Published online by Cambridge University Press: 04 March 2024

The present work focuses on the effect of rough horizontal boundaries on the heat transfer in rotating Rayleigh–Bénard convection. We measure the non-dimensional heat transfer, the Nusselt number  $Nu$, for various strengths of the buoyancy forcing characterized by the Rayleigh number

$Nu$, for various strengths of the buoyancy forcing characterized by the Rayleigh number  $Ra$ (

$Ra$ ( ${10^5}\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }Ra\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }5 \times {10^8}$), and rotation rates characterized by the Ekman number E (

${10^5}\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }Ra\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }5 \times {10^8}$), and rotation rates characterized by the Ekman number E ( $1.4 \times {10^{ - 5}}\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }E\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }7.6 \times {10^{ - 4}}$) for aspect ratios

$1.4 \times {10^{ - 5}}\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }E\mathrm{\ \mathbin{\lower.3ex\hbox{$\buildrel< \over {\smash{\scriptstyle\sim}\vphantom{_x}}$}}\ }7.6 \times {10^{ - 4}}$) for aspect ratios  $\varGamma \approx 1$,

$\varGamma \approx 1$,  $2.8$ and

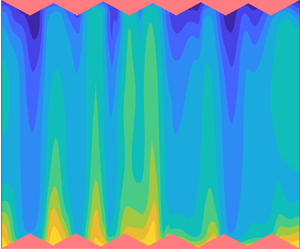

$2.8$ and  $6.7$. Similar to rotating convection with smooth horizontal boundaries, the so-called rotationally constrained (RC), rotation-affected (RA) and rotation-unaffected (RuA) regimes of heat transfer seem to persist for rough horizontal boundaries. However, the transition from the RC regime to RA regime occurs at a lower Rayleigh number for rough boundaries. For all experiments with rough boundaries in this study, the thermal and Ekman boundary layers are in a perturbed state, leading to a significant enhancement in the heat transfer as compared with that for smooth walls. However, the enhancement in heat transfer due to wall roughness is observed to attain a maximum in the RC regime. We perform companion direct numerical simulations of rotating convection over smooth walls to suggest a phenomenology explaining this observation. We propose that the heat transfer enhancement due to wall roughness reaches a maximum when the strength and coherence of the columnar structures are both significant, which enables efficient vertical transport of the additional thermal anomalies generated by the roughness at the top and bottom walls.

$6.7$. Similar to rotating convection with smooth horizontal boundaries, the so-called rotationally constrained (RC), rotation-affected (RA) and rotation-unaffected (RuA) regimes of heat transfer seem to persist for rough horizontal boundaries. However, the transition from the RC regime to RA regime occurs at a lower Rayleigh number for rough boundaries. For all experiments with rough boundaries in this study, the thermal and Ekman boundary layers are in a perturbed state, leading to a significant enhancement in the heat transfer as compared with that for smooth walls. However, the enhancement in heat transfer due to wall roughness is observed to attain a maximum in the RC regime. We perform companion direct numerical simulations of rotating convection over smooth walls to suggest a phenomenology explaining this observation. We propose that the heat transfer enhancement due to wall roughness reaches a maximum when the strength and coherence of the columnar structures are both significant, which enables efficient vertical transport of the additional thermal anomalies generated by the roughness at the top and bottom walls.