1. Introduction

Riblets are streamwise-aligned grooves on a surface that modify wall-bounded turbulent flow. Depending on their viscous–friction-scaled size, riblets can reduce or increase drag compared with a smooth wall. Viscous–friction scaling, denoted in this study by a ‘![]() $+$’ superscript, employs the kinematic viscosity

$+$’ superscript, employs the kinematic viscosity ![]() $\nu$ and mean friction velocity

$\nu$ and mean friction velocity ![]() $u_\tau \equiv \sqrt {\tau _w/\rho }$ with constant fluid density

$u_\tau \equiv \sqrt {\tau _w/\rho }$ with constant fluid density ![]() $\rho$ and mean wall-shear stress (drag per unit plan area)

$\rho$ and mean wall-shear stress (drag per unit plan area) ![]() $\tau _w$. The flow over riblets has been investigated extensively in laboratory experiments (e.g. Walsh & Weinstein Reference Walsh and Weinstein1978; Suzuki & Kasagi Reference Suzuki and Kasagi1994; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997; Lee & Lee Reference Lee and Lee2001), numerical simulations (e.g. Choi, Moin & Kim Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Goldstein & Tuan Reference Goldstein and Tuan1998; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011b; Endrikat et al. Reference Endrikat, Modesti, MacDonald, García-Mayoral, Hutchins and Chung2021b) and model calculations (e.g. Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991; Tullis & Pollard Reference Tullis and Pollard1993; Chavarin & Luhar Reference Chavarin and Luhar2019; Ran, Zare & Jovanović Reference Ran, Zare and Jovanović2021).

$\tau _w$. The flow over riblets has been investigated extensively in laboratory experiments (e.g. Walsh & Weinstein Reference Walsh and Weinstein1978; Suzuki & Kasagi Reference Suzuki and Kasagi1994; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997; Lee & Lee Reference Lee and Lee2001), numerical simulations (e.g. Choi, Moin & Kim Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Goldstein & Tuan Reference Goldstein and Tuan1998; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011b; Endrikat et al. Reference Endrikat, Modesti, MacDonald, García-Mayoral, Hutchins and Chung2021b) and model calculations (e.g. Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991; Tullis & Pollard Reference Tullis and Pollard1993; Chavarin & Luhar Reference Chavarin and Luhar2019; Ran, Zare & Jovanović Reference Ran, Zare and Jovanović2021).

1.1. Large drag-increasing and imperfectly repeated riblets

So far, most studies primarily focused on the drag-reducing regime of small and perfectly repeated riblets, that is, in near-optimal conditions. Off-design conditions are less studied. Large riblets constitute a limiting case of wall roughness and imperfectly repeated riblets challenge the physical ideas behind models that estimate the drag change or an equivalent boundary condition. We analyse these two off-design conditions: large drag-increasing and imperfectly repeated riblets.

One recent study on drag-increasing riblets that are very large in viscous–friction scaling is by Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020), who acquired channel flow pressure-drop measurements in air for trapezoidal riblets with spacings ![]() $8 \lesssim s^+ \lesssim 111$. They observe that riblets appear to exhibit a fully rough behaviour for only a finite range of sizes, beyond which the drag curve peels off from the expected fully rough asymptote. Local hot-wire measurements inside the riblet groove, which revealed how very large riblets interact with the flow, were first reported by Newton, Chung & Hutchins (Reference Newton, Chung and Hutchins2018).

$8 \lesssim s^+ \lesssim 111$. They observe that riblets appear to exhibit a fully rough behaviour for only a finite range of sizes, beyond which the drag curve peels off from the expected fully rough asymptote. Local hot-wire measurements inside the riblet groove, which revealed how very large riblets interact with the flow, were first reported by Newton, Chung & Hutchins (Reference Newton, Chung and Hutchins2018).

Two-scale (also called ‘brother-and-sister’) riblets were initially devised for improved maximum drag reduction, but the oil-channel experiments by Bruse et al. (Reference Bruse, Bechert, von der Hoeven, Hage and Hoppe1993) showed that they have roughly the same minimum skin friction as single-scale riblets. We revisit two-scale riblets starting at sizes around the drag optimum as an idealisation of imperfectly repeated riblets towards estimating the drag performance due to manufacturing inaccuracies such as varying riblet heights. Possible manufacturing techniques are limited by difficulties in fabricating a large area of accurately repeated riblets with minimal variation (West, Sammut & Tang Reference West, Sammut and Tang2018), but accepting a lower quality makes manufacturing faster and more economical (Kaakkunen et al. Reference Kaakkunen, Tiainen, Jaatinen-Värri, Grönman and Lohtander2018). Tiainen et al. (Reference Tiainen, Grönman, Jaatinen-Värri and Pyy2020) measured shape variation statistics of imperfect riblets manufactured with nanosecond laser ablation on a curved airfoil. Their riblet heights are in the range ![]() $0.71\unicode{x2013}1.28$ times the nominal height and they verified in laboratory experiments that the surface nevertheless reduces drag. Without costly drag measurements, however, a priori model estimates of the expected drag or optimal riblet size for given flow conditions assume ideally repeated riblets with a well-defined cross-sectional area, for which the drag reduction relative to a smooth wall follows a near-universal curve (as shown by García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011a). A more accurate drag estimate based on geometry statistics would provide confidence that riblets manufactured with a given technique could reduce drag in full-scale applications without the need for high-fidelity data.

$0.71\unicode{x2013}1.28$ times the nominal height and they verified in laboratory experiments that the surface nevertheless reduces drag. Without costly drag measurements, however, a priori model estimates of the expected drag or optimal riblet size for given flow conditions assume ideally repeated riblets with a well-defined cross-sectional area, for which the drag reduction relative to a smooth wall follows a near-universal curve (as shown by García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011a). A more accurate drag estimate based on geometry statistics would provide confidence that riblets manufactured with a given technique could reduce drag in full-scale applications without the need for high-fidelity data.

1.2. Outer-layer similarity and the roughness function

Most roughness as well as drag-reducing riblets only modify turbulence in a region close to the surface termed the roughness sublayer. One common measure of the roughness-sublayer height is the inhomogeneity of the mean flow (e.g. Raupach, Thom & Edwards Reference Raupach, Thom and Edwards1980; Pokrajac et al. Reference Pokrajac, Finnigan, Manes, McEwan and Nikora2006; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Sharma & García-Mayoral Reference Sharma and García-Mayoral2020). Any measure of the roughness-sublayer height depends on the flow quantity, but it generally scales with the element spacing rather than the element height (Raupach et al. Reference Raupach, Thom and Edwards1980; Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991), as further supported by direct numerical simulations (DNS) of spanwise-aligned bars (MacDonald et al. Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) and post arrays (Sharma & García-Mayoral Reference Sharma and García-Mayoral2020). For riblets, Modesti et al. (Reference Modesti, Endrikat, Hutchins and Chung2021) find that the roughness sublayer of mean secondary (spanwise inhomogeneous) flows extends to a height of about ![]() $0.5s$ above the virtual origin of turbulence or, equivalently, the zero-plane displacement (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is consistent with the study of sinusoidal roughness by Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018). Higher-order statistics may be affected up to greater heights.

$0.5s$ above the virtual origin of turbulence or, equivalently, the zero-plane displacement (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is consistent with the study of sinusoidal roughness by Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018). Higher-order statistics may be affected up to greater heights.

The outer layer of the flow above the roughness sublayer, however, is similar to that above a smooth wall and the logarithmic layer, which is common to the inner and the outer layer, has a slope that is characterised by the same von Kármán constant ![]() $\kappa \approx 0.40$ for both rough and smooth walls. This similarity is a consequence of Townsend's (Reference Townsend1956) hypothesis applied to the flow over relatively small roughness (for which the boundary-layer thickness

$\kappa \approx 0.40$ for both rough and smooth walls. This similarity is a consequence of Townsend's (Reference Townsend1956) hypothesis applied to the flow over relatively small roughness (for which the boundary-layer thickness ![]() $\delta$ far exceeds the roughness or riblet height

$\delta$ far exceeds the roughness or riblet height ![]() $k$ and the friction Reynolds number is high). Contrarily, the hot-wire velocity profiles by Newton et al. (Reference Newton, Chung and Hutchins2018) suggest that very large riblets modify the mean velocity also in the outer layer, although their conclusions are burdened by uncertainties about the friction velocity. Without outer-layer similarity, the roughness function

$k$ and the friction Reynolds number is high). Contrarily, the hot-wire velocity profiles by Newton et al. (Reference Newton, Chung and Hutchins2018) suggest that very large riblets modify the mean velocity also in the outer layer, although their conclusions are burdened by uncertainties about the friction velocity. Without outer-layer similarity, the roughness function ![]() $U^+_{smooth} - U^+$ does not have a constant value

$U^+_{smooth} - U^+$ does not have a constant value ![]() ${\rm \Delta} U^+$ throughout the logarithmic layer. A constant

${\rm \Delta} U^+$ throughout the logarithmic layer. A constant ![]() ${\rm \Delta} U^+$ permits full-scale predictions from scaled experiments or simulations (Flack & Schultz Reference Flack and Schultz2014; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021) by encapsulating the drag difference between two surfaces (Hama Reference Hama1954; Clauser Reference Clauser1956), which is supposedly independent of the outer Reynolds number (Spalart & McLean Reference Spalart and McLean2011; García-Mayoral, Gómez-de-Segura & Fairhall Reference García-Mayoral, Gómez-de-Segura and Fairhall2019).

${\rm \Delta} U^+$ permits full-scale predictions from scaled experiments or simulations (Flack & Schultz Reference Flack and Schultz2014; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021) by encapsulating the drag difference between two surfaces (Hama Reference Hama1954; Clauser Reference Clauser1956), which is supposedly independent of the outer Reynolds number (Spalart & McLean Reference Spalart and McLean2011; García-Mayoral, Gómez-de-Segura & Fairhall Reference García-Mayoral, Gómez-de-Segura and Fairhall2019).

A lack of outer-layer similarity, either in the mean or fluctuations, has been reported over non-transitionally rough porous surfaces (Manes, Poggi & Ridolfi Reference Manes, Poggi and Ridolfi2011), large-pitch transverse bars (Krogstadt & Antonia Reference Krogstadt and Antonia1999; Krogstad & Efros Reference Krogstad and Efros2012; Flack & Schultz Reference Flack and Schultz2014) and wavy roughness (Napoli, Armenio & De Marchis Reference Napoli, Armenio and De Marchis2008; Schultz & Flack Reference Schultz and Flack2009; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021), among others. In some of these cases (Krogstad & Efros Reference Krogstad and Efros2012; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021), outer-layer similarity has been recovered with an even larger scale separation than the oft-quoted ![]() $\delta /k \gg 40$ (Jiménez Reference Jiménez2004). One way to understand the stricter criterion for recovery is the presence of a much larger length scale than

$\delta /k \gg 40$ (Jiménez Reference Jiménez2004). One way to understand the stricter criterion for recovery is the presence of a much larger length scale than ![]() $k$, such as pitch or wavelength of waviness, which sets the size of the roughness sublayer that is correspondingly much larger than the oft-quoted

$k$, such as pitch or wavelength of waviness, which sets the size of the roughness sublayer that is correspondingly much larger than the oft-quoted ![]() $2k$–

$2k$–![]() $3k$ (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Notably, for the riblets of Newton et al. (Reference Newton, Chung and Hutchins2018), the largest length scale of the surface is

$3k$ (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Notably, for the riblets of Newton et al. (Reference Newton, Chung and Hutchins2018), the largest length scale of the surface is ![]() $s=2k$ and the mean-flow inhomogeneity is confined to

$s=2k$ and the mean-flow inhomogeneity is confined to ![]() $0.5s=0.5(2k)=k \lesssim \delta /47$ (based on Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

$0.5s=0.5(2k)=k \lesssim \delta /47$ (based on Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

1.3. Outline

In the present study we extend the analysis of Newton et al. (Reference Newton, Chung and Hutchins2018) and mitigate uncertainties related to the friction velocity by employing a drag balance together with hot-wire measurements (§ 2.1) and combining this with DNS at a comparatively low friction Reynolds number, but with accurately measured friction velocities (§ 2.2).

In § 3.1 we observe a depletion of large-scale energy in hot-wire spectra even at heights above riblet-induced mean-flow inhomogeneity (§ 3.2). Combining hot-wire and DNS data sets gives us confidence that the present large ![]() $s^+$ riblets modify the statistically spanwise uniform mean flow in the logarithmic layer (§ 3.3) despite the large scale separation

$s^+$ riblets modify the statistically spanwise uniform mean flow in the logarithmic layer (§ 3.3) despite the large scale separation ![]() $\delta \gg k$ and a high friction Reynolds number. We propose an explanation in § 3.4. The investigation of turbulence also inside of large riblet grooves leads to a model for the average crest (slip) velocity in § 3.5, that can be used to crudely estimate

$\delta \gg k$ and a high friction Reynolds number. We propose an explanation in § 3.4. The investigation of turbulence also inside of large riblet grooves leads to a model for the average crest (slip) velocity in § 3.5, that can be used to crudely estimate ![]() ${\rm \Delta} U^+$. In § 4 two-scale riblets allow us to also investigate effects of spanwise variations of riblet surfaces on the drag curve. We propose a method for estimating the optimal size of imperfectly manufactured riblets with negligible computational cost, that builds on the hydraulic length

${\rm \Delta} U^+$. In § 4 two-scale riblets allow us to also investigate effects of spanwise variations of riblet surfaces on the drag curve. We propose a method for estimating the optimal size of imperfectly manufactured riblets with negligible computational cost, that builds on the hydraulic length ![]() $\ell _H$ from García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011b)

$\ell _H$ from García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011b)

Throughout this paper, ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ refer to the streamwise, spanwise and wall-normal directions with corresponding velocity components

$z$ refer to the streamwise, spanwise and wall-normal directions with corresponding velocity components ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$.

$w$.

2. Experimental and numerical set-ups

2.1. Hot-wire anemometry in boundary layers

Experiments were performed in an open-return boundary-layer wind tunnel in the Walter Bassett Aerodynamics lab at the University of Melbourne. The test section has dimensions ![]() $5.7\,{\rm m} \times 0.94\,{\rm m} \times 0.38$ m (streamwise

$5.7\,{\rm m} \times 0.94\,{\rm m} \times 0.38$ m (streamwise ![]() $\times$ spanwise

$\times$ spanwise ![]() $\times$ wall normal) with measurements made in the boundary layer developed over the lower surface. Full details of this facility are available in Harun et al. (Reference Harun, Monty, Mathis and Marusic2013). The test surface comprises of two

$\times$ wall normal) with measurements made in the boundary layer developed over the lower surface. Full details of this facility are available in Harun et al. (Reference Harun, Monty, Mathis and Marusic2013). The test surface comprises of two ![]() $1.89\,{\rm m} \times 0.94\,{\rm m}$ (streamwise

$1.89\,{\rm m} \times 0.94\,{\rm m}$ (streamwise ![]() $\times$ spanwise) and three

$\times$ spanwise) and three ![]() $0.63\,{\rm m} \times 0.94\,{\rm m}$ tiles of acetal copolymer into which the trapezoidal riblet geometry with

$0.63\,{\rm m} \times 0.94\,{\rm m}$ tiles of acetal copolymer into which the trapezoidal riblet geometry with ![]() $s/k = 2$, tip angle

$s/k = 2$, tip angle ![]() $\alpha = 30^\circ$ and

$\alpha = 30^\circ$ and ![]() $s = 2.73$ mm (figure 1a) is machined using a custom made trapezoidal end mill. The boundary layer is tripped with a strip of P36 grit sandpaper at the inlet to the working section where the riblet surface starts and all measurements are made

$s = 2.73$ mm (figure 1a) is machined using a custom made trapezoidal end mill. The boundary layer is tripped with a strip of P36 grit sandpaper at the inlet to the working section where the riblet surface starts and all measurements are made ![]() $4$ m downstream of this trip. For the present cases, the flow adjusts to the riblet surface over a streamwise distance of about

$4$ m downstream of this trip. For the present cases, the flow adjusts to the riblet surface over a streamwise distance of about ![]() $50\unicode{x2013}60$ times the boundary-layer thickness before reaching the measurement location. Nominally zero pressure gradient conditions are established by adjusting the flexible perspex ceiling of the working section. Static pressure taps located every

$50\unicode{x2013}60$ times the boundary-layer thickness before reaching the measurement location. Nominally zero pressure gradient conditions are established by adjusting the flexible perspex ceiling of the working section. Static pressure taps located every ![]() ${\rm \Delta} x = 0.5$ m (between streamwise distance

${\rm \Delta} x = 0.5$ m (between streamwise distance ![]() $x=0$ m and

$x=0$ m and ![]() $x=5.5$ m) along the ceiling are used to measure the local pressure difference

$x=5.5$ m) along the ceiling are used to measure the local pressure difference ![]() ${\rm \Delta} p = p_0 - p$, where

${\rm \Delta} p = p_0 - p$, where ![]() $p_0$ is the local static pressure at

$p_0$ is the local static pressure at ![]() $x = 0$ (the entrance to the working section), from which the pressure coefficient

$x = 0$ (the entrance to the working section), from which the pressure coefficient ![]() $C_p$ is computed (

$C_p$ is computed (![]() $\equiv 2{\rm \Delta} p/\rho U_\infty ^2$, where

$\equiv 2{\rm \Delta} p/\rho U_\infty ^2$, where ![]() $U_\infty$ is the free-stream velocity and

$U_\infty$ is the free-stream velocity and ![]() $\rho$ is the air density). For all measurements reported here (riblet surfaces with

$\rho$ is the air density). For all measurements reported here (riblet surfaces with ![]() $U_\infty \in [5, 25]\,{\rm m}\,{\rm s}^{-1}$ in table 1),

$U_\infty \in [5, 25]\,{\rm m}\,{\rm s}^{-1}$ in table 1), ![]() $C_p = 0 \pm 0.06$.

$C_p = 0 \pm 0.06$.

Table 1. Wind tunnel and flow parameters for the hot-wire measurements. For all cases, the spacing-to-height ratio of the riblets is ![]() $s/k=2$ and the tip angle

$s/k=2$ and the tip angle ![]() $\alpha =30^\circ$. The mean friction velocity

$\alpha =30^\circ$. The mean friction velocity ![]() $u_\tau$ is measured using a drag balance. The 99 % boundary-layer thickness

$u_\tau$ is measured using a drag balance. The 99 % boundary-layer thickness ![]() $\delta ^\prime _{99}$ is measured from the virtual origin, here assumed to be

$\delta ^\prime _{99}$ is measured from the virtual origin, here assumed to be ![]() $\ell _t=k/2$ below the riblet crest. The etched (active) length of the hot wire is

$\ell _t=k/2$ below the riblet crest. The etched (active) length of the hot wire is ![]() $l=0.5\,{\rm mm}$.

$l=0.5\,{\rm mm}$.

Boundary-layer profiles are acquired using hot-wire anemometry above both the crest and trough of the riblet geometry (figure 1). Each profile consists of measurements at ![]() $50$ logarithmically spaced wall-normal locations

$50$ logarithmically spaced wall-normal locations ![]() $z$. For the measurements over the trough, the wall-normal starting position for the traverse is below the roughness crest. A modified Dantec 55P05 probe has Wollaston wire with

$z$. For the measurements over the trough, the wall-normal starting position for the traverse is below the roughness crest. A modified Dantec 55P05 probe has Wollaston wire with ![]() $2.5\,\mathrm {\mu }$m diameter platinum core soldered across the probe tips. The 0.5 mm (

$2.5\,\mathrm {\mu }$m diameter platinum core soldered across the probe tips. The 0.5 mm (![]() ${\approx }0.18s$) active sensor length is exposed by etching the silver jacket using nitric acid solution, yielding a length-to-diameter ratio of 200 (as recommended by Ligrani & Bradshaw Reference Ligrani and Bradshaw1987). Since the same probe was used at all free-stream velocities, the viscous-scaled sensor length

${\approx }0.18s$) active sensor length is exposed by etching the silver jacket using nitric acid solution, yielding a length-to-diameter ratio of 200 (as recommended by Ligrani & Bradshaw Reference Ligrani and Bradshaw1987). Since the same probe was used at all free-stream velocities, the viscous-scaled sensor length ![]() $l^+$ increases with

$l^+$ increases with ![]() $U_\infty$ (see table 1). Possible spanwise positioning errors over the crest and trough, and also uncertainty in the etched sensor length

$U_\infty$ (see table 1). Possible spanwise positioning errors over the crest and trough, and also uncertainty in the etched sensor length ![]() $l$, are explored in the Appendix. The hot-wire probe is operated in constant temperature mode with an overheat ratio of

$l$, are explored in the Appendix. The hot-wire probe is operated in constant temperature mode with an overheat ratio of ![]() $1.8$ using an in-house designed Melbourne University constant temperature anemometer (MUCTA). The fluctuating voltage signal output from the MUCTA is sampled at a frequency

$1.8$ using an in-house designed Melbourne University constant temperature anemometer (MUCTA). The fluctuating voltage signal output from the MUCTA is sampled at a frequency ![]() $f=50$ kHz yielding a viscous-scaled sample interval

$f=50$ kHz yielding a viscous-scaled sample interval ![]() $0.05 \lesssim {\rm \Delta} t^+ \lesssim 1.16$ for the range of

$0.05 \lesssim {\rm \Delta} t^+ \lesssim 1.16$ for the range of ![]() $5 < U_\infty < 25\,{\rm m}\,{\rm s}^{-1}$, where

$5 < U_\infty < 25\,{\rm m}\,{\rm s}^{-1}$, where ![]() ${\rm \Delta} t^+ = u_\tau ^2 / (f \nu )$, to ensure adequate resolution of the highest frequencies. Adequate convergence of low frequency turbulent energy (following Hutchins et al. Reference Hutchins, Nickels, Marusic and Chong2009) is achieved with a sampling duration

${\rm \Delta} t^+ = u_\tau ^2 / (f \nu )$, to ensure adequate resolution of the highest frequencies. Adequate convergence of low frequency turbulent energy (following Hutchins et al. Reference Hutchins, Nickels, Marusic and Chong2009) is achieved with a sampling duration ![]() $T$ of

$T$ of ![]() $150s$, which corresponds to

$150s$, which corresponds to ![]() $11\,000 \lesssim T U_\infty / \delta ^\prime _{99} \lesssim 58\,000$ for the present range of free-stream velocities. The hot-wire sensor is calibrated in situ prior to and after each boundary layer traverse by positioning the hot wire in the free stream of the flow adjacent to a Pitot-static tube. Calibration coefficients are obtained by fitting a third-order polynomial to the mean voltage from the MUCTA and Pitot-static tube measured velocity. During the boundary layer traverse experiment, temperature-based interpolation is applied between pre- and post-calibration curves to compensate for any temperature drift. The time average of the acquired streamwise velocity at two

$11\,000 \lesssim T U_\infty / \delta ^\prime _{99} \lesssim 58\,000$ for the present range of free-stream velocities. The hot-wire sensor is calibrated in situ prior to and after each boundary layer traverse by positioning the hot wire in the free stream of the flow adjacent to a Pitot-static tube. Calibration coefficients are obtained by fitting a third-order polynomial to the mean voltage from the MUCTA and Pitot-static tube measured velocity. During the boundary layer traverse experiment, temperature-based interpolation is applied between pre- and post-calibration curves to compensate for any temperature drift. The time average of the acquired streamwise velocity at two ![]() $y$ positions is denoted by

$y$ positions is denoted by ![]() $U(y,z)$. When comparing to a smooth-wall flow, the (virtual) origin of

$U(y,z)$. When comparing to a smooth-wall flow, the (virtual) origin of ![]() $z$ is required, which we denote to be

$z$ is required, which we denote to be ![]() $\ell _t$ below the riblet tips (figure 1a). We generally consider all locations between the groove bottom and riblet crest, but arbitrarily assume

$\ell _t$ below the riblet tips (figure 1a). We generally consider all locations between the groove bottom and riblet crest, but arbitrarily assume ![]() $\ell _t=k/2$ to show profiles for only one realistic origin in some figures, as done by, for example, Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b) for hot-wire measurements above sandpaper roughness. The assumption is employed for figures 3, 4, 8, 9 and 11, but does affect any conclusions drawn based on them.

$\ell _t=k/2$ to show profiles for only one realistic origin in some figures, as done by, for example, Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b) for hot-wire measurements above sandpaper roughness. The assumption is employed for figures 3, 4, 8, 9 and 11, but does affect any conclusions drawn based on them.

Figure 1. (a) Cross-sectional sketch of the riblet surface in the wind tunnel. The shaded areas indicate the spanwise extent and two locations of the active sensor of the hot-wire probe as it traverses in the wall-normal direction. (b) Sketch of the test section with the riblet surface and drag balance consisting of a floating element, an arm with its pivot and a digital scale.

The mean friction velocity ![]() $u_\tau$ is measured using a custom designed cantilever type drag balance of a similar design to that described in Krogstad & Efros (Reference Krogstad and Efros2010). This device has a long moment arm (0.4 m) to maximise sensitivity to the wall-shear stress and minimise sensitivity to any normal forces due to local pressure gradients in the facility. Wall-shear stress was measured on a floating element of size

$u_\tau$ is measured using a custom designed cantilever type drag balance of a similar design to that described in Krogstad & Efros (Reference Krogstad and Efros2010). This device has a long moment arm (0.4 m) to maximise sensitivity to the wall-shear stress and minimise sensitivity to any normal forces due to local pressure gradients in the facility. Wall-shear stress was measured on a floating element of size ![]() $0.43\,{\rm m} \times 0.29\,{\rm m}$ with either a smooth or riblet surface. The gap width surrounding this floating element was

$0.43\,{\rm m} \times 0.29\,{\rm m}$ with either a smooth or riblet surface. The gap width surrounding this floating element was ![]() ${<}1$ mm throughout, and the use of a restorative balance ensured that this gap does not change with

${<}1$ mm throughout, and the use of a restorative balance ensured that this gap does not change with ![]() $U_\infty$. The upstream and downstream edges of the floating element tile are chamfered (undercut) to minimise moments due to pressure forces at the gaps. The drag balance is validated for the smooth surface, with the balance-measured results exhibiting agreement with

$U_\infty$. The upstream and downstream edges of the floating element tile are chamfered (undercut) to minimise moments due to pressure forces at the gaps. The drag balance is validated for the smooth surface, with the balance-measured results exhibiting agreement with ![]() $u_\tau$ obtained from Clauser fitted profiles to within

$u_\tau$ obtained from Clauser fitted profiles to within ![]() $\pm$2 % when

$\pm$2 % when ![]() $U_\infty \approx 5\,{\rm m}\,{\rm s}^{-1}$, improving to

$U_\infty \approx 5\,{\rm m}\,{\rm s}^{-1}$, improving to ![]() $\pm$0.2 % when

$\pm$0.2 % when ![]() $U_\infty \approx 25\,{\rm m}\,{\rm s}^{-1}$.

$U_\infty \approx 25\,{\rm m}\,{\rm s}^{-1}$.

2.2. Direct numerical simulations of minimal-channel flow

We conduct DNS of turbulent and fully developed open channel flow to obtain the flow field over riblets with varying spacing ![]() $s^+$ at friction Reynolds numbers of

$s^+$ at friction Reynolds numbers of ![]() $\delta ^+ \equiv \delta u_{\tau }/\nu = 395$ and

$\delta ^+ \equiv \delta u_{\tau }/\nu = 395$ and ![]() $\delta ^+=1000$ (table 2). Here,

$\delta ^+=1000$ (table 2). Here, ![]() $\delta = z_\delta - z_m$ is the cross-sectional area per channel width, i.e. the half-channel height measured from the riblet mean height

$\delta = z_\delta - z_m$ is the cross-sectional area per channel width, i.e. the half-channel height measured from the riblet mean height ![]() $z_m$ (figure 2). Our data set comprises single-scale trapezoidal riblets with a tip angle

$z_m$ (figure 2). Our data set comprises single-scale trapezoidal riblets with a tip angle ![]() $\alpha =30^\circ$ (case names TA

$\alpha =30^\circ$ (case names TA![]() $s^+$) and two-scale trapezoidal riblets (TM

$s^+$) and two-scale trapezoidal riblets (TM![]() $s^+$) that have one additional half-sized riblet with the same tip angle in the centre of the groove. We previously analysed parts of this data set in (Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). The numerical domain is sketched in figure 2 and geometrical parameters including domain extents are given in table 2. Simulations of smooth-wall flow at matching friction Reynolds numbers serve as a common reference.

$s^+$) that have one additional half-sized riblet with the same tip angle in the centre of the groove. We previously analysed parts of this data set in (Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). The numerical domain is sketched in figure 2 and geometrical parameters including domain extents are given in table 2. Simulations of smooth-wall flow at matching friction Reynolds numbers serve as a common reference.

Table 2. Simulation parameters for the single-scale (TA) and multi-scale (TM) riblet configurations and smooth wall (S) reference flow. Riblet spacing ![]() $s^+$, heights

$s^+$, heights ![]() $k^+$ and

$k^+$ and ![]() $k_1^+$ and sizes

$k_1^+$ and sizes ![]() $\ell _g^+$ (square root of the groove cross-sectional area) and

$\ell _g^+$ (square root of the groove cross-sectional area) and ![]() $\ell _{g,i}^+$ (figure 12 for

$\ell _{g,i}^+$ (figure 12 for ![]() $k_1/k=\{0, 0.5\}$). Mesh spacings

$k_1/k=\{0, 0.5\}$). Mesh spacings ![]() $\Delta$ and domain extents

$\Delta$ and domain extents ![]() $L$. The half-channel height

$L$. The half-channel height ![]() $\delta ^+=L_z^+$ is measured from the riblet mean height and

$\delta ^+=L_z^+$ is measured from the riblet mean height and ![]() $\delta ^{\prime +}$ from the virtual origin (here assumed

$\delta ^{\prime +}$ from the virtual origin (here assumed ![]() $\ell _t=k/2$ below the riblet tips). The total averaging time following initial discarded transients

$\ell _t=k/2$ below the riblet tips). The total averaging time following initial discarded transients ![]() $L_t$ determines the statistical uncertainty

$L_t$ determines the statistical uncertainty ![]() $\zeta ^+$ of

$\zeta ^+$ of ![]() ${\rm \Delta} U^+$ (MacDonald et al. Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017). The drag change

${\rm \Delta} U^+$ (MacDonald et al. Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017). The drag change ![]() ${\rm \Delta} U^+$ is measured at the critical height

${\rm \Delta} U^+$ is measured at the critical height ![]() $z_c^+=0.4 L_y^+$ of these minimal-span channels. Statistical convergence is measured by

$z_c^+=0.4 L_y^+$ of these minimal-span channels. Statistical convergence is measured by ![]() $\varepsilon ^{\prime +}$, the average error of the streamwise mean momentum balance (Vinuesa et al. Reference Vinuesa, Prus, Schlatter and Nagib2016) above the highest riblet crest.

$\varepsilon ^{\prime +}$, the average error of the streamwise mean momentum balance (Vinuesa et al. Reference Vinuesa, Prus, Schlatter and Nagib2016) above the highest riblet crest.

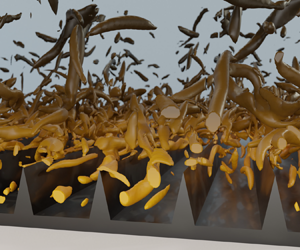

Figure 2. (a) Spanwise-minimal numerical domain of case TA50, which has five riblets with ![]() $s^+=50$ across the span. (b) Sketch illustrating the wall-normal coordinate with the bottom of the groove

$s^+=50$ across the span. (b) Sketch illustrating the wall-normal coordinate with the bottom of the groove ![]() $z=z_b$, the mean height

$z=z_b$, the mean height ![]() $z=z_m$, the virtual origin

$z=z_m$, the virtual origin ![]() $z=0$ and the riblet tips

$z=0$ and the riblet tips ![]() $z=z_t$. The half-channel height

$z=z_t$. The half-channel height ![]() $\delta$ is measured from the mean height and

$\delta$ is measured from the mean height and ![]() $\delta ^\prime$ from the virtual origin,

$\delta ^\prime$ from the virtual origin, ![]() $\ell _t$ below the tips.

$\ell _t$ below the tips.

The Navier–Stokes equations for an incompressible fluid

are solved using the finite volume code Cliff by Cascade Technologies Inc. (Ham, Mattsson & Iaccarino Reference Ham, Mattsson and Iaccarino2006; Ham et al. Reference Ham, Mattsson, Iaccarino and Moin2007). The velocity ![]() $\boldsymbol {u}$ has components

$\boldsymbol {u}$ has components ![]() $(u,v,w)$ in the streamwise (

$(u,v,w)$ in the streamwise (![]() $x$), spanwise (

$x$), spanwise (![]() $y$) and wall-normal (

$y$) and wall-normal (![]() $z$) direction and time is

$z$) direction and time is ![]() $t$. A constant pressure gradient

$t$. A constant pressure gradient ![]() $\mathrm {d}P/\mathrm {d}\kern0.7pt x$ drives the flow in the streamwise direction indicated by

$\mathrm {d}P/\mathrm {d}\kern0.7pt x$ drives the flow in the streamwise direction indicated by ![]() ${\boldsymbol {e}}_{\boldsymbol {x}}$ and

${\boldsymbol {e}}_{\boldsymbol {x}}$ and ![]() $p$ is the fluctuating component of pressure that we solve for.

$p$ is the fluctuating component of pressure that we solve for.

Figure 3. Spectra of the turbulent component of streamwise velocity fluctuations (normalised by ![]() $u_\tau ^2$ and premultiplied by the wavenumber

$u_\tau ^2$ and premultiplied by the wavenumber ![]() $k_x^+$) with contour levels at

$k_x^+$) with contour levels at ![]() $k_x^+ E_{uu}^{x+}=(0.2,0.4,0.6,0.8,1)$ for three riblet sizes at two spanwise positions: in the groove centre (a,c,e) and above the riblet tips (b,d,f). Contours (blue) are for hot-wire riblet data and red lines for DNS (drawn up to

$k_x^+ E_{uu}^{x+}=(0.2,0.4,0.6,0.8,1)$ for three riblet sizes at two spanwise positions: in the groove centre (a,c,e) and above the riblet tips (b,d,f). Contours (blue) are for hot-wire riblet data and red lines for DNS (drawn up to ![]() $z_c$). Bottom axes are normalised by the riblet height. Top axes show

$z_c$). Bottom axes are normalised by the riblet height. Top axes show ![]() $z^+-z_b^+$ for each hot-wire riblet case. For smooth-wall hot-wire contour lines (grey),

$z^+-z_b^+$ for each hot-wire riblet case. For smooth-wall hot-wire contour lines (grey), ![]() $z$ is normalised by

$z$ is normalised by ![]() $k$ from the matching hot-wire riblet case and the origin is assumed at

$k$ from the matching hot-wire riblet case and the origin is assumed at ![]() $(z-z_b)/k=0.5$. Smooth-wall spectra in (a–d) were recorded during the campaign by Wangsawijaya et al. (Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020) in the same facility as the present riblet cases and smooth-wall spectra in (e,f) are from Chandran et al. (Reference Chandran, Baidya, Monty and Marusic2017). Vertical dotted lines mark the riblet crest. Dashed lines represent

$(z-z_b)/k=0.5$. Smooth-wall spectra in (a–d) were recorded during the campaign by Wangsawijaya et al. (Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020) in the same facility as the present riblet cases and smooth-wall spectra in (e,f) are from Chandran et al. (Reference Chandran, Baidya, Monty and Marusic2017). Vertical dotted lines mark the riblet crest. Dashed lines represent ![]() $\lambda _x=30z$ for

$\lambda _x=30z$ for ![]() $z_t < z < \delta _{99}^\prime$. Arrows label a region of reduced energy around

$z_t < z < \delta _{99}^\prime$. Arrows label a region of reduced energy around ![]() $\lambda _x \approx 5\delta _{99}^\prime$.

$\lambda _x \approx 5\delta _{99}^\prime$.

Figure 4. Energy of large-scale motions ![]() $\lambda _x \gtrsim 30z$ (integrated above the dashed line in figure 3e) that are damped by riblets relative to smooth-wall flow (Chandran et al. Reference Chandran, Baidya, Monty and Marusic2017) and sandpaper roughness (Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b, case with

$\lambda _x \gtrsim 30z$ (integrated above the dashed line in figure 3e) that are damped by riblets relative to smooth-wall flow (Chandran et al. Reference Chandran, Baidya, Monty and Marusic2017) and sandpaper roughness (Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b, case with ![]() $k_s^+=22$). Only showing the spanwise location above the riblet groove centre, starting at the height of the crest. Assuming a virtual origin with

$k_s^+=22$). Only showing the spanwise location above the riblet groove centre, starting at the height of the crest. Assuming a virtual origin with ![]() $\ell _t=k/2$.

$\ell _t=k/2$.

The overline ![]() $\overline {(\,\cdot\,)}(z)$ denotes averages in

$\overline {(\,\cdot\,)}(z)$ denotes averages in ![]() $t$,

$t$, ![]() $x$ and

$x$ and ![]() $y$ at one height

$y$ at one height ![]() $z$ above the riblet crest. In analogy to the hot-wire data,

$z$ above the riblet crest. In analogy to the hot-wire data, ![]() $U(y,z)$ is the mean velocity averaged in

$U(y,z)$ is the mean velocity averaged in ![]() $t$,

$t$, ![]() $x$ and over the spanwise extent of the hot-wire probe,

$x$ and over the spanwise extent of the hot-wire probe, ![]() $0.18s$, either centred around

$0.18s$, either centred around ![]() $y=s/2$ (centred above troughs) or around

$y=s/2$ (centred above troughs) or around ![]() $y=s$ (centred above riblet tips). Inside the roughness sublayer,

$y=s$ (centred above riblet tips). Inside the roughness sublayer, ![]() $\bar {u}(z) \ne U(z)$ because

$\bar {u}(z) \ne U(z)$ because ![]() $\overline {(\,\cdot\,)}$ averages over

$\overline {(\,\cdot\,)}$ averages over ![]() $s$ and the hot-wire averages only over

$s$ and the hot-wire averages only over ![]() $0.18s$. Above the roughness sublayer, the flow is statistically spanwise uniform and the averages over the two regions are equal. Furthermore,

$0.18s$. Above the roughness sublayer, the flow is statistically spanwise uniform and the averages over the two regions are equal. Furthermore, ![]() $\tilde {u}\tilde {w} = \langle u \rangle \langle w \rangle - \bar {u} \bar {w}$ denotes the dispersive component of Reynolds stress, which cannot be measured by a single hot wire, because it is due to the

$\tilde {u}\tilde {w} = \langle u \rangle \langle w \rangle - \bar {u} \bar {w}$ denotes the dispersive component of Reynolds stress, which cannot be measured by a single hot wire, because it is due to the ![]() $xt$-averaged spatial variation

$xt$-averaged spatial variation ![]() $\langle \,\boldsymbol {\cdot}\, \rangle (y,z)$ about

$\langle \,\boldsymbol {\cdot}\, \rangle (y,z)$ about ![]() $\overline {(\,\cdot\,)}(z)$ and here

$\overline {(\,\cdot\,)}(z)$ and here ![]() $\bar {w} = 0$ so

$\bar {w} = 0$ so ![]() $\tilde {u}\tilde {w} = \langle u \rangle \langle w \rangle$.

$\tilde {u}\tilde {w} = \langle u \rangle \langle w \rangle$.

All simulations are conducted in minimal-span channels (Jiménez & Moin Reference Jiménez and Moin1991; Flores & Jiménez Reference Flores and Jiménez2010; Hwang Reference Hwang2013), which reduces the computational cost of evaluating the flow over roughness compared with using full-span channels (MacDonald et al. Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017). The flow above ![]() $z_c^+=0.4L_y^+$, where

$z_c^+=0.4L_y^+$, where ![]() $L_y$ is the spanwise domain extent, is unphysically constricted in narrow domains (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015), but the flow field close to the wall is representative of that in full-span channels and allows us to evaluate the effects of riblets (Endrikat et al. Reference Endrikat, Modesti, MacDonald, García-Mayoral, Hutchins and Chung2021b).

$L_y$ is the spanwise domain extent, is unphysically constricted in narrow domains (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015), but the flow field close to the wall is representative of that in full-span channels and allows us to evaluate the effects of riblets (Endrikat et al. Reference Endrikat, Modesti, MacDonald, García-Mayoral, Hutchins and Chung2021b).

3. Effects of large riblets on the flow

The two data sets of flow above large riblets from experiments and simulations have different outer Reynolds numbers (tables 1, 2), but they complement each other at matched ![]() $s^+$ in the common physical and spectral regions analysed in this section. We first consider velocity spectra and then the mean flow.

$s^+$ in the common physical and spectral regions analysed in this section. We first consider velocity spectra and then the mean flow.

3.1. Riblets damp large-scale motions near the wall

Figure 3 shows streamwise spectra of the streamwise velocity component at different heights for three riblet sizes (rows) and two spanwise positions (columns). The spectra demonstrate that large riblets reduce the energy of large-scale motions close to the wall relative to smooth-wall flow. A particularly clear example of this is given in figure 3(e,f), which shows the largest ![]() $s^+$ case. Here, if we compare the filled contours for the riblets with the grey line contours of the smooth wall, we see substantial missing large-scale energy near the wall at

$s^+$ case. Here, if we compare the filled contours for the riblets with the grey line contours of the smooth wall, we see substantial missing large-scale energy near the wall at ![]() $\lambda _x^+ \approx 10\,000\unicode{x2013}50\,000$ and

$\lambda _x^+ \approx 10\,000\unicode{x2013}50\,000$ and ![]() $(z-z_b)/k \lesssim 5$. Over a smooth-wall, long flow structures are coherent down to the viscous buffer region at

$(z-z_b)/k \lesssim 5$. Over a smooth-wall, long flow structures are coherent down to the viscous buffer region at ![]() $z^+ \approx 15$ (Hutchins & Marusic (Reference Hutchins and Marusic2007), Monty, Harun & Marusic (Reference Monty, Harun and Marusic2011), Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Marusic, Schultz and Klewicki2016a), and smooth-wall contours in figure 3). The large riblets, however, significantly weaken the near-wall part of long flow structures in figure 3. Even though these large motions lose energy as they scrape the riblets, the flow structures that scale with distance to the wall in the logarithmic region (Townsend Reference Townsend1976) appear intact (see dashed lines in figure 3, which show

$z^+ \approx 15$ (Hutchins & Marusic (Reference Hutchins and Marusic2007), Monty, Harun & Marusic (Reference Monty, Harun and Marusic2011), Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Marusic, Schultz and Klewicki2016a), and smooth-wall contours in figure 3). The large riblets, however, significantly weaken the near-wall part of long flow structures in figure 3. Even though these large motions lose energy as they scrape the riblets, the flow structures that scale with distance to the wall in the logarithmic region (Townsend Reference Townsend1976) appear intact (see dashed lines in figure 3, which show ![]() $\lambda _x = 30z$). The difference above the large riblets compared with smooth-wall flow is that flow structures scaling with wall distance seem to lack coherence with the wall.

$\lambda _x = 30z$). The difference above the large riblets compared with smooth-wall flow is that flow structures scaling with wall distance seem to lack coherence with the wall.

The DNS spectra only extend to ![]() $\lambda _x^+ = L_x^+ \approx 2000$. The domain length is therefore too short to observe the energy difference at larger scales, but the spectra nevertheless show some of the energy reduction that riblets introduce. The DNS (red) contour lines in figure 3(a–d) run horizontally around

$\lambda _x^+ = L_x^+ \approx 2000$. The domain length is therefore too short to observe the energy difference at larger scales, but the spectra nevertheless show some of the energy reduction that riblets introduce. The DNS (red) contour lines in figure 3(a–d) run horizontally around ![]() $\lambda _x^+ \approx 1000$, where smooth-wall flow with vertical contour lines retains higher energy (only shown for smooth-wall experiments, but contour lines for smooth-wall DNS also run vertically).

$\lambda _x^+ \approx 1000$, where smooth-wall flow with vertical contour lines retains higher energy (only shown for smooth-wall experiments, but contour lines for smooth-wall DNS also run vertically).

Velocity fluctuations in and just above the riblet groove are well resolved in both hot-wire measurements and DNS (figure 3), which allows us to correct for the positional ![]() $z$ error innate to hot-wire measurements by comparing to DNS data with well defined

$z$ error innate to hot-wire measurements by comparing to DNS data with well defined ![]() $z/k$. The

$z/k$. The ![]() $z$ corrections, applied for all figures, are in the range

$z$ corrections, applied for all figures, are in the range ![]() $[-0.57, -0.4]$ mm in the groove centre and in the range

$[-0.57, -0.4]$ mm in the groove centre and in the range ![]() $[-0.55, -0.12]$ mm at the riblet crest. As a reference, the riblet height

$[-0.55, -0.12]$ mm at the riblet crest. As a reference, the riblet height ![]() $k=1.365$ mm. All of these shifts are negative (i.e. downward), consistent with the tunnel floor being pulled upwards slightly by the flow and the probe support shifting downward slightly under aerodynamic loading. The corrections need not be exactly the same at both positions, because the probe is manually repositioned at each spanwise location using a

$k=1.365$ mm. All of these shifts are negative (i.e. downward), consistent with the tunnel floor being pulled upwards slightly by the flow and the probe support shifting downward slightly under aerodynamic loading. The corrections need not be exactly the same at both positions, because the probe is manually repositioned at each spanwise location using a ![]() $z$-positioning microscope (Titan Tool Supply), incurring different positioning errors.

$z$-positioning microscope (Titan Tool Supply), incurring different positioning errors.

In figure 4 we integrate spectra only over long wavelengths ![]() $\lambda _x \gtrsim 30z$, i.e. above the dashed line in figure 3. Comparison to smooth-wall flow with roughly matching

$\lambda _x \gtrsim 30z$, i.e. above the dashed line in figure 3. Comparison to smooth-wall flow with roughly matching ![]() $\delta ^{\prime +}_{99}$ illustrates the reorganisation of near-wall turbulence. The large riblets significantly reduce the streamwise energy of large-scale motions at riblet-scaled heights of at least

$\delta ^{\prime +}_{99}$ illustrates the reorganisation of near-wall turbulence. The large riblets significantly reduce the streamwise energy of large-scale motions at riblet-scaled heights of at least ![]() $z \lesssim z_t+2s$ (or, equivalently,

$z \lesssim z_t+2s$ (or, equivalently, ![]() $z \lesssim z_b + 5k$ as in figure 3) and at outer-scaled heights

$z \lesssim z_b + 5k$ as in figure 3) and at outer-scaled heights ![]() $z\lesssim (0.1\unicode{x2013}0.2) \delta ^\prime _{99}$, i.e. into the logarithmic layer. The sandpaper roughness investigated by Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b), shown by red dashed lines in figure 4, also reduces large-scale energy, but markedly less so than the riblets. The near-wall energy reduction of large flow structures by riblets in figures 3 and 4 is noticeable even at heights above the riblet-induced spanwise inhomogeneity of the mean flow, which we analyse in the following section.

$z\lesssim (0.1\unicode{x2013}0.2) \delta ^\prime _{99}$, i.e. into the logarithmic layer. The sandpaper roughness investigated by Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b), shown by red dashed lines in figure 4, also reduces large-scale energy, but markedly less so than the riblets. The near-wall energy reduction of large flow structures by riblets in figures 3 and 4 is noticeable even at heights above the riblet-induced spanwise inhomogeneity of the mean flow, which we analyse in the following section.

3.2. Roughness sublayer of the mean flow

The mean flow ![]() $U^+(y,z)$, measured at two spanwise positions of the riblet groove, indicates the extent of the roughness sublayer in figure 5: the two profiles overlap for

$U^+(y,z)$, measured at two spanwise positions of the riblet groove, indicates the extent of the roughness sublayer in figure 5: the two profiles overlap for ![]() $z \gtrsim z_t+k$ (above the dotted line) in both experiments and DNS. An exception is the

$z \gtrsim z_t+k$ (above the dotted line) in both experiments and DNS. An exception is the ![]() $s^+=36$ hot-wire profile at the tip position, which differs from the DNS data and does not fully join the hot-wire profile in the groove centre (figure 5a). The mismatch indicates experimental errors for the tip profile, because the DNS profiles for the same

$s^+=36$ hot-wire profile at the tip position, which differs from the DNS data and does not fully join the hot-wire profile in the groove centre (figure 5a). The mismatch indicates experimental errors for the tip profile, because the DNS profiles for the same ![]() $s^+=36$ in figure 5(a) fit the trend observed for all other cases in both data sets: riblet-induced spanwise variations of the mean flow are limited to heights

$s^+=36$ in figure 5(a) fit the trend observed for all other cases in both data sets: riblet-induced spanwise variations of the mean flow are limited to heights ![]() $z\lesssim z_t+k=z_t+0.5s$. The scale separation between the height of the roughness sublayer of the mean flow and

$z\lesssim z_t+k=z_t+0.5s$. The scale separation between the height of the roughness sublayer of the mean flow and ![]() $\delta ^\prime _{99} \approx 47k$ (table 1) is therefore large in our experiments. Nevertheless, the effect of riblets on the turbulence structure (at least

$\delta ^\prime _{99} \approx 47k$ (table 1) is therefore large in our experiments. Nevertheless, the effect of riblets on the turbulence structure (at least ![]() $z \lesssim z_t + 4k$, § 3.1) extends far beyond the spanwise variations of the mean flow.

$z \lesssim z_t + 4k$, § 3.1) extends far beyond the spanwise variations of the mean flow.

Figure 5. Mean streamwise velocity at two spanwise positions: ![]() $y=0$ (at the riblet tips) and

$y=0$ (at the riblet tips) and ![]() $y=s/2$ (in the groove centre). Direct numerical simulation profiles are averaged in

$y=s/2$ (in the groove centre). Direct numerical simulation profiles are averaged in ![]() $y$ only over the

$y$ only over the ![]() $0.18s$ covered respectively by the hot-wire probe and, for this figure only, interpolated to match the experimental

$0.18s$ covered respectively by the hot-wire probe and, for this figure only, interpolated to match the experimental ![]() $s^+$. The portion of profiles shown is below

$s^+$. The portion of profiles shown is below ![]() $z_c$ and, therefore, unaffected by the minimal domain width. The dotted horizontal line marks the approximate extent of the roughness sublayer based on mean-flow inhomogeneity.

$z_c$ and, therefore, unaffected by the minimal domain width. The dotted horizontal line marks the approximate extent of the roughness sublayer based on mean-flow inhomogeneity.

Scaling of the mean-flow roughness sublayer with the horizontal roughness spacing as in figure 5 (with ![]() $0.5s=k$) has more generally been observed for canopy roughness (e.g. Raupach et al. Reference Raupach, Thom and Edwards1980), streamwise ridges (e.g. Wang & Cheng Reference Wang and Cheng2006; Hwang & Lee Reference Hwang and Lee2018), sinusoidal roughness (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018) and smaller riblets (Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). The blocking effect of a smooth wall causes large eddies to mostly produce wall-parallel (inactive) motions (Townsend Reference Townsend1976), but large riblets interact with lateral flow to create mean secondary motions in the cross-stream plane (Goldstein & Tuan Reference Goldstein and Tuan1998; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). Therefore, a convenient measure of the roughness sublayer in DNS is the extent of dispersive (form-induced) stresses due to time-averaged secondary flows. These motions are not defined instantaneously, but they can be sensed statistically as dispersive Reynolds stresses that extend to heights of about half the horizontal roughness period (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

$0.5s=k$) has more generally been observed for canopy roughness (e.g. Raupach et al. Reference Raupach, Thom and Edwards1980), streamwise ridges (e.g. Wang & Cheng Reference Wang and Cheng2006; Hwang & Lee Reference Hwang and Lee2018), sinusoidal roughness (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018) and smaller riblets (Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). The blocking effect of a smooth wall causes large eddies to mostly produce wall-parallel (inactive) motions (Townsend Reference Townsend1976), but large riblets interact with lateral flow to create mean secondary motions in the cross-stream plane (Goldstein & Tuan Reference Goldstein and Tuan1998; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). Therefore, a convenient measure of the roughness sublayer in DNS is the extent of dispersive (form-induced) stresses due to time-averaged secondary flows. These motions are not defined instantaneously, but they can be sensed statistically as dispersive Reynolds stresses that extend to heights of about half the horizontal roughness period (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

In figure 6(a) we confirm, for the present large riblets, that the dispersive Reynolds stresses of secondary flows (indicating mean-flow inhomogeneity) are limited to ![]() $z \lesssim z_t + (0.4\unicode{x2013}0.8)s$, depending on the threshold. Dispersive stresses of blunt, scalloped riblets are confined to similar heights (Rastegari & Akhavan Reference Rastegari and Akhavan2018, figure 5(f)

$z \lesssim z_t + (0.4\unicode{x2013}0.8)s$, depending on the threshold. Dispersive stresses of blunt, scalloped riblets are confined to similar heights (Rastegari & Akhavan Reference Rastegari and Akhavan2018, figure 5(f) ![]() $s=0.288\delta$). The peak value of dispersive stresses in figure 6(b) increases with

$s=0.288\delta$). The peak value of dispersive stresses in figure 6(b) increases with ![]() $s^+$, but approaches a maximum (the negative of viscous-scaled Reynolds shear stress is less than

$s^+$, but approaches a maximum (the negative of viscous-scaled Reynolds shear stress is less than ![]() $1$). The same trend is evident in the time-averaged cross-flow of figure 7, which strengthens with increasing

$1$). The same trend is evident in the time-averaged cross-flow of figure 7, which strengthens with increasing ![]() $s^+$, as discussed by Modesti et al. (Reference Modesti, Endrikat, Hutchins and Chung2021). Furthermore, the roughness sublayer of the two-scale riblets (dashed lines in figure 6a) also scales with

$s^+$, as discussed by Modesti et al. (Reference Modesti, Endrikat, Hutchins and Chung2021). Furthermore, the roughness sublayer of the two-scale riblets (dashed lines in figure 6a) also scales with ![]() $s$, even though the additional half-height riblet in the groove visibly displaces turbulence upwards in figure 7(g–j) compared with the single-scale riblets in figure 7(a–d). The displacement of turbulence and the reduction of dispersive stresses by two-scale riblets in figure 6(b) reduce

$s$, even though the additional half-height riblet in the groove visibly displaces turbulence upwards in figure 7(g–j) compared with the single-scale riblets in figure 7(a–d). The displacement of turbulence and the reduction of dispersive stresses by two-scale riblets in figure 6(b) reduce ![]() ${\rm \Delta} U^+$ at matched

${\rm \Delta} U^+$ at matched ![]() $s^+$ (following the drag decomposition from, e.g. Modesti et al. (Reference Modesti, Endrikat, Hutchins and Chung2021), and shown in § 4). However, in § 4 we consider different measures of the riblet size and demonstrate that the half-height riblets do not actually provide an overall drag benefit compared with the single-scale trapezoidal riblets once their size is scaled appropriately.

$s^+$ (following the drag decomposition from, e.g. Modesti et al. (Reference Modesti, Endrikat, Hutchins and Chung2021), and shown in § 4). However, in § 4 we consider different measures of the riblet size and demonstrate that the half-height riblets do not actually provide an overall drag benefit compared with the single-scale trapezoidal riblets once their size is scaled appropriately.

Figure 6. The extent of DNS dispersive stresses defines the roughness sublayer of mean secondary flows. Profiles of dispersive stresses against ![]() $z/s$ (a) collapse when shown relative to their respective peak value at the riblet tips

$z/s$ (a) collapse when shown relative to their respective peak value at the riblet tips ![]() $-\overline {\tilde {u} \tilde {w}}_t^+$ (b). This is similar to the coherent component of pressure fluctuations analysed by Seo, García-Mayoral & Mani (Reference Seo, García-Mayoral and Mani2015). Dotted lines are empirical approximations.

$-\overline {\tilde {u} \tilde {w}}_t^+$ (b). This is similar to the coherent component of pressure fluctuations analysed by Seo, García-Mayoral & Mani (Reference Seo, García-Mayoral and Mani2015). Dotted lines are empirical approximations.

Figure 7. Cross-flow averaged in time, the streamwise direction and over riblet periods. Contours show wall-normal velocity and lines show the stream function ![]() $\psi ^+ - \psi ^+_w= \pm (1,21,41,61)\times 10^{-4}$ relative to

$\psi ^+ - \psi ^+_w= \pm (1,21,41,61)\times 10^{-4}$ relative to ![]() $\psi ^+_w=0$ on the wall (—– for counterclockwise rotation and - - - - for clockwise rotation).

$\psi ^+_w=0$ on the wall (—– for counterclockwise rotation and - - - - for clockwise rotation).

Figure 8. (a) Mean streamwise velocity from hot-wire measurements with a virtual origin ![]() $\ell _t=k/2$. Only showing the spanwise invariant flow above the roughness sublayer (figure 5). Filled circles mark measurements that are considered to lie within the logarithmic region (lower bound:

$\ell _t=k/2$. Only showing the spanwise invariant flow above the roughness sublayer (figure 5). Filled circles mark measurements that are considered to lie within the logarithmic region (lower bound: ![]() $z^+=\mathrm {max}(100,z_t^+ + 0.5s^+)$, upper bound:

$z^+=\mathrm {max}(100,z_t^+ + 0.5s^+)$, upper bound: ![]() $z=0.19\delta ^\prime _{99}$). Red dashed line: sandpaper roughness for which

$z=0.19\delta ^\prime _{99}$). Red dashed line: sandpaper roughness for which ![]() $u_\tau$ is measured with a drag balance (Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b,

$u_\tau$ is measured with a drag balance (Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b, ![]() $k_s^+=22$,

$k_s^+=22$, ![]() $\delta _{99}^+ \approx 3950$,

$\delta _{99}^+ \approx 3950$, ![]() ${\rm \Delta} U^+ \approx 2.7$,

${\rm \Delta} U^+ \approx 2.7$, ![]() $\delta /k \approx 384$ and

$\delta /k \approx 384$ and ![]() $\kappa \approx 0.378$). Dotted line: smooth-wall flow (Chandran et al. Reference Chandran, Baidya, Monty and Marusic2017). Error bars in (b–d) are for virtual origins between the groove bottom

$\kappa \approx 0.378$). Dotted line: smooth-wall flow (Chandran et al. Reference Chandran, Baidya, Monty and Marusic2017). Error bars in (b–d) are for virtual origins between the groove bottom ![]() $z_b$ (

$z_b$ (![]() $\ell _t=k$) and the riblet crest

$\ell _t=k$) and the riblet crest ![]() $z_t$ (

$z_t$ (![]() $\ell _t=0$). (b) Fitting parameter

$\ell _t=0$). (b) Fitting parameter ![]() $\kappa (s^+)$ that describes the slope of the logarithmic region (dots in a) as a function of the riblet spacing. The fit only marginally depends on the choice of the lower bound. (c) Roughness functions using smooth-wall hot-wire data from Marusic et al. (Reference Marusic, Chauhan, Kulandaivelu and Hutchins2015), Chandran et al. (Reference Chandran, Baidya, Monty and Marusic2017), Wangsawijaya et al. (Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020) and Ramani et al. (Reference Ramani, Nugroho, Busse, Monty, Hutchins and Jelly2020) are only shown above the roughness sublayer and up to

$\kappa (s^+)$ that describes the slope of the logarithmic region (dots in a) as a function of the riblet spacing. The fit only marginally depends on the choice of the lower bound. (c) Roughness functions using smooth-wall hot-wire data from Marusic et al. (Reference Marusic, Chauhan, Kulandaivelu and Hutchins2015), Chandran et al. (Reference Chandran, Baidya, Monty and Marusic2017), Wangsawijaya et al. (Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020) and Ramani et al. (Reference Ramani, Nugroho, Busse, Monty, Hutchins and Jelly2020) are only shown above the roughness sublayer and up to ![]() $z=\delta ^{\prime }_{99}/2$. (d) Drag curve as measured in (c). Direct numerical simulation values are measured at

$z=\delta ^{\prime }_{99}/2$. (d) Drag curve as measured in (c). Direct numerical simulation values are measured at ![]() $z_c$ and matched

$z_c$ and matched ![]() $L_y$ to cancel out minimal-channel effects. Empty circles are for thicker trapezoidal riblets with

$L_y$ to cancel out minimal-channel effects. Empty circles are for thicker trapezoidal riblets with ![]() $\alpha =53.5^\circ$ from Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020, figure 4).

$\alpha =53.5^\circ$ from Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020, figure 4).

3.3. Mean velocity in the logarithmic layer

As shown in the previous section, spanwise variations of the mean flow in the roughness sublayer are confined to about ![]() $z \lesssim z_t+k$, but we next observe that the mean flow

$z \lesssim z_t+k$, but we next observe that the mean flow ![]() $U^+$ is nevertheless modified in the spanwise homogeneous logarithmic layer, where the present riblets damp large-scale energy.

$U^+$ is nevertheless modified in the spanwise homogeneous logarithmic layer, where the present riblets damp large-scale energy.

3.3.1. Increased slope of the mean velocity profile

Figure 8(a) shows a hot-wire velocity profile above a smooth wall (![]() $\cdot \!\cdot \!\cdot \!\cdot \!\cdot \!\cdot$), for which the slope in the logarithmic region is well known to be described by the von Kármán constant

$\cdot \!\cdot \!\cdot \!\cdot \!\cdot \!\cdot$), for which the slope in the logarithmic region is well known to be described by the von Kármán constant ![]() $\kappa \approx 0.40$. The riblet-flow profiles in figure 8(a) are only shown in the spanwise uniform region above the roughness sublayer (figure 5) and we assume a virtual origin at the mid-point of the groove (

$\kappa \approx 0.40$. The riblet-flow profiles in figure 8(a) are only shown in the spanwise uniform region above the roughness sublayer (figure 5) and we assume a virtual origin at the mid-point of the groove (![]() $\ell _t=k/2$) for these profiles. The highlighted logarithmic region in figure 8(a) shows a clear trend of increasing slope with increasing riblet size for this choice of the virtual origin. The outer layers of the flow above the present large riblets and smooth wall are therefore not similar. Figure 8(a) additionally shows a velocity profile above sandpaper roughness from Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b), with the same definition of the virtual origin, as an example of rough-wall flows that commonly have the same

$\ell _t=k/2$) for these profiles. The highlighted logarithmic region in figure 8(a) shows a clear trend of increasing slope with increasing riblet size for this choice of the virtual origin. The outer layers of the flow above the present large riblets and smooth wall are therefore not similar. Figure 8(a) additionally shows a velocity profile above sandpaper roughness from Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016b), with the same definition of the virtual origin, as an example of rough-wall flows that commonly have the same ![]() $\kappa \approx 0.40$ as smooth-wall flows.

$\kappa \approx 0.40$ as smooth-wall flows.

In figure 8(b) we measure the slope of the hot-wire mean profile by fitting a line to the logarithmic region. A reduction in ![]() $\kappa$ with increasing

$\kappa$ with increasing ![]() $s^+$ is clearly visible for any virtual origin between the groove bottom and the riblet crest (error bars). Even with the origin at the riblet crest (top of the error bars),

$s^+$ is clearly visible for any virtual origin between the groove bottom and the riblet crest (error bars). Even with the origin at the riblet crest (top of the error bars), ![]() $\kappa \approx 0.34$ for the largest riblets. To illustrate the effect of the origin on the apparent local value of

$\kappa \approx 0.34$ for the largest riblets. To illustrate the effect of the origin on the apparent local value of ![]() $\kappa = (z^+ \mathrm {d}U^+/\mathrm {d}z^+)^{-1}$, consider a fixed measurement location in the logarithmic layer. A higher origin reduces the distance

$\kappa = (z^+ \mathrm {d}U^+/\mathrm {d}z^+)^{-1}$, consider a fixed measurement location in the logarithmic layer. A higher origin reduces the distance ![]() $z^+$ between the measurement location and the virtual origin, increasing

$z^+$ between the measurement location and the virtual origin, increasing ![]() $\kappa$. In a similar manner, the positional adjustment applied to the hot-wire locations

$\kappa$. In a similar manner, the positional adjustment applied to the hot-wire locations ![]() $z$ in § 3.1, which accounts for the wall and probe-support movement under aerodynamic load, also slightly increased

$z$ in § 3.1, which accounts for the wall and probe-support movement under aerodynamic load, also slightly increased ![]() $\kappa$ relative to the raw data. The friction velocity used for the riblet profiles is measured with a drag balance (§ 2.1) and could include an error. If we were to reduce

$\kappa$ relative to the raw data. The friction velocity used for the riblet profiles is measured with a drag balance (§ 2.1) and could include an error. If we were to reduce ![]() $u_\tau$ to match the DNS profiles in figure 5, the apparent local value of

$u_\tau$ to match the DNS profiles in figure 5, the apparent local value of ![]() $\kappa$ would reduce further.

$\kappa$ would reduce further.

In hot-wire boundary-layer studies ![]() $u_\tau$ and the virtual origin are generally found by forcing

$u_\tau$ and the virtual origin are generally found by forcing ![]() $\kappa =0.4$ (or a close value like

$\kappa =0.4$ (or a close value like ![]() $\kappa =0.384 \pm 0.005$ as determined by Nagib & Chauhan Reference Nagib and Chauhan2008). However, with

$\kappa =0.384 \pm 0.005$ as determined by Nagib & Chauhan Reference Nagib and Chauhan2008). However, with ![]() $u_\tau$ fixed by drag-balance measurements and

$u_\tau$ fixed by drag-balance measurements and ![]() $z$-positional errors corrected by comparing to spectra and mean profiles from DNS (§ 3.1), the position of the virtual origin is the only variable affecting

$z$-positional errors corrected by comparing to spectra and mean profiles from DNS (§ 3.1), the position of the virtual origin is the only variable affecting ![]() $\kappa$. Forcing

$\kappa$. Forcing ![]() $\kappa =0.4$ requires the origin to be about

$\kappa =0.4$ requires the origin to be about ![]() $0.7k$ above the riblet crest (see grey dots in the inset of figure 8b), which seems unrealistic. Other studies of roughness (e.g. Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Grimmond & Oke Reference Grimmond and Oke1999) and small

$0.7k$ above the riblet crest (see grey dots in the inset of figure 8b), which seems unrealistic. Other studies of roughness (e.g. Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Grimmond & Oke Reference Grimmond and Oke1999) and small ![]() $s^+$ riblets (e.g. Luchini et al. Reference Luchini, Manzo and Pozzi1991; Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a) use various definitions, but all place the virtual origin below the roughness crest, as summarised by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021). Therefore, reasonable adjustments to the virtual origin or to

$s^+$ riblets (e.g. Luchini et al. Reference Luchini, Manzo and Pozzi1991; Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a) use various definitions, but all place the virtual origin below the roughness crest, as summarised by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021). Therefore, reasonable adjustments to the virtual origin or to ![]() $u_\tau$ cannot force

$u_\tau$ cannot force ![]() $\kappa \approx 0.4$, which provides confidence that

$\kappa \approx 0.4$, which provides confidence that ![]() $\kappa$ is indeed a function of

$\kappa$ is indeed a function of ![]() $s^+$ for the present large riblets, as shown in figure 8(b).

$s^+$ for the present large riblets, as shown in figure 8(b).

3.3.2. Outer-layer similarity

Breugem, Boersma & Uittenbogaard (Reference Breugem, Boersma and Uittenbogaard2006) and Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010) observe reduced ![]() $\kappa$ above the permeable walls of porous surfaces at low friction Reynolds numbers (

$\kappa$ above the permeable walls of porous surfaces at low friction Reynolds numbers (![]() $\delta ^+ \lesssim 678$ and

$\delta ^+ \lesssim 678$ and ![]() $\delta ^+ \lesssim 432$, respectively) and suggest the changes to the mean profile may be due to the wall-normal permeability of their surfaces. Small riblets can be interpreted as behaving similar to a porous surface, with an effective porosity that increases with riblet size (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011b; Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a). Reasoning for reduced

$\delta ^+ \lesssim 432$, respectively) and suggest the changes to the mean profile may be due to the wall-normal permeability of their surfaces. Small riblets can be interpreted as behaving similar to a porous surface, with an effective porosity that increases with riblet size (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011b; Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021a). Reasoning for reduced ![]() $\kappa$ above permeable surfaces may therefore also be applicable to riblets. However, Manes et al. (Reference Manes, Poggi and Ridolfi2011) show that insufficient separation between inner and outer length scales explains the trend of reducing

$\kappa$ above permeable surfaces may therefore also be applicable to riblets. However, Manes et al. (Reference Manes, Poggi and Ridolfi2011) show that insufficient separation between inner and outer length scales explains the trend of reducing ![]() $\kappa$ in the studies by Breugem et al. (Reference Breugem, Boersma and Uittenbogaard2006) and Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010), in which the roughness sublayer based on Reynolds stresses induced by the wall porosity likely extends into the logarithmic layer.

$\kappa$ in the studies by Breugem et al. (Reference Breugem, Boersma and Uittenbogaard2006) and Suga et al. (Reference Suga, Matsumura, Ashitaka, Tominaga and Kaneda2010), in which the roughness sublayer based on Reynolds stresses induced by the wall porosity likely extends into the logarithmic layer.

For the present riblets, the roughness sublayer based on the extent of wall-parallel inhomogeneity of the mean flow is limited to ![]() $z \lesssim z_t+k$ (figure 5). This extent of the direct influence of riblets is small in outer units for all our experimental cases (table 1), suggesting that outer-layer similarity should exist above

$z \lesssim z_t+k$ (figure 5). This extent of the direct influence of riblets is small in outer units for all our experimental cases (table 1), suggesting that outer-layer similarity should exist above ![]() $z \approx z_t+k$ contrary to what we observe in figure 8. One way to rule out insufficient scale separation for the present riblets would be to repeat the experiments at matched

$z \approx z_t+k$ contrary to what we observe in figure 8. One way to rule out insufficient scale separation for the present riblets would be to repeat the experiments at matched ![]() $s^+$, but at an even higher

$s^+$, but at an even higher ![]() $\delta /k$ (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is not possible with the current set-up. Nevertheless, unlike the surfaces that have been demonstrated to recover outer-layer similarity at larger scale separation (Krogstad & Efros Reference Krogstad and Efros2012; Flack & Schultz Reference Flack and Schultz2014; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021), the present riblets lack an obvious larger scale that could limit outer-layer similarity by farther extending the roughness sublayer of the mean flow. In this sense, the present riblets are exceptional. In fact, the scale separation for the experimental data

$\delta /k$ (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which is not possible with the current set-up. Nevertheless, unlike the surfaces that have been demonstrated to recover outer-layer similarity at larger scale separation (Krogstad & Efros Reference Krogstad and Efros2012; Flack & Schultz Reference Flack and Schultz2014; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021), the present riblets lack an obvious larger scale that could limit outer-layer similarity by farther extending the roughness sublayer of the mean flow. In this sense, the present riblets are exceptional. In fact, the scale separation for the experimental data ![]() $\delta _{99}^\prime /k \approx 47$ is roughly constant (table 1), but

$\delta _{99}^\prime /k \approx 47$ is roughly constant (table 1), but ![]() $\kappa$ reduces nevertheless as

$\kappa$ reduces nevertheless as ![]() $\delta _{99}^{\prime +}$ and