1. Introduction

The interaction of compliant surfaces with wall-bounded flows has been the subject of research over the last decades since the early experiments published by Kramer (Reference Kramer1957, Reference Kramer1962). The main research has been focussed on the application of compliant coatings to delay laminar-to-turbulent transition, reduce frictional drag and suppress flow-induced noise and vibrations.

Theoretical analyses on system instabilities, direct numerical simulations (DNS) and experimental investigations have shown the opportunities and limitations of compliant materials in achieving the aforementioned goals, resulting in a series of contradictions and controversies. A review on classical and more recent studies are given by Bushnell, Hefner & Ash (Reference Bushnell, Hefner and Ash1977), Riley, Gad-el Hak & Metcalfe (Reference Riley, Gad-el Hak and Metcalfe1988) and Gad-el Hak (Reference Gad-el Hak2002), which indicates a valuable direction to the state-of-the-art research on compliant walls.

The present knowledge regarding possible turbulent drag reduction quantifies the compliance of flexible walls as a result of the response to the pressure fluctuations in the turbulent boundary layer. Dominant near-wall flow structures instigate quasi-periodic bursting events and result in velocity fluctuations in the streamwise and wall-normal directions (i.e. ![]() $u'$ and

$u'$ and ![]() $v'$, respectively), which, when correlated, are the elementary components of the Reynolds shear stress

$v'$, respectively), which, when correlated, are the elementary components of the Reynolds shear stress ![]() $-\rho \langle u'v' \rangle$ in the turbulent boundary layer with

$-\rho \langle u'v' \rangle$ in the turbulent boundary layer with ![]() $\rho$ as the fluid density (Tennekes & Lumley Reference Tennekes and Lumley1972; Robinson Reference Robinson1991). The velocity fluctuations contribute to the near-wall pressure fluctuations as is indicated by the conservation of momentum for incompressible flows:

$\rho$ as the fluid density (Tennekes & Lumley Reference Tennekes and Lumley1972; Robinson Reference Robinson1991). The velocity fluctuations contribute to the near-wall pressure fluctuations as is indicated by the conservation of momentum for incompressible flows:

The pressure gradient ![]() $\boldsymbol {\nabla } p$ is related to the velocity fluctuations in time and space, in the absence of external forces. The bursting events in the turbulent boundary layer result in local pressure fluctuations that are able to deform the flexible wall, dependent on the material properties of the compliant layer. Possible reduction of turbulent drag is based on the hypothesis that a compliant surface is triggered by a pre-bursting event and should thereby impede a new burst formation. Favourable wall dynamics in streamwise (

$\boldsymbol {\nabla } p$ is related to the velocity fluctuations in time and space, in the absence of external forces. The bursting events in the turbulent boundary layer result in local pressure fluctuations that are able to deform the flexible wall, dependent on the material properties of the compliant layer. Possible reduction of turbulent drag is based on the hypothesis that a compliant surface is triggered by a pre-bursting event and should thereby impede a new burst formation. Favourable wall dynamics in streamwise (![]() $u_c$) and wall-normal directions (

$u_c$) and wall-normal directions (![]() $v_c$) suppress the related velocity fluctuations

$v_c$) suppress the related velocity fluctuations ![]() $u'$ and

$u'$ and ![]() $v'$, which might result in lower Reynolds stresses when assuming

$v'$, which might result in lower Reynolds stresses when assuming ![]() $-\rho \langle (u'+u_c)(v'+v_c) \rangle$ (Kulik et al. Reference Kulik, Rodyakin, Suh, Lee and Chun2005).

$-\rho \langle (u'+u_c)(v'+v_c) \rangle$ (Kulik et al. Reference Kulik, Rodyakin, Suh, Lee and Chun2005).

The response of a compliant surface to the pressure fluctuations in a turbulent shear flow was theoretically examined by Duncan (Reference Duncan1986), Chase (Reference Chase1991) and more recently by Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019). The surface response is directly linked to the shear stress and the pressure pulses related to the flow structures in a turbulent boundary layer. Surface instabilities occurred when the ratio between the dynamic pressure of the flow ![]() $p_{rms}$ with respect to the shear modulus of the coating

$p_{rms}$ with respect to the shear modulus of the coating ![]() $|G^*|$ exceeded a critical value, which was related to the turbulent flow conditions in combination with coating properties, such as geometry, the size of the fluctuation, coating density and layer thickness (Kulik Reference Kulik2012). Nevertheless, it is still unclear what induces the onset of surface instabilities under turbulent flow conditions.

$|G^*|$ exceeded a critical value, which was related to the turbulent flow conditions in combination with coating properties, such as geometry, the size of the fluctuation, coating density and layer thickness (Kulik Reference Kulik2012). Nevertheless, it is still unclear what induces the onset of surface instabilities under turbulent flow conditions.

The flow-induced surface instabilities (FISIs) have been classified into two main types of wave phenomena (Gad-El-Hak, Blackwelder & Riley Reference Gad-El-Hak, Blackwelder and Riley1984; Carpenter & Garrad Reference Carpenter and Garrad1986; Gad-el Hak Reference Gad-el Hak1986), static divergence and wave flutter, both of which move in the streamwise flow direction. Static-divergence waves are damping instabilities due to the viscous properties of the coating material and are slowly moving waves ![]() $U_{wave}\sim 0.05 U_{bulk}$ with very large amplitudes and large wavelengths. Wave flutter is an elastic instability that can be stabilised by damping and the waves propagate much faster

$U_{wave}\sim 0.05 U_{bulk}$ with very large amplitudes and large wavelengths. Wave flutter is an elastic instability that can be stabilised by damping and the waves propagate much faster ![]() $U_{wave} \sim C_t$ with lower amplitudes and shorter wavelengths, where the shear-wave velocity of the compliant material is defined by

$U_{wave} \sim C_t$ with lower amplitudes and shorter wavelengths, where the shear-wave velocity of the compliant material is defined by ![]() $C_t=(|G^*|/\rho _c)^{1/2}$ with

$C_t=(|G^*|/\rho _c)^{1/2}$ with ![]() $|G^*|$ as the shear modulus of the coating and

$|G^*|$ as the shear modulus of the coating and ![]() $\rho _c$ as the coating density.

$\rho _c$ as the coating density.

The interaction between turbulent flows and compliant surfaces has also been investigated by several DNS. Often, the wall dynamics is modelled as a mass, damper and spring system, where the wall motions are restricted to the wall-normal direction in most studies. Endo & Himeno (Reference Endo and Himeno2002) observed that the compliant wall moves upwards in the presence of a low-pressure region on the wall and vice versa. They reported a small drag reduction of 2–3 %, whereas minimal changes in the velocity field were observed, although the pressure field was drastically affected. Furthermore, Fukagata et al. (Reference Fukagata, Kern, Chatelain, Koumoutsakos and Kasagi2008) reported a drag reduction of 8 % due to the decrease of the near-wall Reynolds stress forced by the wall motions. However, the turbulent drag increased in a doubled computational domain in the streamwise direction, which was attributed to extensive large wall-normal velocity fluctuations. Kim & Choi (Reference Kim and Choi2014) indicated that very stiff compliant surfaces had minimal effects on the skin-friction drag and the coherent turbulent structures. They showed that soft materials induced large-amplitude waves due to wall resonance, which travelled in the downstream direction. These wall motions increased the fluid motions in the near-wall region significantly. A turbulent boundary layer flow over a compliant surface was also modelled by Xia, Huang & Xu (Reference Xia, Huang and Xu2019) and indicated that the Reynolds shear stress and pressure fluctuation were generally enhanced by the wall compliance for all their cases. Rosti & Brandt (Reference Rosti and Brandt2017) performed numerical simulations of a turbulent channel flow over an incompressible viscous hyper-elastic wall, which was solved with a one-continuum formulation. The turbulent skin friction increased with decreasing elasticity for a fixed bulk Reynolds number ![]() $Re_b$. This result was attributed to the flow being more correlated in the spanwise direction that amplifies the turbulent Reynolds stresses in the fluid, similar to flows over rough and porous walls. An additional DNS study of Rosti & Brandt (Reference Rosti and Brandt2020) indicated a second distinctive mechanism for turbulence production when the bulk Reynolds number

$Re_b$. This result was attributed to the flow being more correlated in the spanwise direction that amplifies the turbulent Reynolds stresses in the fluid, similar to flows over rough and porous walls. An additional DNS study of Rosti & Brandt (Reference Rosti and Brandt2020) indicated a second distinctive mechanism for turbulence production when the bulk Reynolds number ![]() $Re_b$ was lowered. At a low Reynolds number, the velocity fluctuations were mainly generated by the small oscillations of the elastic wall that contributed to the turbulent kinetic energy at the fluid–surface interface.

$Re_b$ was lowered. At a low Reynolds number, the velocity fluctuations were mainly generated by the small oscillations of the elastic wall that contributed to the turbulent kinetic energy at the fluid–surface interface.

Many experimental studies have been performed on instantaneous wall deformation in relation to wall-bounded flow, which are considered essential for the understanding of the physics of the fluid–surface interaction (Hansen & Hunston Reference Hansen and Hunston1974; Hansen et al. Reference Hansen, Hunston, Ni and Reischman1980; McMichael, Klebanoff & Mease Reference McMichael, Klebanoff and Mease1980; Hansen & Hunston Reference Hansen and Hunston1983; Hess, Peattie & Schwarz Reference Hess, Peattie and Schwarz1993; Lee, Fisher & Schwarz Reference Lee, Fisher and Schwarz1993a,Reference Lee, Fisher and Schwarzb, Reference Lee, Fisher and Schwarz1995; Zhang, Miorini & Katz Reference Zhang, Miorini and Katz2015; Zhang et al. Reference Zhang, Wang, Blake and Katz2017; Huynh & McKeon Reference Huynh and McKeon2020; Wang, Koley & Katz Reference Wang, Koley and Katz2020). Several techniques have been applied to measure the surface deformations and to quantify the flow velocities. Lee et al. (Reference Lee, Fisher and Schwarz1993a) reported the combination of holographic interferometry with laser Doppler velocimetry, whereas Lee et al. (Reference Lee, Fisher and Schwarz1995) used a laser-based electro-optic transducer combined with hot-wire measurements. The latter study also reported a reduction in turbulent activity (i.e. Reynolds stresses).

Non-intrusive diagnostic methods are highly desired to avoid impediment of the surface deformations. Recent studies of Zhang et al. (Reference Zhang, Miorini and Katz2015, Reference Zhang, Wang, Blake and Katz2017) and Wang et al. (Reference Wang, Koley and Katz2020) reported the simultaneous use of Mach–Zehnder interferometry in combination with particle image velocimetry (PIV). For a relative stiff compliant surface, the interaction between the flow and wall deformations was shown to be one-way coupled, where the surface deformations were very small and correlated with the local fluid pressure fluctuations. The wall deformations did not increase the turbulence level of the flow when smaller than one wall unit, although they affected the velocity profile in the viscous sublayer, i.e. ![]() $y^+<5$. Two-way coupling was achieved with a softer compliant wall, where large deformations of the surface changed the turbulent structures in the boundary layer as well (Wang et al. Reference Wang, Koley and Katz2020). Huynh & McKeon (Reference Huynh and McKeon2020) investigated the compliant wall response to the flow structure in a turbulent boundary layer forced by a dynamic roughness element. The combination of 2D-PIV and a stereo digital image correlation (DIC) method was applied to quantify the flow velocity and surface deformations, respectively. The results verified the direct interaction between the forced flow mode and the compliant surface.

$y^+<5$. Two-way coupling was achieved with a softer compliant wall, where large deformations of the surface changed the turbulent structures in the boundary layer as well (Wang et al. Reference Wang, Koley and Katz2020). Huynh & McKeon (Reference Huynh and McKeon2020) investigated the compliant wall response to the flow structure in a turbulent boundary layer forced by a dynamic roughness element. The combination of 2D-PIV and a stereo digital image correlation (DIC) method was applied to quantify the flow velocity and surface deformations, respectively. The results verified the direct interaction between the forced flow mode and the compliant surface.

A similar mechanism of flow–surface interaction is the wave generation on a liquid surface by a turbulent wind, which was investigated by Paquier, Moisy & Rabaud (Reference Paquier, Moisy and Rabaud2015). The instantaneous surface deformations were measured using the optical method called free-surface synthetic schlieren (Moisy, Rabaud & Salsac Reference Moisy, Rabaud and Salsac2009). The method is based on the analysis of the refracted background image visualised through the liquid/air-interface, similar to the principle of background-oriented schlieren (BOS) (Richard & Raffel Reference Richard and Raffel2001; Raffel Reference Raffel2015). At low wind velocities, the surface deformations were disordered wrinkles with small amplitude, which propagated rapidly in the streamwise direction. The magnitude of the surface amplitude scaled almost linearly with the wind velocity. The wrinkles were considered to be the surface response to the pressure fluctuations travelling in the turbulent boundary layer, which was verified by Perrard et al. (Reference Perrard, Lozano-Durán, Rabaud, Benzaquen and Moisy2019). Above a certain wind velocity threshold a second regime arose, where the liquid–air interface was dominated by well-defined transverse waves propagating in the direction of the wind. The growth rate of the surface amplitude related to the wind velocity was significantly higher than in the first regime. Furthermore, the wave amplitude had a spatial growth in the streamwise direction whereas this was not the case in the wrinkle regime.

The use of compliant surfaces to control the flow conditions passively is a most interesting research topic. The focus of the present work is to investigate and better understand the interaction between a turbulent boundary layer flow and a compliant surface. In particular, the spatial and temporal response of the coating in combination with the change of fluid motions in the near-wall region as a function of the coating properties and the general flow conditions. Special interests are the parametric conditions that force a transition in the coating response. For that purpose, we apply three compliant walls with different material stiffnesses and analyse their surface response to turbulent boundary layer flow. We implement the BOS method similar to Moisy et al. (Reference Moisy, Rabaud and Salsac2009) in order to reconstruct the instantaneous surface deformations. In addition, we also explore the dissimilarities of the velocity profile and turbulence statistics compared with those of a rigid wall. Finally, we elaborate on the opportunities to reduce the turbulent skin friction when applying a compliant surface.

The TU Delft water tunnel facilitate the boundary layer flow experiments over a flat plate, similar to the research of Zverkhovskyi (Reference Zverkhovskyi2014). Three in-house produced compliant coatings with different material properties are embedded in flat test plates, in order to explore the interface wave characteristics as a function of the coating properties and the bulk velocity (![]() $U_b$). Measurements are taken of (i) the mean skin friction over the total length of the plate using a force balance, (ii) the instantaneous surface deformation field of the coating surface using BOS and (iii) the flow velocity field using 2D PIV/PTV. The outline of this paper is as follows: § 2 discusses the experimental facility, the coating material and the diagnostic methods; the results obtained are discussed in § 3; the main findings are summarised in § 4.

$U_b$). Measurements are taken of (i) the mean skin friction over the total length of the plate using a force balance, (ii) the instantaneous surface deformation field of the coating surface using BOS and (iii) the flow velocity field using 2D PIV/PTV. The outline of this paper is as follows: § 2 discusses the experimental facility, the coating material and the diagnostic methods; the results obtained are discussed in § 3; the main findings are summarised in § 4.

2. Experimental approach

2.1. Water tunnel facility

The experiments have been performed in the water tunnel at the Delft University of Technology figure 1 that was previously used in the investigation by Foeth (Reference Foeth2008). Zverkhovskyi (Reference Zverkhovskyi2014) adapted and utilised the test section to investigate the drag reducing ability of air cavities. The adapted test section is open at the top, which makes it possible to mount test plates in order to determine the frictional properties of various surfaces via a force balance system. The inlet cross-section area is ![]() $300\ {\rm mm}\times 300\ {\rm mm}$, whereas the outlet cross-section area is

$300\ {\rm mm}\times 300\ {\rm mm}$, whereas the outlet cross-section area is ![]() $300\ {\rm mm}\times 315\ {\rm mm}$ due to an inclined bottom wall. The sloped wall largely compensates for the boundary layer growth in the streamwise direction, such that a nearly constant free stream velocity

$300\ {\rm mm}\times 315\ {\rm mm}$ due to an inclined bottom wall. The sloped wall largely compensates for the boundary layer growth in the streamwise direction, such that a nearly constant free stream velocity ![]() $U_b$ and zero pressure gradient is maintained. The boundary layer thickness

$U_b$ and zero pressure gradient is maintained. The boundary layer thickness ![]() $\delta _{99}$ located at 1.7 m downstream (i.e. region of interest) is characterised as

$\delta _{99}$ located at 1.7 m downstream (i.e. region of interest) is characterised as ![]() $\delta _{99}=0.057U_b^{-1/7}$. The maximum friction velocity Reynolds number is

$\delta _{99}=0.057U_b^{-1/7}$. The maximum friction velocity Reynolds number is ![]() $Re_\tau =8.3\times 10^3$ at the maximum applied bulk velocity of

$Re_\tau =8.3\times 10^3$ at the maximum applied bulk velocity of ![]() $5.4\ {\rm m}\ {\rm s}^{-1}$ (

$5.4\ {\rm m}\ {\rm s}^{-1}$ (![]() ${\sim }500\ {\rm L} {\rm s}^{-1}$), which corresponds to a similar range as reported by Wang et al. (Reference Wang, Koley and Katz2020). The Reynolds number is defined by

${\sim }500\ {\rm L} {\rm s}^{-1}$), which corresponds to a similar range as reported by Wang et al. (Reference Wang, Koley and Katz2020). The Reynolds number is defined by ![]() $Re_\tau = \delta _{99}u_\tau /\nu$, with the boundary layer thickness

$Re_\tau = \delta _{99}u_\tau /\nu$, with the boundary layer thickness ![]() $\delta _{99}$, the wall-friction velocity

$\delta _{99}$, the wall-friction velocity ![]() $u_\tau$ and the kinematic viscosity

$u_\tau$ and the kinematic viscosity ![]() $\nu$. The wall-friction velocity

$\nu$. The wall-friction velocity ![]() $u_\tau$ is derived from

$u_\tau$ is derived from ![]() $\tau _w=\rho _f u_\tau ^2$, with

$\tau _w=\rho _f u_\tau ^2$, with ![]() $\tau _w$ the determined wall shear stress over a rigid wall and

$\tau _w$ the determined wall shear stress over a rigid wall and ![]() $\rho _f$ the fluid density. The boundary layers at the wall are tripped just before the entrance of the test section to ensure a turbulent boundary layer at all relevant tunnel velocities. The test plates have a total surface area of

$\rho _f$ the fluid density. The boundary layers at the wall are tripped just before the entrance of the test section to ensure a turbulent boundary layer at all relevant tunnel velocities. The test plates have a total surface area of ![]() $1998\ {\rm mm}\times 297\ {\rm mm}$ and have free in-plane movement during the force measurements. The gaps around the test plate (approximately 1.0–1.5 mm) are shielded in order to minimise possible flow disturbances. The test section is fully optically accessible through bottom and side walls, which makes it possible to apply the BOS and PIV measurements.

$1998\ {\rm mm}\times 297\ {\rm mm}$ and have free in-plane movement during the force measurements. The gaps around the test plate (approximately 1.0–1.5 mm) are shielded in order to minimise possible flow disturbances. The test section is fully optically accessible through bottom and side walls, which makes it possible to apply the BOS and PIV measurements.

Figure 1. Schematic illustration of the water tunnel (Zverkhovskyi Reference Zverkhovskyi2014); shape and dimensions not to scale. The flow is from left to right.

2.2. Compliant material

Polydimethylsiloxane (PDMS) has conventionally been applied as compliant viscoelastic material in fluid–surface interaction studies (Hess et al. Reference Hess, Peattie and Schwarz1993; Choi et al. Reference Choi, Yang, Clayton, Glover, Atlar, Semenov and Kulik1997; Colley et al. Reference Colley, Thomas, Carpenter and Cooper1999; Zhang et al. Reference Zhang, Miorini and Katz2015, Reference Zhang, Wang, Blake and Katz2017). Nevertheless, due to a continuous progress of covalent cross-link reactions between polymer chains, PDMS samples experience an ageing process that modifies the mechanical properties of the material (Bandyopadhyay et al. Reference Bandyopadhyay, Henoch, Hrubes, Semenov, Amirov, Kulik, Malyuga, Choi and Escudier2005; Boiko et al. Reference Boiko, Kulik, Chun and Lee2011). Ongoing and future research on the coating-equipped test plates require a viscoelastic material that maintains its mechanical properties over a sufficient period of time.

Compliant material has been produced in-house from a mixture of triblock-copolymer polystyrene-b-(ethylene-co-butylene)-b-styrene (S-EB-S) and mid-block selective paraffin oil. The SEBS (Kraton G-1650E) has a molar mass of ![]() ${\pm }100.000\ {\rm g}\ {\rm mol}^{-1}$ and styrene content of around 29 %. The paraffin oil (Sigma-Aldrich, 18512) has a dynamic viscosity of

${\pm }100.000\ {\rm g}\ {\rm mol}^{-1}$ and styrene content of around 29 %. The paraffin oil (Sigma-Aldrich, 18512) has a dynamic viscosity of ![]() $110\unicode{x2013}230\ {\rm mPa}\ {\rm s}$ and a density of

$110\unicode{x2013}230\ {\rm mPa}\ {\rm s}$ and a density of ![]() $0.827\unicode{x2013}0.89\ {\rm g}\ {\rm cm}^{-3}$ at

$0.827\unicode{x2013}0.89\ {\rm g}\ {\rm cm}^{-3}$ at ![]() $20\,^\circ {\rm C}$. The styrene endblocks are thermodynamically incompatible with the paraffin oil and group themselves into micelles to minimise interfacial area, which are considered to be the cross-link points in the material. These points are connected by the EB mid-blocks via physical cross-linking and give formation to a three-dimensional network, as illustrated in figure 2. A higher concentration of SEBS increases the micelles and cross-link density, which in part determines the mechanical properties of the viscoelastic material. Other parameters that influence the mechanical properties are the molar mass and the styrene content of the triblock copolymer and the type of hydrocarbon oil (Dürrschmidt & Hoffmann Reference Dürrschmidt and Hoffmann2001; Kim, Paglicawan & Balasubramanian Reference Kim, Paglicawan and Balasubramanian2006; Lattermann & Krekhova Reference Lattermann and Krekhova2006).

$20\,^\circ {\rm C}$. The styrene endblocks are thermodynamically incompatible with the paraffin oil and group themselves into micelles to minimise interfacial area, which are considered to be the cross-link points in the material. These points are connected by the EB mid-blocks via physical cross-linking and give formation to a three-dimensional network, as illustrated in figure 2. A higher concentration of SEBS increases the micelles and cross-link density, which in part determines the mechanical properties of the viscoelastic material. Other parameters that influence the mechanical properties are the molar mass and the styrene content of the triblock copolymer and the type of hydrocarbon oil (Dürrschmidt & Hoffmann Reference Dürrschmidt and Hoffmann2001; Kim, Paglicawan & Balasubramanian Reference Kim, Paglicawan and Balasubramanian2006; Lattermann & Krekhova Reference Lattermann and Krekhova2006).

Figure 2. SEBS/Oil micelles network formation. (a) Bridges: each styrene endblock colonises in a different micelle. (b) Loops: each styrene endblock colonises in the same micelle. (c) Dangling ends: one styrene endblock remains unsettled. Illustration based on Laurer et al. (Reference Laurer, Mulling, Khan, Spontak and Bukovnik1998).

Three coatings with different material stiffness ![]() $|G^*|$ are obtained by increasing the SEBS concentration. The material properties are characterised on their rheological behaviour using a rheometer (ARES-G2, TA Instruments) with a parallel plate geometry with a diameter of 25 mm. A temperature-sweep procedure estimates the polymer flow temperature

$|G^*|$ are obtained by increasing the SEBS concentration. The material properties are characterised on their rheological behaviour using a rheometer (ARES-G2, TA Instruments) with a parallel plate geometry with a diameter of 25 mm. A temperature-sweep procedure estimates the polymer flow temperature ![]() $T_m$, which is of great interest for the material post-processing to obtain a smooth coating surface on the test plates. The results confirm the material stiffness

$T_m$, which is of great interest for the material post-processing to obtain a smooth coating surface on the test plates. The results confirm the material stiffness ![]() $|G^*|$ and the polymer flow temperature

$|G^*|$ and the polymer flow temperature ![]() $T_m$ increases with increasing SEBS concentration (table 1). The shear wave velocities

$T_m$ increases with increasing SEBS concentration (table 1). The shear wave velocities ![]() $C_t = (|G^*|/\rho _c)^{1/2}$ are within the range of the flow velocities of the water tunnel and, thus, surface deformations and/or instabilities are expected. The material is considered to be incompressible within the range of operation (i.e. bulk modulus

$C_t = (|G^*|/\rho _c)^{1/2}$ are within the range of the flow velocities of the water tunnel and, thus, surface deformations and/or instabilities are expected. The material is considered to be incompressible within the range of operation (i.e. bulk modulus ![]() $K \sim 5\ {\rm GPa}$), which presumes a Poisson's ratio of

$K \sim 5\ {\rm GPa}$), which presumes a Poisson's ratio of ![]() $\sigma \simeq 0.5$.

$\sigma \simeq 0.5$.

Table 1. Material properties of the three compliant coatings at standard conditions. The frequency-averaged storage modulus ![]() $G'$ and loss modulus

$G'$ and loss modulus ![]() $G''$ determine the complex shear modulus

$G''$ determine the complex shear modulus ![]() $G^*= G'+iG''$ with

$G^*= G'+iG''$ with ![]() $|G^*|=\sqrt {(G')^2+(G'')^2}$. The shear wave velocity is given by

$|G^*|=\sqrt {(G')^2+(G'')^2}$. The shear wave velocity is given by ![]() $C_t = (|G^*|/\rho _c)^{1/2}$.

$C_t = (|G^*|/\rho _c)^{1/2}$.

The refractive index of the coating is required in order to reconstruct the coating deformations at the surface interface. The refractive indices ![]() $n_i$ are measured with an Abbe refractometer and are summarised in table 1.

$n_i$ are measured with an Abbe refractometer and are summarised in table 1.

The coating-equipped test plates are obtained by liquifying and re-solidifying the compliant material using a large oven. This method of material processing delivers a homogeneous coating layer thickness of ![]() $h_c=5$ mm with an interface surface that is considered to be hydrodynamically smooth.

$h_c=5$ mm with an interface surface that is considered to be hydrodynamically smooth.

2.3. Surface deformation measurements

The instantaneous deformation field ![]() $\zeta (x,y,t)$ of the compliant surface are measured by the BOS method similar to that of Moisy et al. (Reference Moisy, Rabaud and Salsac2009). A random dot pattern (

$\zeta (x,y,t)$ of the compliant surface are measured by the BOS method similar to that of Moisy et al. (Reference Moisy, Rabaud and Salsac2009). A random dot pattern (![]() $100\ {\rm mm}\times 100\ {\rm mm}$) is used with non-overlapping dots, dot size

$100\ {\rm mm}\times 100\ {\rm mm}$) is used with non-overlapping dots, dot size ![]() $D_d\sim 0.4$ mm and a dot density of 40 %. This corresponds to a number of dots

$D_d\sim 0.4$ mm and a dot density of 40 %. This corresponds to a number of dots ![]() $N_I \approx 6$ for a

$N_I \approx 6$ for a ![]() $32 \times 32$ pixels interrogation window and a particle-per-pixel

$32 \times 32$ pixels interrogation window and a particle-per-pixel ![]() $N_{ppp}\approx 0.125$, leading to more than 90 % of good vectors (Adrian & Westerweel Reference Adrian and Westerweel2011). The random dot pattern is placed behind the coating–fluid interface and was back-illuminated by a homogeneous LED screen. Both are submerged below the free surface of the water above the test plate. The dot pattern is front-observed by a high-speed 4-megapixel camera (Imager HS, LaVision) via a mirror that is placed below the test section (figure 3). A distorted image of the reference dot pattern is the result of light rays passing through the deformed interface. The apparent local displacement of the reference image is computed via an in-house DIC algorithm and is directly proportional to the local surface gradient (Elwell Reference Elwell2005). A multigrid interrogation approach is used with a final window size of

$N_{ppp}\approx 0.125$, leading to more than 90 % of good vectors (Adrian & Westerweel Reference Adrian and Westerweel2011). The random dot pattern is placed behind the coating–fluid interface and was back-illuminated by a homogeneous LED screen. Both are submerged below the free surface of the water above the test plate. The dot pattern is front-observed by a high-speed 4-megapixel camera (Imager HS, LaVision) via a mirror that is placed below the test section (figure 3). A distorted image of the reference dot pattern is the result of light rays passing through the deformed interface. The apparent local displacement of the reference image is computed via an in-house DIC algorithm and is directly proportional to the local surface gradient (Elwell Reference Elwell2005). A multigrid interrogation approach is used with a final window size of ![]() $16\times 16$ pixels with a 50 % overlap, leading to a displacement field with a high resolution (i.e. vector/8 pixels). A simple median filter method is applied to detect spurious vectors that are replaced by linear interpolation (Westerweel & Scarano Reference Westerweel and Scarano2005). The final interrogation window is smaller than required for

$16\times 16$ pixels with a 50 % overlap, leading to a displacement field with a high resolution (i.e. vector/8 pixels). A simple median filter method is applied to detect spurious vectors that are replaced by linear interpolation (Westerweel & Scarano Reference Westerweel and Scarano2005). The final interrogation window is smaller than required for ![]() $N_I \approx 6$. However, the computed displacement fields are similar to the correlation with a

$N_I \approx 6$. However, the computed displacement fields are similar to the correlation with a ![]() $32 \times 32$ pixels interrogation window. The reconstruction of the surface interface is further discussed in Appendix A.1.

$32 \times 32$ pixels interrogation window. The reconstruction of the surface interface is further discussed in Appendix A.1.

Figure 3. BOS set-up in order to perform surface deformation measurements. The camera observes the random dot pattern via a mirror and the transparent coating material. The total distance between the camera and the dot pattern is ![]() $H=1400$ mm. The flow moves from left to right.

$H=1400$ mm. The flow moves from left to right.

The refraction method has to fulfil at least two requirements for a reliable reconstruction of the surface deformation, as discussed by Moisy et al. (Reference Moisy, Rabaud and Salsac2009). First, the camera–pattern distance ![]() $H$ needs to be large enough compared with the field size

$H$ needs to be large enough compared with the field size ![]() $L$ to meet the paraxial approximation. In the present case, the field of view (FOV) has an area of

$L$ to meet the paraxial approximation. In the present case, the field of view (FOV) has an area of ![]() $100\ {\rm mm}\times 100\ {\rm mm}$ in the centre of the plate and the camera–pattern distance is around

$100\ {\rm mm}\times 100\ {\rm mm}$ in the centre of the plate and the camera–pattern distance is around ![]() $H=1400$ mm thereby satisfying the paraxial approximation, i.e.

$H=1400$ mm thereby satisfying the paraxial approximation, i.e. ![]() $\beta \simeq L/(\sqrt {2}H) \ll 1$. Second, the wave amplitude and surface curvature need to be small to fulfil the linear approximation. The DIC algorithm is inferior when strong surface deformations occur; strong strained refracted patterns or dots that move in opposite directions within one interrogation window will result in bad displacement vectors. A dot-tracking algorithm (DTA) would be more appropriate when strong deformations occur; see Charruault et al. (Reference Charruault, Greidanus, Breugem and Westerweel2018). The pattern–surface distance is minimal 15 mm and could be increased by inserting glass spacer plates of various thicknesses

$\beta \simeq L/(\sqrt {2}H) \ll 1$. Second, the wave amplitude and surface curvature need to be small to fulfil the linear approximation. The DIC algorithm is inferior when strong surface deformations occur; strong strained refracted patterns or dots that move in opposite directions within one interrogation window will result in bad displacement vectors. A dot-tracking algorithm (DTA) would be more appropriate when strong deformations occur; see Charruault et al. (Reference Charruault, Greidanus, Breugem and Westerweel2018). The pattern–surface distance is minimal 15 mm and could be increased by inserting glass spacer plates of various thicknesses ![]() $h_g=2$, 10 or 20 mm. An increase in pattern–surface distance amplifies the deformations and with that the resolution. However, it may also lead to ray crossing in regions of large strain resulting in inaccurate displacement values preventing an unambiguous reconstruction of the coating surface.

$h_g=2$, 10 or 20 mm. An increase in pattern–surface distance amplifies the deformations and with that the resolution. However, it may also lead to ray crossing in regions of large strain resulting in inaccurate displacement values preventing an unambiguous reconstruction of the coating surface.

2.4. Flow velocity measurements

Particle image velocimetry is used to study the instantaneous velocity fields and turbulent statistics of the turbulent flow. A standard 2D-2C PIV configuration is applied to the test facility, as is displayed in figure 4. The FOV is around ![]() $8.7\times 7.0\ {\rm mm}^2$ in streamwise and wall-normal direction, respectively, and is situated 1.7 m downstream from the entrance of the test section. The FOV is illuminated by a light sheet

$8.7\times 7.0\ {\rm mm}^2$ in streamwise and wall-normal direction, respectively, and is situated 1.7 m downstream from the entrance of the test section. The FOV is illuminated by a light sheet ![]() $\Delta z_0<1$ mm using a double-pulsed 50 mW Nd:YAG laser (Litron L-class 50-50) and is located in the centre of the tunnel. The images are recorded by a

$\Delta z_0<1$ mm using a double-pulsed 50 mW Nd:YAG laser (Litron L-class 50-50) and is located in the centre of the tunnel. The images are recorded by a ![]() $1280\times 1024$ pixel CCD camera (FlowMaster, LaVision) and show a part of the wall and the near-wall flow region. Hollow glass particles (Sphericell,

$1280\times 1024$ pixel CCD camera (FlowMaster, LaVision) and show a part of the wall and the near-wall flow region. Hollow glass particles (Sphericell, ![]() $d_p = 10\ \mathrm {\mu }{\rm m}$) are used as tracers, with a nominal particle density of approximately

$d_p = 10\ \mathrm {\mu }{\rm m}$) are used as tracers, with a nominal particle density of approximately ![]() $\rho _d = 1.1\times 10^3\ {\rm kg}\ {\rm m}^{-3}$. The response timescale of particle relaxation

$\rho _d = 1.1\times 10^3\ {\rm kg}\ {\rm m}^{-3}$. The response timescale of particle relaxation ![]() $\tau _p=d_p^2 \rho _p/(18\rho _f \nu )$ is

$\tau _p=d_p^2 \rho _p/(18\rho _f \nu )$ is ![]() $5.6\ \mathrm {\mu }{\rm s}$. The particles are expected to follow the flow even in the near-wall region as the expected inner turbulence timescale is minimally

$5.6\ \mathrm {\mu }{\rm s}$. The particles are expected to follow the flow even in the near-wall region as the expected inner turbulence timescale is minimally ![]() ${\tau _\nu =\nu /u_\tau ^2>20\ \mathrm {\mu }{\rm s}}$. Calibration is done using a calibration grid with a dot spacing of 0.5 mm. The pixel size is

${\tau _\nu =\nu /u_\tau ^2>20\ \mathrm {\mu }{\rm s}}$. Calibration is done using a calibration grid with a dot spacing of 0.5 mm. The pixel size is ![]() $6.7\ \mathrm {\mu }{\rm m}$, resulting in a

$6.7\ \mathrm {\mu }{\rm m}$, resulting in a ![]() $M_0=1$ magnification. A total of 500 successive PIV image pairs are taken at a low frequency (3–4 Hz) to ensure reliable statistical convergence of the mean velocity field and turbulent parameters. The time delay

$M_0=1$ magnification. A total of 500 successive PIV image pairs are taken at a low frequency (3–4 Hz) to ensure reliable statistical convergence of the mean velocity field and turbulent parameters. The time delay ![]() $\Delta t$ between the first and second image is chosen such that the particle displacement between the two images is around 8–10 pixels from the wall. Data analysis is performed using commercial software (DaVis v7, LaVison). A multi-pass correlation is used, with a final interrogation window size of

$\Delta t$ between the first and second image is chosen such that the particle displacement between the two images is around 8–10 pixels from the wall. Data analysis is performed using commercial software (DaVis v7, LaVison). A multi-pass correlation is used, with a final interrogation window size of ![]() $64 \times 64$ pixels with a 75 % overlap resulting in a vector spacing of 0.11 mm. The final

$64 \times 64$ pixels with a 75 % overlap resulting in a vector spacing of 0.11 mm. The final ![]() $64\times 64$ pixels window is the minimum size to satisfy the criterion of at least five particles per interrogation window.

$64\times 64$ pixels window is the minimum size to satisfy the criterion of at least five particles per interrogation window.

Figure 4. Illustration of the experimental PIV set-up applied to the test section of the facility. The FOV is located 1.7 m downstream from the entrance of the test section and at the centreline of the water tunnel. The flow moves from left to right.

Close to the wall, the velocity profiles show relatively low spatial resolution due to the large interrogation window. The corresponding vector spacing is 7–20 wall units (![]() $y^+$) for bulk velocities

$y^+$) for bulk velocities ![]() $U_b= 1.7 \unicode{x2013} 5.2\ {\rm m}\ {\rm s}^{-1}$ (

$U_b= 1.7 \unicode{x2013} 5.2\ {\rm m}\ {\rm s}^{-1}$ (![]() $Re_\tau =3.3\times 10^3\unicode{x2013}8.0\times 10^3$), respectively. The reconstruction of the velocity profile closer to the wall requires a higher spatial resolution and is obtained by applying particle tracking velocimetry (PTV), which determines the displacement of individual particle images close to the wall (

$Re_\tau =3.3\times 10^3\unicode{x2013}8.0\times 10^3$), respectively. The reconstruction of the velocity profile closer to the wall requires a higher spatial resolution and is obtained by applying particle tracking velocimetry (PTV), which determines the displacement of individual particle images close to the wall (![]() $y<1$ mm). The spatial resolution of the mean velocity profile is enhanced up to 1 pixel, by means of the so-called super-resolution method (Keane, Adrian & Zhang Reference Keane, Adrian and Zhang1995). First, an in-house PIV correlation algorithm with elongated interrogation windows (

$y<1$ mm). The spatial resolution of the mean velocity profile is enhanced up to 1 pixel, by means of the so-called super-resolution method (Keane, Adrian & Zhang Reference Keane, Adrian and Zhang1995). First, an in-house PIV correlation algorithm with elongated interrogation windows (![]() ${\sim }64\ {\rm pixels}\times 32\ {\rm pixels}$, 50 % overlap) is used that provides identical results as the earlier used commercial software. Second, the measured estimate of the local velocity field is used as an input for the PTV processing, thus improving the successful and fast detection of particle pairs by substantially reducing the search area. The particle image displacement between two successive images with

${\sim }64\ {\rm pixels}\times 32\ {\rm pixels}$, 50 % overlap) is used that provides identical results as the earlier used commercial software. Second, the measured estimate of the local velocity field is used as an input for the PTV processing, thus improving the successful and fast detection of particle pairs by substantially reducing the search area. The particle image displacement between two successive images with ![]() $\Delta t$ in between results in the velocity of all individual particles. The mean velocity profile is obtained by spatial and temporal averaging of the particle velocities with respect to the mean position of the compliant wall.

$\Delta t$ in between results in the velocity of all individual particles. The mean velocity profile is obtained by spatial and temporal averaging of the particle velocities with respect to the mean position of the compliant wall.

3. Results and discussion

3.1. Friction force measurements

The measured friction force ![]() $\bar {F}$ represents the averaged shear stress

$\bar {F}$ represents the averaged shear stress ![]() $\bar {\tau }$ times the total test plate area

$\bar {\tau }$ times the total test plate area ![]() $A$, such that

$A$, such that ![]() $\bar {\tau }=\bar {F}/A$. Figure 5(a) shows the averaged shear stress

$\bar {\tau }=\bar {F}/A$. Figure 5(a) shows the averaged shear stress ![]() $\bar {\tau }$ against the bulk velocity

$\bar {\tau }$ against the bulk velocity ![]() $U_b$. Following Zverkhovskyi (Reference Zverkhovskyi2014), the results are highly reproducible and are compared with two common smooth-surface curves, the Grigson and the Prandtl–Schlichting correlation curves. For low bulk velocities, the friction values of all three coatings are similar to those of a rigid smooth surface. Above a bulk velocity of

$U_b$. Following Zverkhovskyi (Reference Zverkhovskyi2014), the results are highly reproducible and are compared with two common smooth-surface curves, the Grigson and the Prandtl–Schlichting correlation curves. For low bulk velocities, the friction values of all three coatings are similar to those of a rigid smooth surface. Above a bulk velocity of ![]() $U_b>4.5\ {\rm m}\ {\rm s}^{-1}$ or

$U_b>4.5\ {\rm m}\ {\rm s}^{-1}$ or ![]() $Re_\tau >7.1\times 10^3$, the shear stress of coating 1 deviates more and more with increasing bulk velocity

$Re_\tau >7.1\times 10^3$, the shear stress of coating 1 deviates more and more with increasing bulk velocity ![]() $U_b$. Coatings 2 and 3 maintain their smooth surface behaviour up to the maximum applied bulk velocity.

$U_b$. Coatings 2 and 3 maintain their smooth surface behaviour up to the maximum applied bulk velocity.

Figure 5. (a) Wall shear stress ![]() $\bar {\tau }$ as a function of water tunnel bulk velocity

$\bar {\tau }$ as a function of water tunnel bulk velocity ![]() $U_b$. Coating 1 (see table 1) deviates from the estimated correlation lines of Grigson and Prandtl–Schlichting at

$U_b$. Coating 1 (see table 1) deviates from the estimated correlation lines of Grigson and Prandtl–Schlichting at ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ and above. (b) Estimated surface roughness

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ and above. (b) Estimated surface roughness ![]() $k_s$ related to the measured drag coefficient

$k_s$ related to the measured drag coefficient ![]() $C_d$. The dot/dashed line represents the viscous sublayer thickness

$C_d$. The dot/dashed line represents the viscous sublayer thickness ![]() $\delta _v= 5 \nu /u_\tau$, based on Grigson's correlation.

$\delta _v= 5 \nu /u_\tau$, based on Grigson's correlation.

The coatings are considered to be sensitive to pressure forces, which induce surface irregularities and deformations. The most sensitive surface is coating 1 due to its low shear modulus ![]() $|G^*|$. For coating 1, the measured increase of shear stress

$|G^*|$. For coating 1, the measured increase of shear stress ![]() $\bar {\tau }$ is presumed to be the consequence of a transition to surface roughness caused by the surface deformations. An estimation of the surface roughness values

$\bar {\tau }$ is presumed to be the consequence of a transition to surface roughness caused by the surface deformations. An estimation of the surface roughness values ![]() $k_s$ is obtained by using the drag coefficients

$k_s$ is obtained by using the drag coefficients ![]() $C_d=\bar {\tau }/(\frac {1}{2}\rho U_b^2)$ in combination with the flat-plate friction diagram (White Reference White1999). Below

$C_d=\bar {\tau }/(\frac {1}{2}\rho U_b^2)$ in combination with the flat-plate friction diagram (White Reference White1999). Below ![]() $U_b\sim 4.5\ {\rm m}\ {\rm s}^{-1}$, the coating plate is considered as hydrodynamically smooth, which typically indicates a surface roughness of

$U_b\sim 4.5\ {\rm m}\ {\rm s}^{-1}$, the coating plate is considered as hydrodynamically smooth, which typically indicates a surface roughness of ![]() $k_s^+<5$. As shown in figure 5(b), beyond

$k_s^+<5$. As shown in figure 5(b), beyond ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ the effective surface roughness increases from

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ the effective surface roughness increases from ![]() $k_s=40\ \mathrm {\mu }{\rm m}$ to

$k_s=40\ \mathrm {\mu }{\rm m}$ to ![]() $130\ \mathrm {\mu }{\rm m}$ (i.e.

$130\ \mathrm {\mu }{\rm m}$ (i.e. ![]() $k_s^+=6$ to 27).

$k_s^+=6$ to 27).

3.2. Surface reconstruction

3.2.1. Global results and deformation scaling

For all cases, a total of 2000 consecutive height fields ![]() $\zeta (x,y,t)$ are used to analyse the interaction of the turbulent boundary layer with the compliant wall. The root-mean-square (r.m.s.) value of the surface height

$\zeta (x,y,t)$ are used to analyse the interaction of the turbulent boundary layer with the compliant wall. The root-mean-square (r.m.s.) value of the surface height ![]() $\zeta _{rms}$ increases with increasing bulk velocity

$\zeta _{rms}$ increases with increasing bulk velocity ![]() $U_b$ (figure 6a). For coating 1, an obvious sharp transition is observed around

$U_b$ (figure 6a). For coating 1, an obvious sharp transition is observed around ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ (or

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ (or ![]() $Re_\tau =7.1\times 10^3$), beyond which the r.m.s. values grow considerably faster. This supports the argumentation that the exceptional frictional increase, as observed in the force measurements (see figure 5a), is due to an increase in the surface roughness related to growing waves with significant amplitudes.

$Re_\tau =7.1\times 10^3$), beyond which the r.m.s. values grow considerably faster. This supports the argumentation that the exceptional frictional increase, as observed in the force measurements (see figure 5a), is due to an increase in the surface roughness related to growing waves with significant amplitudes.

Figure 6. Vertical displacement of coatings 1, 2 and 3. (a) Root-mean-square values ![]() $\zeta _{rms}$ as a function of the bulk velocity

$\zeta _{rms}$ as a function of the bulk velocity ![]() $U_b$. The estimated one-way/two-way regime transition of coating 1 occurs when the surface deformation is around

$U_b$. The estimated one-way/two-way regime transition of coating 1 occurs when the surface deformation is around ![]() $\zeta _{rms}>\delta _v/2$. (b) Scaled r.m.s. values

$\zeta _{rms}>\delta _v/2$. (b) Scaled r.m.s. values ![]() $\zeta _{rms}$ to coating thickness

$\zeta _{rms}$ to coating thickness ![]() $h_c$ in relation to the scaled pressure fluctuations

$h_c$ in relation to the scaled pressure fluctuations ![]() $p_{rms}$ to coating shear modulus

$p_{rms}$ to coating shear modulus ![]() $|G^*|$. The scaling factor 0.0364 of the one-way coupled regime is a fit parameter.

$|G^*|$. The scaling factor 0.0364 of the one-way coupled regime is a fit parameter.

Several authors pointed out the dominant near-wall flow structures to cause pressure fluctuation in the turbulent boundary layer (Tennekes & Lumley Reference Tennekes and Lumley1972; Duncan, Waxman & Tulin Reference Duncan, Waxman and Tulin1985; Robinson Reference Robinson1991). In their turn, the pressure fluctuations are capable of deforming the compliant surface of the wall. Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019) demonstrated the surface deformation of the present coatings using an analytical one-way coupling approach. It was indicated that the shear stress has marginal influence on the vertical displacement and is mainly driven by the pressure fluctuations, which has also been concluded by Perrard et al. (Reference Perrard, Lozano-Durán, Rabaud, Benzaquen and Moisy2019) and Wang et al. (Reference Wang, Koley and Katz2020). The surface-pressure fluctuation level ![]() $p_{rms}$ is estimated, based on the empirical model of the pressure spectrum by Goody (Reference Goody2002, Reference Goody2004). The empirical relation of the surface-pressure fluctuation level

$p_{rms}$ is estimated, based on the empirical model of the pressure spectrum by Goody (Reference Goody2002, Reference Goody2004). The empirical relation of the surface-pressure fluctuation level ![]() $p_{rms}$ is given by Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019)

$p_{rms}$ is given by Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019)

where ![]() $R_T$ is the ratio of the outer layer to inner layer timescales:

$R_T$ is the ratio of the outer layer to inner layer timescales: ![]() $R_T=(\delta _{99}/U_b)/(\nu /u_\tau ^2)$. Here we use the boundary layer thickness

$R_T=(\delta _{99}/U_b)/(\nu /u_\tau ^2)$. Here we use the boundary layer thickness ![]() $\delta _{99}$ and the wall-friction velocity

$\delta _{99}$ and the wall-friction velocity ![]() $u_{\tau }$ at a streamwise position

$u_{\tau }$ at a streamwise position ![]() $x=1.7$ m, where

$x=1.7$ m, where ![]() $u_\tau$ is estimated based on the shear stress values

$u_\tau$ is estimated based on the shear stress values ![]() $\tau _{\kappa }$ of table 2. It should be noted that the

$\tau _{\kappa }$ of table 2. It should be noted that the ![]() $p_{rms}$ values slightly deviate compared with the values presented by Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019), where

$p_{rms}$ values slightly deviate compared with the values presented by Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019), where ![]() $u_\tau$ is based on 6/7

$u_\tau$ is based on 6/7![]() $\bar {\tau }$. The present results show that the vertical displacement of all coatings scale to

$\bar {\tau }$. The present results show that the vertical displacement of all coatings scale to ![]() $p_{rms}/|G^*|$ and collapse on a single line in the one-way coupled regime (figure 6b). This indicates that the turbulent flow and the related surface-pressure fluctuations

$p_{rms}/|G^*|$ and collapse on a single line in the one-way coupled regime (figure 6b). This indicates that the turbulent flow and the related surface-pressure fluctuations ![]() $p_{rms}$ deform the compliant coating in proportion to the inverse of the coating stiffness (i.e.

$p_{rms}$ deform the compliant coating in proportion to the inverse of the coating stiffness (i.e. ![]() $1/|G^*|$). The force measurements indicate that the surface deformations have a negligible effect on the turbulent flow, showing that this is an one-way coupled regime. As can be seen in figure 6(b), coating 1 deviates from the initial line beyond

$1/|G^*|$). The force measurements indicate that the surface deformations have a negligible effect on the turbulent flow, showing that this is an one-way coupled regime. As can be seen in figure 6(b), coating 1 deviates from the initial line beyond ![]() $p_{rms}/|G^*|>0.076$. This is considered as the two-way coupled regime for coating 1, where the surface deformation affects the turbulent flow. The estimated one-way/two-way regime transition of coating 1 occurs when

$p_{rms}/|G^*|>0.076$. This is considered as the two-way coupled regime for coating 1, where the surface deformation affects the turbulent flow. The estimated one-way/two-way regime transition of coating 1 occurs when ![]() $\zeta _{rms}>\delta _v/2$. Based on this criterion, the transition towards a two-way coupled regime for coating 2 and coating 3 is predicted to be around

$\zeta _{rms}>\delta _v/2$. Based on this criterion, the transition towards a two-way coupled regime for coating 2 and coating 3 is predicted to be around ![]() $U_b=6.8\ {\rm m}\ {\rm s}^{-1}$ (i.e.

$U_b=6.8\ {\rm m}\ {\rm s}^{-1}$ (i.e. ![]() $p_{rms}/|G^*|\sim 0.045$) and

$p_{rms}/|G^*|\sim 0.045$) and ![]() $U_b=9.9\ {\rm m}\ {\rm s}^{-1}$ (i.e.

$U_b=9.9\ {\rm m}\ {\rm s}^{-1}$ (i.e. ![]() $p_{rms}/|G^*|\sim 0.042$), respectively, although this is still a premature conclusion due to insufficient amount of data in this regime.

$p_{rms}/|G^*|\sim 0.042$), respectively, although this is still a premature conclusion due to insufficient amount of data in this regime.

Table 2. Estimated local shear stress via the force measurements (![]() $\tau _{\bar {\tau }}$) and the log-fit method (

$\tau _{\bar {\tau }}$) and the log-fit method (![]() $\tau _\kappa$) for the smooth flat plate and the coated plate, as a function of the bulk velocity

$\tau _\kappa$) for the smooth flat plate and the coated plate, as a function of the bulk velocity ![]() $U_b$.

$U_b$.

3.3. Surface pattern dependency on the flow conditions

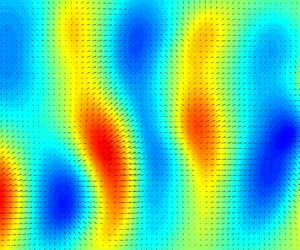

Figure 7 presents six instantaneous height fields ![]() $\zeta (x,y,t)$ of coating 1 with increasing bulk velocity

$\zeta (x,y,t)$ of coating 1 with increasing bulk velocity ![]() $U_b$ from

$U_b$ from ![]() $0.9\ {\rm m}\ {\rm s}^{-1}$ to

$0.9\ {\rm m}\ {\rm s}^{-1}$ to ![]() $5.0\ {\rm m}\ {\rm s}^{-1}$, which corresponds to

$5.0\ {\rm m}\ {\rm s}^{-1}$, which corresponds to ![]() $Re_\tau =2.0\times 10^3\unicode{x2013}7.8\times 10^3$. The time series movies of the surface deformation at the related bulk velocities are available in the supplementary material (online). The time series show that the deformations move in the same direction as the fluid flow (i.e. from left to right). At low bulk velocities, the surface deformations exhibit elongated patterns in streamwise direction (figure 7a; movie 1). The wave amplitudes grow with increasing bulk velocity, while the deformation pattern becomes more random-oriented (figures 7b and 7c; movies 2 and 3). Positive surface undulations (crests)

$Re_\tau =2.0\times 10^3\unicode{x2013}7.8\times 10^3$. The time series movies of the surface deformation at the related bulk velocities are available in the supplementary material (online). The time series show that the deformations move in the same direction as the fluid flow (i.e. from left to right). At low bulk velocities, the surface deformations exhibit elongated patterns in streamwise direction (figure 7a; movie 1). The wave amplitudes grow with increasing bulk velocity, while the deformation pattern becomes more random-oriented (figures 7b and 7c; movies 2 and 3). Positive surface undulations (crests) ![]() $\zeta _c>0$ are usually preceded and/or succeeded by comparably dimensioned valleys

$\zeta _c>0$ are usually preceded and/or succeeded by comparably dimensioned valleys ![]() $\zeta _v<0$, which is attributed to the incompressibility of the coating material. At the transition velocity

$\zeta _v<0$, which is attributed to the incompressibility of the coating material. At the transition velocity ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$, the random-oriented pattern is maintained in combination with incidentally appearing wave packets with much larger amplitudes (

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$, the random-oriented pattern is maintained in combination with incidentally appearing wave packets with much larger amplitudes (![]() ${\pm }100\ \mathrm {\mu }{\rm m}$), where the wave crests are more oriented in spanwise direction (figure 7d; movie 4). The change in surface pattern orientation with increasing bulk velocity is in agreement with the DNS results of Rosti & Brandt (Reference Rosti and Brandt2017) and the experimental results of Wang et al. (Reference Wang, Koley and Katz2020). Beyond the transition velocity

${\pm }100\ \mathrm {\mu }{\rm m}$), where the wave crests are more oriented in spanwise direction (figure 7d; movie 4). The change in surface pattern orientation with increasing bulk velocity is in agreement with the DNS results of Rosti & Brandt (Reference Rosti and Brandt2017) and the experimental results of Wang et al. (Reference Wang, Koley and Katz2020). Beyond the transition velocity ![]() $U_b>4.5\ {\rm m}\ {\rm s}^{-1}$, the surface deformations grow considerably larger than before, and the wave trains start to dominate the surface height field (figure 7e and 7f; movies 5 and 6). The time series of the surface height fields

$U_b>4.5\ {\rm m}\ {\rm s}^{-1}$, the surface deformations grow considerably larger than before, and the wave trains start to dominate the surface height field (figure 7e and 7f; movies 5 and 6). The time series of the surface height fields ![]() $\zeta (x,y,t)$ show that the wave trains are occasionally overtaken by waves with smaller amplitudes, which indicates that two types of waves exist that are travelling in the streamwise direction on the fluid–surface interface with different wave dynamics. The r.m.s. value of the surface height field

$\zeta (x,y,t)$ show that the wave trains are occasionally overtaken by waves with smaller amplitudes, which indicates that two types of waves exist that are travelling in the streamwise direction on the fluid–surface interface with different wave dynamics. The r.m.s. value of the surface height field ![]() $\zeta _{rms}$ (figure 6, coating 1) shows the sharp transition in amplitude growth with increasing bulk velocity

$\zeta _{rms}$ (figure 6, coating 1) shows the sharp transition in amplitude growth with increasing bulk velocity ![]() $U_b$. This is due to the increase in wave height as well as the increase in the percentage of surface area covered by these high-amplitude waves, as shown in figure 8. This is also visualised and supported by the instantaneous height fields

$U_b$. This is due to the increase in wave height as well as the increase in the percentage of surface area covered by these high-amplitude waves, as shown in figure 8. This is also visualised and supported by the instantaneous height fields ![]() $\zeta (x,y,t)$.

$\zeta (x,y,t)$.

Figure 7. Instantaneous surface height fields ![]() $\zeta (x,y)$ of coating 1 with increasing flow velocity

$\zeta (x,y)$ of coating 1 with increasing flow velocity ![]() $U_b$. The flow moves from left to right. The colour scales vary for the different bulk velocities. The time series movies of the surface deformation are available in the supplementary material (online) available at https://doi.org/10.1017/jfm.2022.774.

$U_b$. The flow moves from left to right. The colour scales vary for the different bulk velocities. The time series movies of the surface deformation are available in the supplementary material (online) available at https://doi.org/10.1017/jfm.2022.774.

Figure 8. (a) Percentage of surface area (coating 1) that is covered with waves where the absolute value of the crest ![]() $|\zeta _c|$ or the valley

$|\zeta _c|$ or the valley ![]() $|\zeta _v|$ is respectively higher or lower than the viscous boundary layer

$|\zeta _v|$ is respectively higher or lower than the viscous boundary layer ![]() $\delta _v$. The dotted line represents the data-fitted sigmoid curve. (b) Table presenting the viscous boundary layer thickness

$\delta _v$. The dotted line represents the data-fitted sigmoid curve. (b) Table presenting the viscous boundary layer thickness ![]() $\delta _v$, the coating surface fluctuation

$\delta _v$, the coating surface fluctuation ![]() $\zeta _{rms}$ (coating 1) and the percentage of

$\zeta _{rms}$ (coating 1) and the percentage of ![]() $|\zeta _c|,|\zeta _v|>\delta _v$ related to the flow conditions.

$|\zeta _c|,|\zeta _v|>\delta _v$ related to the flow conditions.

The height fields ![]() $\zeta (x,y,t)$ of coatings 2 and 3 (not shown) maintain the random-oriented surface pattern with increasing bulk velocity

$\zeta (x,y,t)$ of coatings 2 and 3 (not shown) maintain the random-oriented surface pattern with increasing bulk velocity ![]() $U_b$ up to the maximum bulk velocity in this study. Seemingly, the deformation pattern with the accompanying undulations reduces in size, whereas the wave amplitudes increase with increasing bulk velocity. A more quantitative analysis of the pattern dimensions and wave dynamics is discussed in §§ 3.4 and 3.5, respectively.

$U_b$ up to the maximum bulk velocity in this study. Seemingly, the deformation pattern with the accompanying undulations reduces in size, whereas the wave amplitudes increase with increasing bulk velocity. A more quantitative analysis of the pattern dimensions and wave dynamics is discussed in §§ 3.4 and 3.5, respectively.

3.4. Spatial correlation

The spatial structure of the surface wave is characterised by using the 2D two-point spatial correlation coefficient of the surface height field ![]() $C(r_x,r_y)$, which is defined as

$C(r_x,r_y)$, which is defined as

The ![]() $xy$-correlation maps of coating 1 can be found in Appendix A.3.1. The characteristic wavelength

$xy$-correlation maps of coating 1 can be found in Appendix A.3.1. The characteristic wavelength ![]() $\lambda _x$ in streamwise direction is estimated by analysing the correlation function, where the correlation coefficient equals

$\lambda _x$ in streamwise direction is estimated by analysing the correlation function, where the correlation coefficient equals ![]() $C(r_x,r_y)=C(\lambda _x/6,0)=0.5$. Likewise, the characteristic wave width

$C(r_x,r_y)=C(\lambda _x/6,0)=0.5$. Likewise, the characteristic wave width ![]() $\lambda _y$ in spanwise direction is determined by

$\lambda _y$ in spanwise direction is determined by ![]() $C(r_x,r_y)=C(0,\lambda _y/6)=0.5$. Figure 9 shows the estimated length scales

$C(r_x,r_y)=C(0,\lambda _y/6)=0.5$. Figure 9 shows the estimated length scales ![]() $\lambda _x$ and

$\lambda _x$ and ![]() $\lambda _y$ of the surface deformation of coatings 1, 2 and 3 in relation to the bulk velocity

$\lambda _y$ of the surface deformation of coatings 1, 2 and 3 in relation to the bulk velocity ![]() $U_b$. Initially, coating 1 shows a reduction of the wavelength

$U_b$. Initially, coating 1 shows a reduction of the wavelength ![]() $\lambda _x$ at very low bulk velocities down to

$\lambda _x$ at very low bulk velocities down to ![]() $\lambda _x\sim 15$ mm around

$\lambda _x\sim 15$ mm around ![]() $U_b=2.0\unicode{x2013}2.5 \ {\rm m}\ {\rm s}^{-1}$. This equals the wavelength of the predicted peak response with

$U_b=2.0\unicode{x2013}2.5 \ {\rm m}\ {\rm s}^{-1}$. This equals the wavelength of the predicted peak response with ![]() $\lambda _x=3h_c$, as reported by Kulik, Lee & Chun (Reference Kulik, Lee and Chun2008), Zhang et al. (Reference Zhang, Wang, Blake and Katz2017) and Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019). When the flow velocity increases, the wavelength

$\lambda _x=3h_c$, as reported by Kulik, Lee & Chun (Reference Kulik, Lee and Chun2008), Zhang et al. (Reference Zhang, Wang, Blake and Katz2017) and Benschop et al. (Reference Benschop, Greidanus, Delfos, Westerweel and Breugem2019). When the flow velocity increases, the wavelength ![]() $\lambda _x$ grows linearly up to

$\lambda _x$ grows linearly up to ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$, from where a rapid transition occurs of the wavelength

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$, from where a rapid transition occurs of the wavelength ![]() $\lambda _x$ decreasing again to a wavelength value around

$\lambda _x$ decreasing again to a wavelength value around ![]() $\lambda _x \sim 11$ mm. The characteristic wavelength

$\lambda _x \sim 11$ mm. The characteristic wavelength ![]() $\lambda _x$ of coatings 2 and 3 decreases with increasing bulk velocity, however, the minimum wavelength of coating 2 seems to be restricted to

$\lambda _x$ of coatings 2 and 3 decreases with increasing bulk velocity, however, the minimum wavelength of coating 2 seems to be restricted to ![]() $\lambda _x\sim 15$ mm at high flow velocities (i.e.

$\lambda _x\sim 15$ mm at high flow velocities (i.e. ![]() $\lambda _x/h_c\sim 3$). Regarding the wave width, coating 1 has

$\lambda _x/h_c\sim 3$). Regarding the wave width, coating 1 has ![]() $\lambda _y$ values around

$\lambda _y$ values around ![]() $20\unicode{x2013}25$ mm before the rapid transition of surface deformation, after which the value quickly increases to

$20\unicode{x2013}25$ mm before the rapid transition of surface deformation, after which the value quickly increases to ![]() $\lambda _y \sim 33$ mm. This confirms that the surface deformation pattern and the shape of pre- and post-transition waves are very different. Coatings 2 and 3 show a decreasing wave width

$\lambda _y \sim 33$ mm. This confirms that the surface deformation pattern and the shape of pre- and post-transition waves are very different. Coatings 2 and 3 show a decreasing wave width ![]() $\lambda _y$ with increasing bulk flow velocities.

$\lambda _y$ with increasing bulk flow velocities.

Figure 9. (a) Streamwise ![]() $\lambda _x$ and (b) spanwise

$\lambda _x$ and (b) spanwise ![]() $\lambda _y$ length scales versus bulk velocity

$\lambda _y$ length scales versus bulk velocity ![]() $U_b$.

$U_b$.

Figure 10 presents the scaled characteristic wave parameters ![]() $\lambda _x/h_c$ and

$\lambda _x/h_c$ and ![]() $\lambda _y/h_c$ in relation to the estimated dominant pressure fluctuations over the coating stiffness, i.e.

$\lambda _y/h_c$ in relation to the estimated dominant pressure fluctuations over the coating stiffness, i.e. ![]() $p_{rms}/|G^*|$. In the first part

$p_{rms}/|G^*|$. In the first part ![]() $p_{rms}/|G^*|<0.01$, the results of coating 1, 2 and 3 collapse on a single curve, where the wavelength

$p_{rms}/|G^*|<0.01$, the results of coating 1, 2 and 3 collapse on a single curve, where the wavelength ![]() $\lambda _x/h_c$ decreases with increasing flow velocity. This is identical to the phenomenon where the sizes of the flow structures decrease with increasing Reynolds number

$\lambda _x/h_c$ decreases with increasing flow velocity. This is identical to the phenomenon where the sizes of the flow structures decrease with increasing Reynolds number ![]() $Re_\tau$, such that

$Re_\tau$, such that ![]() $\lambda _x \propto Re_\tau ^{-1}$. This has previously been reported by Perrard et al. (Reference Perrard, Lozano-Durán, Rabaud, Benzaquen and Moisy2019) in the study on the effect of turbulent wind on a liquid surface. Similarly, the nearly isotropic surface pattern is suggested to be created by the cores of the vortices acting on the compliant wall. Nevertheless, figure 10(a) indicates that the values start to deflect from the initial line beyond

$\lambda _x \propto Re_\tau ^{-1}$. This has previously been reported by Perrard et al. (Reference Perrard, Lozano-Durán, Rabaud, Benzaquen and Moisy2019) in the study on the effect of turbulent wind on a liquid surface. Similarly, the nearly isotropic surface pattern is suggested to be created by the cores of the vortices acting on the compliant wall. Nevertheless, figure 10(a) indicates that the values start to deflect from the initial line beyond ![]() $p_{rms}/|G^*|>0.01$, suggesting a different type of coating response to the turbulent flow. This is further discussed in § 3.5.

$p_{rms}/|G^*|>0.01$, suggesting a different type of coating response to the turbulent flow. This is further discussed in § 3.5.

Figure 10. (a) Streamwise ![]() $\lambda _x/h_c$ and (b) spanwise

$\lambda _x/h_c$ and (b) spanwise ![]() $\lambda _y/h_c$ length scales versus

$\lambda _y/h_c$ length scales versus ![]() $p_{rms}/|G^*|$.

$p_{rms}/|G^*|$.

3.5. Spatiotemporal correlation

Height–time diagrams for three flow conditions (coating 1) are visualised in figure 11, namely for bulk velocities ![]() $U_b=3.5$,

$U_b=3.5$, ![]() $4.5$ and

$4.5$ and ![]() $5.4\ {\rm m}\ {\rm s}^{-1}$. The height-time diagrams are compiled by plotting a narrow strip of the surface deformation

$5.4\ {\rm m}\ {\rm s}^{-1}$. The height-time diagrams are compiled by plotting a narrow strip of the surface deformation ![]() $\zeta (x,y,t)$ in the streamwise direction into the

$\zeta (x,y,t)$ in the streamwise direction into the ![]() $(x,t)$-plane, resulting in the surface deformation

$(x,t)$-plane, resulting in the surface deformation ![]() $\zeta (x,t)$ along the middle of the plate. Before the transition at

$\zeta (x,t)$ along the middle of the plate. Before the transition at ![]() $U_b<4.5\ {\rm m}\ {\rm s}^{-1}$ (figure 11a), one type of surface undulations propagate over the interface in streamwise direction. Around the transition velocity, shorter line segments of high amplitude propagate at a considerably lower velocity (figure 11b). These wave packets become more dominant for the higher bulk velocities. It is observed in figure 11(c) that these slow-moving wave packets are bounded by fast-moving low-amplitude waves, which have a propagation velocity similar as the travelling velocity of the coherent flow structures.

$U_b<4.5\ {\rm m}\ {\rm s}^{-1}$ (figure 11a), one type of surface undulations propagate over the interface in streamwise direction. Around the transition velocity, shorter line segments of high amplitude propagate at a considerably lower velocity (figure 11b). These wave packets become more dominant for the higher bulk velocities. It is observed in figure 11(c) that these slow-moving wave packets are bounded by fast-moving low-amplitude waves, which have a propagation velocity similar as the travelling velocity of the coherent flow structures.

Figure 11. Height–time diagrams of the surface deformation ![]() $\zeta (x,t)$ along the middle of the plate in streamwise direction, for bulk velocities (a)

$\zeta (x,t)$ along the middle of the plate in streamwise direction, for bulk velocities (a) ![]() $U_b=3.5\ {\rm m}\ {\rm s}^{-1}$, (b)

$U_b=3.5\ {\rm m}\ {\rm s}^{-1}$, (b) ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ and (c)

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$ and (c) ![]() $U_b=5.4\ {\rm m}\ {\rm s}^{-1}$.

$U_b=5.4\ {\rm m}\ {\rm s}^{-1}$.

The analysis of the spatiotemporal correlation of the surface deformation ![]() $\zeta (x,y,t)$ makes it possible to determine the characteristic propagation velocity of the surface wave

$\zeta (x,y,t)$ makes it possible to determine the characteristic propagation velocity of the surface wave ![]() $c_w$ in relation to the flow conditions. The spatiotemporal correlation

$c_w$ in relation to the flow conditions. The spatiotemporal correlation ![]() $C(r_x,\tau )$ is the spatially and temporally averaged two-time two-point correlation of the surface deformation

$C(r_x,\tau )$ is the spatially and temporally averaged two-time two-point correlation of the surface deformation ![]() $\zeta (x,y,t)$:

$\zeta (x,y,t)$:

The spatiotemporal correlation maps of coating 1 can be found in Appendix A.3.2. In general, the velocity of the propagating waves increases linearly with the bulk velocity, such that ![]() $c_{w_1}=0.7\unicode{x2013}0.8U_b$ (figure 12). This corresponds to the propagation velocity of the highest-intensity turbulent pressure fluctuations high up in the turbulent boundary layer far away from the wall (Willmarth Reference Willmarth1975), which indicates that the pressure fluctuations are responsible for the present surface deformation. Wang et al. (Reference Wang, Koley and Katz2020) reported slightly lower phase velocity of the travelling waves, namely 0.66

$c_{w_1}=0.7\unicode{x2013}0.8U_b$ (figure 12). This corresponds to the propagation velocity of the highest-intensity turbulent pressure fluctuations high up in the turbulent boundary layer far away from the wall (Willmarth Reference Willmarth1975), which indicates that the pressure fluctuations are responsible for the present surface deformation. Wang et al. (Reference Wang, Koley and Katz2020) reported slightly lower phase velocity of the travelling waves, namely 0.66![]() $U_b$. However, the spectral peak of their wavenumber–frequency spectra shifts with increasing bulk velocity to

$U_b$. However, the spectral peak of their wavenumber–frequency spectra shifts with increasing bulk velocity to ![]() $k_x-\omega$ values where the advection velocity of the waves is around

$k_x-\omega$ values where the advection velocity of the waves is around ![]() $0.7\unicode{x2013}0.8U_b$, in agreement with our results.

$0.7\unicode{x2013}0.8U_b$, in agreement with our results.

Figure 12. Propagation velocity of the surface wave ![]() $c_w/U_b$ of coating 1, 2 and 3 as a function of the bulk velocity

$c_w/U_b$ of coating 1, 2 and 3 as a function of the bulk velocity ![]() $U_b$.

$U_b$.

For coating 1, the transition to shorter waves with higher amplitudes modifies the corresponding correlation map of ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$; small wiggles appear around the local maximum of the correlation values. The wave packets start to dominate the coating–fluid interface. The propagation velocity of these waves is significantly lower than the primary waves before transition, namely

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$; small wiggles appear around the local maximum of the correlation values. The wave packets start to dominate the coating–fluid interface. The propagation velocity of these waves is significantly lower than the primary waves before transition, namely ![]() $c_{w_2}\sim 17\,\%$ of

$c_{w_2}\sim 17\,\%$ of ![]() $U_b$. In this velocity regime

$U_b$. In this velocity regime ![]() $U_b>4.5\ {\rm m}\ {\rm s}^{-1}$, the travelling waves on the surface of coating 2 and 3 maintain the propagation velocity similar to the pressure fluctuations of the flow, namely 70–80 % of

$U_b>4.5\ {\rm m}\ {\rm s}^{-1}$, the travelling waves on the surface of coating 2 and 3 maintain the propagation velocity similar to the pressure fluctuations of the flow, namely 70–80 % of ![]() $U_b$.

$U_b$.

The point of deflection of the initial line in figure 10(a) starts around ![]() $p_{rms}/|G^*|\sim 0.01$ that incidentally corresponds with

$p_{rms}/|G^*|\sim 0.01$ that incidentally corresponds with ![]() $c_w/C_t\sim 1$ (figure 13a), i.e. the propagation velocity of the surface waves equals the shear wave velocity of the coating materials. This is in agreement with the theoretical work by Duncan (Reference Duncan1986), where the response of a viscoelastic coating to the pressure fluctuations in a turbulent boundary layer changes at

$c_w/C_t\sim 1$ (figure 13a), i.e. the propagation velocity of the surface waves equals the shear wave velocity of the coating materials. This is in agreement with the theoretical work by Duncan (Reference Duncan1986), where the response of a viscoelastic coating to the pressure fluctuations in a turbulent boundary layer changes at ![]() $U_b/C_t\sim 1.2$. The coating response in this next regime is still considered to be stable, where the wavelength increases with increasing flow velocity; very similar to the surface response of coating 1 in the current study. At

$U_b/C_t\sim 1.2$. The coating response in this next regime is still considered to be stable, where the wavelength increases with increasing flow velocity; very similar to the surface response of coating 1 in the current study. At ![]() $c_w/C_t\sim 1$, the characteristic wavelength equals

$c_w/C_t\sim 1$, the characteristic wavelength equals ![]() $\lambda _x \approx 3h_c$ and grows with increasing flow velocity up to

$\lambda _x \approx 3h_c$ and grows with increasing flow velocity up to ![]() $\lambda _x \approx 4h_c$ at

$\lambda _x \approx 4h_c$ at ![]() $c_w/C_t\sim 2.6$ (i.e. at

$c_w/C_t\sim 2.6$ (i.e. at ![]() $U_b=4.5\ {\rm m}\ {\rm s}^{-1}$).

$U_b=4.5\ {\rm m}\ {\rm s}^{-1}$).

Figure 13. (a) Scaled propagation velocity of surface wave ![]() $c_w/C_t$ of coatings 1, 2 and 3 as a function of the scaled wavelength