1. Introduction

The film flow along an inclined substrate is a hydrodynamic configuration encountered in numerous environmental and technological applications. Characteristic examples of the former may involve the motion of lava flows (Balmforth et al. Reference Balmforth, Craster, Rust and Sassi2006), debris flow (Allouche et al. Reference Allouche, Botton, Millet, Henry, Dagois-Bohy, Güzel and Ben Hadid2017) and biofilms (Kumar et al. Reference Kumar, Karig, Acharya, Neethirajan, Mukherjee, Retterer and Doktycz2013). Regarding technological applications, they typically involve coating in microelectronics (Stillwagon & Larson Reference Stillwagon and Larson1990; Kistler & Schweizer Reference Kistler and Schweizer1997), industrial heat and mass transfer applications (Sisoev, Matar & Lawrence Reference Sisoev, Matar and Lawrence2005; Guichet & Jouhara Reference Guichet and Jouhara2020), distillation columns (Battisti, Machado & Marangoni Reference Battisti, Machado and Marangoni2020) and falling film reactors (Yeong et al. Reference Yeong, Gavriilidis, Zapf, Kost, Hessel and Boyde2006). In practice, the substrates are frequently rough, either intentionally or accidentally, due to the presence of cavities, pillars, corrugations, or arrested particles and drops on them. The interaction between the irregularities of the topography and the fluid layer often results in a complicated nonlinear dynamical behaviour. Another significant aspect of the dynamics of the flow is the rheology of the material since, in such types of flows, the liquid may be a polymer solution or a suspension of particles which, in principle, exhibit non-Newtonian properties. The rheology of the material may considerably affect the flow, introducing interesting effects on the flow arrangement and the film shape, especially when the film exhibits viscoelastic properties. However, elastic phenomena are often overlooked since most of the existing studies consider the flow of Newtonian liquids. The understanding of the associated mechanisms and interplay of viscoelastic properties with geometrical characteristics of the substrate is of great importance since it may increase the process quality in many industrial applications.

An early attempt to study the dynamics of film flow over a variable topography was made by Pozrikidis (Reference Pozrikidis1988). He studied the two-dimensional (2-D) flow of a Newtonian liquid over a wavy wall using the boundary integral method. Moreover, Stillwagon & Larson (Reference Stillwagon and Larson1990) and Kalliadasis, Bielarz & Homsy (Reference Kalliadasis, Bielarz and Homsy2000) determined the thickness variation of the film over a trench during the spin coating process using lubrication theory and the longwave approximation, respectively. In the limit of low viscosity liquids, they found that the dynamics of the film depends on the characteristics of the obstacle, while the free surface develops a capillary ridge just before the step-down and depression before the step-up region. Later, Gaskell et al. (Reference Gaskell, Jimack, Sellier, Thompson and Wilson2004) and Veremieiev et al. (Reference Veremieiev, Thompson, Lee and Gaskell2010) extended the latter study to moderate values of fluid viscosity and surface tension by solving the inertialess 2-D Navier–Stokes equations for a film flowing over a trench. The transition to the inertia-dominated regime was studied by Bontozoglou & Serifi (Reference Bontozoglou and Serifi2008) for a Newtonian film flowing along a vertical substrate with isolated steps. They showed that the capillary ridge and depression before the step-down and step-up change their streamwise length scale when inertia is introduced in the flow. Primarily, their analysis showed that the computed streamwise length decreases with increasing flow rate. Next, Wierschem et al. (Reference Wierschem, Bontozoglou, Heining, Uecker and Aksel2008) and Nguyen & Bontozoglou (Reference Nguyen and Bontozoglou2011) solved the steady film flow over corrugated substrates with small and finite wall amplitudes, respectively. They demonstrated that resonance is possible between the undulations of the substrate and the free surface. In all the aforementioned studies, the film was considered to wet the solid structure completely. We should mention, however, that a complete wetting state cannot always be achieved, especially when the substrate is deep and aligned with the gravitational force; hence, air may be entrapped inside the topographical features (Giacomello et al. Reference Giacomello, Chinappi, Meloni and Casciola2012; Karapetsas et al. Reference Karapetsas, Lampropoulos, Dimakopoulos and Tsamopoulos2017; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2017; Pettas, Dimakopoulos & Tsamopoulos Reference Pettas, Dimakopoulos and Tsamopoulos2020).

Most of the studies in the literature have focused on Newtonian fluids over uneven surfaces. The first attempt to address the interaction between fluid elasticity and inertia was made by Saprykin, Koopmans & Kalliadasis (Reference Saprykin, Koopmans and Kalliadasis2007), who studied the flow over a variable topography of an Oldroyd-B fluid using lubrication theory and assuming very weak fluid elasticity. Later on, Pavlidis, Dimakopoulos & Tsamopoulos (Reference Pavlidis, Dimakopoulos and Tsamopoulos2010) and Pavlidis et al. (Reference Pavlidis, Karapetsas, Dimakopoulos and Tsamopoulos2016) solved the 2-D momentum equations for a viscoelastic film flowing over a topography featuring rectangular trenches employing the exponential Phan-Thien Tanner (ePTT) model (Phan-Thien Reference Phan-Thien1978), which introduces the most common viscoelastic properties. Recently, Pettas, Dimakopoulos & Tsamopoulos (Reference Pettas, Dimakopoulos and Tsamopoulos2020) investigated the steady flow of a polymer solution over a partially coated substrate.

However, a typical characteristic of film flows, either Newtonian or non-Newtonian, is the spontaneous appearance of wavy interfacial instabilities at the free surface if a critical volume flux is exceeded (Haar Reference Haar1965). Early efforts to investigate the flow instabilities of film over flat substrates were reported by Benjamin (Reference Benjamin1957) and Yih (Reference Yih1963). They showed that the flow first becomes unstable to longwave disturbances above a critical value of the flow rate, which depends only on the angle of inclination and fluid viscosity. Subsequent studies examined various aspects of the flow stability in both the linear and nonlinear regimes (Larson Reference Larson1992; Salamon, Armstrong & Brown Reference Salamon, Armstrong and Brown1994; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012), while some works also considered the case of surfactant-laden films (Scheid et al Reference Scheid, Oron, Colinet, Thiele and Legros2002; Bull & Grotberg Reference Bull and Grotberg2003; Karapetsas & Bontozoglou Reference Karapetsas and Bontozoglou2013, Reference Karapetsas and Bontozoglou2014). Interfacial instabilities, however, can be enhanced or mitigated by the topography of the substrate. Experimental studies on the stability of liquid films flowing over weak, periodical, rectangular trenches have demonstrated that the critical value of the flow rate is shifted to higher values as the steepness of the substrate increases (Vlachogiannis & Bontozoglou Reference Vlachogiannis and Bontozoglou2002; Argyriadi, Vlachogiannis & Bontozoglou Reference Argyriadi, Vlachogiannis and Bontozoglou2006). More recently, D'Alessio, Pascal & Jasmine (Reference D'Alessio, Pascal and Jasmine2009) examined the effects of surface tension and the presence of the bottom wall on the stability of the flow over an uneven surface. They showed that for weak to moderate surface tension, the presence of the topography tends to stabilize the flow. Trifonov (Reference Trifonov2014) performed a theoretical study by directly solving the Navier–Stokes equations while employing the Bloch–Floquet theory to account for disturbances of arbitrary wavelengths. In contrast to film flow over an inclined plane, he found that the flow is stabilized, especially under longwave disturbances. Consequently, the most critical disturbance appears to be for moderate wavenumbers.

An attempt to summarize all the above results was made by Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) by presenting stability maps (comparing experimental observations and theoretical predictions) in the parameter space of the inclination angle, viscosity, and corrugation amplitude and wavelength of the topography. The linear stability analysis presented by these authors also confirmed the existence of short-wave instabilities under specific values of the flow rate, in line with the experimental evidence provided earlier by Cao, Vlachogiannis & Bontozoglou (Reference Cao, Vlachogiannis and Bontozoglou2013). Schörner & Aksel (Reference Schörner and Aksel2018) were able to identify six characteristic stability map patterns that unify the linear instability of Newtonian films flowing over undulated inclines, reporting that the flow stability follows a universal pathway, which they called the ‘stability cycle’. Finally, Dauth & Aksel (Reference Dauth and Aksel2018) studied the nonlinear evolution of waves and reported wave breaking and the route to chaos (Dauth & Aksel Reference Dauth and Aksel2019).

Although a significant number of applications may involve liquids, which may be either a polymeric solution or a suspension of particles (in general, both exhibit non-Newtonian properties), all the aforementioned studies refer to Newtonian liquids. An attempt to consider non-Newtonian effects was made by Millet et al. (Reference Millet, Botton, Rousset and Ben Hadid2008) and Ruyer-Quil, Chakraborty & Dandapat (Reference Ruyer-Quil, Chakraborty and Dandapat2012), who examined the case of a liquid following a generalized Newtonian law flowing over a flat surface using the Carreau model and a modified power-law model, respectively. These studies show that shear-thinning has a destabilizing effect on the flow, while shear-thickening has the opposite effect. Recently, Allouche et al. (Reference Allouche, Botton, Millet, Henry, Dagois-Bohy, Güzel and Ben Hadid2017) confirmed the previous theoretical predictions experimentally. When it comes to the stability analysis of viscoelastic liquids, most of the studies in the literature are restricted to flows over a flat surface (Gupta Reference Gupta1967; Lai Reference Lai1967; Shaqfeh, Larson & Fredrickson Reference Shaqfeh, Larson and Fredrickson1989). The effect of substrate topography was taken into account by Davalos-Orozco (Reference Davalos-Ozorco2013), who examined the flow over a shallow corrugated wall of a viscoelastic fluid following the Oldroyd-B model. According to this study, the deformation of the free surface due to the presence of the substrate undulations may lead to stabilization by fluid elasticity. Very recently, Sharma, Ray & Papageorgiou (Reference Sharma, Ray and Papageorgiou2019), also employing lubrication theory, showed that the impact of elasticity on the stability of the inertialess flow is profoundly affected by the geometrical characteristics of the substrate. They found that as the wavelength of the periodic wall increases, the topography initially exerts a destabilizing influence, while for shorter wall-wavelengths, the topography may stabilize the flow. More recently, Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b) were able to examine the flow of a viscoelastic film (following the ePTT model) over a wavy substrate of arbitrary, but single amplitude, wavelength and inclination angle by solving the 2-D momentum conservation equations directly while employing the Bloch–Floquet theory to account for disturbances of arbitrary wavelengths. They considered both 2-D and three-dimensional (3-D) disturbances and examined the impact of the elasticity, inertia and surface tension on the stability of the flow, demonstrating the stabilizing effect of fluid elasticity. This work also demonstrated that shear-thinning, often encountered in viscoelastic liquids, has a destabilizing effect in qualitative agreement with the study of Allouche et al. (Reference Allouche, Botton, Millet, Henry, Dagois-Bohy, Güzel and Ben Hadid2017).

The main objective of the present study is to examine the dynamics and the stability of viscoelastic films flowing over a substrate featuring a periodic array of sharp rectangular trenches. This configuration has a clear advantage over previous configurations studied in the literature since, by independently varying the unit length, depth, width and inclination angle, it is possible to examine substrates with very different types of structures, i.e. ranging from substrates with wide trenches to pillared surfaces. These types of substrates are extensively studied nowadays for two main reasons: (a) they appear in electronic components, such as memory boards Stillwagon & Larson (Reference Stillwagon and Larson1990), and (b) they induce superhydrophobic properties to otherwise inert solid surfaces, reducing drag and, hence, promoting flow and surface cleaning, Cottin-Bizonne et al. (Reference Cottin-Bizonne, Barrat, Bocquet and Charlaix2009), Crowdy (Reference Crowdy2017) and Erbil (Reference Erbil2020). As will be shown below, the shape of the substrate topography, in combination with the effect of fluid elasticity, may considerably influence the stability of the flow; interestingly, it is also demonstrated that the topography shape has a non-trivial effect even on the stability of Newtonian film flows. Below, we present a detailed discussion on the mechanisms which affect the flow and provide detailed flow maps that cover a wide range of the parameter space both in terms of the liquid properties and geometrical characteristics of the substrate. To do so, we solve the 2-D steady state momentum balance equations, employing the ePTT constitutive model to account for the viscoelastic properties of the liquid, and perform a linear stability analysis of the flow subjected to 2-D disturbances; by employing the Bloch–Floquet theory, disturbances of arbitrary wavelengths (not necessarily matching the periodicity of the substrate topography) are considered.

The structure of the study is as follows: in § 2, we present the problem formulation along with the governing equations, while in § 3 we briefly describe the numerical implementation. In § 4, we initially proceed with validating our in-house model results against previous experimental observations and theoretical predictions. Next, in § 5 we present and discuss our results relating to the steady state flow patterns and the stability of the flow. Finally, we summarize our results in § 6.

2. Problem formulation

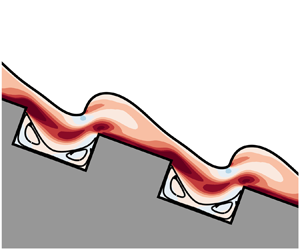

We consider the steady free-surface flow of a viscoelastic liquid over a substrate with a periodic array of rectangular trenches; a schematic is presented in figure 1. The flow is driven by gravity, while the substrate is inclined by an angle ![]() $\alpha $. In what follows, the symbol ‘*’ and the bold variables will indicate a dimensional and a tensorial quantity, respectively. The liquid is incompressible, with constant density,

$\alpha $. In what follows, the symbol ‘*’ and the bold variables will indicate a dimensional and a tensorial quantity, respectively. The liquid is incompressible, with constant density, ![]() ${\rho ^\ast }$, surface tension,

${\rho ^\ast }$, surface tension, ![]() ${\sigma ^\ast }$, relaxation time,

${\sigma ^\ast }$, relaxation time, ![]() $\lambda _e^\ast $ and total zero-shear viscosity,

$\lambda _e^\ast $ and total zero-shear viscosity, ![]() ${\mu ^\ast } = \mu _p^\ast + \mu _s^\ast $ where

${\mu ^\ast } = \mu _p^\ast + \mu _s^\ast $ where ![]() $\mu _p^\ast $ and

$\mu _p^\ast $ and ![]() $\mu _s^\ast $ are the polymer and the solvent viscosities, respectively. The primitive flow variable is the volumetric flow rate per unit length in the transverse direction,

$\mu _s^\ast $ are the polymer and the solvent viscosities, respectively. The primitive flow variable is the volumetric flow rate per unit length in the transverse direction, ![]() ${q^\ast }$. For the base state flow, we consider a periodic domain that consists of a single unit cell. The viscoelastic film thickness at the entrance of the periodic domain is denoted by

${q^\ast }$. For the base state flow, we consider a periodic domain that consists of a single unit cell. The viscoelastic film thickness at the entrance of the periodic domain is denoted by ![]() ${H^\ast }$. At distance

${H^\ast }$. At distance ![]() $L_1^\ast $ from the entrance of the unit cell, the film encounters a rectangular cavity with a width

$L_1^\ast $ from the entrance of the unit cell, the film encounters a rectangular cavity with a width ![]() ${W^\ast }$ and depth,

${W^\ast }$ and depth, ![]() ${D^\ast }$, while the distance from the right end of the trench to the exit of the flow domain is denoted by

${D^\ast }$, while the distance from the right end of the trench to the exit of the flow domain is denoted by ![]() $L_2^\ast $. The origins of the cartesian coordinate system are located at the entrance of the flow domain, with the x-axis and y-axis in the directions parallel and normal to the wall at

$L_2^\ast $. The origins of the cartesian coordinate system are located at the entrance of the flow domain, with the x-axis and y-axis in the directions parallel and normal to the wall at ![]() $x = 0$, respectively.

$x = 0$, respectively.

Figure 1. Schematic of the gravity-driven, free-surface flow over a substrate with rectangular trenches inclined with respect to the horizontal by an angle ![]() $\alpha $. Here, L* is the length of the unit cell of the periodic substrate, while

$\alpha $. Here, L* is the length of the unit cell of the periodic substrate, while ![]() $L_1^\ast $ and

$L_1^\ast $ and ![]() $L_2^\ast $ depict the inflow and outflow lengths of the corresponding unit cell. The topographical feature is characterized by a width

$L_2^\ast $ depict the inflow and outflow lengths of the corresponding unit cell. The topographical feature is characterized by a width ![]() ${W^\ast }$ and depth

${W^\ast }$ and depth ![]() ${D^\ast }$ while the film height at the entrance of the domain is denoted by

${D^\ast }$ while the film height at the entrance of the domain is denoted by ![]() ${H^\ast }$.

${H^\ast }$.

Traditionally in film flows, all the lengths are scaled with the flat film thickness, ![]() $H_N^\ast $, and all the velocity components with the mean Nusselt film velocity,

$H_N^\ast $, and all the velocity components with the mean Nusselt film velocity, ![]() $U_N^\ast $, defined as

$U_N^\ast $, defined as

\begin{equation}H_{N}^\ast = {q^\ast }^{1/3}\; {\left( {\frac{{3{\mu^\ast }}}{{{\rho^\ast }{g^\ast }\,\textrm{sin}(a)}}} \right)^{1/3}},\quad U_N^\ast = {q^\ast }^{2/3}\; {\left( {\frac{{{\rho^\ast }{g^\ast }\,\textrm{sin}(a)}}{{3{\mu^\ast }}}} \right)^{1/3}}.\end{equation}

\begin{equation}H_{N}^\ast = {q^\ast }^{1/3}\; {\left( {\frac{{3{\mu^\ast }}}{{{\rho^\ast }{g^\ast }\,\textrm{sin}(a)}}} \right)^{1/3}},\quad U_N^\ast = {q^\ast }^{2/3}\; {\left( {\frac{{{\rho^\ast }{g^\ast }\,\textrm{sin}(a)}}{{3{\mu^\ast }}}} \right)^{1/3}}.\end{equation}This scaling, for example, has been used by Pavlidis, Dimakopoulos & Tsamopoulos (Reference Pavlidis, Dimakopoulos and Tsamopoulos2010) and Pavlidis et al. (Reference Pavlidis, Karapetsas, Dimakopoulos and Tsamopoulos2016) for the study of the steady viscoelastic film flow over topography. It is apparent, however, that with the above scaling both the length and velocity scales are affected by the flowrate, see (2.1a,b). Such a dependence introduces difficulties in the interpretation of the results and, therefore, it is preferable to use an alternative scaling involving quantities that are independent of the flow rate. To do so, we introduce the capillary and viscous length scales of the liquid, respectively, defined as

\begin{equation}l_c^\ast = {\left( {\frac{{{\sigma^\ast }}}{{{\rho^\ast }{g^\ast }}}} \right)^{1/2}},\quad l_v^\ast = {\left( {\frac{{{\mu^\ast }^2}}{{{\rho^\ast }^2{g^\ast }}}} \right)^{1/3}}.\end{equation}

\begin{equation}l_c^\ast = {\left( {\frac{{{\sigma^\ast }}}{{{\rho^\ast }{g^\ast }}}} \right)^{1/2}},\quad l_v^\ast = {\left( {\frac{{{\mu^\ast }^2}}{{{\rho^\ast }^2{g^\ast }}}} \right)^{1/3}}.\end{equation}

Note that these lengths depend on the liquid properties, such as density, zero-shear viscosity and surface tension. The viscous length varies over a much broader range than the capillary length due to the broader variation of ![]() ${\mu ^\ast }$, while surface tension and density of most common polymeric solutions vary over a much shorter range.

${\mu ^\ast }$, while surface tension and density of most common polymeric solutions vary over a much shorter range.

Hereafter, we scale all lengths by ![]() $l_c^\ast $; the same choice was also made by (Trifonov Reference Trifonov2014; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019a; Pettas, Dimakopoulos & Tsamopoulos Reference Pettas, Dimakopoulos and Tsamopoulos2020). By scaling all lengths by the capillary length,

$l_c^\ast $; the same choice was also made by (Trifonov Reference Trifonov2014; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019a; Pettas, Dimakopoulos & Tsamopoulos Reference Pettas, Dimakopoulos and Tsamopoulos2020). By scaling all lengths by the capillary length, ![]() $l_c^\ast $, the dimensionless lengths of the substrate geometry become independent of the primitive flow rate. Moreover, velocities are scaled by

$l_c^\ast $, the dimensionless lengths of the substrate geometry become independent of the primitive flow rate. Moreover, velocities are scaled by ![]() $U_N^\ast $, time is scaled by

$U_N^\ast $, time is scaled by ![]() $l_c^\ast{/}U_N^\ast $, while the pressure and stress components are scaled by the following viscous scale:

$l_c^\ast{/}U_N^\ast $, while the pressure and stress components are scaled by the following viscous scale: ![]() ${\mu ^\ast }U_N^\ast{/}l_c^\ast $. Introducing the above characteristic scales, the dimensionless numbers that arise in the governing equations are the Reynolds number

${\mu ^\ast }U_N^\ast{/}l_c^\ast $. Introducing the above characteristic scales, the dimensionless numbers that arise in the governing equations are the Reynolds number ![]() $Re$, Kapitza number

$Re$, Kapitza number ![]() $Ka$, elasticity number

$Ka$, elasticity number ![]() $El$, viscosity ratio

$El$, viscosity ratio ![]() $\beta $ and inclination angle

$\beta $ and inclination angle ![]() $\alpha $; their definition is given in table 1. Since the main objective of the paper is to study the impact of the topographical irregularities on the stability of the flow, we examine cases for a constant value of the Kapitza number, i.e.

$\alpha $; their definition is given in table 1. Since the main objective of the paper is to study the impact of the topographical irregularities on the stability of the flow, we examine cases for a constant value of the Kapitza number, i.e. ![]() $Ka = 2$. This particular choice of

$Ka = 2$. This particular choice of ![]() $Ka$ corresponds to a typical value for liquids that have been used in experiments of coating flows, e.g. solutions of polyethylene oxide (PEO) or Poly-methyl-methacrylate (PMMA) (see Bornside, Macosko & Scriven Reference Bornside, Macosko and Scriven1991; Borkar et al. Reference Borkar, Tsamopoulos, Gupta and Gupta1994; Becerra & Carvalho Reference Becerra and Carvalho2011). Note that this value of Ka corresponds to a case for which the capillary and viscous lengths are constant and equal to

$Ka$ corresponds to a typical value for liquids that have been used in experiments of coating flows, e.g. solutions of polyethylene oxide (PEO) or Poly-methyl-methacrylate (PMMA) (see Bornside, Macosko & Scriven Reference Bornside, Macosko and Scriven1991; Borkar et al. Reference Borkar, Tsamopoulos, Gupta and Gupta1994; Becerra & Carvalho Reference Becerra and Carvalho2011). Note that this value of Ka corresponds to a case for which the capillary and viscous lengths are constant and equal to ![]() $l_c^\ast = 1.45\ \textrm{mm}$ and

$l_c^\ast = 1.45\ \textrm{mm}$ and ![]() $l_v^\ast = 1.02\ \textrm{mm}$, respectively.

$l_v^\ast = 1.02\ \textrm{mm}$, respectively.

Table 1. Dimensionless parameters and their representative values.

At this point, it is also convenient to define an additional parameter that compares the geometric characteristics of the inflow and outflow region of the unit cell with the width of the groove, named ![]() ${T_r}$:

${T_r}$:

By changing the aspect ratio, ![]() ${T_r}$, while keeping constant the total length of the unit cell, we can study the effect of the topographical structures on the formation of the steady free surface. Two limits arise either for large or small values of

${T_r}$, while keeping constant the total length of the unit cell, we can study the effect of the topographical structures on the formation of the steady free surface. Two limits arise either for large or small values of ![]() ${T_r}$. Note that for

${T_r}$. Note that for ![]() ${T_r} \to \infty $ the inflow and outflow region of the domain is much larger than the trench width

${T_r} \to \infty $ the inflow and outflow region of the domain is much larger than the trench width ![]() $({L_1} + {L_2} \gg W)$, and the substrate is almost flat. On the contrary, as

$({L_1} + {L_2} \gg W)$, and the substrate is almost flat. On the contrary, as ![]() ${T_r} \to 0$ the inflow and outflow regions are much smaller than the width of the groove

${T_r} \to 0$ the inflow and outflow regions are much smaller than the width of the groove ![]() $({L_1} + {L_2} \ll W)$, and the substrate tends to have a pillar-like structure.

$({L_1} + {L_2} \ll W)$, and the substrate tends to have a pillar-like structure.

2.1. Governing equations and boundary conditions

The governing equations of the flow are the momentum and mass conservation equations, which in the time-dependent dimensionless form are

\begin{equation}\begin{array}{l} Re\,C{a^{ - 1/2}}{\left( {\dfrac{{\textrm{sin}\,a}}{3}} \right)^{1/2}}\left( {\; \dfrac{{\partial \boldsymbol{u}}}{{\partial t}} + (\boldsymbol{u} - {\boldsymbol{u}_m})\boldsymbol{\cdot }\boldsymbol{\nabla }\boldsymbol{u}} \right) + \boldsymbol{\nabla }P - \boldsymbol{\nabla }\boldsymbol{\cdot }\boldsymbol{\tau } - C{a^{ - 1}}\boldsymbol{g} = 0,\\ \end{array}\end{equation}

\begin{equation}\begin{array}{l} Re\,C{a^{ - 1/2}}{\left( {\dfrac{{\textrm{sin}\,a}}{3}} \right)^{1/2}}\left( {\; \dfrac{{\partial \boldsymbol{u}}}{{\partial t}} + (\boldsymbol{u} - {\boldsymbol{u}_m})\boldsymbol{\cdot }\boldsymbol{\nabla }\boldsymbol{u}} \right) + \boldsymbol{\nabla }P - \boldsymbol{\nabla }\boldsymbol{\cdot }\boldsymbol{\tau } - C{a^{ - 1}}\boldsymbol{g} = 0,\\ \end{array}\end{equation}

Here, ![]() $\boldsymbol{u} = {({u_x},{u_y})^\textrm{T}}$, P,

$\boldsymbol{u} = {({u_x},{u_y})^\textrm{T}}$, P, ![]() $\boldsymbol{\tau }$ denote the velocity, pressure and stress fields on the flow domain, respectively;

$\boldsymbol{\tau }$ denote the velocity, pressure and stress fields on the flow domain, respectively; ![]() $\boldsymbol{\nabla } = {({\partial _x},{\partial _y})^\textrm{T}}$ denotes the gradient operator for a cartesian coordinate system, while

$\boldsymbol{\nabla } = {({\partial _x},{\partial _y})^\textrm{T}}$ denotes the gradient operator for a cartesian coordinate system, while ![]() ${\boldsymbol{u}_m} = \partial \boldsymbol{x}/\partial t$ denotes the velocity of the mesh nodes, and

${\boldsymbol{u}_m} = \partial \boldsymbol{x}/\partial t$ denotes the velocity of the mesh nodes, and ![]() $g = {(\textrm{sin}\,\alpha , - \textrm{cos}\,\alpha )^\textrm{T}}$ is the unit vector in the direction of gravity. The capillary number,

$g = {(\textrm{sin}\,\alpha , - \textrm{cos}\,\alpha )^\textrm{T}}$ is the unit vector in the direction of gravity. The capillary number, ![]() $Ca = {\mu ^\ast }U_N^\ast{/}\sigma $, which arises in the above equation is not an independent variable, but is related to the previously defined dimensionless quantities via the expression

$Ca = {\mu ^\ast }U_N^\ast{/}\sigma $, which arises in the above equation is not an independent variable, but is related to the previously defined dimensionless quantities via the expression

\begin{equation}Ca = K{a^{ - 1}}R{e^{2/3}}\; {\left( {\frac{{\textrm{sin}\,a}}{3}} \right)^{1/3}}.\end{equation}

\begin{equation}Ca = K{a^{ - 1}}R{e^{2/3}}\; {\left( {\frac{{\textrm{sin}\,a}}{3}} \right)^{1/3}}.\end{equation}

The extra stress tensor, ![]() $\boldsymbol{\tau }$, is split into a purely Newtonian part and a polymeric contribution,

$\boldsymbol{\tau }$, is split into a purely Newtonian part and a polymeric contribution, ![]() ${\boldsymbol{\tau }_p}$, defined as

${\boldsymbol{\tau }_p}$, defined as

where ![]() $\dot{\boldsymbol{\gamma }} = (\boldsymbol{\nabla }\boldsymbol{u} + \boldsymbol{\nabla }{\boldsymbol{u}^\textrm{T}})/2$ is the rate of strain.

$\dot{\boldsymbol{\gamma }} = (\boldsymbol{\nabla }\boldsymbol{u} + \boldsymbol{\nabla }{\boldsymbol{u}^\textrm{T}})/2$ is the rate of strain.

To account for the viscoelasticity of the material, we use the affine exponential model by Phan-Thien and Tanner (ePTT) (Phan-Thien Reference Phan-Thien1978):

where ![]() $Wi = \lambda _e^\ast {U_N}/l_c^\ast $ is the Weissenberg number. Wi can be expressed as a function of the elasticity number El, i.e.

$Wi = \lambda _e^\ast {U_N}/l_c^\ast $ is the Weissenberg number. Wi can be expressed as a function of the elasticity number El, i.e. ![]() $Wi = El\,K{a^{1/2}}Ca$. Note that the elasticity number, El, as defined in table 1, denotes the ratio of the relaxation time of the polymeric solution with the viscous timescale,

$Wi = El\,K{a^{1/2}}Ca$. Note that the elasticity number, El, as defined in table 1, denotes the ratio of the relaxation time of the polymeric solution with the viscous timescale, ![]() $t_v^\ast = {({\mu ^\ast }/{\rho ^\ast }{g^{{\ast} 2}})^{1/3}}$. For our parametric study, it is preferable to use the elasticity number, instead of Wi, since El depends only on material properties – the relaxation time, zero-shear viscosity and liquid density – which facilitates direct comparison with experiments; whereas Wi depends on the volumetric flow rate and, hence, on Re, see relevant discussion in Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b). Finite values of the parameter

$t_v^\ast = {({\mu ^\ast }/{\rho ^\ast }{g^{{\ast} 2}})^{1/3}}$. For our parametric study, it is preferable to use the elasticity number, instead of Wi, since El depends only on material properties – the relaxation time, zero-shear viscosity and liquid density – which facilitates direct comparison with experiments; whereas Wi depends on the volumetric flow rate and, hence, on Re, see relevant discussion in Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b). Finite values of the parameter ![]() $\varepsilon $ set an upper limit to the elongational viscosity, which increases as the parameter decreases, while it introduces elongational and shear thinning to the fluid model. The ePTT model is reduced to the Oldroyd-B model by setting the value of the parameter

$\varepsilon $ set an upper limit to the elongational viscosity, which increases as the parameter decreases, while it introduces elongational and shear thinning to the fluid model. The ePTT model is reduced to the Oldroyd-B model by setting the value of the parameter ![]() $\varepsilon $ equal to zero and to the Upper Convective Maxwell model by additionally setting

$\varepsilon $ equal to zero and to the Upper Convective Maxwell model by additionally setting ![]() $\beta $ equal to zero.

$\beta $ equal to zero.

Accounting for the boundary conditions, along the free surface of the film, a local interface force balance is imposed between the normal stress and capillary forces,

where ![]() $\boldsymbol{n}$ is the outward unit vector to the free surfaces and

$\boldsymbol{n}$ is the outward unit vector to the free surfaces and ![]() $\boldsymbol{t}$ is the unit tangent vector pointing in the clockwise direction (see Ruschak Reference Ruschak1980). Note that the air in contact with the interface is at the ambient air pressure, which is set equal to zero,

$\boldsymbol{t}$ is the unit tangent vector pointing in the clockwise direction (see Ruschak Reference Ruschak1980). Note that the air in contact with the interface is at the ambient air pressure, which is set equal to zero, ![]() ${P_{air}} = 0$. Also, the interfaces obey the kinematic condition

${P_{air}} = 0$. Also, the interfaces obey the kinematic condition

while along the walls of the substrate, we impose the usual no-slip, no-penetration boundary conditions. Moreover, at the inflow and the outflow of the unit cell, periodic boundary conditions are employed. Note that for the purposes of the present study, we assume that the steady flow has the same periodicity as the substrate structure (i.e. we assume that the steady solution is L-periodic),

The remaining degree of freedom, the film height at the entrance of the unit cell ![]() ${H^\ast }$, is determined by requiring that the dimensionless flow rate is equal to unity:

${H^\ast }$, is determined by requiring that the dimensionless flow rate is equal to unity:

3. Numerical Implementation

3.1. Base state – steady state solution

The base flow is steady, 2-D and is assumed to be L-periodic. In order to solve the above set of equations at steady state numerically, we employ the mixed finite element/Galerkin method (Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2015; Pavlidis et al. Reference Pavlidis, Karapetsas, Dimakopoulos and Tsamopoulos2016) along with an elliptic grid generation scheme (Dimakopoulos & Tsamopoulos Reference Dimakopoulos and Tsamopoulos2003; Chatzidai et al. Reference Chatzidai, Giannousakis, Dimakopoulos and Tsamopoulos2009) to account for the free surface deformation. The corresponding weak formulation of the governing equations is presented in detail in the Appendix of Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019a). Moreover, to trace the steady-state solution in parameter space, a pseudo-arc-length continuation is incorporated as part of the solution of the finite element code (see Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2017; Varchanis, Dimakopoulos & Tsamopoulos Reference Varchanis, Dimakopoulos and Tsamopoulos2017).

3.2. Linear stability analysis

We consider the stability of this steady flow subjected to infinitesimal 2-D perturbations. To account for the perturbed physical domain (x, y), we map it to a known reference domain (η, ξ). The variables are written in the computational domain and are decomposed into a part which corresponds to the base state solution and an infinitesimal disturbance using the following ansatz:

\begin{equation}\left[ {\begin{array}{@{}c@{}} \boldsymbol{u}\\ {\begin{array}{@{}c@{}} P\\ {\begin{array}{@{}c@{}} \boldsymbol{G}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_p}}\\ \boldsymbol{x} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi ,t) = \left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_b}}\\ {\begin{array}{@{}c@{}} {{P_b}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_b}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,b}}}\\ {{\boldsymbol{x}_b}} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi ) + \delta \left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{\boldsymbol{x}_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi )\,{\textrm{e}^{\lambda t}}.\end{equation}

\begin{equation}\left[ {\begin{array}{@{}c@{}} \boldsymbol{u}\\ {\begin{array}{@{}c@{}} P\\ {\begin{array}{@{}c@{}} \boldsymbol{G}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_p}}\\ \boldsymbol{x} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi ,t) = \left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_b}}\\ {\begin{array}{@{}c@{}} {{P_b}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_b}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,b}}}\\ {{\boldsymbol{x}_b}} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi ) + \delta \left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{\boldsymbol{x}_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right](\eta ,\xi )\,{\textrm{e}^{\lambda t}}.\end{equation}

The first terms on the right-hand side of these equations represent the steady state solution, indicated by the subscript ‘b’, while the second ones are the perturbation. The subscript ‘d’ corresponds to the spatial variation of the disturbance while ![]() $\delta \ll 1$; the

$\delta \ll 1$; the ![]() ${\boldsymbol{x}_d}$ is the disturbance of the position vector. According to our ansatz, an exponential dependence on time is assumed; here, λ denotes the growth rate. If the calculated λ turns out to have a positive real part, the disturbance grows with time, and therefore the corresponding steady state is considered unstable. Introducing the expression (3.1) in the weak formulation of the time-dependent governing equations and the corresponding boundary conditions (2.4)–(2.11), and neglecting terms of order higher than the first in the perturbation parameter

${\boldsymbol{x}_d}$ is the disturbance of the position vector. According to our ansatz, an exponential dependence on time is assumed; here, λ denotes the growth rate. If the calculated λ turns out to have a positive real part, the disturbance grows with time, and therefore the corresponding steady state is considered unstable. Introducing the expression (3.1) in the weak formulation of the time-dependent governing equations and the corresponding boundary conditions (2.4)–(2.11), and neglecting terms of order higher than the first in the perturbation parameter ![]() $\delta $, the linearized equations are derived; a detailed description is provided in appendix A of Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b).

$\delta $, the linearized equations are derived; a detailed description is provided in appendix A of Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b).

3.3. Periodic boundary conditions and implementation of Floquet–Bloch theory

For flows over periodically structured surfaces, the most unstable disturbance may have a wavelength that exceeds the period of the domain. Thus, it becomes evident that if one assumes periodic conditions for the disturbances between the inflow and outflow boundaries, the overall linear stability of the system cannot be captured unless a sufficiently long computational domain is considered. This would imply a formidable computational cost in the case where longwave disturbances are the most unstable ones, as is typical for thin-film flows. As we will discuss below, the most appropriate and efficient way to deal with this issue is to employ the Floquet–Bloch theory, which allows us to model the flow over a structured surface by considering the small periodic domain of the topography. This accomplishes a considerable reduction to the computational cost, while examining disturbances with wavelengths that may extend over multiple trenches or fractions thereof. According to Bloch's theorem (Pain Reference Pain2008), it is sufficient to look for solutions such that the disturbances between the inflow and outflow of the unit cell are related to each other with the following expression:

\begin{equation}{\left. {\left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{y_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right]} \right|_{x = 0}} = {\left. {\left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{y_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right]} \right|_{x = L}}\,{\textrm{e}^{2\mathrm{\pi }Q\textrm{i}}}.\end{equation}

\begin{equation}{\left. {\left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{y_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right]} \right|_{x = 0}} = {\left. {\left[ {\begin{array}{@{}c@{}} {{\boldsymbol{u}_d}}\\ {\begin{array}{@{}c@{}} {{P_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{G}_d}}\\ {\begin{array}{@{}c@{}} {{\boldsymbol{\tau }_{p,d}}}\\ {{y_d}} \end{array}} \end{array}} \end{array}} \end{array}} \right]} \right|_{x = L}}\,{\textrm{e}^{2\mathrm{\pi }Q\textrm{i}}}.\end{equation}

Using this formulation, the unknown disturbances ![]() $({\boldsymbol{u}_d},{P_d},{\boldsymbol{G}_d},{\boldsymbol{\tau }_{p,d}},{y_d})$ will be determined by imposing (3.2) at the edges of the periodic domain, ensuring that for finite real values of Q, the disturbances will not be L-periodic. It may be shown that it is sufficient to examine the values of

$({\boldsymbol{u}_d},{P_d},{\boldsymbol{G}_d},{\boldsymbol{\tau }_{p,d}},{y_d})$ will be determined by imposing (3.2) at the edges of the periodic domain, ensuring that for finite real values of Q, the disturbances will not be L-periodic. It may be shown that it is sufficient to examine the values of ![]() $Q \in [0,0.5]$ (Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b). For example, when

$Q \in [0,0.5]$ (Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019b). For example, when ![]() $Q = 0.5$, the imposed perturbation has a wavelength that is twice the size of the physical domain, whereas

$Q = 0.5$, the imposed perturbation has a wavelength that is twice the size of the physical domain, whereas ![]() $Q \to 0$ corresponds to disturbances with wavelength much larger than the size of the periodic domain. Disturbances with

$Q \to 0$ corresponds to disturbances with wavelength much larger than the size of the periodic domain. Disturbances with ![]() $Q = 0$ should be distinguished, since in that case (3.2) reduces to typical periodic boundary conditions. Thus, this case corresponds to disturbances that have the same period or aliquots of the basic solution, i.e. correspond to superharmonic instabilities.

$Q = 0$ should be distinguished, since in that case (3.2) reduces to typical periodic boundary conditions. Thus, this case corresponds to disturbances that have the same period or aliquots of the basic solution, i.e. correspond to superharmonic instabilities.

3.4. The Arnoldi algorithm

After we discretize the linearized set of equations, we end up with a generalized eigenvalue problem of the form

where ![]() $\boldsymbol{A}$ and

$\boldsymbol{A}$ and ![]() $\boldsymbol{M}$ are the Jacobian and the mass matrix, respectively, with

$\boldsymbol{M}$ are the Jacobian and the mass matrix, respectively, with ![]() $\lambda $ the eigenvalues and

$\lambda $ the eigenvalues and ![]() $\boldsymbol{w}$ the corresponding eigenvectors. This eigenvalue problem is solved using Arnoldi's method combined with the shift-and-invert transformation, which allows us to locate only the eigenvalues of interest; for determining critical conditions, we need those eigenvalues with the smallest real part (Christodoulou Reference Christodoulou1990; Natarajan Reference Natarajan1992; Karapetsas & Tsamopoulos Reference Karapetsas and Tsamopoulos2013; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2015). According to our framework, the solution is stable if the real parts of all eigenvalues are less than or equal to zero for all values of Q. To implement Arnoldi's algorithm, we use the public domain code ARPACK (Lehoucq, Sorensen & Yang Reference Lehoucq, Sorensen and Yang1997), while the accuracy of the converged eigenpairs is independently checked by evaluating the residual

$\boldsymbol{w}$ the corresponding eigenvectors. This eigenvalue problem is solved using Arnoldi's method combined with the shift-and-invert transformation, which allows us to locate only the eigenvalues of interest; for determining critical conditions, we need those eigenvalues with the smallest real part (Christodoulou Reference Christodoulou1990; Natarajan Reference Natarajan1992; Karapetsas & Tsamopoulos Reference Karapetsas and Tsamopoulos2013; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2015). According to our framework, the solution is stable if the real parts of all eigenvalues are less than or equal to zero for all values of Q. To implement Arnoldi's algorithm, we use the public domain code ARPACK (Lehoucq, Sorensen & Yang Reference Lehoucq, Sorensen and Yang1997), while the accuracy of the converged eigenpairs is independently checked by evaluating the residual ![]() $|{\boldsymbol{Aw} - \lambda \; \boldsymbol{Mw}} |$, and this quantity is always less than 10−12 for the reported results.

$|{\boldsymbol{Aw} - \lambda \; \boldsymbol{Mw}} |$, and this quantity is always less than 10−12 for the reported results.

4. Validation

The accuracy of our numerical results is verified by examining their convergence with mesh refinement. Since the sharp changes of the topography and particularly the sharp corners in viscoelastic flows may give rise to singularities (see Karapetsas & Tsamopoulos Reference Karapetsas and Tsamopoulos2013; Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2015), they may strongly influence the flow. Hence, we have performed a detailed mesh convergence study focusing οn these areas to identify the most suitable mesh to use in our calculations. Moreover, although we had no numerical difficulties with keeping the corners sharp, we have examined the possible influence on the flow of turning them to circular sections, because this is often reported in the literature (see Schörner et al. Reference Schörner, Reck, Aksel and Trifonov2018). When the local radius of curvature was up to dimensionless 0.1, we observed no effect on the solution. All these tests are reported in the Appendix.

Before we proceed with the discussion of our results, we present a series of validation tests of our in-house code with experimental observations and theoretical predictions for relevant flows found in the literature. To this end, we have examined the stability of Newtonian films over substrates with rectangular trenches subjected to 2-D disturbances, and we present in figure 2 the theoretical and experimental data for two different liquids, Elbesil 100 and Elbesil 145, the properties of which are given in table 2.

Figure 2. Comparison of the predicted neutral curves with previous numerical and experimental studies. The liquids that have been used are (a) Elbesil 100 and (b) Elbesil 145 (see table 2); the inclination angle is ![]() $a = 10^\circ $ and the geometric parameters are

$a = 10^\circ $ and the geometric parameters are ![]() ${T_r} = 0.05$,

${T_r} = 0.05$, ![]() $D = 5.506$. In panels (a) and (b), the length of the unit cell is

$D = 5.506$. In panels (a) and (b), the length of the unit cell is ![]() $L = 13.765$ and 20.648

$L = 13.765$ and 20.648 ![]() $({L_1} = {L_2} = 0.05)$, respectively. The orange dashed lines and the cyan dots indicate the theoretical analysis and the experimental data, respectively, of Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018). Finally, the continuous black lines correspond to our study.

$({L_1} = {L_2} = 0.05)$, respectively. The orange dashed lines and the cyan dots indicate the theoretical analysis and the experimental data, respectively, of Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018). Finally, the continuous black lines correspond to our study.

Table 2. Newtonian fluids and their properties that are used for validation.

In figure 2 we present the dependence of the critical ![]() $R{e_c}$ on the frequency of the instability. According to our formulation, the dimensional frequency is related to the imaginary part of the eigenmode via the following expression:

$R{e_c}$ on the frequency of the instability. According to our formulation, the dimensional frequency is related to the imaginary part of the eigenmode via the following expression:

By scaling the dimensional frequency with ![]() $t{_v^{\ast - 1}}$ the dimensionless frequency is given by the following expression:

$t{_v^{\ast - 1}}$ the dimensionless frequency is given by the following expression:

We present in figure 2 the stability maps obtained both theoretically and experimentally by Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) along with our numerical predictions (shown with the continuous black line) for Elbesil 100 (see figure 2a) and Elbesil 145 (see figure 2b) for ![]() $L = 13.765$ and 20.648, respectively. In both cases, our predictions are in excellent agreement with theoretical and experimental results found in the literature. We note, though, that there is a slight deviation between our theoretical analysis and that of Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) (which is more obvious in figure 2b) due to the different details of the considered substrate. In our case, we have used a topography with sharp edges, as in the experimental structure, while Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) considered smoothed rectangular trenches for their theoretical analysis. Interestingly, our predictions are closer to the experimental observations, underlining the relative importance of the different shape of the topography on the stability of the film.

$L = 13.765$ and 20.648, respectively. In both cases, our predictions are in excellent agreement with theoretical and experimental results found in the literature. We note, though, that there is a slight deviation between our theoretical analysis and that of Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) (which is more obvious in figure 2b) due to the different details of the considered substrate. In our case, we have used a topography with sharp edges, as in the experimental structure, while Schörner et al. (Reference Schörner, Reck, Aksel and Trifonov2018) considered smoothed rectangular trenches for their theoretical analysis. Interestingly, our predictions are closer to the experimental observations, underlining the relative importance of the different shape of the topography on the stability of the film.

Interestingly, above a specific value of Re, the experimental observations deviate from the theoretical results, see figure 2(b) for ![]() $Re \gt 12$. At this point, we should mention that there is no guarantee that all base flow formations in this particular experiment correspond to the steady state solution considered in the theoretical model. We speculate though that thick films may have different flow arrangements (i.e. L-periodicity of the steady fluid flow may have broken down). Our hypothesis is reinforced by the study of Tseluiko, Blyth & Papageorgiou (Reference Tseluiko, Blyth and Papageorgiou2013), who observed that the film flow might experience a sequence of multiple steady states where the solution may, in general, not be L-periodic.

$Re \gt 12$. At this point, we should mention that there is no guarantee that all base flow formations in this particular experiment correspond to the steady state solution considered in the theoretical model. We speculate though that thick films may have different flow arrangements (i.e. L-periodicity of the steady fluid flow may have broken down). Our hypothesis is reinforced by the study of Tseluiko, Blyth & Papageorgiou (Reference Tseluiko, Blyth and Papageorgiou2013), who observed that the film flow might experience a sequence of multiple steady states where the solution may, in general, not be L-periodic.

5. Results and discussion

Numerical solutions were obtained over a wide range of parameter values. The ‘base’ case, however, has typical dimensional values of ![]() $L = 20$,

$L = 20$, ![]() ${L_1} = {L_2} = 5$,

${L_1} = {L_2} = 5$, ![]() $\; W = 10$ and

$\; W = 10$ and ![]() $D = 5$; from (2.3), assuming the above geometrical characteristics, it is also derived that

$D = 5$; from (2.3), assuming the above geometrical characteristics, it is also derived that ![]() ${T_r} = 1$. This set of parameters will be kept constant throughout the paper unless stated otherwise.

${T_r} = 1$. This set of parameters will be kept constant throughout the paper unless stated otherwise.

5.1. Steady state

We start with a brief discussion of the steady state solution. As mentioned above, a detailed discussion of this problem has been presented by Pavlidis, Dimakopoulos & Tsamopoulos (Reference Pavlidis, Dimakopoulos and Tsamopoulos2010) and Pavlidis et al. (Reference Pavlidis, Karapetsas, Dimakopoulos and Tsamopoulos2016). It is important to note, though, that these authors have used a different scaling (i.e. based on the film thickness); therefore, we find that it will be useful to briefly discuss the results in the light of the scaling employed herein (i.e. based on the capillary length scale), which may also provide new insight. Moreover, we will focus on cases with unit cells of considerably smaller length than the ones examined by Pavlidis, Dimakopoulos & Tsamopoulos (Reference Pavlidis, Dimakopoulos and Tsamopoulos2010) and Pavlidis et al. (Reference Pavlidis, Karapetsas, Dimakopoulos and Tsamopoulos2016), making the surface tension effects more prominent.

In figure 3, we consider a substrate with ![]() $L = 20$,

$L = 20$, ![]() ${T_r} = 1$ and

${T_r} = 1$ and ![]() $D = 5$ and present the streamline pattern for an Oldroyd-B liquid

$D = 5$ and present the streamline pattern for an Oldroyd-B liquid ![]() $(\varepsilon = 0)$. As representative values, we choose

$(\varepsilon = 0)$. As representative values, we choose ![]() $Ka = 2$ and

$Ka = 2$ and ![]() $El = 3$ since in coating applications, the flowing materials typically have a high viscosity

$El = 3$ since in coating applications, the flowing materials typically have a high viscosity ![]() $(Ka \lt 6)$ and short relaxation time (Borkar et al. Reference Borkar, Tsamopoulos, Gupta and Gupta1994; Becerra & Carvalho Reference Becerra and Carvalho2011); the ratio of the Newtonian solvent viscosity over the total zero shear viscosity is

$(Ka \lt 6)$ and short relaxation time (Borkar et al. Reference Borkar, Tsamopoulos, Gupta and Gupta1994; Becerra & Carvalho Reference Becerra and Carvalho2011); the ratio of the Newtonian solvent viscosity over the total zero shear viscosity is ![]() $\beta = 0.10$, and the angle of inclination is

$\beta = 0.10$, and the angle of inclination is ![]() $\alpha = 10^\circ$. Moreover, figure 3(a–d) shows the streamline pattern of the flow for different values of

$\alpha = 10^\circ$. Moreover, figure 3(a–d) shows the streamline pattern of the flow for different values of ![]() $Re = 3,8,12,30$, respectively. As Nguyen & Bontozoglou (Reference Nguyen and Bontozoglou2011) described in a Newtonian liquid, many characteristics of the flow field can be explained by considering the flow as ballistic flow, where the ejection platform for the fluid is the flat part of the substrate at the inflow. The magnitude of Re determines the distance the fluid can travel before it ‘lands’ somewhere inside the cavity.

$Re = 3,8,12,30$, respectively. As Nguyen & Bontozoglou (Reference Nguyen and Bontozoglou2011) described in a Newtonian liquid, many characteristics of the flow field can be explained by considering the flow as ballistic flow, where the ejection platform for the fluid is the flat part of the substrate at the inflow. The magnitude of Re determines the distance the fluid can travel before it ‘lands’ somewhere inside the cavity.

Figure 3. Steady states of the film flow over the substrate for (a) ![]() $Re = 3$, (b)

$Re = 3$, (b) ![]() $Re = 8$, (c)

$Re = 8$, (c) ![]() $Re = 12$ and (d)

$Re = 12$ and (d) ![]() $Re = 30$. The liquid parameters are

$Re = 30$. The liquid parameters are ![]() $Ka = 2$,

$Ka = 2$, ![]() $El = 3$,

$El = 3$, ![]() $\beta = 0.10$, for an Oldroyd-B fluid while the geometrical characteristics of the substrate are

$\beta = 0.10$, for an Oldroyd-B fluid while the geometrical characteristics of the substrate are ![]() $L = 20$,

$L = 20$, ![]() ${T_r} = 1$ and

${T_r} = 1$ and ![]() $D = 5$. The inclination angle is

$D = 5$. The inclination angle is ![]() $\alpha = 10^\circ $.

$\alpha = 10^\circ $.

Starting with figure 3(a), low values of Re correspond to thin films, while the streamlines and the film shape depict that the fluid lands closer to the upstream wall. Hence, a local minimum is formed at the free surface while a vortex arises at the upstream concave corner of the substrate. Increasing the flow rate to moderate values, see figure 3(b,c), the injected liquid impacts the liquid ahead and with the aid of elasticity, causing the formation of a cusp. This is clearly a non-Newtonian effect since in the case of Newtonian liquids, the interface remains smooth for all values of Re and can be attributed to the fluid elasticity. With increasing inertia, the two recirculation regions expand and merge into one large eddy inside the cavity. For very large values of Re, inertia prevails, and the film surpasses the trench without significant redirection of the flow, figure 3(d). After that point, the free surface deformations decrease due to the increased film thickness, while the eddy expands and occupies the entire area of the groove.

5.1.1. Effect of elasticity

The impact of the elasticity in the flow arrangement is apparent when we examine its effect on the amplitude of the free-surface deformation, A, which can be defined as

In figure 4(a), we present the dependence of A on Re for polymer solutions that exhibit various relaxation times (El changes). For low values of the flowrate ![]() $(Re \to 0)$, the deformation of the free surface was calculated to be

$(Re \to 0)$, the deformation of the free surface was calculated to be ![]() $A \approx 0.57$ for all values of El. Hence, in the absence of inertia, the film closely follows the shape of the wall, whereas the viscoelastic effects become negligible. In the opposite limit, at high values of the Reynolds number, the film succeeds in surpassing the topographical structures, and the shape of the steady free surface tends to acquire a planar shape, since the liquid near the interface does not feel the presence of the substrate topography. However, at moderate values of Re

$A \approx 0.57$ for all values of El. Hence, in the absence of inertia, the film closely follows the shape of the wall, whereas the viscoelastic effects become negligible. In the opposite limit, at high values of the Reynolds number, the film succeeds in surpassing the topographical structures, and the shape of the steady free surface tends to acquire a planar shape, since the liquid near the interface does not feel the presence of the substrate topography. However, at moderate values of Re ![]() $(3 \lt Re \lt 20)$, the presence of the substrate structure along with the interplay between the inertia, gravity and surface tension causes a prominent rise in the amplitude of the free surface deformation. This effect is often referred to as ‘resonance’ in the literature (Bontozoglou & Papapolymerou Reference Bontozoglou and Papapolymerou1998; Wierschem & Aksel Reference Wierschem and Aksel2004), while it was experimentally validated by Vlachogiannis and Bontozoglou (Reference Vlachogiannis and Bontozoglou2002) and Argyriadi, Vlachogiannis & Bontozoglou (Reference Argyriadi, Vlachogiannis and Bontozoglou2006). This is an outcome of the interaction between the reflected wave of the free surface and the capillary waves that travel in the upstream direction of the flow. The point of resonance corresponds to a specific value of the Reynolds number,

$(3 \lt Re \lt 20)$, the presence of the substrate structure along with the interplay between the inertia, gravity and surface tension causes a prominent rise in the amplitude of the free surface deformation. This effect is often referred to as ‘resonance’ in the literature (Bontozoglou & Papapolymerou Reference Bontozoglou and Papapolymerou1998; Wierschem & Aksel Reference Wierschem and Aksel2004), while it was experimentally validated by Vlachogiannis and Bontozoglou (Reference Vlachogiannis and Bontozoglou2002) and Argyriadi, Vlachogiannis & Bontozoglou (Reference Argyriadi, Vlachogiannis and Bontozoglou2006). This is an outcome of the interaction between the reflected wave of the free surface and the capillary waves that travel in the upstream direction of the flow. The point of resonance corresponds to a specific value of the Reynolds number, ![]() $R{e_{res}}$, for which the surface velocity of the fluid is equal to the phase velocity of the capillary waves. In the case of a Newtonian liquid, which is depicted by the black dashed line in figure 4(a), the resonance point arises at

$R{e_{res}}$, for which the surface velocity of the fluid is equal to the phase velocity of the capillary waves. In the case of a Newtonian liquid, which is depicted by the black dashed line in figure 4(a), the resonance point arises at ![]() $Re = 10.4$, where the amplitude of the free surface deformation obtains its maximum value, 0.98.

$Re = 10.4$, where the amplitude of the free surface deformation obtains its maximum value, 0.98.

Figure 4. (a) Amplitude of the free surface, A, as a function of the Reynolds number for various values of El while the dashed black line indicates the case of a Newtonian liquid. (b,c) Film shape and spatial variation of normal stress component, ![]() ${\tau _{p,xx}}$, for

${\tau _{p,xx}}$, for ![]() $El = 1$ and

$El = 1$ and ![]() $El = 2$, respectively, and the same Reynolds number,

$El = 2$, respectively, and the same Reynolds number, ![]() $Re = 14$. The remaining parameters are

$Re = 14$. The remaining parameters are ![]() $Ka = 2$,

$Ka = 2$, ![]() $\varepsilon = 0$ and

$\varepsilon = 0$ and ![]() $\beta = 0.10$. The inclination angle

$\beta = 0.10$. The inclination angle ![]() $\alpha = 10^\circ $.

$\alpha = 10^\circ $.

Increasing the elasticity number, the amplitude of the free surface is not affected either for ![]() $Re \to 0$ or high values of Re. Nevertheless, for small values of Re even a small amount of elasticity leads to the decrease of A since the bulk elasticity of the fluid resists the deformation imposed by the solid wall. Therefore, the amplitude of the free surface decreases up to

$Re \to 0$ or high values of Re. Nevertheless, for small values of Re even a small amount of elasticity leads to the decrease of A since the bulk elasticity of the fluid resists the deformation imposed by the solid wall. Therefore, the amplitude of the free surface decreases up to ![]() $Re \approx 3.5$. For moderate values of Re, the elasticity has the opposite effect and tends to amplify the free surface deformation. As shown in figure 4(a), on increasing El, the maximum amplitude of the free surface increases considerably (for

$Re \approx 3.5$. For moderate values of Re, the elasticity has the opposite effect and tends to amplify the free surface deformation. As shown in figure 4(a), on increasing El, the maximum amplitude of the free surface increases considerably (for ![]() $El = 1,2,3$ the maximum value of A is

$El = 1,2,3$ the maximum value of A is ![]() $0.98,1.38,1.67$, respectively).

$0.98,1.38,1.67$, respectively).

We note, though, that elasticity shifts ![]() $R{e_{res}}$ to higher values, which can be attributed to some extent to fluid elasticity generating a force that opposes the effect of inertia. To rationalize this mechanism, it is convenient to describe the relevant mechanisms in terms of a single viscoelastic fluid parcel of constant volume. Note that a viscoelastic fluid parcel can undergo all rearrangements of a Newtonian one – translation, rotation and stretching – but exhibits stronger resistance to the last of these, which is dictated by the presence of the viscoelastic stresses. Besides, the presence of the stress gradients that are generated by the substrate morphology force it to be extended or compressed in the direction of the flow, while the value of

$R{e_{res}}$ to higher values, which can be attributed to some extent to fluid elasticity generating a force that opposes the effect of inertia. To rationalize this mechanism, it is convenient to describe the relevant mechanisms in terms of a single viscoelastic fluid parcel of constant volume. Note that a viscoelastic fluid parcel can undergo all rearrangements of a Newtonian one – translation, rotation and stretching – but exhibits stronger resistance to the last of these, which is dictated by the presence of the viscoelastic stresses. Besides, the presence of the stress gradients that are generated by the substrate morphology force it to be extended or compressed in the direction of the flow, while the value of ![]() ${\tau _{p,xx}}$ is a measure of that stretching. Consequently, the fluid parcel is stretched in the upstream corner

${\tau _{p,xx}}$ is a measure of that stretching. Consequently, the fluid parcel is stretched in the upstream corner ![]() $({\tau _{p,xx}} \gt 0)$ and compressed at the downstream corner

$({\tau _{p,xx}} \gt 0)$ and compressed at the downstream corner ![]() $({\tau _{p,xx}} \lt 0)$, see figure 4(b,c). For moderate values of Re it undergoes a ballistic trajectory, while the magnitude of Re determines the distance it can travel before it ‘lands’ somewhere inside the cavity. Simultaneously, the build-up of viscoelastic stress gradients at the upstream convex corner tries to prevent this movement.

$({\tau _{p,xx}} \lt 0)$, see figure 4(b,c). For moderate values of Re it undergoes a ballistic trajectory, while the magnitude of Re determines the distance it can travel before it ‘lands’ somewhere inside the cavity. Simultaneously, the build-up of viscoelastic stress gradients at the upstream convex corner tries to prevent this movement.

The elongation of the fluid parcel in the x-direction by the ![]() $xx$-stress gradients causes additional shrinkage in the y-direction, via volume preservation. As a result,

$xx$-stress gradients causes additional shrinkage in the y-direction, via volume preservation. As a result, ![]() ${\tau _{p,yy}}$ obtains negative values in the upstream convex corner of the trench, see figure 5(a,b). The stress variation in the y-direction will decrease the height of the free surface locally. On the contrary, at the downstream convex corner, the fluid parcel is squeezed, resulting in positive values of

${\tau _{p,yy}}$ obtains negative values in the upstream convex corner of the trench, see figure 5(a,b). The stress variation in the y-direction will decrease the height of the free surface locally. On the contrary, at the downstream convex corner, the fluid parcel is squeezed, resulting in positive values of ![]() ${\tau _{p,yy}}$ with the additional pushing the free surface to increase the hump, as shown in figure 3.

${\tau _{p,yy}}$ with the additional pushing the free surface to increase the hump, as shown in figure 3.

Figure 5. Film shape and spatial variation of the normal stress component, ![]() ${\tau _{p,yy}}$, for (a)

${\tau _{p,yy}}$, for (a) ![]() $El = 1$ and (b)

$El = 1$ and (b) ![]() $El = 2.0$ at

$El = 2.0$ at ![]() $Re = 14$. The remaining parameters are

$Re = 14$. The remaining parameters are ![]() $Ka = 2$,

$Ka = 2$, ![]() $\varepsilon = 0$, and

$\varepsilon = 0$, and ![]() $\beta = 0.10$. The inclination angle

$\beta = 0.10$. The inclination angle ![]() $\alpha = 10^\circ $.

$\alpha = 10^\circ $.

5.1.2. Effect of the topography

Next, we examine the impact of the geometrical characteristics of the substrate on the deformation of the free surface. In figure 6(a) we present the amplitude of the steady free-surface distortions as a function of Re for various values of D. For shallow trenches (D = 1), the free surface acquires a smoother shape since the film easily surpasses the cavities of the periodic topography, see figure 6(b). With increasing depth of the trench, the amplitude of the free-surface deformation increases considerably, since it becomes more difficult for the film to surpass the step-up region and therefore gives rise to a more prominent static hump near the downstream wall, see figure 6(c). Interestingly, for large trench depths ![]() $(D \ge 3)$ the dependence of A on Re remains unaffected; in figure 6(a), the curves for

$(D \ge 3)$ the dependence of A on Re remains unaffected; in figure 6(a), the curves for ![]() $D = 5$ and 7 are almost identical. Clearly, beyond some critical value of D the amplitude of the free surface deformations is independent of the depth of the topographical features. When the structures are deep, the mainstream region of the film does not feel the presence of the bottom wall, i.e. the generation of the eddy in the midplane smooths out the wall structure. Thus, the existence of the recirculation also provides a limitation, to some extent, to the effect of elasticity for trenches with large depths.

$D = 5$ and 7 are almost identical. Clearly, beyond some critical value of D the amplitude of the free surface deformations is independent of the depth of the topographical features. When the structures are deep, the mainstream region of the film does not feel the presence of the bottom wall, i.e. the generation of the eddy in the midplane smooths out the wall structure. Thus, the existence of the recirculation also provides a limitation, to some extent, to the effect of elasticity for trenches with large depths.

Figure 6. (a) Relative amplitude of the free surface, A, as a function of the Reynolds number for ![]() $D = 1$ (red),

$D = 1$ (red), ![]() $D = 2$ (green),

$D = 2$ (green), ![]() $D = 5$ (blue) and

$D = 5$ (blue) and ![]() $D = 7$ (orange). (b,c) Spatial variation of normal stress component,

$D = 7$ (orange). (b,c) Spatial variation of normal stress component, ![]() ${\tau _{p,xx}}$ and the streamline pattern for

${\tau _{p,xx}}$ and the streamline pattern for ![]() $D = 1$

$D = 1$ ![]() $(Re = 11.8)$ and

$(Re = 11.8)$ and ![]() $D = 7$

$D = 7$ ![]() $(Re = 13.8)$, respectively. The remaining parameters are

$(Re = 13.8)$, respectively. The remaining parameters are ![]() $Ka = 2$,

$Ka = 2$, ![]() $El = 3$,

$El = 3$, ![]() $\varepsilon = 0.0$,

$\varepsilon = 0.0$, ![]() $\beta = 0.10$ and

$\beta = 0.10$ and ![]() $\alpha = 10^\circ $.

$\alpha = 10^\circ $.

Another significant factor that affects the steady film formation is the shape and the size of the topographical structure. In figure 7(a), we present the amplitude of the free surface deformation as a function of Re for different types of topographical features. To this end, we keep the length of the unit cell ![]() $(L = 20)$ constant, and vary the aspect ratio,

$(L = 20)$ constant, and vary the aspect ratio, ![]() ${T_r}$, as defined in (2.3). High values of

${T_r}$, as defined in (2.3). High values of ![]() ${T_r}$ correspond to cases where the inflow and outflow region of the domain is much larger than the trench width (e.g. see figure 7b), whereas low values of

${T_r}$ correspond to cases where the inflow and outflow region of the domain is much larger than the trench width (e.g. see figure 7b), whereas low values of ![]() ${T_r}$ correspond to cases with pillar-like structures (e.g. see figure 7c). As shown in figure 7(a), for

${T_r}$ correspond to cases with pillar-like structures (e.g. see figure 7c). As shown in figure 7(a), for ![]() ${T_r} = 4$, the free surface is relatively smooth even at the peak of the resonance. For such high values of

${T_r} = 4$, the free surface is relatively smooth even at the peak of the resonance. For such high values of ![]() ${T_r}$, the size of the trench is relatively small with respect to the rest of the substrate, and the film flow tends to the simple Nusselt flow limit. Figure 7(b) depicts the film shape and the spatial variation of the normal stress component for

${T_r}$, the size of the trench is relatively small with respect to the rest of the substrate, and the film flow tends to the simple Nusselt flow limit. Figure 7(b) depicts the film shape and the spatial variation of the normal stress component for ![]() ${T_r} = 4$ and

${T_r} = 4$ and ![]() $Re = 11.8$; this value of Re corresponds to the case with maximum deformation. Clearly, the film surpasses the cavity easily with very little interfacial deformation and a low level of stresses in the cavity; the picture remains almost the same over the entire range of Re.

$Re = 11.8$; this value of Re corresponds to the case with maximum deformation. Clearly, the film surpasses the cavity easily with very little interfacial deformation and a low level of stresses in the cavity; the picture remains almost the same over the entire range of Re.

Figure 7. (a) Relative amplitude of the free surface, A, as a function of the Reynolds number for various values of ![]() ${T_r}$. (b,c) Film shape and spatial variation of normal stress component,

${T_r}$. (b,c) Film shape and spatial variation of normal stress component, ![]() ${\tau _{p,xx}}$, for

${\tau _{p,xx}}$, for ![]() ${T_r} = 4$ and

${T_r} = 4$ and ![]() ${T_r} = 0.10$ for

${T_r} = 0.10$ for ![]() $Re = 11.8$ and

$Re = 11.8$ and ![]() $Re = 17.6$, respectively. The remaining parameters are

$Re = 17.6$, respectively. The remaining parameters are ![]() $Ka = 2$,

$Ka = 2$, ![]() $El = 3$,

$El = 3$, ![]() $\varepsilon = 0.0$,

$\varepsilon = 0.0$, ![]() $\beta = 0.10$ and

$\beta = 0.10$ and ![]() $\alpha = 10^\circ $.

$\alpha = 10^\circ $.

On decreasing the value of ![]() ${T_r}$, the relative width of the cavity increases. As a result, the redirection of the flow is inevitable, with more fluid going through the cavity. Therefore, the resonance of the free surface with the bottom undulations becomes stronger, resulting in a considerable increase of the maximum interfacial deformation. As depicted in figure 7(a), the amplitude of the free surface deformation at the resonance point is inversely proportional to

${T_r}$, the relative width of the cavity increases. As a result, the redirection of the flow is inevitable, with more fluid going through the cavity. Therefore, the resonance of the free surface with the bottom undulations becomes stronger, resulting in a considerable increase of the maximum interfacial deformation. As depicted in figure 7(a), the amplitude of the free surface deformation at the resonance point is inversely proportional to ![]() ${T_r}$. For

${T_r}$. For ![]() ${T_r} = 0.10$, A is found to be equal to 2.23. Also, for this particular case, we observe a change in the slope of A for

${T_r} = 0.10$, A is found to be equal to 2.23. Also, for this particular case, we observe a change in the slope of A for ![]() $Re \approx 11$. As showed by Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019a), the latter phenomenon is connected with a new resonance point related to the cusp formation at the steady free surface. For

$Re \approx 11$. As showed by Pettas et al. (Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019a), the latter phenomenon is connected with a new resonance point related to the cusp formation at the steady free surface. For ![]() ${T_r} = 0.1$ (see figure 7c), the maximum normal polymeric stress field arises at the inflow and outflow regions of the unit cell where the polymeric chains are squeezed to conform with the fluid flow arrangement, while residual stresses are convected from one unit cell to the other producing a stronger polymeric stress field. Therefore, the elastic phenomena are more prominent, resulting in amplification of the free-surface deformation.

${T_r} = 0.1$ (see figure 7c), the maximum normal polymeric stress field arises at the inflow and outflow regions of the unit cell where the polymeric chains are squeezed to conform with the fluid flow arrangement, while residual stresses are convected from one unit cell to the other producing a stronger polymeric stress field. Therefore, the elastic phenomena are more prominent, resulting in amplification of the free-surface deformation.

5.2. Linear stability

So far, we have investigated the impact of non-Newtonian properties on the steady free-surface formation. In this section, we will discuss the stability of the steady flow subjected to infinitesimal, 2-D disturbances. Since much of the work in the literature has focused on the stability of flow under longwave disturbances and to provide the proper context, we will briefly discuss the predictions of our model for ![]() $Q \to 0$. Then we will proceed with the discussion of the linear stability for disturbances with arbitrary wavelengths. Our analysis is focused mainly on the stability of an Oldroyd-B fluid, whereas in the last subsection, we will investigate the effect of varying shear and extensional viscosity in the flow stability by employing the ePTT constitutive model.

$Q \to 0$. Then we will proceed with the discussion of the linear stability for disturbances with arbitrary wavelengths. Our analysis is focused mainly on the stability of an Oldroyd-B fluid, whereas in the last subsection, we will investigate the effect of varying shear and extensional viscosity in the flow stability by employing the ePTT constitutive model.

5.2.1. Longwave disturbances