ and ![]() $\alpha$ are the local density, specific heat at constant pressure, and thermal diffusivity, respectively.

$\alpha$ are the local density, specific heat at constant pressure, and thermal diffusivity, respectively.

Such governing equations must satisfy boundary conditions at both internal and external boundaries of the computational domain. At the internal interface between the flue gas and the solid cylinder or solid ![]() $\text {CO}_2$, two types of boundary conditions are considered.

$\text {CO}_2$, two types of boundary conditions are considered.

On the one hand, at the gas–solid interface ![]() $I$ satisfying the criterion

$I$ satisfying the criterion ![]() $y_i p > p_e$, the gaseous

$y_i p > p_e$, the gaseous ![]() $\text {CO}_2$ desublimates to generate the solid

$\text {CO}_2$ desublimates to generate the solid ![]() $\text {CO}_2$ and release heat. Such a desublimation process at the internal interface

$\text {CO}_2$ and release heat. Such a desublimation process at the internal interface ![]() $I$ is described by boundary conditions as

$I$ is described by boundary conditions as

These equations describe the no-slip velocity (2.11), the mass conservation (2.12), and the conjugate heat transfer (2.13a,b) boundary conditions. In these equations, ![]() $\boldsymbol {n}$ is the interface normal pointing to the gas phase,

$\boldsymbol {n}$ is the interface normal pointing to the gas phase, ![]() $+$ and

$+$ and ![]() $-$ denote parameters on either side of

$-$ denote parameters on either side of ![]() $I$,

$I$, ![]() $k=\alpha \rho c_p$ is the thermal conductivity, and

$k=\alpha \rho c_p$ is the thermal conductivity, and ![]() $q$ is the heat flux caused by

$q$ is the heat flux caused by ![]() $\text {CO}_2$ desublimation.

$\text {CO}_2$ desublimation.

On the other hand, at the gas–solid interface ![]() $I_n$ satisfying

$I_n$ satisfying ![]() $y_i p \leqslant p_e$, there is no

$y_i p \leqslant p_e$, there is no ![]() $\text {CO}_2$ desublimation, and the no-flux boundary condition is adopted for mass conservation. Thus the boundary conditions at the internal interface

$\text {CO}_2$ desublimation, and the no-flux boundary condition is adopted for mass conservation. Thus the boundary conditions at the internal interface ![]() $I_n$ reduce to

$I_n$ reduce to

At the external boundaries of the computational domain, boundary conditions are set as follows. First, at the inlet (![]() $x=0$), the component mass fraction, temperature and velocity are specified. This is because the flue gas is injected into the domain at a specific operation condition. Then, at the outlet (

$x=0$), the component mass fraction, temperature and velocity are specified. This is because the flue gas is injected into the domain at a specific operation condition. Then, at the outlet (![]() $x=l_x$), the zero-gradient velocity and the no-flux conditions for temperature and mass fraction are applied. A fully developed flow is thus considered there, and the flue gas can flow out freely. Finally, at the bottom (

$x=l_x$), the zero-gradient velocity and the no-flux conditions for temperature and mass fraction are applied. A fully developed flow is thus considered there, and the flue gas can flow out freely. Finally, at the bottom (![]() $y=0$) and top (

$y=0$) and top (![]() $y=l_y$), the periodic conditions are imposed. Note that the additional front (

$y=l_y$), the periodic conditions are imposed. Note that the additional front (![]() $z=0$) and back (

$z=0$) and back (![]() $z=l_z$) boundaries in 3-D simulations are also treated as periodic ones. These boundary conditions are described by

$z=l_z$) boundaries in 3-D simulations are also treated as periodic ones. These boundary conditions are described by

In order to model ![]() $\text {CO}_2$ desublimation using the LB method, the above physical parameters should be converted to those in the lattice units. For this purpose, dimensionless parameters are derived to act as the conversion criteria between the two systems of units. By introducing the characteristic length

$\text {CO}_2$ desublimation using the LB method, the above physical parameters should be converted to those in the lattice units. For this purpose, dimensionless parameters are derived to act as the conversion criteria between the two systems of units. By introducing the characteristic length ![]() $L$, velocity

$L$, velocity ![]() $U$, temperature

$U$, temperature ![]() $T_{ch}$ and density

$T_{ch}$ and density ![]() $\rho _g$, dimensionless parameters marked by asterisks are derived as

$\rho _g$, dimensionless parameters marked by asterisks are derived as

\begin{equation} \left.\begin{gathered} \boldsymbol{x}^* = \frac{\boldsymbol{u}}{L}, \quad t^* = \frac{t U}{L}, \quad \boldsymbol{u}^* = \frac{\boldsymbol{u}}{U}, \quad \rho^* = \frac{\rho}{\rho_g}, \quad p^* = \frac{p}{\rho_g U^2}, \quad T^* = \frac{T}{T_{ch}}, \\ m_r^* = \frac{m_r}{\rho_lU}, \quad h_r^* = \frac{h_r}{c_{p,g}T_{ch}}, \quad k_r^* = k_rU, \quad \textit{Re} = \frac{LU}{\nu}, \quad \textit{Pe} = \frac{LU}{D}, \quad \textit{Pr} = \frac{\nu}{\alpha_g}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \boldsymbol{x}^* = \frac{\boldsymbol{u}}{L}, \quad t^* = \frac{t U}{L}, \quad \boldsymbol{u}^* = \frac{\boldsymbol{u}}{U}, \quad \rho^* = \frac{\rho}{\rho_g}, \quad p^* = \frac{p}{\rho_g U^2}, \quad T^* = \frac{T}{T_{ch}}, \\ m_r^* = \frac{m_r}{\rho_lU}, \quad h_r^* = \frac{h_r}{c_{p,g}T_{ch}}, \quad k_r^* = k_rU, \quad \textit{Re} = \frac{LU}{\nu}, \quad \textit{Pe} = \frac{LU}{D}, \quad \textit{Pr} = \frac{\nu}{\alpha_g}. \end{gathered}\right\} \end{equation}

The subscript ![]() $g$ refers to physical properties of the flue gas. From such dimensionless derivations, key characteristic numbers are obtained, such as the Reynolds number

$g$ refers to physical properties of the flue gas. From such dimensionless derivations, key characteristic numbers are obtained, such as the Reynolds number ![]() $\textit {Re}$, the Péclet number

$\textit {Re}$, the Péclet number ![]() $\textit {Pe}$, and the Prandtl number

$\textit {Pe}$, and the Prandtl number ![]() $\textit {Pr}$. In the following LB simulations, a match of these dimensionless variables ensures the same desublimation properties between the lattice space and the real physical coordinate.

$\textit {Pr}$. In the following LB simulations, a match of these dimensionless variables ensures the same desublimation properties between the lattice space and the real physical coordinate.

3. Numerical method

Considering different thermophysical properties between the gas and solid phases, (2.10) is recast as

with the source term ![]() $F_T$ being

$F_T$ being

The derivation details can be found in our earlier work (Lei et al. Reference Lei, Wang and Luo2021).

To solve the governing equations (2.7)–(2.9) and (3.1) in two and three dimensions, the 2-D nine-velocity (D2Q9) and 3-D fifteen-velocity (D3Q15) multiple-relaxation-time (MRT) LB models are developed, respectively (Pan, Luo & Miller Reference Pan, Luo and Miller2006; Guo & Shu Reference Guo and Shu2013; Lei & Luo Reference Lei and Luo2019). The corresponding discrete velocities ![]() $\boldsymbol {e}_i$ and weight coefficients

$\boldsymbol {e}_i$ and weight coefficients ![]() $w_i$ are provided in Appendix A.

$w_i$ are provided in Appendix A.

In the proposed LB models, a set of evolution equations is built as (Guo & Shu Reference Guo and Shu2013; Lei & Luo Reference Lei and Luo2019; Lei et al. Reference Lei, Wang and Luo2021)

\begin{align} h_i \left( \boldsymbol{x} + \boldsymbol{e}_i \delta _t, t + \delta _t \right) - h_i\left( \boldsymbol{x}, t \right) &={-} \left( \boldsymbol{\mathsf{M}}^{{-}1} \boldsymbol{\mathsf{S}}_t \boldsymbol{\mathsf{M}} \right)_{ij} \left[ h_j \left( \boldsymbol{x}, t \right) - h_j ^{eq} \left( \boldsymbol{x}, t \right) \right]\nonumber\\ &\quad + \delta _t \bar{F}_{T,i} + \frac{\delta _t^ 2}{2}\,\frac{\partial \bar{F}_{T,i}}{\partial t}, \end{align}

\begin{align} h_i \left( \boldsymbol{x} + \boldsymbol{e}_i \delta _t, t + \delta _t \right) - h_i\left( \boldsymbol{x}, t \right) &={-} \left( \boldsymbol{\mathsf{M}}^{{-}1} \boldsymbol{\mathsf{S}}_t \boldsymbol{\mathsf{M}} \right)_{ij} \left[ h_j \left( \boldsymbol{x}, t \right) - h_j ^{eq} \left( \boldsymbol{x}, t \right) \right]\nonumber\\ &\quad + \delta _t \bar{F}_{T,i} + \frac{\delta _t^ 2}{2}\,\frac{\partial \bar{F}_{T,i}}{\partial t}, \end{align}

where ![]() $i$ and

$i$ and ![]() $j$ are discrete directions, and

$j$ are discrete directions, and ![]() $f_i(\boldsymbol {x}, t)$,

$f_i(\boldsymbol {x}, t)$, ![]() $g_i(\boldsymbol {x},t)$ and

$g_i(\boldsymbol {x},t)$ and ![]() $h_i(\boldsymbol {x},t)$ are distribution functions for the density, the

$h_i(\boldsymbol {x},t)$ are distribution functions for the density, the ![]() $\textrm {CO}_2$ mass fraction and the temperature fields, respectively. The corresponding equilibrium distribution functions

$\textrm {CO}_2$ mass fraction and the temperature fields, respectively. The corresponding equilibrium distribution functions ![]() $f_i^{eq}$,

$f_i^{eq}$, ![]() $g_i^{eq}$ and

$g_i^{eq}$ and ![]() $h_i^{eq}$ are given as

$h_i^{eq}$ are given as

\begin{gather} f_i^{eq} = w_i \left[\rho_g + \rho_p \left( \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right) \right], \end{gather}

\begin{gather} f_i^{eq} = w_i \left[\rho_g + \rho_p \left( \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right) \right], \end{gather} \begin{gather}g_i^{eq} = w_i Y \left[ 1 + \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right], \end{gather}

\begin{gather}g_i^{eq} = w_i Y \left[ 1 + \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right], \end{gather} \begin{gather}h_{i}^{eq} = w_i T \left[ 1 + \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right]. \end{gather}

\begin{gather}h_{i}^{eq} = w_i T \left[ 1 + \frac{\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}}{c_s^2} + \frac{\left(\boldsymbol{e}_i \boldsymbol{\cdot} \boldsymbol{u}\right)^2}{2 c_s^4} - \frac{\boldsymbol{u}^2}{2 c_s^2} \right]. \end{gather}

Here, ![]() $\rho _p$ is a variable related to the gas pressure as

$\rho _p$ is a variable related to the gas pressure as ![]() $\rho _p= p / c_s^2$, where

$\rho _p= p / c_s^2$, where ![]() $c_s = e/ \sqrt {3}$ is the lattice sound velocity;

$c_s = e/ \sqrt {3}$ is the lattice sound velocity; ![]() $e=\delta _x/\delta _t$ is the lattice speed and is set as

$e=\delta _x/\delta _t$ is the lattice speed and is set as ![]() $e=1$ in the following simulations, with

$e=1$ in the following simulations, with ![]() $\delta _x$ and

$\delta _x$ and ![]() $\delta _t$ denoting the lattice spacing and time step, respectively. This LB model for incompressible fluid flows can reduce compressible errors (Guo & Shu Reference Guo and Shu2013).

$\delta _t$ denoting the lattice spacing and time step, respectively. This LB model for incompressible fluid flows can reduce compressible errors (Guo & Shu Reference Guo and Shu2013).

To avoid discrete lattice effects, the distribution function for the thermal source term (![]() $F_T$) is defined as (Guo & Zhao Reference Guo and Zhao2002; Shi & Guo Reference Shi and Guo2009)

$F_T$) is defined as (Guo & Zhao Reference Guo and Zhao2002; Shi & Guo Reference Shi and Guo2009)

with ![]() $\tau _t$ being the relaxation time. The time derivatives in (3.2c) (

$\tau _t$ being the relaxation time. The time derivatives in (3.2c) (![]() $\partial \rho c_p / \partial t$) and (3.5) (

$\partial \rho c_p / \partial t$) and (3.5) (![]() $\partial \bar {F}_{T,i} / \partial t$) are treated by the backward scheme. In the evolution equations (3.3)–(3.5),

$\partial \bar {F}_{T,i} / \partial t$) are treated by the backward scheme. In the evolution equations (3.3)–(3.5), ![]() $\boldsymbol{\mathsf{S}}$,

$\boldsymbol{\mathsf{S}}$, ![]() $\boldsymbol{\mathsf{S}}_y$ and

$\boldsymbol{\mathsf{S}}_y$ and ![]() $\boldsymbol{\mathsf{S}}_t$ are the diagonal relaxation matrices, while

$\boldsymbol{\mathsf{S}}_t$ are the diagonal relaxation matrices, while ![]() $\boldsymbol{\mathsf{M}}$ is the transformation matrix to map distribution functions from the physical space to the moment space. More details about the transformation are provided in Appendix A. Based on the distribution functions, the macroscopic variables can be calculated finally as

$\boldsymbol{\mathsf{M}}$ is the transformation matrix to map distribution functions from the physical space to the moment space. More details about the transformation are provided in Appendix A. Based on the distribution functions, the macroscopic variables can be calculated finally as

In order to obtain the accurate solution of (2.7)–(2.9) and (3.1) by the above LB models, boundary conditions for macroscopic variables in (2.11)–(2.19) should be satisfied. Note, however, that the fundamental variables in LB equations are discrete distribution functions (i.e. ![]() $f_i(\boldsymbol {x}, t)$,

$f_i(\boldsymbol {x}, t)$, ![]() $g_i(\boldsymbol {x},t)$ and

$g_i(\boldsymbol {x},t)$ and ![]() $h_i(\boldsymbol {x},t)$). It is thus necessary to build LB boundary schemes to transform the boundary conditions for macroscopic variables to those for discrete distribution functions.

$h_i(\boldsymbol {x},t)$). It is thus necessary to build LB boundary schemes to transform the boundary conditions for macroscopic variables to those for discrete distribution functions.

On the one hand, treatments of the external boundary conditions are introduced. For the specified inlet in (2.17) and the fully developed outlet in (2.18), the non-equilibrium extrapolation boundary scheme is applied to reconstruct the unknown distribution functions (Guo & Shu Reference Guo and Shu2013). For the periodic top and bottom boundaries in (2.19), the outgoing distribution functions from the top re-enter the domain from the bottom, and vice versa (Guo & Shu Reference Guo and Shu2013). This scheme is also applied for the periodic front and back boundaries in (2.19).

On the other hand, LB schemes are built for modelling boundary conditions at the internal boundaries ![]() $I$ and

$I$ and ![]() $I_n$. For the gas–solid interface

$I_n$. For the gas–solid interface ![]() $I$ with the desublimation of

$I$ with the desublimation of ![]() $\textrm {CO}_2$, three boundary treatments are required. First, the conjugate heat transfer in (2.13a,b) is satisfied automatically by solving the energy conservation equation (3.1). Then the no-slip velocity condition in (2.11) is addressed by the halfway bounce-back scheme, with the unknown distribution functions at the gas grid

$\textrm {CO}_2$, three boundary treatments are required. First, the conjugate heat transfer in (2.13a,b) is satisfied automatically by solving the energy conservation equation (3.1). Then the no-slip velocity condition in (2.11) is addressed by the halfway bounce-back scheme, with the unknown distribution functions at the gas grid ![]() $\boldsymbol {x}_g$ adjacent to

$\boldsymbol {x}_g$ adjacent to ![]() $I$ being (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

$I$ being (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

Here, the superscript ![]() $'$ denotes the post-collision distribution function,

$'$ denotes the post-collision distribution function, ![]() $i$ is the direction opposite to

$i$ is the direction opposite to ![]() $\bar {\imath }$ (i.e.

$\bar {\imath }$ (i.e. ![]() $\boldsymbol {e}_i = -\boldsymbol {e}_{\bar {\imath }}$), and

$\boldsymbol {e}_i = -\boldsymbol {e}_{\bar {\imath }}$), and ![]() $\boldsymbol {e}_i$ points to the solid phase. Finally, to solve the mass conservation condition in (2.12), the

$\boldsymbol {e}_i$ points to the solid phase. Finally, to solve the mass conservation condition in (2.12), the ![]() $\textrm {CO}_2$ mass fraction gradient at interface

$\textrm {CO}_2$ mass fraction gradient at interface ![]() $I$ (

$I$ (![]() $\boldsymbol {\nabla } Y^I$) is calculated based on the finite-difference scheme as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

$\boldsymbol {\nabla } Y^I$) is calculated based on the finite-difference scheme as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

where ![]() $Y^g$ is the

$Y^g$ is the ![]() $\textrm {CO}_2$ mass fraction at the gas grid neighbouring the interface

$\textrm {CO}_2$ mass fraction at the gas grid neighbouring the interface ![]() $I$. By inserting (3.12) into (2.12) and using the ideal gas law, the value of

$I$. By inserting (3.12) into (2.12) and using the ideal gas law, the value of ![]() $Y^I$ is calculated as

$Y^I$ is calculated as

Hence the mass conservation condition reduces to a given ![]() $\textrm {CO}_2$ mass fraction value

$\textrm {CO}_2$ mass fraction value ![]() $Y^I$. The halfway bounce-back scheme is used to solve this boundary condition, and the unknown distribution functions at the gas grid are computed as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

$Y^I$. The halfway bounce-back scheme is used to solve this boundary condition, and the unknown distribution functions at the gas grid are computed as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

In addition, for the interface ![]() $I_n$ without

$I_n$ without ![]() $\textrm {CO}_2$ desublimation, the conjugate heat transfer in (2.16a,b) and the no-slip velocity in (2.14) are addressed as conducted at interface

$\textrm {CO}_2$ desublimation, the conjugate heat transfer in (2.16a,b) and the no-slip velocity in (2.14) are addressed as conducted at interface ![]() $I$. In other words, the halfway bounce-back scheme applied to solve the no-flux condition for mass fraction in (2.15) becomes,

$I$. In other words, the halfway bounce-back scheme applied to solve the no-flux condition for mass fraction in (2.15) becomes,

With the desublimation process, solid ![]() $\textrm {CO}_2$ is generated to form an SCL on the cooled cylinder surface, and the movement of solid

$\textrm {CO}_2$ is generated to form an SCL on the cooled cylinder surface, and the movement of solid ![]() $\textrm {CO}_2$ with the fluid flow is not considered. The pore structure of the SCL is updated based on the mass conservation equation (2.6) for the solid

$\textrm {CO}_2$ with the fluid flow is not considered. The pore structure of the SCL is updated based on the mass conservation equation (2.6) for the solid ![]() $\textrm {CO}_2$. In LB simulations, this structure evolution is realized by the commonly used VOP method (Kang et al. Reference Kang, Lichtner and Zhang2006; Zhou et al. Reference Zhou, Xu, Xia, Li and Qin2020). Explicitly, a grid mesh is selected that is fine enough to cover the computational domain. Thus each grid node of the domain can be assumed to represent only one material: the solid cylinder, the solid

$\textrm {CO}_2$. In LB simulations, this structure evolution is realized by the commonly used VOP method (Kang et al. Reference Kang, Lichtner and Zhang2006; Zhou et al. Reference Zhou, Xu, Xia, Li and Qin2020). Explicitly, a grid mesh is selected that is fine enough to cover the computational domain. Thus each grid node of the domain can be assumed to represent only one material: the solid cylinder, the solid ![]() $\textrm {CO}_2$ or the flue gas. In the VOP method, each grid node (or pixel) holds a control volume of size

$\textrm {CO}_2$ or the flue gas. In the VOP method, each grid node (or pixel) holds a control volume of size ![]() $1\times 1 \times 1$ in lattice units, with the grid node being located at the centre of the volume. At each grid node, the volume of solid

$1\times 1 \times 1$ in lattice units, with the grid node being located at the centre of the volume. At each grid node, the volume of solid ![]() $\textrm {CO}_2$ is noted as

$\textrm {CO}_2$ is noted as ![]() $V_s$. Initially, values of

$V_s$. Initially, values of ![]() $V_s$ are set as

$V_s$ are set as ![]() $V_s=1$ at solid

$V_s=1$ at solid ![]() $\textrm {CO}_2$ grids,

$\textrm {CO}_2$ grids, ![]() $V_s=0$ at gas grids, and

$V_s=0$ at gas grids, and ![]() $V_s=0$ at cylinder grids, respectively. As the desublimation process continues,

$V_s=0$ at cylinder grids, respectively. As the desublimation process continues, ![]() $V_s$ changes according to (2.6), and it is updated at each time step as

$V_s$ changes according to (2.6), and it is updated at each time step as

Considering that each grid node can be occupied by one material, the desublimated volume is not included in the grid node until ![]() $V_s$ exceeds the threshold value. That is, as the value of

$V_s$ exceeds the threshold value. That is, as the value of ![]() $V_s$ doubles at a solid

$V_s$ doubles at a solid ![]() $\textrm {CO}_2$ grid (i.e.

$\textrm {CO}_2$ grid (i.e. ![]() $V_s=2$) or increases to

$V_s=2$) or increases to ![]() $V_s=1$ at a cylinder grid, one of its neighbouring gas grid nodes is chosen to be converted into a solid

$V_s=1$ at a cylinder grid, one of its neighbouring gas grid nodes is chosen to be converted into a solid ![]() $\textrm {CO}_2$ grid. The ratios of the desublimation probability between the nearest and diagonal grid nodes are set as

$\textrm {CO}_2$ grid. The ratios of the desublimation probability between the nearest and diagonal grid nodes are set as ![]() $R_{dp}=1:0.125$ in three dimensions and

$R_{dp}=1:0.125$ in three dimensions and ![]() $R_{dp}=1:0.25$ in two dimensions, respectively. These selected

$R_{dp}=1:0.25$ in two dimensions, respectively. These selected ![]() $R_{dp}$ values are consistent with the ratios of weight coefficients

$R_{dp}$ values are consistent with the ratios of weight coefficients ![]() $w_i$ between the nearest and diagonal directions. The sensitivity of

$w_i$ between the nearest and diagonal directions. The sensitivity of ![]() $\textrm {CO}_2$ desublimation properties to the value of

$\textrm {CO}_2$ desublimation properties to the value of ![]() $R_{dp}$ has been evaluated in Appendix B, thus verifying the reliability of the selected

$R_{dp}$ has been evaluated in Appendix B, thus verifying the reliability of the selected ![]() $R_{dp}$ above.

$R_{dp}$ above.

4. Results and discussion

The developed MRT LB models are programmed in the C language, with the Message Passing Interface library being applied for parallel computing. The LB code is verified by two cases: one is the desublimation of ![]() $\textrm {CO}_2$ on the surface of a single cylinder immersed in the quiescent flue gas; the other is the desublimation of

$\textrm {CO}_2$ on the surface of a single cylinder immersed in the quiescent flue gas; the other is the desublimation of ![]() $\textrm {CO}_2$ inside a packed bed fed with flue gas. As demonstrated in Appendix C, the present numerical results agree well with existing simulations and experiments, validating the proposed LB models and verifying their implementation. In addition, for a comprehensive model validation, key sub-models of the proposed MRT LB method have been tested in the supplementary material available at https://doi.org/10.1017/jfm.2023.227. Subsequently, pore-scale simulations are conducted to investigate

$\textrm {CO}_2$ inside a packed bed fed with flue gas. As demonstrated in Appendix C, the present numerical results agree well with existing simulations and experiments, validating the proposed LB models and verifying their implementation. In addition, for a comprehensive model validation, key sub-models of the proposed MRT LB method have been tested in the supplementary material available at https://doi.org/10.1017/jfm.2023.227. Subsequently, pore-scale simulations are conducted to investigate ![]() $\textrm {CO}_2$ desublimation on the packing cylinder as shown in figure 1. Considering that the computational domain is selected from the cryogenic bed, the volume fraction of void space is set as the bed porosity Ali et al. (Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014). Thus key geometrical parameters of the computational domain are set as length

$\textrm {CO}_2$ desublimation on the packing cylinder as shown in figure 1. Considering that the computational domain is selected from the cryogenic bed, the volume fraction of void space is set as the bed porosity Ali et al. (Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014). Thus key geometrical parameters of the computational domain are set as length ![]() $l_x=14.7\ \textrm {mm}$, width

$l_x=14.7\ \textrm {mm}$, width ![]() $l_y=14.7\ \textrm {mm}$, depth

$l_y=14.7\ \textrm {mm}$, depth ![]() $l_z=0.69\ \textrm {mm}$, cylinder diameter

$l_z=0.69\ \textrm {mm}$, cylinder diameter ![]() $l_d=10.0\ \textrm {mm}$, and the void volume fraction

$l_d=10.0\ \textrm {mm}$, and the void volume fraction ![]() $\phi =0.637$. From such a 3-D structure, an

$\phi =0.637$. From such a 3-D structure, an ![]() $x- y$ cross-section at a random location

$x- y$ cross-section at a random location ![]() $z_r$ is selected for 2-D simulations (see the front view in figure 1).

$z_r$ is selected for 2-D simulations (see the front view in figure 1).

In the computational domain, a cooled cylinder at temperature ![]() $T_w$ is placed in the centre area for

$T_w$ is placed in the centre area for ![]() $\textrm {CO}_2$ desublimation, and the remaining void space (or flow paths) is initially filled with pure

$\textrm {CO}_2$ desublimation, and the remaining void space (or flow paths) is initially filled with pure ![]() $\textrm {N}_2$ at temperature

$\textrm {N}_2$ at temperature ![]() $T_w$. The incompressible flue gas at the initial condition

$T_w$. The incompressible flue gas at the initial condition ![]() $(T_0, Y_0, u_0, p_0 )$ is injected from the inlet, and the component

$(T_0, Y_0, u_0, p_0 )$ is injected from the inlet, and the component ![]() $\textrm {CO}_2$ desublimates on the surface of the cooled cylinder. The desublimation parameters are set as

$\textrm {CO}_2$ desublimates on the surface of the cooled cylinder. The desublimation parameters are set as ![]() $k_r=10^{-6}\ \textrm {s}\ \textrm {m}^{-1}$ and

$k_r=10^{-6}\ \textrm {s}\ \textrm {m}^{-1}$ and ![]() $h_r=5.682\times 10^5\ \textrm {J}\ \textrm {kg}^{-1}$ (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010). The initial conditions of the flue gas are

$h_r=5.682\times 10^5\ \textrm {J}\ \textrm {kg}^{-1}$ (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010). The initial conditions of the flue gas are ![]() $T_0=293\ \textrm {K}$,

$T_0=293\ \textrm {K}$, ![]() $Y_0=1$ and

$Y_0=1$ and ![]() $p_0=0.1\ \textrm {MPa}$. Based on the equilibrium pressure in (2.4), the freezing point of

$p_0=0.1\ \textrm {MPa}$. Based on the equilibrium pressure in (2.4), the freezing point of ![]() $\textrm {CO}_2$ corresponding to

$\textrm {CO}_2$ corresponding to ![]() $p_0=0.1\ \textrm {MPa}$ can be calculated as

$p_0=0.1\ \textrm {MPa}$ can be calculated as ![]() $T_f=194.6\ \textrm {K}$. The inlet velocity of the flue gas

$T_f=194.6\ \textrm {K}$. The inlet velocity of the flue gas ![]() $u_0$ and the cylinder temperature

$u_0$ and the cylinder temperature ![]() $T_w$ are left for changing the desublimation conditions. Thermophysical properties of the flue gas, the solid

$T_w$ are left for changing the desublimation conditions. Thermophysical properties of the flue gas, the solid ![]() $\textrm {CO}_2$ and the solid cylinder are fixed as

$\textrm {CO}_2$ and the solid cylinder are fixed as ![]() $\rho _g=1.46\ \textrm {kg}\ \textrm {m}^{-3}$,

$\rho _g=1.46\ \textrm {kg}\ \textrm {m}^{-3}$, ![]() $c_{p,g}=0.846\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$,

$c_{p,g}=0.846\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$, ![]() $\alpha _{g}=5.02\times 10^{-6}\ \textrm {m}^{2} \textrm {s}^{-1}$,

$\alpha _{g}=5.02\times 10^{-6}\ \textrm {m}^{2} \textrm {s}^{-1}$, ![]() $\rho _s=1.56\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$,

$\rho _s=1.56\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$, ![]() $c_{p,s}=0.967\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$,

$c_{p,s}=0.967\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$, ![]() $\alpha _{s}=4.64\times 10^{-7}\ \textrm {m}^2\ \textrm {s}^{-1}$,

$\alpha _{s}=4.64\times 10^{-7}\ \textrm {m}^2\ \textrm {s}^{-1}$, ![]() $\rho _c=2.55\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$,

$\rho _c=2.55\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$, ![]() $c_{p,c}=0.841\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$, and

$c_{p,c}=0.841\ \textrm {kJ}\ \textrm {kg}^{-1}\ \textrm {K}^{-1}$, and ![]() $\alpha _{c}=3.74\times 10^{-7}\ \textrm {m}^2\ \textrm {s}^{-1}$. Here, the subscripts

$\alpha _{c}=3.74\times 10^{-7}\ \textrm {m}^2\ \textrm {s}^{-1}$. Here, the subscripts ![]() $g$,

$g$, ![]() $s$ and

$s$ and ![]() $c$ represent properties of the flue gas, the solid

$c$ represent properties of the flue gas, the solid ![]() $\textrm {CO}_2$ and the solid cylinder, respectively. The gas viscosity and the

$\textrm {CO}_2$ and the solid cylinder, respectively. The gas viscosity and the ![]() $\textrm {CO}_2$ diffusion coefficient are

$\textrm {CO}_2$ diffusion coefficient are ![]() $\nu =7.12\times 10^{-6}\ \textrm {m}^2\ \textrm {s}^{-1}$ and

$\nu =7.12\times 10^{-6}\ \textrm {m}^2\ \textrm {s}^{-1}$ and ![]() $D=1.63\times 10^{-5}\ \textrm {m}^2\ \textrm {s}^{-1}$, respectively. In the subsequent simulations, the conversion between the physical and lattice units is based on a match of the dimensionless parameters in (2.20), with characteristic parameters being selected as

$D=1.63\times 10^{-5}\ \textrm {m}^2\ \textrm {s}^{-1}$, respectively. In the subsequent simulations, the conversion between the physical and lattice units is based on a match of the dimensionless parameters in (2.20), with characteristic parameters being selected as

Before proceeding further, grid convergence tests have been carried out. A mesh of size ![]() $640 \times 640 \times 30$ with lattice resolution

$640 \times 640 \times 30$ with lattice resolution ![]() $0.0219\ \textrm {mm}$ is selected to describe the computational domain in figure 1. In 2-D simulations, an

$0.0219\ \textrm {mm}$ is selected to describe the computational domain in figure 1. In 2-D simulations, an ![]() $x- y$ cross-section is selected randomly from the 3-D domain, thus the mesh size is

$x- y$ cross-section is selected randomly from the 3-D domain, thus the mesh size is ![]() $640 \times 640$. More details about the grid convergence tests are provided in Appendix D and the supplementary material.

$640 \times 640$. More details about the grid convergence tests are provided in Appendix D and the supplementary material.

Given the periodic front and back boundaries of the computational domain, the desublimation of ![]() $\textrm {CO}_2$ is first simulated in two dimensions. A comparison with 3-D simulations is then provided to verify the reliability of 2-D results. In the subsequent simulations, the range of

$\textrm {CO}_2$ is first simulated in two dimensions. A comparison with 3-D simulations is then provided to verify the reliability of 2-D results. In the subsequent simulations, the range of ![]() $u_0$ from

$u_0$ from ![]() $1.22\times 10^{-3}\ \textrm {m}\ \textrm {s}^{-1}$ to

$1.22\times 10^{-3}\ \textrm {m}\ \textrm {s}^{-1}$ to ![]() $6.1\times 10^{-2}\ \textrm {m}\ \textrm {s}^{-1}$, and the range of

$6.1\times 10^{-2}\ \textrm {m}\ \textrm {s}^{-1}$, and the range of ![]() $T_w$ from

$T_w$ from ![]() $100\ \textrm {K}$ to

$100\ \textrm {K}$ to ![]() $180\ \textrm {K}$, are covered. These two parameters (i.e.

$180\ \textrm {K}$, are covered. These two parameters (i.e. ![]() $u_0$ and

$u_0$ and ![]() $T_w$) are characterized by the Péclet number

$T_w$) are characterized by the Péclet number ![]() $\textit {Pe}$ and the dimensionless subcooling degree

$\textit {Pe}$ and the dimensionless subcooling degree ![]() $\Delta T_{sub}=(T_f-T_w)/T_{ch}$, respectively. The corresponding

$\Delta T_{sub}=(T_f-T_w)/T_{ch}$, respectively. The corresponding ![]() $\textit {Pe}$ and

$\textit {Pe}$ and ![]() $\Delta T_{sub}$ locate in the ranges

$\Delta T_{sub}$ locate in the ranges ![]() $[1.1, 55]$ and

$[1.1, 55]$ and ![]() $[0.05, 0.32]$, respectively. Each simulation test is continued until the maximum thickness of the SCL (

$[0.05, 0.32]$, respectively. Each simulation test is continued until the maximum thickness of the SCL (![]() $\delta _{fm}$) reaches the termination condition

$\delta _{fm}$) reaches the termination condition ![]() $\delta _{fm}=0.048l_x$. The termination time instant in each test is denoted as

$\delta _{fm}=0.048l_x$. The termination time instant in each test is denoted as ![]() $t_e$. For the quantitative analysis, the coordinates

$t_e$. For the quantitative analysis, the coordinates ![]() $(x, y, z)$ are transformed to the coordinates

$(x, y, z)$ are transformed to the coordinates ![]() $(r, \theta, z )$ (see figure 1). The coordinates ranges are set as

$(r, \theta, z )$ (see figure 1). The coordinates ranges are set as ![]() $0 \leqslant x \leqslant l_x$,

$0 \leqslant x \leqslant l_x$, ![]() $0 \leqslant y \leqslant l_y$ and

$0 \leqslant y \leqslant l_y$ and ![]() $0 \leqslant z \leqslant l_z$ for

$0 \leqslant z \leqslant l_z$ for ![]() $(x, y, z)$, and

$(x, y, z)$, and ![]() $l_d/2 < r \leqslant l_x/2$,

$l_d/2 < r \leqslant l_x/2$, ![]() $0 \leqslant \theta < 2{\rm \pi}$ and

$0 \leqslant \theta < 2{\rm \pi}$ and ![]() $0 \leqslant z \leqslant l_z$ for

$0 \leqslant z \leqslant l_z$ for ![]() $(r, \theta, z )$. Here, the coordinate

$(r, \theta, z )$. Here, the coordinate ![]() $r$ starts from

$r$ starts from ![]() $l_d/2$ because we focus on the space with the flue gas and the solid

$l_d/2$ because we focus on the space with the flue gas and the solid ![]() $\textrm {CO}_2$. Both of these coordinate systems are used to describe the

$\textrm {CO}_2$. Both of these coordinate systems are used to describe the ![]() $\textrm {CO}_2$ desublimation properties.

$\textrm {CO}_2$ desublimation properties.

4.1.  $\textrm {CO}_2$ desublimation characteristics

$\textrm {CO}_2$ desublimation characteristics

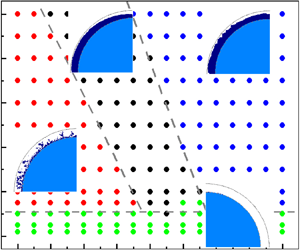

To discuss the general properties of ![]() $\textrm {CO}_2$ desublimation on the cooled cylinder surface, a case with the subcooling degree

$\textrm {CO}_2$ desublimation on the cooled cylinder surface, a case with the subcooling degree ![]() $\Delta T_{sub}=0.17$ and Péclet number

$\Delta T_{sub}=0.17$ and Péclet number ![]() $\textit {Pe}=11$ is first simulated in two dimensions. This case is referred to as case Base. The simulated

$\textit {Pe}=11$ is first simulated in two dimensions. This case is referred to as case Base. The simulated ![]() $\textrm {CO}_2$ desublimation properties are illustrated in figure 2, including contours of solid

$\textrm {CO}_2$ desublimation properties are illustrated in figure 2, including contours of solid ![]() $\textrm {CO}_2$, temperature (

$\textrm {CO}_2$, temperature (![]() $T$) and

$T$) and ![]() $\textrm {CO}_2$ mass fraction (

$\textrm {CO}_2$ mass fraction (![]() $Y$) at two time instants

$Y$) at two time instants ![]() $t=8.9, 55.8\ \textrm {s}$. As the desublimation process goes on,

$t=8.9, 55.8\ \textrm {s}$. As the desublimation process goes on, ![]() $\textrm {CO}_2$ deposits on the cylinder surface to generate the SCL, which is observed to be thicker in the front surface area (facing the inlet) and thinner in the back surface area (facing the outlet). This uneven desublimation is driven by the continuous gas injection from the inlet. Also, distributions of

$\textrm {CO}_2$ deposits on the cylinder surface to generate the SCL, which is observed to be thicker in the front surface area (facing the inlet) and thinner in the back surface area (facing the outlet). This uneven desublimation is driven by the continuous gas injection from the inlet. Also, distributions of ![]() $Y$ show that the outgoing

$Y$ show that the outgoing ![]() $\textrm {CO}_2$ mass fraction is obviously smaller than the injected value. This indicates that a large portion of the injected