1 Introduction

The flow of an annular film on the outside of a rotating circular cylinder is a fascinating and much-studied problem. It finds numerous applications in industry from its uses in spin coating in microfabrication to rotational moulding (Ruschak Reference Ruschak1985). Rotational flows have received extensive attention since the early work of Yih (Reference Yih1960), who studied the problem of a rotating drum partially submerged in a liquid bath, both experimentally and theoretically using a linear stability analysis. In the same year Phillips (Reference Phillips1960) analysed the linear stability of a related system, where the drum was partially filled, under the assumption that the system was inviscid, and compared against experimental results. Pedley (Reference Pedley1967) similarly analysed inviscid, rotating, free-surface flow on the inside or outside of a cylinder in the linear regime.

The nonlinear problem was originally modelled by Moffatt (Reference Moffatt1977), inspired by the question of what volume of honey can sustainably be held on a rotating knife. By assuming the film to be thin, and incorporating the effects of gravity and rotation only, Moffatt solved this by finding limiting solutions for given parameters. Pukhnachev (Reference Pukhnachev1977) developed a similar thin-film model that incorporated the effects of surface tension. While both considered the case of flow on the outside of a cylinder (coating flow), the leading-order equations derived are equally valid for flow on the inside of a cylinder (rimming flow). Indeed the latter problem has also proven of be of significant interest (Thoroddsen & Mahadevan Reference Thoroddsen and Mahadevan1997; Hosoi & Mahadevan Reference Hosoi and Mahadevan1999). However, at higher orders, the models are not equivalent (Lopes, Thiele & Hazel Reference Lopes, Thiele and Hazel2018); our focus here will be on coating flows.

A full treatment of the problem requires a model that incorporates the subtle interplay of gravity, surface tension, viscous effects, inertia (including centrifugation), rotational effects and potentially even dewetting effects (Thiele Reference Thiele2011; Lin et al. Reference Lin, Rogers, Tseluiko and Thiele2016) (all other models, including the ones derived herein, implicitly assume complete wetting). As a result, since the pioneering work of Moffatt and Pukhnachev, many authors have extended this coating flow problem. For example, in their original form the thin-film equations did not even conserve the mass of fluid in the system; this was resolved by Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2004) by extending the thin-film solution to an additional order. Benilov & O’Brien (Reference Benilov and O’Brien2005), Noakes, King & Riley (Reference Noakes, King and Riley2006) and Kelmanson (Reference Kelmanson2009) incorporated inertia into the model, while Weidner, Schwartz & Eres (Reference Weidner, Schwartz and Eres1997) and Evans, Schwartz & Roy (Reference Evans, Schwartz and Roy2005) extended the model to three dimensions in the absence and presence of cylinder rotation, respectively. Reisfeld & Bankoff (Reference Reisfeld and Bankoff1992) incorporated non-isothermal effects, showing that, for a heated cylinder, thermocapillarity would act in concert with gravity, speeding the draining effect, or the reverse for cooled cylinders.

The solutions to these models have been investigated at length. Pukhnachov (Reference Pukhnachov2005a,Reference Pukhnachovb) and Karabut (Reference Karabut2007) studied the existence and uniqueness of steady state solutions to the thin-film equations. Kelmanson (Reference Kelmanson2009) examined how the incorporation of inertia affected these results, showing that it caused the location of the maximum point to be displaced downwards. Recently, Lopes et al. (Reference Lopes, Thiele and Hazel2018) investigated the steady state solutions to the Moffatt problem by means of both a finite-element-based Stokes solver, and a reduced-order model derived using a variational approach. In both cases the parameter space was explored using numerical path continuation. They were able to identify regimes for weak surface tension that supported up to four solutions for a single set of parameters. Notably classical models displayed no multiplicity of solutions, while the variational model displayed at most two solutions for a given set of parameters. The authors attributed this to the improved hydrostatic approximation, as the variational model retains the complete curvature in the capillary term.

For sufficiently thin films at high rotation rates the film is close to solid-body rotation; the deviation of the period of the film from the period of the rotation of the cylinder is a subtle phenomenon that has been investigated both analytically (Hinch & Kelmanson Reference Hinch and Kelmanson2003; Kelmanson Reference Kelmanson2009) and using sophisticated numerical algorithms (Groh & Kelmanson Reference Groh and Kelmanson2009, Reference Groh and Kelmanson2012, Reference Groh and Kelmanson2014). It has also been observed that the models support shock-like solutions: such structures, and the approach to them, have been a particular focus in recent years (Wilson, Hunt & Duffy Reference Wilson, Hunt and Duffy2002; Hinch, Kelmanson & Metcalfe Reference Hinch, Kelmanson and Metcalfe2004; Tougher, Wilson & Duffy Reference Tougher, Wilson and Duffy2009).

As pointed out by Wray, Papageorgiou & Matar (Reference Wray, Papageorgiou and Matar2017b), a common assumption used by most lubrication models is that the thickness of a film is small relative to both the characteristic wavelength of disturbances to the flow, and to the radii of curvature of the substrate. Indeed, this is the case for all models discussed thus far. However, this is quite a stringent assumption, imposing, in particular, a parabolic flow profile that is inappropriately restrictive for all but the thinnest films. Indeed the preliminary results of Peterson, Jimack & Kelmanson (Reference Peterson, Jimack and Kelmanson2001) showed, as expected, increasing error for the lubrication model of Pukhnachev (Reference Pukhnachev1977) for increasing film thicknesses. As a consequence the majority of studies looking at thick layers have relied on numerical computation of the velocity profiles (Hansen & Kelmanson Reference Hansen and Kelmanson1994). In the absence of inertia, Wray et al. (Reference Wray, Papageorgiou and Matar2017b) were able to derive a low-order model that gave good agreement with direct numerical simulations (DNS) by relaxing the assumption on the radius of curvature and using the weighted residual integral boundary-layer (WRIBL) formulation of Ruyer-Quil & Manneville (Reference Ruyer-Quil and Manneville2000). The method of weighted residuals is essentially a separation-of-variables, Galerkin-type approach in which a coupled pair of evolution equations is determined for the local film height  $h$ and depth-integrated liquid flux

$h$ and depth-integrated liquid flux  $q$. While successful in its original intended purpose of improving the modelling of inertia in falling film flows on a plane (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Scheid, Ruyer-Quil & Manneville Reference Scheid, Ruyer-Quil and Manneville2006; Chakraborty et al. Reference Chakraborty, Nguyen, Ruyer-Quil and Bontozoglou2014), the technique has also proven to result in excellent agreement with both DNS and experimental results in flows on a fibre (Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008), as well as in flows incorporating other physical effects such as thermocapillarity (Kalliadasis et al. Reference Kalliadasis, Demekhin, Ruyer-Quil and Velarde2003), electrostatic effects (Wray, Matar & Papageorgiou Reference Wray, Matar and Papageorgiou2017a) or blowing and suction (Thompson, Tseluiko & Papageorgiou Reference Thompson, Tseluiko and Papageorgiou2016). Notably, the full second-order model is rather complicated (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000), requiring the solution of four coupled equations. Via a complex Padé regularisation procedure, Scheid et al. (Reference Scheid, Ruyer-Quil and Manneville2006) were able to deduce a simpler ‘regularised’ two-equation model that was fully consistent at second order. However, in this (Scheid et al. Reference Scheid, Ruyer-Quil and Manneville2006) and other (Wray et al. Reference Wray, Matar and Papageorgiou2017a) contexts it was seen that this regularised model offered little or no improvement in accuracy over the ‘simplified model’ derived by neglecting second-order inertial effects; it is therefore this simplified model on which the thick-film model of Wray et al. (Reference Wray, Papageorgiou and Matar2017b) is based.

$q$. While successful in its original intended purpose of improving the modelling of inertia in falling film flows on a plane (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Scheid, Ruyer-Quil & Manneville Reference Scheid, Ruyer-Quil and Manneville2006; Chakraborty et al. Reference Chakraborty, Nguyen, Ruyer-Quil and Bontozoglou2014), the technique has also proven to result in excellent agreement with both DNS and experimental results in flows on a fibre (Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008), as well as in flows incorporating other physical effects such as thermocapillarity (Kalliadasis et al. Reference Kalliadasis, Demekhin, Ruyer-Quil and Velarde2003), electrostatic effects (Wray, Matar & Papageorgiou Reference Wray, Matar and Papageorgiou2017a) or blowing and suction (Thompson, Tseluiko & Papageorgiou Reference Thompson, Tseluiko and Papageorgiou2016). Notably, the full second-order model is rather complicated (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000), requiring the solution of four coupled equations. Via a complex Padé regularisation procedure, Scheid et al. (Reference Scheid, Ruyer-Quil and Manneville2006) were able to deduce a simpler ‘regularised’ two-equation model that was fully consistent at second order. However, in this (Scheid et al. Reference Scheid, Ruyer-Quil and Manneville2006) and other (Wray et al. Reference Wray, Matar and Papageorgiou2017a) contexts it was seen that this regularised model offered little or no improvement in accuracy over the ‘simplified model’ derived by neglecting second-order inertial effects; it is therefore this simplified model on which the thick-film model of Wray et al. (Reference Wray, Papageorgiou and Matar2017b) is based.

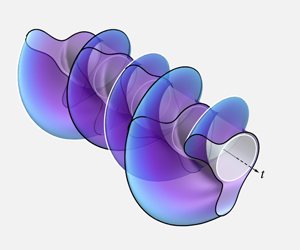

Experiments (Moffatt Reference Moffatt1977; Preziosi & Joseph Reference Preziosi and Joseph1988; Melo & Douady Reference Melo and Douady1993; Kelmanson Reference Kelmanson1995; de Bruyn Reference de Bruyn1997), thin-film models (Kelmanson Reference Kelmanson1995; Evans et al. Reference Evans, Schwartz and Roy2005) and linear stability analyses (Noakes, King & Riley Reference Noakes, King and Riley2005; Benilov & Lapin Reference Benilov and Lapin2013) have shown that the fluid layer coating the rotating cylinder can be unstable to axial perturbations for sufficiently high rotation rates. In particular, in his experiments involving syrup, Moffatt (Reference Moffatt1977) observed that this resulted in the formation of asymmetric ‘syrup rings’ spaced regularly in the axial direction. The model described here may be readily extended to the three-dimensional situation, but for the moment we confine our attention to two-dimensional flows. This is an important preliminary step in both validation and gaining understanding before investigating the three-dimensional case. Furthermore, in the presence of external effects (such as electric fields) the natural instabilities may be purely two-dimensional.

The intent of the paper is twofold: first, to develop and validate a model suitable for thick fluid flows, and second, to investigate the parametric behaviour of the system. In this context ‘thick’ indicates that the radius of curvature of the substrate is of the same order as the thickness of the film. In the past attention has primarily been focussed on the regimes accessible to thin-film models; we extend this here. Therefore we begin by formulating the problem in § 2. We derive the low-order model in § 3. In § 4 we validate our model against an Orr–Sommerfeld analysis in the linear regime, and against DNS in the nonlinear regime. Both the low-order model and the DNS are then used to explore parameter space (the computational methods for which are explained in detail in §§ A.1, A.3 and A.3). We examine some of the details of modelling flows on curved substrates in § 4.4. Finally we give our conclusions in § 5.

2 Problem formulation

2.1 Governing equations

Consider the flow of an incompressible liquid of density  $\unicode[STIX]{x1D70C}$ and dynamic viscosity

$\unicode[STIX]{x1D70C}$ and dynamic viscosity  $\unicode[STIX]{x1D707}$ hanging from a cylinder of radius

$\unicode[STIX]{x1D707}$ hanging from a cylinder of radius  $R$ rotating with angular velocity

$R$ rotating with angular velocity  $C_{V}$. We assume that the gas–liquid interface has constant surface tension coefficient

$C_{V}$. We assume that the gas–liquid interface has constant surface tension coefficient  $\unicode[STIX]{x1D70E}$. The axis of the cylinder is aligned horizontally, with the gravity

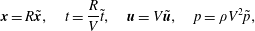

$\unicode[STIX]{x1D70E}$. The axis of the cylinder is aligned horizontally, with the gravity  $\boldsymbol{g}$ acting vertically. We work in cylindrical coordinates centred on the axis of the cylinder and neglect all variations and velocities in the axial direction. We non-dimensionalise the system as

$\boldsymbol{g}$ acting vertically. We work in cylindrical coordinates centred on the axis of the cylinder and neglect all variations and velocities in the axial direction. We non-dimensionalise the system as

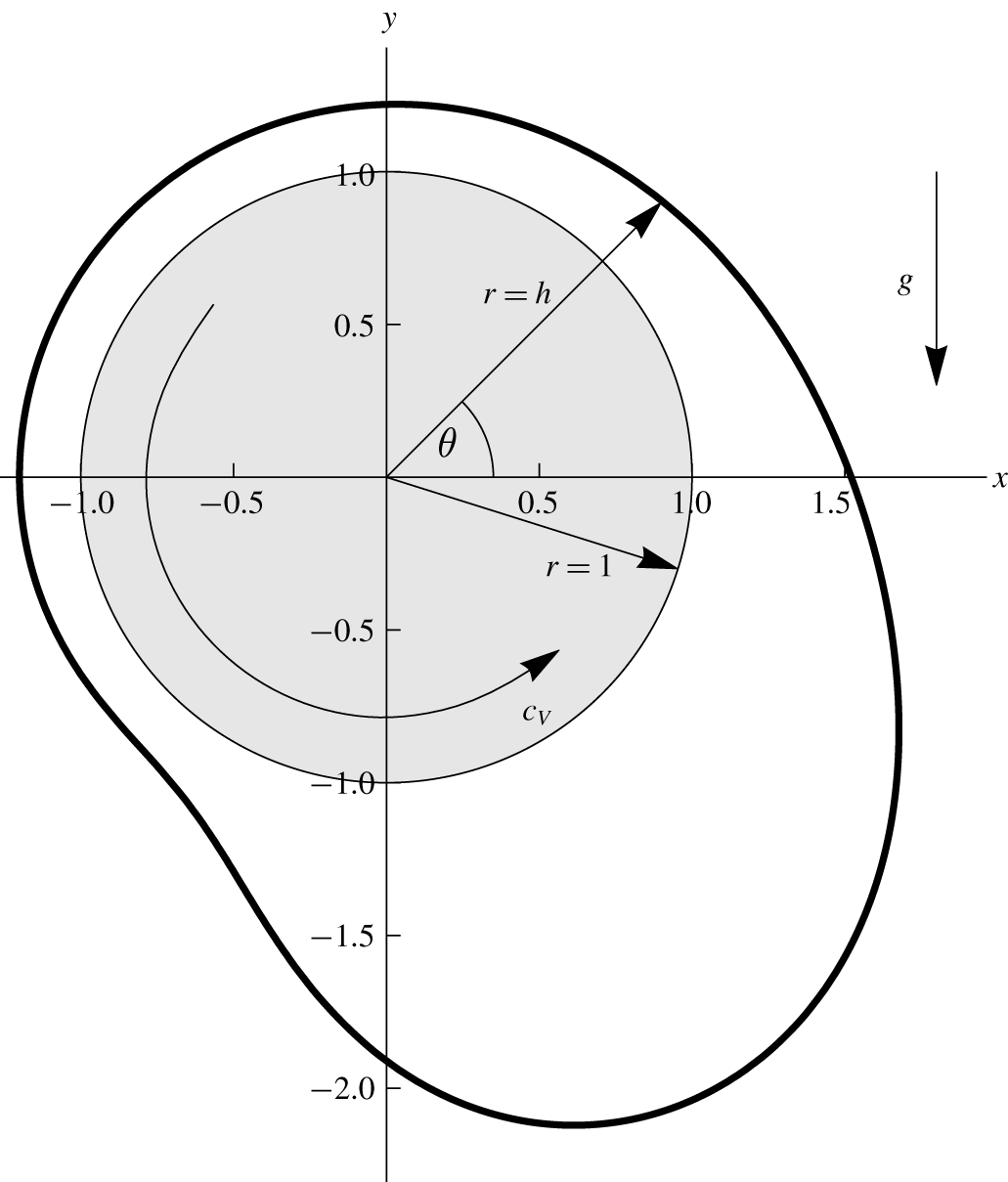

$$\begin{eqnarray}\boldsymbol{x}=R\tilde{\boldsymbol{x}},\quad t=\frac{R}{V}\tilde{t},\quad \boldsymbol{u}=V\tilde{\boldsymbol{u}},\quad p=\unicode[STIX]{x1D70C}V^{2}\tilde{p},\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{x}=R\tilde{\boldsymbol{x}},\quad t=\frac{R}{V}\tilde{t},\quad \boldsymbol{u}=V\tilde{\boldsymbol{u}},\quad p=\unicode[STIX]{x1D70C}V^{2}\tilde{p},\end{eqnarray}$$ where  $\boldsymbol{u}=(u,v)$ is the usual velocity in polar coordinates and

$\boldsymbol{u}=(u,v)$ is the usual velocity in polar coordinates and  $p$ is the pressure. We use the gravity-based scaling for velocity

$p$ is the pressure. We use the gravity-based scaling for velocity  $V=\sqrt{Rg}$ so as to explicitly retain a dimensionless rotation rate as a system parameter. The system is shown schematically in figure 1.

$V=\sqrt{Rg}$ so as to explicitly retain a dimensionless rotation rate as a system parameter. The system is shown schematically in figure 1.

Figure 1. Geometry of the problem considered in the present work. The disk has unit radius, with the interface lying at  $r=h$. Gravity acts vertically downwards. The disk rotates with angular velocity

$r=h$. Gravity acts vertically downwards. The disk rotates with angular velocity  $c_{V}$ in the anti-clockwise direction.

$c_{V}$ in the anti-clockwise direction.

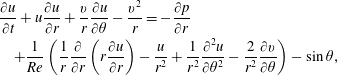

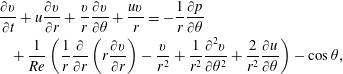

Discarding the tilde notation, the system is governed by the Navier–Stokes and continuity equations,

$$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}-\frac{v^{2}}{r}=-\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}r}\nonumber\\ \displaystyle & & \displaystyle \quad +\frac{1}{Re}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}\right)-\frac{u}{r^{2}}+\frac{1}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}-\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)-\sin \unicode[STIX]{x1D703},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}-\frac{v^{2}}{r}=-\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}r}\nonumber\\ \displaystyle & & \displaystyle \quad +\frac{1}{Re}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}\right)-\frac{u}{r^{2}}+\frac{1}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}-\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)-\sin \unicode[STIX]{x1D703},\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}+\frac{uv}{r}=-\frac{1}{r}\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{1}{Re}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}\right)-\frac{v}{r^{2}}+\frac{1}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}+\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)-\cos \unicode[STIX]{x1D703},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}+\frac{uv}{r}=-\frac{1}{r}\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{1}{Re}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}\right)-\frac{v}{r^{2}}+\frac{1}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}+\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)-\cos \unicode[STIX]{x1D703},\end{eqnarray}$$ $$\begin{eqnarray}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}+\frac{u}{r}+\frac{1}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}=0,\end{eqnarray}$$

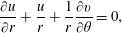

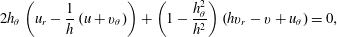

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}+\frac{u}{r}+\frac{1}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}=0,\end{eqnarray}$$ while at the interface  $r=h$ the tangential stress condition is

$r=h$ the tangential stress condition is

$$\begin{eqnarray}2h_{\unicode[STIX]{x1D703}}\left(u_{r}-\frac{1}{h}\left(u+v_{\unicode[STIX]{x1D703}}\right)\right)+\left(1-\frac{h_{\unicode[STIX]{x1D703}}^{2}}{h^{2}}\right)\left(hv_{r}-v+u_{\unicode[STIX]{x1D703}}\right)=0,\end{eqnarray}$$

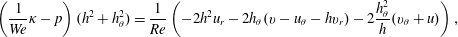

$$\begin{eqnarray}2h_{\unicode[STIX]{x1D703}}\left(u_{r}-\frac{1}{h}\left(u+v_{\unicode[STIX]{x1D703}}\right)\right)+\left(1-\frac{h_{\unicode[STIX]{x1D703}}^{2}}{h^{2}}\right)\left(hv_{r}-v+u_{\unicode[STIX]{x1D703}}\right)=0,\end{eqnarray}$$the normal stress condition is

$$\begin{eqnarray}\left(\frac{1}{We}\unicode[STIX]{x1D705}-p\right)(h^{2}+h_{\unicode[STIX]{x1D703}}^{2})=\frac{1}{Re}\left(-2h^{2}u_{r}-2h_{\unicode[STIX]{x1D703}}(v-u_{\unicode[STIX]{x1D703}}-hv_{r})-2\frac{h_{\unicode[STIX]{x1D703}}^{2}}{h}(v_{\unicode[STIX]{x1D703}}+u)\right),\end{eqnarray}$$

$$\begin{eqnarray}\left(\frac{1}{We}\unicode[STIX]{x1D705}-p\right)(h^{2}+h_{\unicode[STIX]{x1D703}}^{2})=\frac{1}{Re}\left(-2h^{2}u_{r}-2h_{\unicode[STIX]{x1D703}}(v-u_{\unicode[STIX]{x1D703}}-hv_{r})-2\frac{h_{\unicode[STIX]{x1D703}}^{2}}{h}(v_{\unicode[STIX]{x1D703}}+u)\right),\end{eqnarray}$$and the kinematic condition, together with the continuity equation and impermeability at the cylinder wall, imply

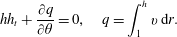

$$\begin{eqnarray}hh_{t}+\frac{\unicode[STIX]{x2202}q}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}=0,\quad q=\int _{1}^{h}v\,\text{d}r.\end{eqnarray}$$

$$\begin{eqnarray}hh_{t}+\frac{\unicode[STIX]{x2202}q}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}=0,\quad q=\int _{1}^{h}v\,\text{d}r.\end{eqnarray}$$The no-slip and impermeability conditions are

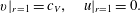

$$\begin{eqnarray}v|_{r=1}=c_{V},\quad u|_{r=1}=0.\end{eqnarray}$$

$$\begin{eqnarray}v|_{r=1}=c_{V},\quad u|_{r=1}=0.\end{eqnarray}$$Our system is thus governed by the dimensionless groups

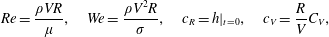

$$\begin{eqnarray}Re=\frac{\unicode[STIX]{x1D70C}VR}{\unicode[STIX]{x1D707}},\quad We=\frac{\unicode[STIX]{x1D70C}V^{2}R}{\unicode[STIX]{x1D70E}},\quad c_{R}=h|_{t=0},\quad c_{V}=\frac{R}{V}C_{V},\end{eqnarray}$$

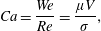

$$\begin{eqnarray}Re=\frac{\unicode[STIX]{x1D70C}VR}{\unicode[STIX]{x1D707}},\quad We=\frac{\unicode[STIX]{x1D70C}V^{2}R}{\unicode[STIX]{x1D70E}},\quad c_{R}=h|_{t=0},\quad c_{V}=\frac{R}{V}C_{V},\end{eqnarray}$$respectively a Reynolds number representing the relative significance of inertia compared to viscous effects, a Weber number encoding the balance of inertial effects to surface tension, the undisturbed (uniform) radius of the interface, and the angular velocity of the disk (in this study always positive and thus rotating in an anticlockwise sense). We note that on occasion it will be useful to consider the Capillary number

$$\begin{eqnarray}Ca=\frac{We}{Re}=\frac{\unicode[STIX]{x1D707}V}{\unicode[STIX]{x1D70E}},\end{eqnarray}$$

$$\begin{eqnarray}Ca=\frac{We}{Re}=\frac{\unicode[STIX]{x1D707}V}{\unicode[STIX]{x1D70E}},\end{eqnarray}$$which gives the relative significance of viscous effects compared to surface tension, as this is often used in some of the cited literature.

3 Modelling

We begin by deriving a thick-film long-wave model. As detailed by Wray et al. (Reference Wray, Papageorgiou and Matar2017b), first a boundary-layer-like equation is derived. While we are of course not studying a boundary layer, the terminology is common due to structural similarities of the equations (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Kalliadasis et al. Reference Kalliadasis, Demekhin, Ruyer-Quil and Velarde2003; Scheid et al. Reference Scheid, Ruyer-Quil and Manneville2006; Oron & Heining Reference Oron and Heining2008; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008; Wray et al. Reference Wray, Matar and Papageorgiou2017a). Key to this process is that the thickness of the film is allowed to be of the same order as the radius of curvature of the substrate, hence being a ‘thick-film’ model. Then a low-order model is derived by applying the method of weighted residuals (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000). Our dimensional scaling is slightly different here to that used by Wray et al. (Reference Wray, Papageorgiou and Matar2017b), however, as we allow  $Re=O(1)$ it does not affect the long-wave scalings.

$Re=O(1)$ it does not affect the long-wave scalings.

3.1 Long-wave boundary-layer equation

In order to make analytic progress, we use the long-wave methodology proposed by Wray et al. (Reference Wray, Papageorgiou and Matar2017b). In particular, the substitutions

$$\begin{eqnarray}\displaystyle u\mapsto \unicode[STIX]{x1D716}u,\quad \unicode[STIX]{x2202}_{\unicode[STIX]{x1D703}}\mapsto \unicode[STIX]{x1D716}\unicode[STIX]{x2202}_{\unicode[STIX]{x1D703}},\quad \unicode[STIX]{x2202}_{t}\mapsto \unicode[STIX]{x1D716}\unicode[STIX]{x2202}_{t}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle u\mapsto \unicode[STIX]{x1D716}u,\quad \unicode[STIX]{x2202}_{\unicode[STIX]{x1D703}}\mapsto \unicode[STIX]{x1D716}\unicode[STIX]{x2202}_{\unicode[STIX]{x1D703}},\quad \unicode[STIX]{x2202}_{t}\mapsto \unicode[STIX]{x1D716}\unicode[STIX]{x2202}_{t}, & & \displaystyle\end{eqnarray}$$ are made, where  $\unicode[STIX]{x1D716}$ is a small parameter. Following the standard terminology of Ruyer-Quil & Manneville (Reference Ruyer-Quil and Manneville2000), this is an ‘ordering parameter’ which serves only to assert the relative size of a particular term. In particular, it does not constitute an actual physical rescaling of space; it is merely an assertion about the relative sizes of terms and their derivatives. The technique is discussed further by Kalliadasis et al. (Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011, Chap. 6) (see also Thompson et al. (Reference Thompson, Tseluiko and Papageorgiou2016), Trevelyan, Pereira & Kalliadasis (Reference Trevelyan, Pereira and Kalliadasis2012)). This approach has been used and validated extensively, giving excellent results (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Kalliadasis et al. Reference Kalliadasis, Demekhin, Ruyer-Quil and Velarde2003; Scheid et al. Reference Scheid, Ruyer-Quil and Manneville2006; Oron & Heining Reference Oron and Heining2008; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008; Wray et al. Reference Wray, Matar and Papageorgiou2017a). We note that the streamwise (azimuthal) coordinate has a fixed domain length of

$\unicode[STIX]{x1D716}$ is a small parameter. Following the standard terminology of Ruyer-Quil & Manneville (Reference Ruyer-Quil and Manneville2000), this is an ‘ordering parameter’ which serves only to assert the relative size of a particular term. In particular, it does not constitute an actual physical rescaling of space; it is merely an assertion about the relative sizes of terms and their derivatives. The technique is discussed further by Kalliadasis et al. (Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011, Chap. 6) (see also Thompson et al. (Reference Thompson, Tseluiko and Papageorgiou2016), Trevelyan, Pereira & Kalliadasis (Reference Trevelyan, Pereira and Kalliadasis2012)). This approach has been used and validated extensively, giving excellent results (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Kalliadasis et al. Reference Kalliadasis, Demekhin, Ruyer-Quil and Velarde2003; Scheid et al. Reference Scheid, Ruyer-Quil and Manneville2006; Oron & Heining Reference Oron and Heining2008; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008; Wray et al. Reference Wray, Matar and Papageorgiou2017a). We note that the streamwise (azimuthal) coordinate has a fixed domain length of  $2\unicode[STIX]{x03C0}$ which may cast doubt on the validity of the long-wave assumption; indeed, there are certain possible flows that could violate the stated asymptotic approximations. However, there are many physical contexts in which azimuthal variations would be of higher order. These include situations where a field variable depends only on the radial coordinate to leading order, situations where the radius of the cylinder is large relative to thickness of the film, and situations where a film varies slowly on the

$2\unicode[STIX]{x03C0}$ which may cast doubt on the validity of the long-wave assumption; indeed, there are certain possible flows that could violate the stated asymptotic approximations. However, there are many physical contexts in which azimuthal variations would be of higher order. These include situations where a field variable depends only on the radial coordinate to leading order, situations where the radius of the cylinder is large relative to thickness of the film, and situations where a film varies slowly on the  $[\!0,2\unicode[STIX]{x03C0}\!)$ domain (save perhaps in some small matching/shock region, where the asymptotic assumptions are violated, and yet the results are of appreciable accuracy nonetheless (Mazouchi & Homsy Reference Mazouchi and Homsy2001; Gaskell et al. Reference Gaskell, Jimack, Sellier, Thompson and Wilson2004)). In contexts where the assumptions are in fact violated, the derived system may be treated as a model in the sense of Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001), where justification is provided a posteriori via extensive validation against direct numerical computations.

$[\!0,2\unicode[STIX]{x03C0}\!)$ domain (save perhaps in some small matching/shock region, where the asymptotic assumptions are violated, and yet the results are of appreciable accuracy nonetheless (Mazouchi & Homsy Reference Mazouchi and Homsy2001; Gaskell et al. Reference Gaskell, Jimack, Sellier, Thompson and Wilson2004)). In contexts where the assumptions are in fact violated, the derived system may be treated as a model in the sense of Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001), where justification is provided a posteriori via extensive validation against direct numerical computations.

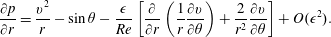

Under the above substitutions (3.1), the  $r$-component of the momentum equation (2.2) becomes

$r$-component of the momentum equation (2.2) becomes

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}r}=\frac{v^{2}}{r}-\sin \unicode[STIX]{x1D703}-\frac{\unicode[STIX]{x1D716}}{Re}\left[\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)+\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right]+O(\unicode[STIX]{x1D716}^{2}).\end{eqnarray}$$

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}p}{\unicode[STIX]{x2202}r}=\frac{v^{2}}{r}-\sin \unicode[STIX]{x1D703}-\frac{\unicode[STIX]{x1D716}}{Re}\left[\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right)+\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\right]+O(\unicode[STIX]{x1D716}^{2}).\end{eqnarray}$$ Integrating this from  $r$ to

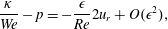

$r$ to  $h$ subject to the first-order truncation of the normal stress,

$h$ subject to the first-order truncation of the normal stress,

$$\begin{eqnarray}\frac{\unicode[STIX]{x1D705}}{We}-p=-\frac{\unicode[STIX]{x1D716}}{Re}2u_{r}+O(\unicode[STIX]{x1D716}^{2}),\end{eqnarray}$$

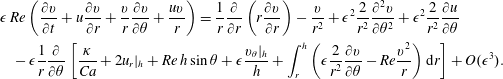

$$\begin{eqnarray}\frac{\unicode[STIX]{x1D705}}{We}-p=-\frac{\unicode[STIX]{x1D716}}{Re}2u_{r}+O(\unicode[STIX]{x1D716}^{2}),\end{eqnarray}$$ and substituting into the  $\unicode[STIX]{x1D703}$-component of the momentum equation (2.3) gives the boundary-layer equation

$\unicode[STIX]{x1D703}$-component of the momentum equation (2.3) gives the boundary-layer equation

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D716}\,Re\left(\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}+\frac{uv}{r}\right)=\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}\right)-\frac{v}{r^{2}}+\unicode[STIX]{x1D716}^{2}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}+\unicode[STIX]{x1D716}^{2}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \quad -\,\unicode[STIX]{x1D716}\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left[\frac{\unicode[STIX]{x1D705}}{Ca}+2u_{r}|_{h}+Re\,h\sin \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}\frac{v_{\unicode[STIX]{x1D703}}|_{h}}{h}+\int _{r}^{h}\left(\unicode[STIX]{x1D716}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}-Re\frac{v^{2}}{r}\right)\text{d}r\right]+O(\unicode[STIX]{x1D716}^{3}).\nonumber\\ \displaystyle & & \displaystyle\end{eqnarray}$$

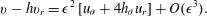

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D716}\,Re\left(\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}t}+u\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}+\frac{v}{r}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}+\frac{uv}{r}\right)=\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(r\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}r}\right)-\frac{v}{r^{2}}+\unicode[STIX]{x1D716}^{2}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}^{2}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}^{2}}+\unicode[STIX]{x1D716}^{2}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \quad -\,\unicode[STIX]{x1D716}\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left[\frac{\unicode[STIX]{x1D705}}{Ca}+2u_{r}|_{h}+Re\,h\sin \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}\frac{v_{\unicode[STIX]{x1D703}}|_{h}}{h}+\int _{r}^{h}\left(\unicode[STIX]{x1D716}\frac{2}{r^{2}}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}-Re\frac{v^{2}}{r}\right)\text{d}r\right]+O(\unicode[STIX]{x1D716}^{3}).\nonumber\\ \displaystyle & & \displaystyle\end{eqnarray}$$The tangential stress condition at the interface (2.5) truncated at second order is

$$\begin{eqnarray}v-hv_{r}=\unicode[STIX]{x1D716}^{2}\left[u_{\unicode[STIX]{x1D703}}+4h_{\unicode[STIX]{x1D703}}u_{r}\right]+O(\unicode[STIX]{x1D716}^{3}).\end{eqnarray}$$

$$\begin{eqnarray}v-hv_{r}=\unicode[STIX]{x1D716}^{2}\left[u_{\unicode[STIX]{x1D703}}+4h_{\unicode[STIX]{x1D703}}u_{r}\right]+O(\unicode[STIX]{x1D716}^{3}).\end{eqnarray}$$3.2 Weighted residual model

We now develop a low-order model based on the boundary-layer equation (3.4) following the method of weighted residuals (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000). The leading-order solution is determined in the same way as the classical gradient expansion, while higher orders are computed by projecting onto an appropriately expanded set of basis functions for the cross-stream coordinate  $r$. In general, the determination of these basis functions and the subsequent projection is a laborious process, but Ruyer-Quil & Manneville demonstrated that the methodology could be simplified considerably by a weighted integral procedure, with the weight

$r$. In general, the determination of these basis functions and the subsequent projection is a laborious process, but Ruyer-Quil & Manneville demonstrated that the methodology could be simplified considerably by a weighted integral procedure, with the weight  $w$ being the solution to the adjoint of the leading-order problem. This accounts for the higher-order corrections to the model while avoiding the explicit determination of the higher-order basis functions or their coefficients. We therefore begin by solving the leading-order problem,

$w$ being the solution to the adjoint of the leading-order problem. This accounts for the higher-order corrections to the model while avoiding the explicit determination of the higher-order basis functions or their coefficients. We therefore begin by solving the leading-order problem,

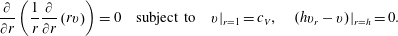

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(rv\right)\right)=0\quad \text{subject to}\quad v|_{r=1}=c_{V},\quad (hv_{r}-v)|_{r=h}=0.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(rv\right)\right)=0\quad \text{subject to}\quad v|_{r=1}=c_{V},\quad (hv_{r}-v)|_{r=h}=0.\end{eqnarray}$$The solution to this is just solid-body rotation,

$$\begin{eqnarray}v=c_{V}r.\end{eqnarray}$$

$$\begin{eqnarray}v=c_{V}r.\end{eqnarray}$$ To proceed to higher order, we project onto a suitable set of basis functions  $f_{n}(r)$, with the dependence on

$f_{n}(r)$, with the dependence on  $\unicode[STIX]{x1D703}$ and

$\unicode[STIX]{x1D703}$ and  $t$ given by the coefficients

$t$ given by the coefficients  $a_{n}$

$a_{n}$

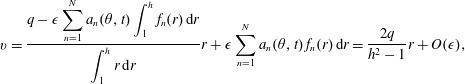

$$\begin{eqnarray}v=\frac{q-\unicode[STIX]{x1D716}\displaystyle \mathop{\sum }_{n=1}^{N}a_{n}(\unicode[STIX]{x1D703},t)\int _{1}^{h}f_{n}(r)\,\text{d}r}{\displaystyle \int _{1}^{h}r\,\text{d}r}r+\unicode[STIX]{x1D716}\mathop{\sum }_{n=1}^{N}a_{n}(\unicode[STIX]{x1D703},t)\,f_{n}(r)\,\text{d}r=\frac{2q}{h^{2}-1}r+O(\unicode[STIX]{x1D716}^{}),\end{eqnarray}$$

$$\begin{eqnarray}v=\frac{q-\unicode[STIX]{x1D716}\displaystyle \mathop{\sum }_{n=1}^{N}a_{n}(\unicode[STIX]{x1D703},t)\int _{1}^{h}f_{n}(r)\,\text{d}r}{\displaystyle \int _{1}^{h}r\,\text{d}r}r+\unicode[STIX]{x1D716}\mathop{\sum }_{n=1}^{N}a_{n}(\unicode[STIX]{x1D703},t)\,f_{n}(r)\,\text{d}r=\frac{2q}{h^{2}-1}r+O(\unicode[STIX]{x1D716}^{}),\end{eqnarray}$$ where this form has been selected so as to retain the relation  $q=\int _{1}^{h}v\,\text{d}r$ correct to second order. Explicit computation of the

$q=\int _{1}^{h}v\,\text{d}r$ correct to second order. Explicit computation of the  $a_{n}$ (and their corresponding basis functions) can be avoided by a suitable choice of weighting function

$a_{n}$ (and their corresponding basis functions) can be avoided by a suitable choice of weighting function  $w$. This weight is the solution of the adjoint of the leading-order problem, and hence depends on the problem being solved, including its geometry (Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008). For viscous flow on a rotating disk, this weight is (Wray et al. Reference Wray, Papageorgiou and Matar2017b)

$w$. This weight is the solution of the adjoint of the leading-order problem, and hence depends on the problem being solved, including its geometry (Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008). For viscous flow on a rotating disk, this weight is (Wray et al. Reference Wray, Papageorgiou and Matar2017b)

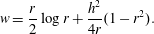

$$\begin{eqnarray}w=\frac{r}{2}\log r+\frac{h^{2}}{4r}(1-r^{2}).\end{eqnarray}$$

$$\begin{eqnarray}w=\frac{r}{2}\log r+\frac{h^{2}}{4r}(1-r^{2}).\end{eqnarray}$$ Multiplying (3.4) by  $w$ and integrating across the film thickness, and observing that

$w$ and integrating across the film thickness, and observing that

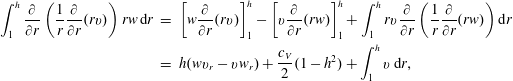

$$\begin{eqnarray}\displaystyle \int _{1}^{h}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rv)\right)rw\,\text{d}r & = & \displaystyle \left[w\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rv)\right]_{1}^{h}-\left[v\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rw)\right]_{1}^{h}+\int _{1}^{h}rv\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rw)\right)\text{d}r\nonumber\\ \displaystyle & = & \displaystyle h(wv_{r}-vw_{r})+\frac{c_{V}}{2}(1-h^{2})+\int _{1}^{h}v\,\text{d}r,\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \int _{1}^{h}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rv)\right)rw\,\text{d}r & = & \displaystyle \left[w\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rv)\right]_{1}^{h}-\left[v\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rw)\right]_{1}^{h}+\int _{1}^{h}rv\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}\left(\frac{1}{r}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}(rw)\right)\text{d}r\nonumber\\ \displaystyle & = & \displaystyle h(wv_{r}-vw_{r})+\frac{c_{V}}{2}(1-h^{2})+\int _{1}^{h}v\,\text{d}r,\end{eqnarray}$$gives the final governing equation,

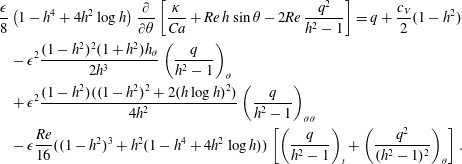

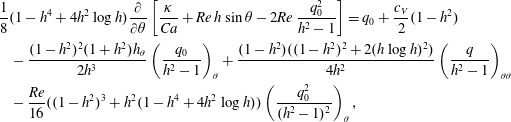

$$\begin{eqnarray}\displaystyle & & \displaystyle \hspace{-24.0pt}\frac{\unicode[STIX]{x1D716}}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left[\frac{\unicode[STIX]{x1D705}}{Ca}+Re\,h\sin \unicode[STIX]{x1D703}-2Re\,\frac{q^{2}}{h^{2}-1}\right]=q+\frac{c_{V}}{2}(1-h^{2})\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad -\,\unicode[STIX]{x1D716}^{2}\frac{(1-h^{2})^{2}(1+h^{2})h_{\unicode[STIX]{x1D703}}}{2h^{3}}\left(\frac{q}{h^{2}-1}\right)_{\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad +\,\unicode[STIX]{x1D716}^{2}\frac{(1-h^{2})((1-h^{2})^{2}+2(h\log h)^{2})}{4h^{2}}\left(\frac{q}{h^{2}-1}\right)_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad -\,\unicode[STIX]{x1D716}\frac{Re}{16}((1-h^{2})^{3}+h^{2}(1-h^{4}+4h^{2}\log h))\left[\left(\frac{q}{h^{2}-1}\right)_{t}+\left(\frac{q^{2}}{(h^{2}-1)^{2}}\right)_{\unicode[STIX]{x1D703}}\right].\end{eqnarray}$$

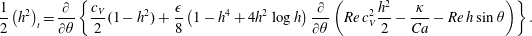

$$\begin{eqnarray}\displaystyle & & \displaystyle \hspace{-24.0pt}\frac{\unicode[STIX]{x1D716}}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left[\frac{\unicode[STIX]{x1D705}}{Ca}+Re\,h\sin \unicode[STIX]{x1D703}-2Re\,\frac{q^{2}}{h^{2}-1}\right]=q+\frac{c_{V}}{2}(1-h^{2})\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad -\,\unicode[STIX]{x1D716}^{2}\frac{(1-h^{2})^{2}(1+h^{2})h_{\unicode[STIX]{x1D703}}}{2h^{3}}\left(\frac{q}{h^{2}-1}\right)_{\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad +\,\unicode[STIX]{x1D716}^{2}\frac{(1-h^{2})((1-h^{2})^{2}+2(h\log h)^{2})}{4h^{2}}\left(\frac{q}{h^{2}-1}\right)_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad -\,\unicode[STIX]{x1D716}\frac{Re}{16}((1-h^{2})^{3}+h^{2}(1-h^{4}+4h^{2}\log h))\left[\left(\frac{q}{h^{2}-1}\right)_{t}+\left(\frac{q^{2}}{(h^{2}-1)^{2}}\right)_{\unicode[STIX]{x1D703}}\right].\end{eqnarray}$$ This represents the main novel result of the paper and, together with the kinematic condition (2.7), constitutes a closed system governing the evolution of the film thickness  $h$ and the flux

$h$ and the flux  $q$.

$q$.

For the purposes of the computations, we reverse the long-wave scalings (3.1) – in particular, the terms preceded by  $\unicode[STIX]{x1D716}$ are still expected to exhibit values of the appropriate order, but this rescaling avoids setting an arbitrary value for

$\unicode[STIX]{x1D716}$ are still expected to exhibit values of the appropriate order, but this rescaling avoids setting an arbitrary value for  $\unicode[STIX]{x1D716}$. Note that, other than the term

$\unicode[STIX]{x1D716}$. Note that, other than the term  $-2Re(q^{2}/h^{2}-1)$ and the terms on the final line, equation (3.11) is identical to the expression given in Wray et al. (Reference Wray, Papageorgiou and Matar2017b) (up to trivial differences in scalings), incorporating the effects of capillarity, gravity, viscosity and the driving effect of the rotating cylinder. The remaining terms constitute the incorporation of inertia into the problem. We note that of particular interest is the term

$-2Re(q^{2}/h^{2}-1)$ and the terms on the final line, equation (3.11) is identical to the expression given in Wray et al. (Reference Wray, Papageorgiou and Matar2017b) (up to trivial differences in scalings), incorporating the effects of capillarity, gravity, viscosity and the driving effect of the rotating cylinder. The remaining terms constitute the incorporation of inertia into the problem. We note that of particular interest is the term  $-2Re(q^{2}/h^{2}-1)$: this enters via the aberrant

$-2Re(q^{2}/h^{2}-1)$: this enters via the aberrant  $O(1)$ term

$O(1)$ term  $v^{2}/r$ in the cross-stream pressure term (3.2). Such inertial terms in the cross-stream momentum equation are typically of too small an order to enter via the pressure in other geometries (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Oron & Heining Reference Oron and Heining2008; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008); we shall see later that this term represents a centrifugal instability and its incorporation is crucial for accurate modelling.

$v^{2}/r$ in the cross-stream pressure term (3.2). Such inertial terms in the cross-stream momentum equation are typically of too small an order to enter via the pressure in other geometries (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Oron & Heining Reference Oron and Heining2008; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008); we shall see later that this term represents a centrifugal instability and its incorporation is crucial for accurate modelling.

Finally, we note that this model has two main differences to previous models in the literature: firstly, a long-wave thick-film scaling (3.1) is used to derive the boundary-layer equation (3.4); secondly the method of weighted residuals is used to derive the coupled  $h$ and

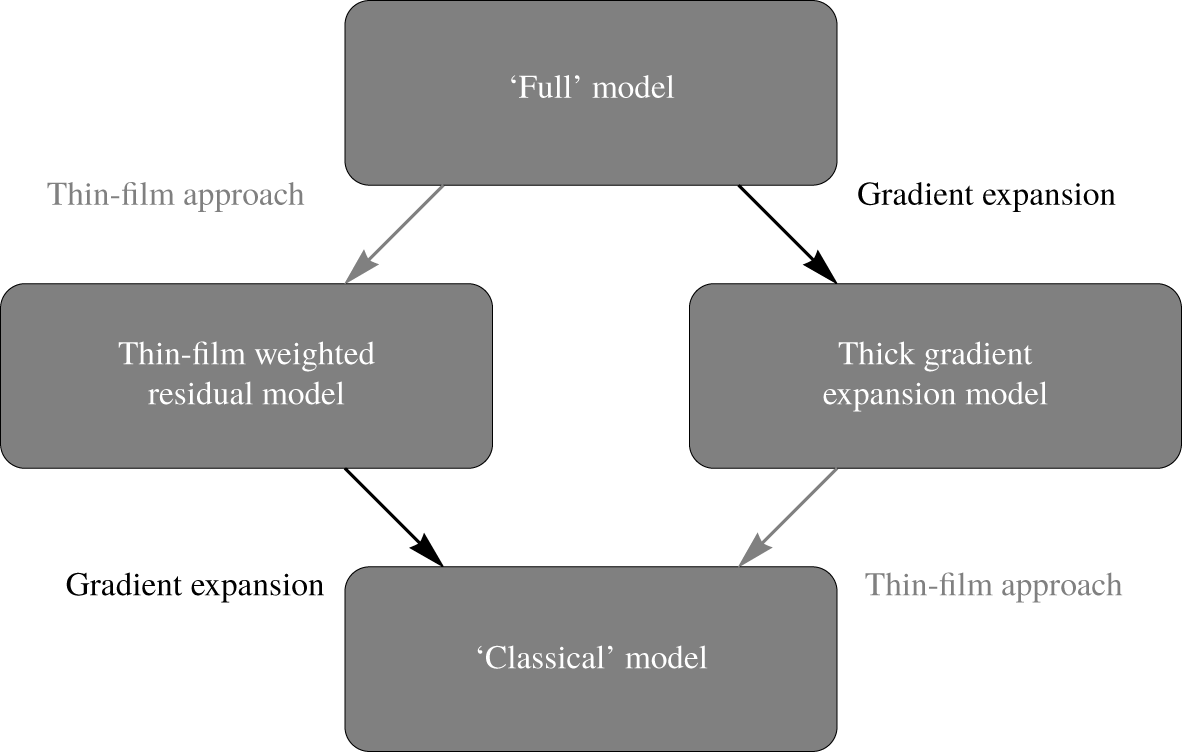

$h$ and  $q$ evolution equations (2.7), (3.11). To help quantify the contribution of each of the two elements to the final model, we derive two simplified equations that each use only of these techniques. We will find that the classic thin-film gradient expansion model of Kelmanson (Reference Kelmanson2009) is recoverable as an appropriate limit of each of these equations. The relationship between the models is given schematically in figure 2.

$q$ evolution equations (2.7), (3.11). To help quantify the contribution of each of the two elements to the final model, we derive two simplified equations that each use only of these techniques. We will find that the classic thin-film gradient expansion model of Kelmanson (Reference Kelmanson2009) is recoverable as an appropriate limit of each of these equations. The relationship between the models is given schematically in figure 2.

3.2.1 Thin-film weighted residual model

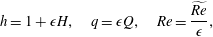

An appropriate thin-film (but still weighted residual) formulation can be derived from (3.11) by applying the scalings

$$\begin{eqnarray}h=1+\unicode[STIX]{x1D716}H,\quad q=\unicode[STIX]{x1D716}Q,\quad Re=\frac{\widetilde{Re}}{\unicode[STIX]{x1D716}},\end{eqnarray}$$

$$\begin{eqnarray}h=1+\unicode[STIX]{x1D716}H,\quad q=\unicode[STIX]{x1D716}Q,\quad Re=\frac{\widetilde{Re}}{\unicode[STIX]{x1D716}},\end{eqnarray}$$ discarding the tilde decoration and expanding for small  $\unicode[STIX]{x1D716}$, giving

$\unicode[STIX]{x1D716}$, giving

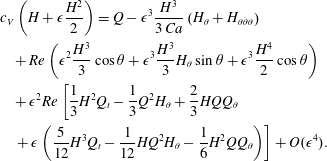

$$\begin{eqnarray}\displaystyle & & \displaystyle c_{V}\left(H+\unicode[STIX]{x1D716}\frac{H^{2}}{2}\right)=Q-\unicode[STIX]{x1D716}^{3}\frac{H^{3}}{3\,Ca}\left(H_{\unicode[STIX]{x1D703}}+H_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,Re\left(\unicode[STIX]{x1D716}^{2}\frac{H^{3}}{3}\cos \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}^{3}\frac{H^{3}}{3}H_{\unicode[STIX]{x1D703}}\sin \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}^{3}\frac{H^{4}}{2}\cos \unicode[STIX]{x1D703}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,\unicode[STIX]{x1D716}^{2}Re\left[\frac{1}{3}H^{2}Q_{t}-\frac{1}{3}Q^{2}H_{\unicode[STIX]{x1D703}}+\frac{2}{3}HQQ_{\unicode[STIX]{x1D703}}\right.\nonumber\\ \displaystyle & & \displaystyle \left.\quad +\,\unicode[STIX]{x1D716}\left(\frac{5}{12}H^{3}Q_{t}-\frac{1}{12}HQ^{2}H_{\unicode[STIX]{x1D703}}-\frac{1}{6}H^{2}QQ_{\unicode[STIX]{x1D703}}\right)\right]+O(\unicode[STIX]{x1D716}^{4}).\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle c_{V}\left(H+\unicode[STIX]{x1D716}\frac{H^{2}}{2}\right)=Q-\unicode[STIX]{x1D716}^{3}\frac{H^{3}}{3\,Ca}\left(H_{\unicode[STIX]{x1D703}}+H_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,Re\left(\unicode[STIX]{x1D716}^{2}\frac{H^{3}}{3}\cos \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}^{3}\frac{H^{3}}{3}H_{\unicode[STIX]{x1D703}}\sin \unicode[STIX]{x1D703}+\unicode[STIX]{x1D716}^{3}\frac{H^{4}}{2}\cos \unicode[STIX]{x1D703}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,\unicode[STIX]{x1D716}^{2}Re\left[\frac{1}{3}H^{2}Q_{t}-\frac{1}{3}Q^{2}H_{\unicode[STIX]{x1D703}}+\frac{2}{3}HQQ_{\unicode[STIX]{x1D703}}\right.\nonumber\\ \displaystyle & & \displaystyle \left.\quad +\,\unicode[STIX]{x1D716}\left(\frac{5}{12}H^{3}Q_{t}-\frac{1}{12}HQ^{2}H_{\unicode[STIX]{x1D703}}-\frac{1}{6}H^{2}QQ_{\unicode[STIX]{x1D703}}\right)\right]+O(\unicode[STIX]{x1D716}^{4}).\end{eqnarray}$$This is complemented by the thin-film version of the kinematic condition (2.7),

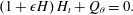

$$\begin{eqnarray}\left(1+\unicode[STIX]{x1D716}H\right)H_{t}+Q_{\unicode[STIX]{x1D703}}=0.\end{eqnarray}$$

$$\begin{eqnarray}\left(1+\unicode[STIX]{x1D716}H\right)H_{t}+Q_{\unicode[STIX]{x1D703}}=0.\end{eqnarray}$$We refer to this as the thin-film weighted residual or WRIBL model.

Figure 2. The relationship between the full long-wave model (equations (2.7), (3.11), § 3.2), the thin-film weighted residual model (equations (3.13), (3.14), § 3.2.1), the long-wave gradient expansion model (equation (3.18), § 3.2.2) and the thin-film gradient expansion model as derived by Kelmanson (Reference Kelmanson2009) (equation (3.19), § 3.2.3).

3.2.2 Thick-film gradient expansion model

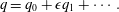

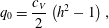

In order to perform a gradient expansion (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000), we make the substitution

$$\begin{eqnarray}q=q_{0}+\unicode[STIX]{x1D716}q_{1}+\cdots \,.\end{eqnarray}$$

$$\begin{eqnarray}q=q_{0}+\unicode[STIX]{x1D716}q_{1}+\cdots \,.\end{eqnarray}$$ We then solve for successive  $q_{i}$ in (3.11), giving

$q_{i}$ in (3.11), giving

$$\begin{eqnarray}\displaystyle & \displaystyle q_{0}=\frac{c_{V}}{2}\left(h^{2}-1\right), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle q_{0}=\frac{c_{V}}{2}\left(h^{2}-1\right), & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle q_{1}=\frac{1}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left(\frac{\unicode[STIX]{x1D705}}{Ca}+Re\,h\sin \unicode[STIX]{x1D703}-Re\,c_{V}^{2}\frac{h^{2}}{2}\right). & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle q_{1}=\frac{1}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left(\frac{\unicode[STIX]{x1D705}}{Ca}+Re\,h\sin \unicode[STIX]{x1D703}-Re\,c_{V}^{2}\frac{h^{2}}{2}\right). & \displaystyle\end{eqnarray}$$Substitution of these into (2.7) gives the appropriate gradient expansion model as

$$\begin{eqnarray}\frac{1}{2}\left(h^{2}\right)_{t}=\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left\{\frac{c_{V}}{2}(1-h^{2})+\frac{\unicode[STIX]{x1D716}}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left(Re\,c_{V}^{2}\frac{h^{2}}{2}-\frac{\unicode[STIX]{x1D705}}{Ca}-Re\,h\sin \unicode[STIX]{x1D703}\right)\right\}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{1}{2}\left(h^{2}\right)_{t}=\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left\{\frac{c_{V}}{2}(1-h^{2})+\frac{\unicode[STIX]{x1D716}}{8}\left(1-h^{4}+4h^{2}\log h\right)\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left(Re\,c_{V}^{2}\frac{h^{2}}{2}-\frac{\unicode[STIX]{x1D705}}{Ca}-Re\,h\sin \unicode[STIX]{x1D703}\right)\right\}.\end{eqnarray}$$ Note that the only additional terms accrued at  $O(\unicode[STIX]{x1D716}^{2})$ would arise from the inertial terms which are themselves only valid at first order and so we stop at

$O(\unicode[STIX]{x1D716}^{2})$ would arise from the inertial terms which are themselves only valid at first order and so we stop at  $q_{1}$.

$q_{1}$.

3.2.3 Recovery of existing models

We can recover the model (2.14) of Kelmanson (Reference Kelmanson2009) up to third order as a special case of both (3.18) and (3.13), (3.14) (and hence of the full model (2.7), (3.11)). As a consequence we can therefore recover other systems which are a specialisation of Kelmanson, such as those of Moffatt (Reference Moffatt1977) and Pukhnachev (Reference Pukhnachev1977). In particular, performing a thin-film expansion  $(h=1+\unicode[STIX]{x1D6FF}H)$ on (3.18) or a gradient expansion

$(h=1+\unicode[STIX]{x1D6FF}H)$ on (3.18) or a gradient expansion  $(Q=Q_{0}+\unicode[STIX]{x1D6FF}Q_{1}+\cdots \,)$ on (3.13), followed by rescaling

$(Q=Q_{0}+\unicode[STIX]{x1D6FF}Q_{1}+\cdots \,)$ on (3.13), followed by rescaling  $\unicode[STIX]{x1D6FF}$ and

$\unicode[STIX]{x1D6FF}$ and  $\unicode[STIX]{x1D716}$, gives

$\unicode[STIX]{x1D716}$, gives

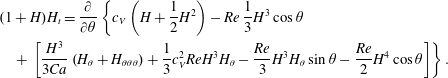

$$\begin{eqnarray}\displaystyle & & \displaystyle \hspace{-24.0pt}(1+H)H_{t}=\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left\{c_{V}\left(H+\frac{1}{2}H^{2}\right)-Re\,\frac{1}{3}H^{3}\cos \unicode[STIX]{x1D703}\right.\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad \left.+\,\left[\frac{H^{3}}{3Ca}\left(H_{\unicode[STIX]{x1D703}}+H_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\right)+\frac{1}{3}c_{V}^{2}ReH^{3}H_{\unicode[STIX]{x1D703}}-\frac{Re}{3}H^{3}H_{\unicode[STIX]{x1D703}}\sin \unicode[STIX]{x1D703}-\frac{Re}{2}H^{4}\cos \unicode[STIX]{x1D703}\right]\right\}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \hspace{-24.0pt}(1+H)H_{t}=\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}\left\{c_{V}\left(H+\frac{1}{2}H^{2}\right)-Re\,\frac{1}{3}H^{3}\cos \unicode[STIX]{x1D703}\right.\nonumber\\ \displaystyle & & \displaystyle \hspace{-24.0pt}\quad \left.+\,\left[\frac{H^{3}}{3Ca}\left(H_{\unicode[STIX]{x1D703}}+H_{\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}\unicode[STIX]{x1D703}}\right)+\frac{1}{3}c_{V}^{2}ReH^{3}H_{\unicode[STIX]{x1D703}}-\frac{Re}{3}H^{3}H_{\unicode[STIX]{x1D703}}\sin \unicode[STIX]{x1D703}-\frac{Re}{2}H^{4}\cos \unicode[STIX]{x1D703}\right]\right\}.\end{eqnarray}$$4 Results

In § 3, we derived four low-order models, related to one another as shown in figure 2:

(i) the ‘full’ long-wave model (2.7), (3.11) (

$\unicode[STIX]{x1D70E}_{LW}$);

$\unicode[STIX]{x1D70E}_{LW}$);(ii) the thin-film weighted residual model (3.13), (3.14) (

$\unicode[STIX]{x1D70E}_{TF}$);

$\unicode[STIX]{x1D70E}_{TF}$);(iii) the long-wave gradient expansion model (3.18) (

$\unicode[STIX]{x1D70E}_{GR}$);

$\unicode[STIX]{x1D70E}_{GR}$);(iv) the ‘classical’ thin-film gradient expansion model (3.19) (

$\unicode[STIX]{x1D70E}_{CL}$),

$\unicode[STIX]{x1D70E}_{CL}$),

where the  $\unicode[STIX]{x1D70E}_{i}$ denote the growth rate of the most unstable linear mode of each model, respectively.

$\unicode[STIX]{x1D70E}_{i}$ denote the growth rate of the most unstable linear mode of each model, respectively.

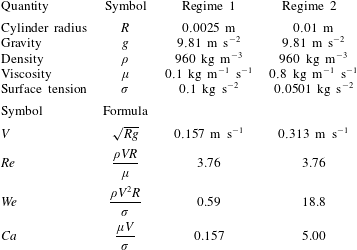

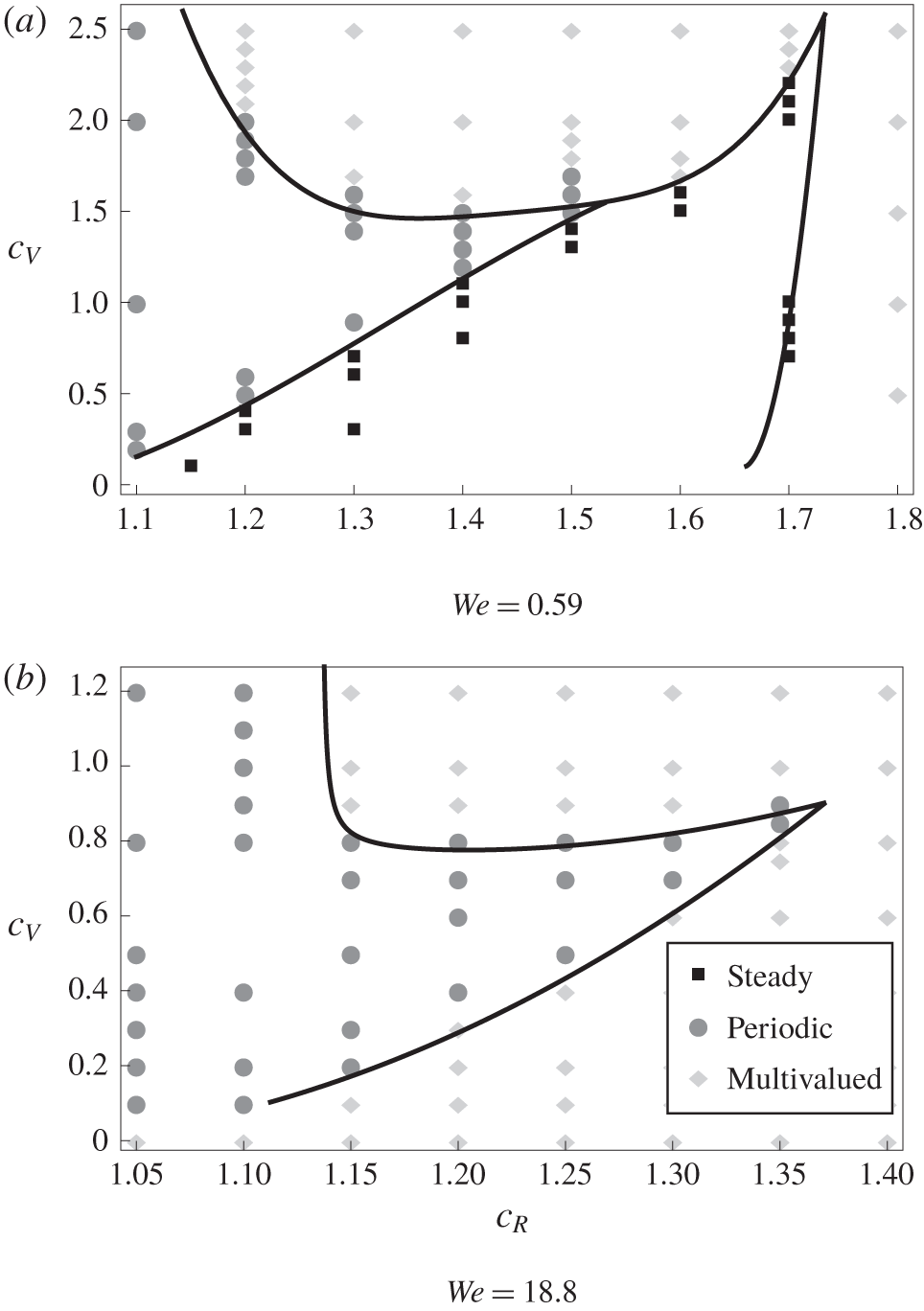

We validate the models against one another, as well as against direct numerical simulations of the full governing equations, in both the linear and nonlinear regimes, studied in §§ 4.1 and 4.2 respectively. It is found that only the full long-wave model provides consistently good agreement with the exact solutions across the considered parameter ranges. As a consequence, a combination of DNS and the long-wave model are used to map out parameter space in § 4.3. The problem is characterised by the four dimensionless groups  $Re,We,c_{R}$ and

$Re,We,c_{R}$ and  $c_{V}$ defined in (2.8); in order to investigate the corresponding four-dimensional parameter space we examine two different regimes as given in table 1. Both regimes have

$c_{V}$ defined in (2.8); in order to investigate the corresponding four-dimensional parameter space we examine two different regimes as given in table 1. Both regimes have  $Re=3.76$, which ensures that inertia is significant but not dominant, but differing Weber numbers. We then perform parametric studies by varying the rotation rate

$Re=3.76$, which ensures that inertia is significant but not dominant, but differing Weber numbers. We then perform parametric studies by varying the rotation rate  $c_{V}$ and the fluid mass

$c_{V}$ and the fluid mass  $c_{R}$.

$c_{R}$.

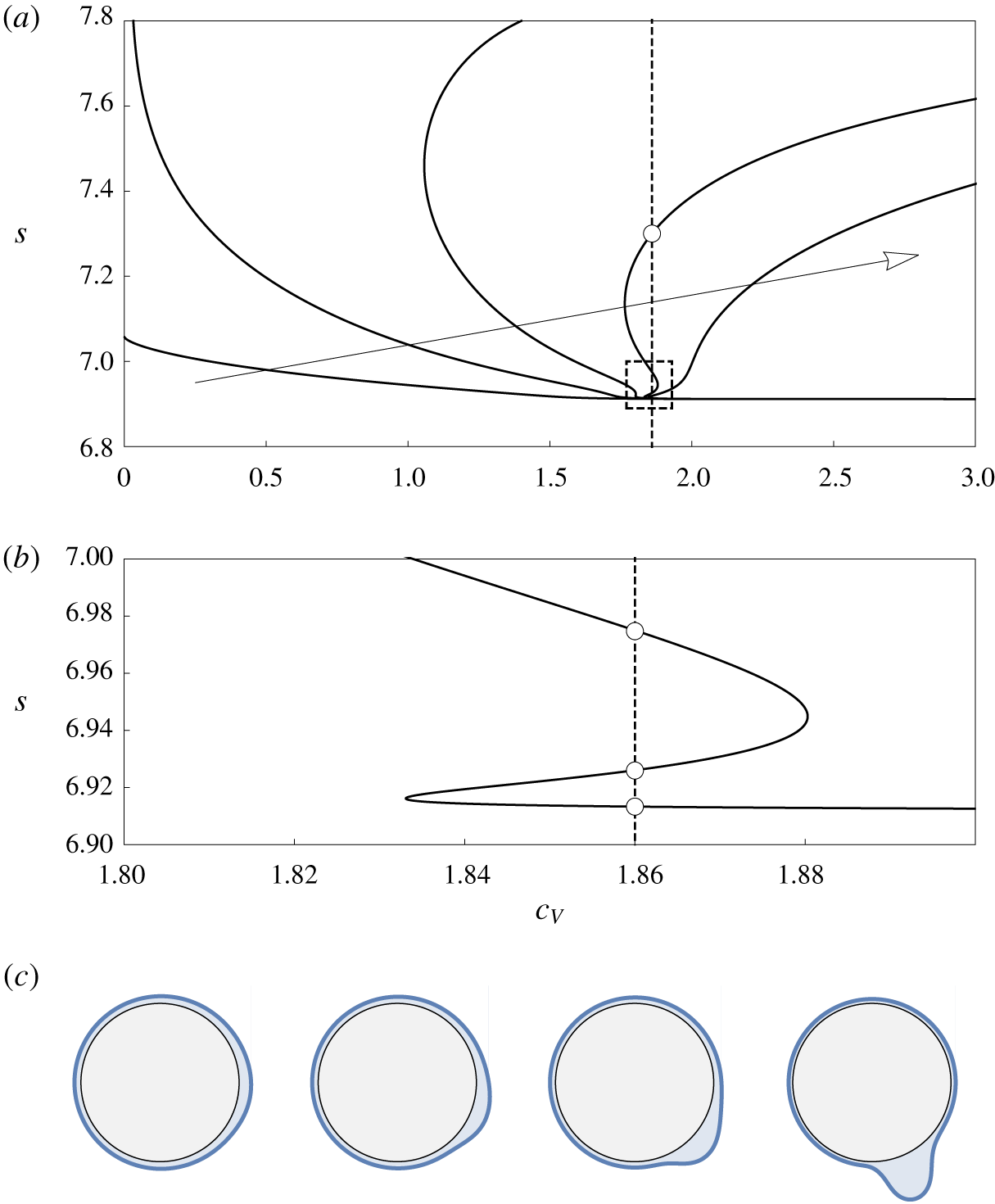

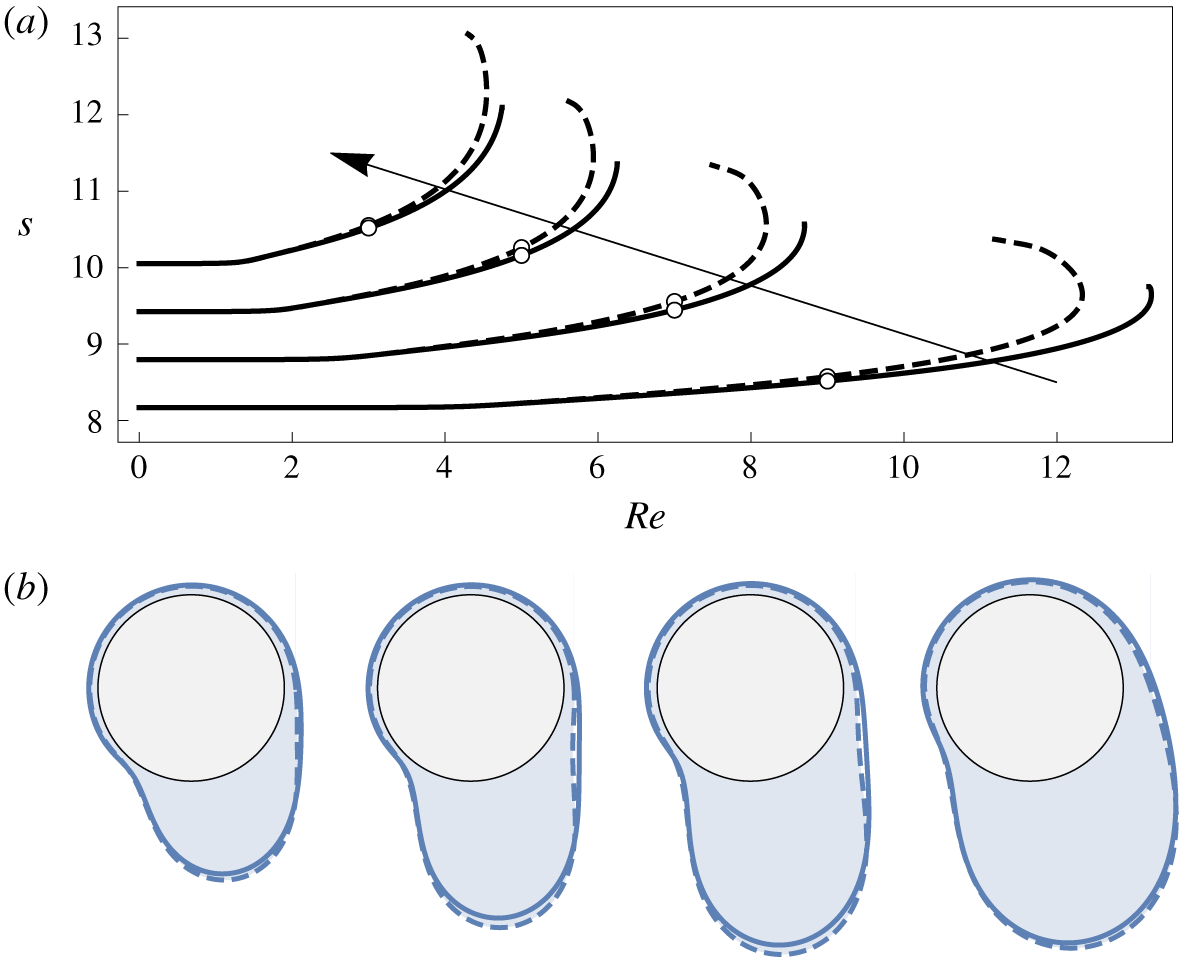

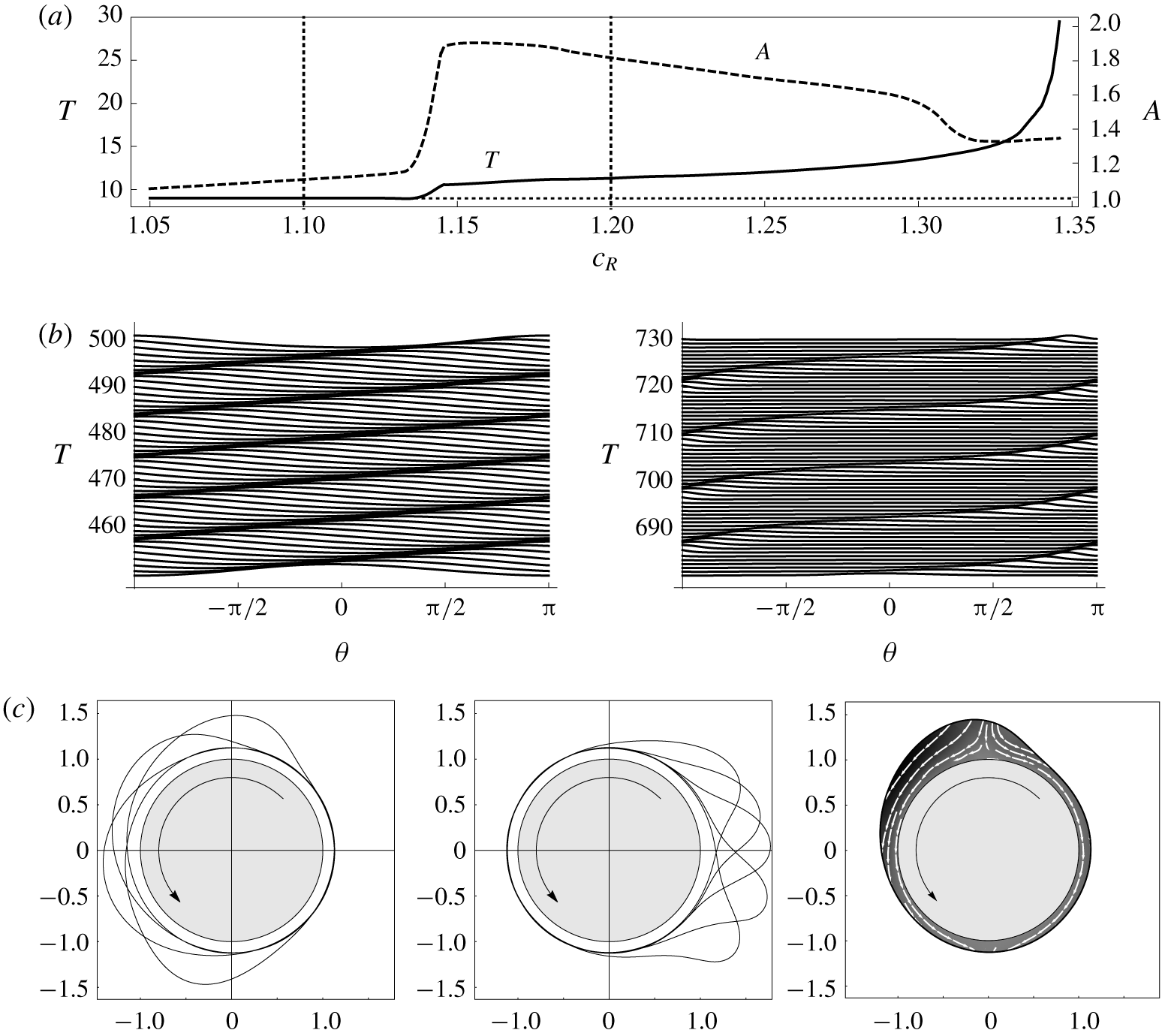

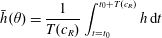

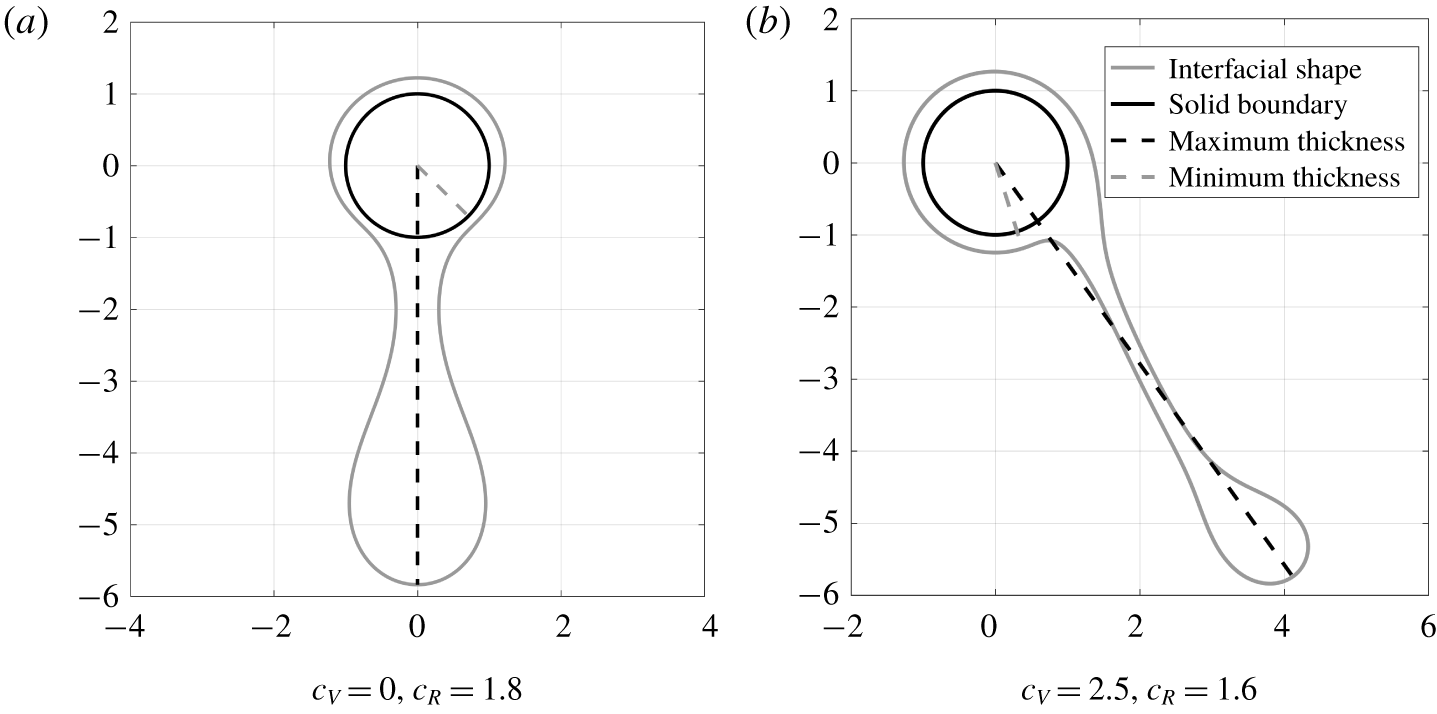

For high values of the rotation rate and/or fluid mass, the interface tends to become multivalued due to centrifugation and/or gravity respectively. This behaviour, which potentially includes dripping or other forms of rupture, is examined using DNS in § 4.3.3. Prior to the onset of this multivalued regime, the system exhibits either periodic or steady state behaviour, with lower rotation rates and greater fluid masses tending to favour steady states due to the dominance of gravitational effects. The steady states are examined in § 4.3.1, including parametric dependence on Reynolds number  $Re$ as well as the intricate limit point structures observed for low rotation rates by Lopes et al. (Reference Lopes, Thiele and Hazel2018). The periodic states show a complex variation of period and amplitude for increasing values of

$Re$ as well as the intricate limit point structures observed for low rotation rates by Lopes et al. (Reference Lopes, Thiele and Hazel2018). The periodic states show a complex variation of period and amplitude for increasing values of  $c_{V}$. A characteristic example is studied in detail in § 4.3.2, including analysis of the bifurcations observed transitioning between regimes.

$c_{V}$. A characteristic example is studied in detail in § 4.3.2, including analysis of the bifurcations observed transitioning between regimes.

Table 1. Dimensional variables corresponding to the two regimes examined here. Regime 2 is more easily realised physically but has too high a capillary number to observe some of the more unusual phenomena found in Regime 1.

4.1 Linear stability with no gravity

When the cylinder is spinning rapidly, or in a microgravity environment, the destabilising effect of the gravity is dominated by that of centrifugation (Evans et al. Reference Evans, Schwartz and Roy2004). In this case the gravitational effects may be neglected, and the system admits a base state with an interface of uniform thickness  $\bar{h}$. Computing the linear stability of this state is a useful mechanism for validating the models, as comparison with the exact solution is known to provide a stringent test: even in the absence of inertia, the one-equation models give poor predictions of the linear stability (Wray et al. Reference Wray, Matar and Papageorgiou2017a). In addition, this analysis allows us to isolate the importance of different physical mechanisms analytically, providing useful insight into the problem. In the absence of gravity, the velocity scaling

$\bar{h}$. Computing the linear stability of this state is a useful mechanism for validating the models, as comparison with the exact solution is known to provide a stringent test: even in the absence of inertia, the one-equation models give poor predictions of the linear stability (Wray et al. Reference Wray, Matar and Papageorgiou2017a). In addition, this analysis allows us to isolate the importance of different physical mechanisms analytically, providing useful insight into the problem. In the absence of gravity, the velocity scaling  $V=\sqrt{Rg}$ is no longer suitable; instead we scale based on the Reynolds number. In order to retain direct comparison with the other sections we allow

$V=\sqrt{Rg}$ is no longer suitable; instead we scale based on the Reynolds number. In order to retain direct comparison with the other sections we allow  $V$ to be defined by

$V$ to be defined by

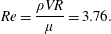

$$\begin{eqnarray}Re=\frac{\unicode[STIX]{x1D70C}VR}{\unicode[STIX]{x1D707}}=3.76.\end{eqnarray}$$

$$\begin{eqnarray}Re=\frac{\unicode[STIX]{x1D70C}VR}{\unicode[STIX]{x1D707}}=3.76.\end{eqnarray}$$ For all low-order models we computed the stability of this state via a standard linearisation procedure about the base state, followed by a decomposition into normal modes of the form  $\text{e}^{\unicode[STIX]{x1D70E}t+\text{i}n\unicode[STIX]{x1D703}}$, so that

$\text{e}^{\unicode[STIX]{x1D70E}t+\text{i}n\unicode[STIX]{x1D703}}$, so that  $\unicode[STIX]{x1D70E}$ is the growth rate and

$\unicode[STIX]{x1D70E}$ is the growth rate and  $n$ is an integer wavenumber. For the two-equation models (the full long-wave model and the thin-film weighted residual model) the basic solution for the flux may be extracted by assuming both the height and the flux to be constant. We do not give explicit dispersion relations due to their comparative complexity.

$n$ is an integer wavenumber. For the two-equation models (the full long-wave model and the thin-film weighted residual model) the basic solution for the flux may be extracted by assuming both the height and the flux to be constant. We do not give explicit dispersion relations due to their comparative complexity.

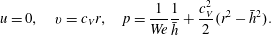

To validate these results, we compare against a linearisation of the full governing equations. The corresponding basic state is

$$\begin{eqnarray}u=0,\quad v=c_{V}r,\quad p=\frac{1}{We}\frac{1}{\bar{h}}+\frac{c_{V}^{2}}{2}(r^{2}-\bar{h}^{2}).\end{eqnarray}$$

$$\begin{eqnarray}u=0,\quad v=c_{V}r,\quad p=\frac{1}{We}\frac{1}{\bar{h}}+\frac{c_{V}^{2}}{2}(r^{2}-\bar{h}^{2}).\end{eqnarray}$$ A streamfunction formulation for the perturbations followed by linearisation and decomposition into normal modes results in an Orr–Sommerfeld system that was solved using a Chebyshev–Tau algorithm (Dongarra, Straughan & Walker Reference Dongarra, Straughan and Walker1996). The most unstable mode is denoted by  $\unicode[STIX]{x1D70E}_{OS}$.

$\unicode[STIX]{x1D70E}_{OS}$.

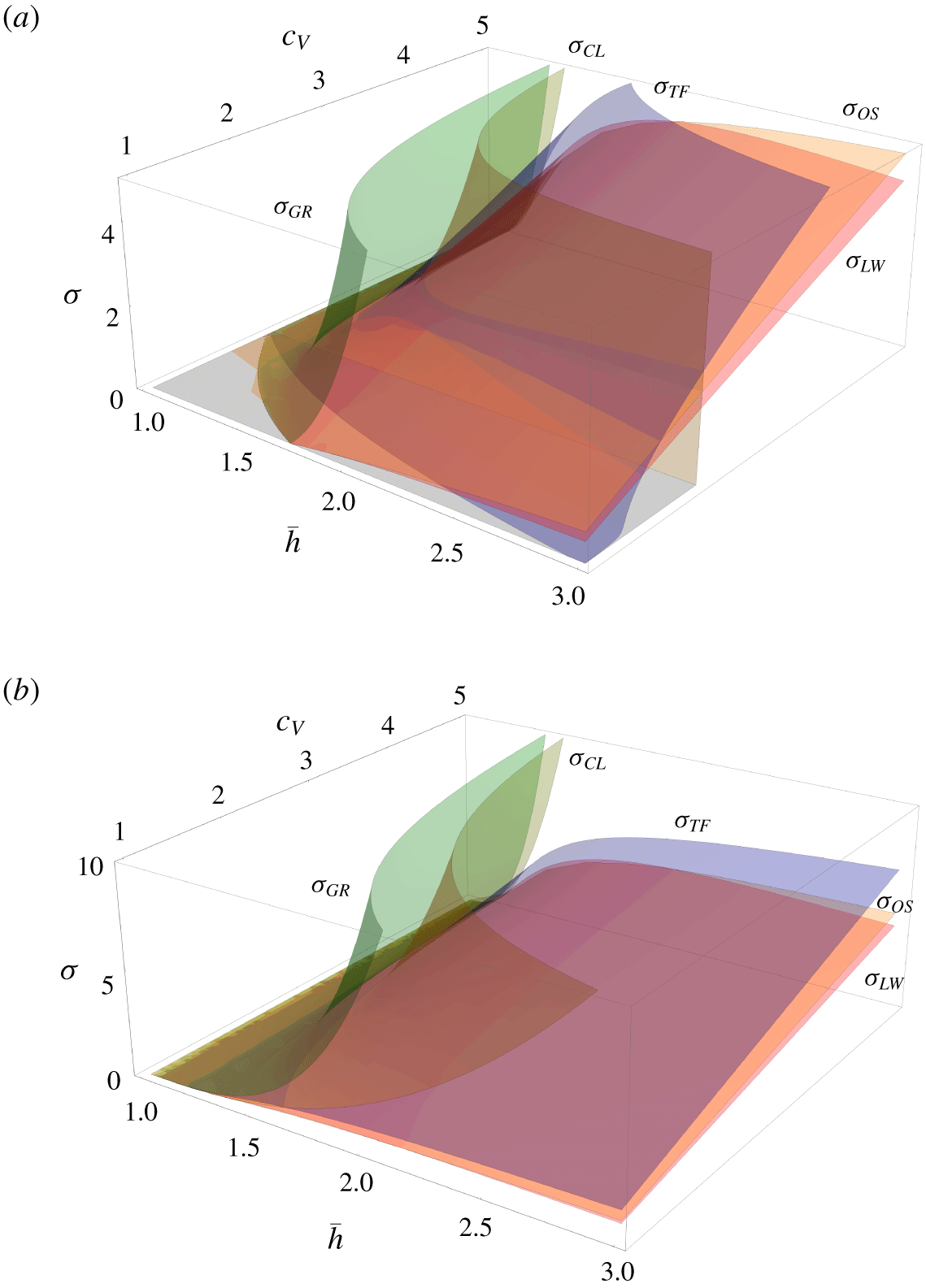

We look at both Regimes 1 and 2 from table 1 for  $n=2$ in figure 3, where Regime 1 is described by

$n=2$ in figure 3, where Regime 1 is described by  $We=0.59$ and Regime 2 by

$We=0.59$ and Regime 2 by  $We=18.8$. In general the long-wave model exhibits closest agreement with the Orr–Sommerfeld results, followed by the thin-film weighted residual model. The one-equation models (the thick-film gradient model and the classical model) exhibit strong disagreement with the Orr–Sommerfeld solution for all but the thinnest films at moderate rotation rates. All models correctly predict increasing growth rates for increasing values of

$We=18.8$. In general the long-wave model exhibits closest agreement with the Orr–Sommerfeld results, followed by the thin-film weighted residual model. The one-equation models (the thick-film gradient model and the classical model) exhibit strong disagreement with the Orr–Sommerfeld solution for all but the thinnest films at moderate rotation rates. All models correctly predict increasing growth rates for increasing values of  $c_{V}$ due to the increased effect of centrifugation, although the one-equation models dramatically over-predict this effect. This will be analysed in detail shortly. Notably, for increasing values of

$c_{V}$ due to the increased effect of centrifugation, although the one-equation models dramatically over-predict this effect. This will be analysed in detail shortly. Notably, for increasing values of  $\bar{h}$ the Orr–Sommerfeld solution predicts a levelling in the growth rate, as previously observed by Wray et al. (Reference Wray, Papageorgiou and Matar2017b) in the absence of inertia. This again is better replicated by the two-equation models.

$\bar{h}$ the Orr–Sommerfeld solution predicts a levelling in the growth rate, as previously observed by Wray et al. (Reference Wray, Papageorgiou and Matar2017b) in the absence of inertia. This again is better replicated by the two-equation models.

Figure 3. Growth rates as a function of rotation speed  $c_{V}$ and undisturbed interfacial radius

$c_{V}$ and undisturbed interfacial radius  $\bar{h}$ for

$\bar{h}$ for  $n=2$: (a) Regime 1; (b) Regime 2 from table 1.

$n=2$: (a) Regime 1; (b) Regime 2 from table 1.

All models perform better in Regime 2. This is because this regime has a higher value of the Weber number, corresponding to weaker surface tension. The models are predicated on a leading-order solid-body rotational flow; the smaller the Weber number the greater the deviation from this and the worse the models perform. Similarly, for smaller values of  $c_{V}$ the rotational base flow is less dominant and so the agreement is weaker.

$c_{V}$ the rotational base flow is less dominant and so the agreement is weaker.

Of particular interest is the behaviour as  $c_{V}\rightarrow \infty$. For moderate

$c_{V}\rightarrow \infty$. For moderate  $c_{V}$ the system is expected to be approximately in solid-body rotation, but for larger values of

$c_{V}$ the system is expected to be approximately in solid-body rotation, but for larger values of  $c_{V}$ centrifugation dominates. Expanding the respective growth rates for large

$c_{V}$ centrifugation dominates. Expanding the respective growth rates for large  $c_{V}$ we find

$c_{V}$ we find

$$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{CL}\sim \frac{(\bar{h}-1)^{3}}{3\bar{h}}n^{2}Re\,c_{V}^{2}+O(c_{V}), & \displaystyle \nonumber\\ \displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{GR}\sim {\textstyle \frac{1}{8}}(\bar{h}^{4}-4\bar{h}^{2}\log (\bar{h})-1)n^{2}Re\,c_{V}^{2}+O(c_{V}), & \displaystyle \nonumber\\ \displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{TF}\sim \frac{(\bar{h}+1)\sqrt{(1-\bar{h})\bar{h}((\bar{h}-14)\bar{h}-3)}}{2\bar{h}(5\bar{h}-1)}n\,c_{V}+O(1), & \displaystyle \nonumber\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{CL}\sim \frac{(\bar{h}-1)^{3}}{3\bar{h}}n^{2}Re\,c_{V}^{2}+O(c_{V}), & \displaystyle \nonumber\\ \displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{GR}\sim {\textstyle \frac{1}{8}}(\bar{h}^{4}-4\bar{h}^{2}\log (\bar{h})-1)n^{2}Re\,c_{V}^{2}+O(c_{V}), & \displaystyle \nonumber\\ \displaystyle & \displaystyle \unicode[STIX]{x1D70E}_{TF}\sim \frac{(\bar{h}+1)\sqrt{(1-\bar{h})\bar{h}((\bar{h}-14)\bar{h}-3)}}{2\bar{h}(5\bar{h}-1)}n\,c_{V}+O(1), & \displaystyle \nonumber\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & & \displaystyle \displaystyle \unicode[STIX]{x1D70E}_{LW}\sim \frac{\sqrt{2(\bar{h}-1)(\bar{h}+1)(\bar{h}^{4}-4\bar{h}^{2}\log (\bar{h})-1)(-\bar{h}^{4}+4\bar{h}^{2}+4(\bar{h}^{2}-2)\bar{h}^{2}\log (\bar{h})-3)}}{2\bar{h}^{6}-3\bar{h}^{4}-4\bar{h}^{4}\log (\bar{h})+2\bar{h}^{2}-1}\nonumber\\ \displaystyle & & \displaystyle \phantom{\unicode[STIX]{x1D70E}_{LW}\sim }\times \,n\,c_{V}+O(1).\nonumber\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \displaystyle \unicode[STIX]{x1D70E}_{LW}\sim \frac{\sqrt{2(\bar{h}-1)(\bar{h}+1)(\bar{h}^{4}-4\bar{h}^{2}\log (\bar{h})-1)(-\bar{h}^{4}+4\bar{h}^{2}+4(\bar{h}^{2}-2)\bar{h}^{2}\log (\bar{h})-3)}}{2\bar{h}^{6}-3\bar{h}^{4}-4\bar{h}^{4}\log (\bar{h})+2\bar{h}^{2}-1}\nonumber\\ \displaystyle & & \displaystyle \phantom{\unicode[STIX]{x1D70E}_{LW}\sim }\times \,n\,c_{V}+O(1).\nonumber\end{eqnarray}$$ In agreement with the Orr–Sommerfeld computations, the thin-film weighted residual and full long-wave model both correctly predict that the growth rate scales linearly with  $c_{V}$, whereas the one-equation models (the classical model and the long-wave gradient model) incorrectly predict that it scales quadratically with

$c_{V}$, whereas the one-equation models (the classical model and the long-wave gradient model) incorrectly predict that it scales quadratically with  $c_{V}$. This is due to the way the respective models treat the physics of centrifugation. This effect enters primarily via the

$c_{V}$. This is due to the way the respective models treat the physics of centrifugation. This effect enters primarily via the  $-v^{2}/r$ term in the

$-v^{2}/r$ term in the  $r$-momentum equation (2.2). In a film flow such as the present one, this manifests as a disturbance to the pressure as observed in (3.2). It therefore enters the system as an adjustment to the streamwise velocity, or in this low-order formulation, the flux. Thus it should be treated as a dynamic wave, with the primary balance being between the rate of change of the streamwise velocity

$r$-momentum equation (2.2). In a film flow such as the present one, this manifests as a disturbance to the pressure as observed in (3.2). It therefore enters the system as an adjustment to the streamwise velocity, or in this low-order formulation, the flux. Thus it should be treated as a dynamic wave, with the primary balance being between the rate of change of the streamwise velocity  $v_{t}$ and the pressure gradient, resulting in the growth rate scaling with

$v_{t}$ and the pressure gradient, resulting in the growth rate scaling with  $c_{V}$. Similarly, as

$c_{V}$. Similarly, as  $v_{t}$ scales with the azimuthal gradient of the pressure, the two-equation models correctly predict a linear dependence on the wavenumber

$v_{t}$ scales with the azimuthal gradient of the pressure, the two-equation models correctly predict a linear dependence on the wavenumber  $n$. In the one-equation formulations, the slaving of the flux to the height erroneously forces this centrifugation to enter via a kinematic wave, resulting in the incorrect dependence on both

$n$. In the one-equation formulations, the slaving of the flux to the height erroneously forces this centrifugation to enter via a kinematic wave, resulting in the incorrect dependence on both  $n$ and

$n$ and  $c_{V}$. Note that this also spuriously results in the expressions for the one-equation models depending on the Reynolds number. The final observation of interest is that as the rotation rate increases the most unstable mode will actually increase – this is related to the observation of Evans et al. (Reference Evans, Schwartz and Roy2004) of an increasing cutoff wavenumber for increasing rotation rate.

$c_{V}$. Note that this also spuriously results in the expressions for the one-equation models depending on the Reynolds number. The final observation of interest is that as the rotation rate increases the most unstable mode will actually increase – this is related to the observation of Evans et al. (Reference Evans, Schwartz and Roy2004) of an increasing cutoff wavenumber for increasing rotation rate.

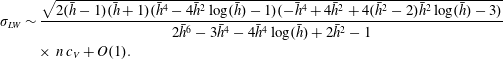

Figure 4. Growth rates corresponding to Regime 1 in table 1. (a,b) Effect of varying  $c_{V}$ for

$c_{V}$ for  $\bar{h}=1.5$; (a)

$\bar{h}=1.5$; (a)  $n=2$, (b)

$n=2$, (b)  $n=4$. (c,d) Effect of varying

$n=4$. (c,d) Effect of varying  $\bar{h}$ for

$\bar{h}$ for  $c_{V}=1.5$; (c)

$c_{V}=1.5$; (c)  $n=2$, (d)

$n=2$, (d)  $n=4$.

$n=4$.

We look in more detail at some characteristic cases in figure 4. In particular, for Regime 1 we examine the effect of varying  $c_{V}$ for a fixed

$c_{V}$ for a fixed  $\bar{h}$ (a,b), and of varying

$\bar{h}$ (a,b), and of varying  $\bar{h}$ for a fixed

$\bar{h}$ for a fixed  $c_{V}$ (c,d), for both

$c_{V}$ (c,d), for both  $n=2$ (a,c) and

$n=2$ (a,c) and  $n=4$ (b,d). In the top row we see the anticipated dependence on

$n=4$ (b,d). In the top row we see the anticipated dependence on  $c_{V}$ and

$c_{V}$ and  $n$ playing out: for the one-equation models the growth rate scales quadratically with the rotation rate

$n$ playing out: for the one-equation models the growth rate scales quadratically with the rotation rate  $c_{V}$ whereas the two-equation models (correctly) exhibit a linear scaling. What is more, the gradient of the lines for the two-equation models scale with

$c_{V}$ whereas the two-equation models (correctly) exhibit a linear scaling. What is more, the gradient of the lines for the two-equation models scale with  $n$ so that the gradient of the growth rates in (b) is approximately double that in

$n$ so that the gradient of the growth rates in (b) is approximately double that in  $(a)$.

$(a)$.

In the second row we see the behaviour with varying  $\bar{h}$. In particular, this elucidates the

$\bar{h}$. In particular, this elucidates the  $\bar{h}-1\ll 1$ region omitted in figure 3(a) as it falls outside the plotting region. For small values of

$\bar{h}-1\ll 1$ region omitted in figure 3(a) as it falls outside the plotting region. For small values of  $\bar{h}$, capillarity dominates, stabilising the flow. Note that this effect is stronger in (d) as this corresponds to a higher value of the wavenumber (

$\bar{h}$, capillarity dominates, stabilising the flow. Note that this effect is stronger in (d) as this corresponds to a higher value of the wavenumber ( $n=4$) resulting in a stronger stabilising effect. For increasing values of

$n=4$) resulting in a stronger stabilising effect. For increasing values of  $\bar{h}$ more fluid is further away from the axis of rotation, resulting in a stronger effect of centrifugation. This effect eventually dominates and results in instabilities. Of interest is the levelling behaviour observed for the largest values of

$\bar{h}$ more fluid is further away from the axis of rotation, resulting in a stronger effect of centrifugation. This effect eventually dominates and results in instabilities. Of interest is the levelling behaviour observed for the largest values of  $\bar{h}$; this is an effect that the one-equation models fail to pick up, satisfying power laws (

$\bar{h}$; this is an effect that the one-equation models fail to pick up, satisfying power laws ( $\unicode[STIX]{x1D70E}_{CL}\sim \bar{h}^{2},\unicode[STIX]{x1D70E}_{GR}\sim \bar{h}^{4}$). In particular, for the classical linear stability the coefficient is even of the wrong sign, predicting successively greater decay rates for increasing

$\unicode[STIX]{x1D70E}_{CL}\sim \bar{h}^{2},\unicode[STIX]{x1D70E}_{GR}\sim \bar{h}^{4}$). In particular, for the classical linear stability the coefficient is even of the wrong sign, predicting successively greater decay rates for increasing  $\bar{h}$. This failure is natural, however: in this region the terms neglected due to their azimuthal derivatives are more important, and the treatment of all disturbances as kinematic waves in the one-equation models becomes successively less valid.

$\bar{h}$. This failure is natural, however: in this region the terms neglected due to their azimuthal derivatives are more important, and the treatment of all disturbances as kinematic waves in the one-equation models becomes successively less valid.

4.2 Nonlinear validation

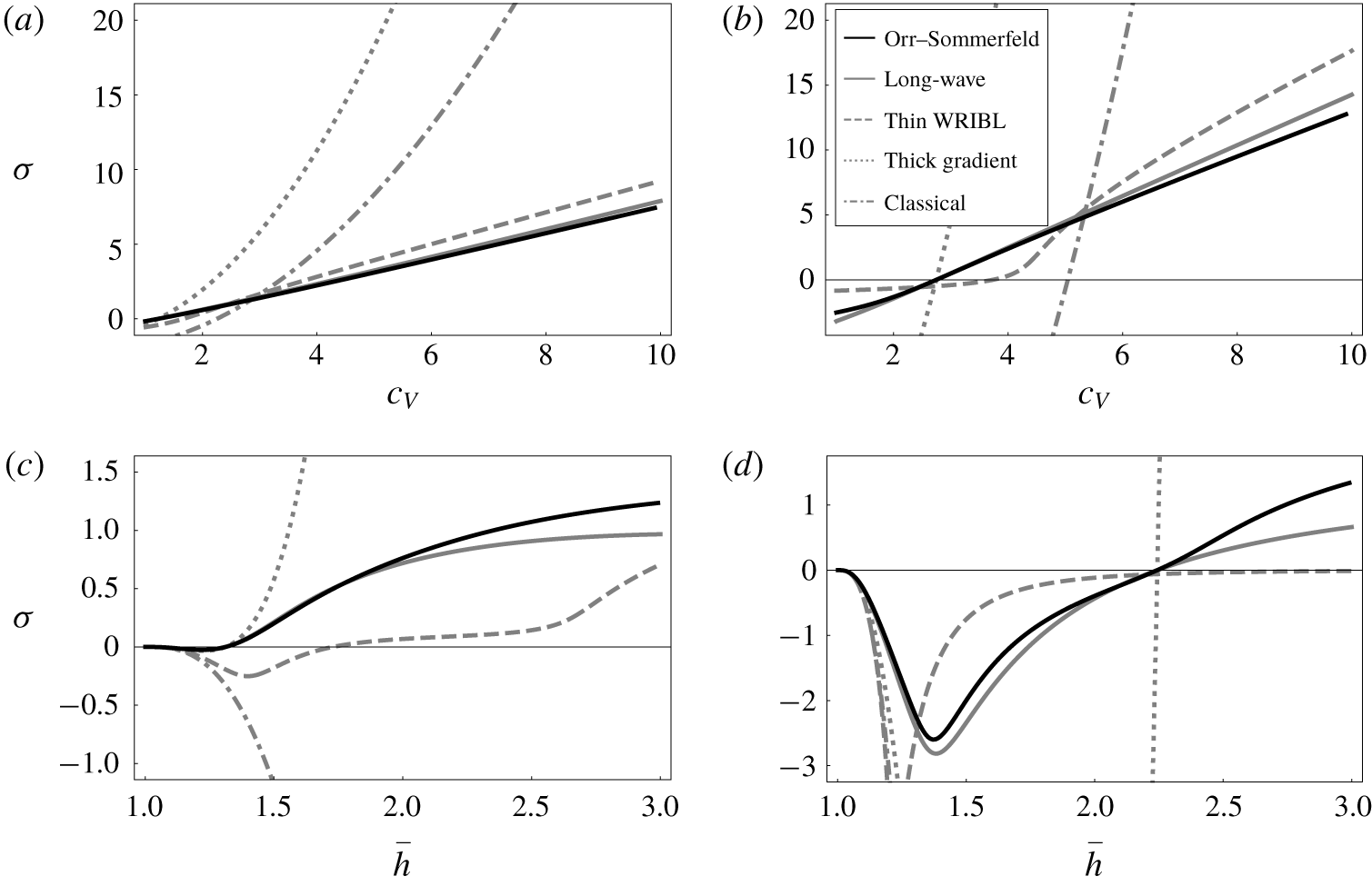

In order to provide additional insight into the properties of the previously discussed reduced-order methodologies, we wish to validate the models against the results of the DNS. We again use the two regimes given in table 1. In each of these, we can now perform a parametric study on the two remaining parameters: the rotational speed of the disc  $c_{V}$ and the initial radius of the fluid

$c_{V}$ and the initial radius of the fluid  $c_{R}$. We mapped out parameter space using transient computations as described in appendix A.1. Note that the current modelling method cannot track the interface into a multivalued regime due to our parameterisation by the azimuthal angle

$c_{R}$. We mapped out parameter space using transient computations as described in appendix A.1. Note that the current modelling method cannot track the interface into a multivalued regime due to our parameterisation by the azimuthal angle  $\unicode[STIX]{x1D703}$. In addition, at this threshold the interfacial slopes are so large that the long-wave reduction is no longer valid. However, there may be other parametrisations that afford continuation beyond this point. Bezier curves were fitted to the transition boundaries as plotted in figure 5. The steady/periodic boundary observed for Regime 1 was also validated using path continuation as described in appendix A.2. Direct numerical simulations (expanded upon in appendix A.3) were performed along the identified transition boundaries to validate the predictions of the long-wave model – the results of these computations are given as symbols in figure 5.

$\unicode[STIX]{x1D703}$. In addition, at this threshold the interfacial slopes are so large that the long-wave reduction is no longer valid. However, there may be other parametrisations that afford continuation beyond this point. Bezier curves were fitted to the transition boundaries as plotted in figure 5. The steady/periodic boundary observed for Regime 1 was also validated using path continuation as described in appendix A.2. Direct numerical simulations (expanded upon in appendix A.3) were performed along the identified transition boundaries to validate the predictions of the long-wave model – the results of these computations are given as symbols in figure 5.

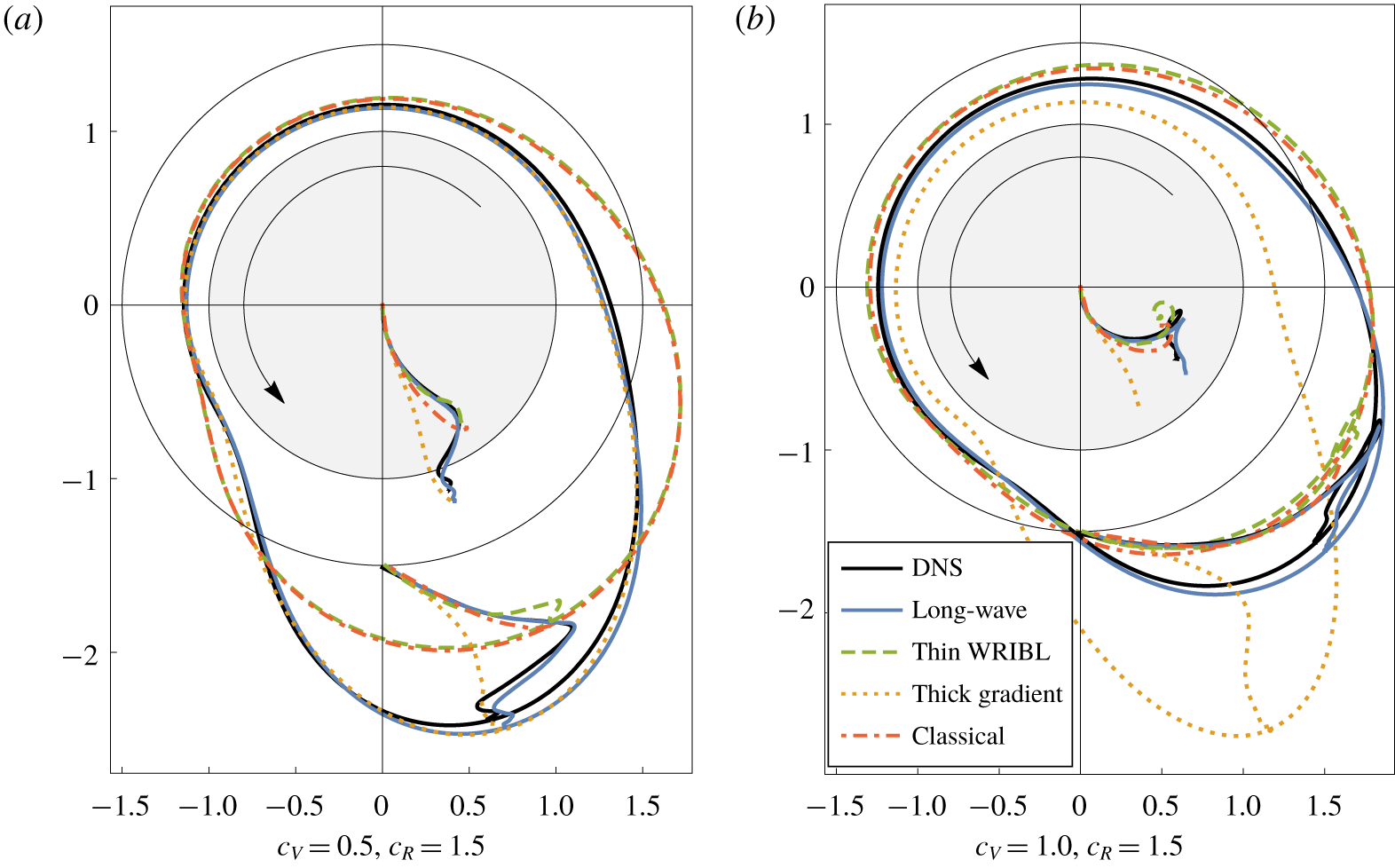

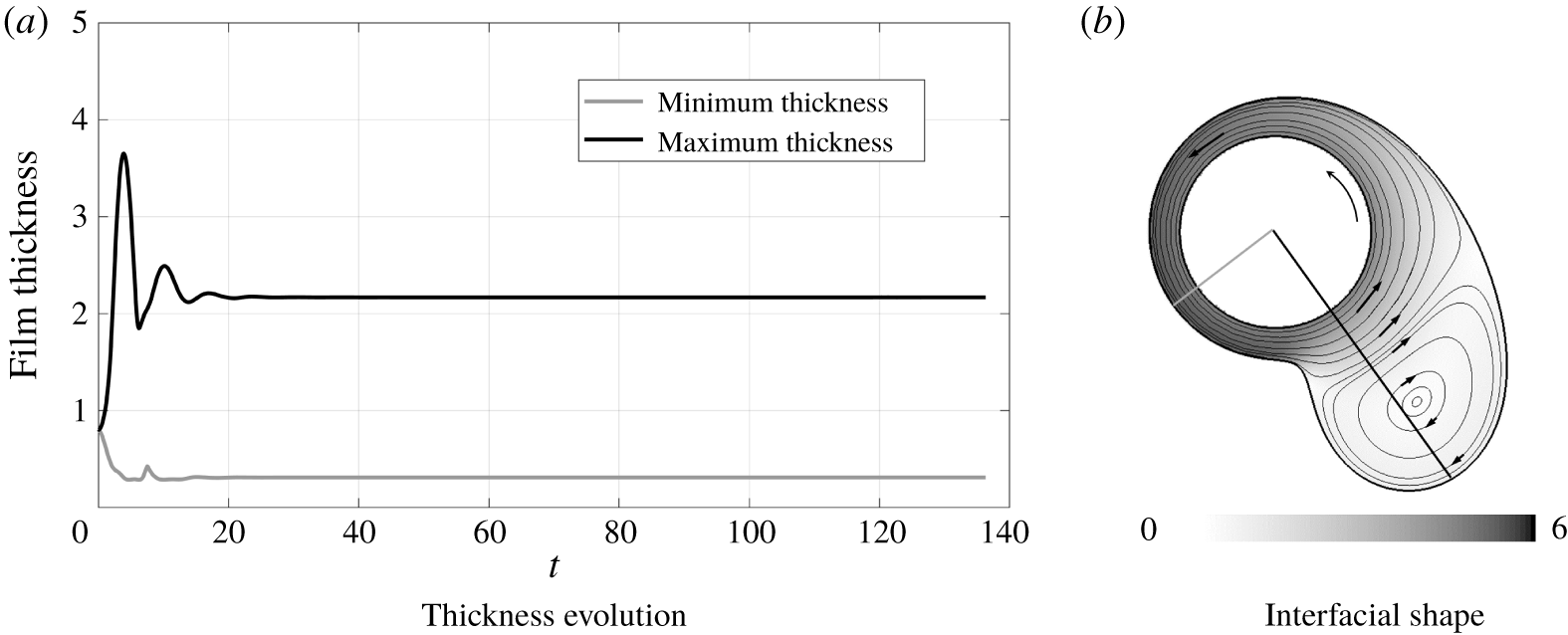

In light of the good observed agreement, we will defer detailed investigation of the long-wave model to § 4.3, and instead examine the accuracy of the other models. In figure 6 we compare the four models for two parameter regimes. Videos of these two scenarios are included as Movie 1 and Movie 2 in the supplementary material available at https://doi.org/10.1017/jfm.2020.421.

4.2.1 Low speed, thick flow:  $c_{V}=0.5,c_{R}=1.5$.

$c_{V}=0.5,c_{R}=1.5$.

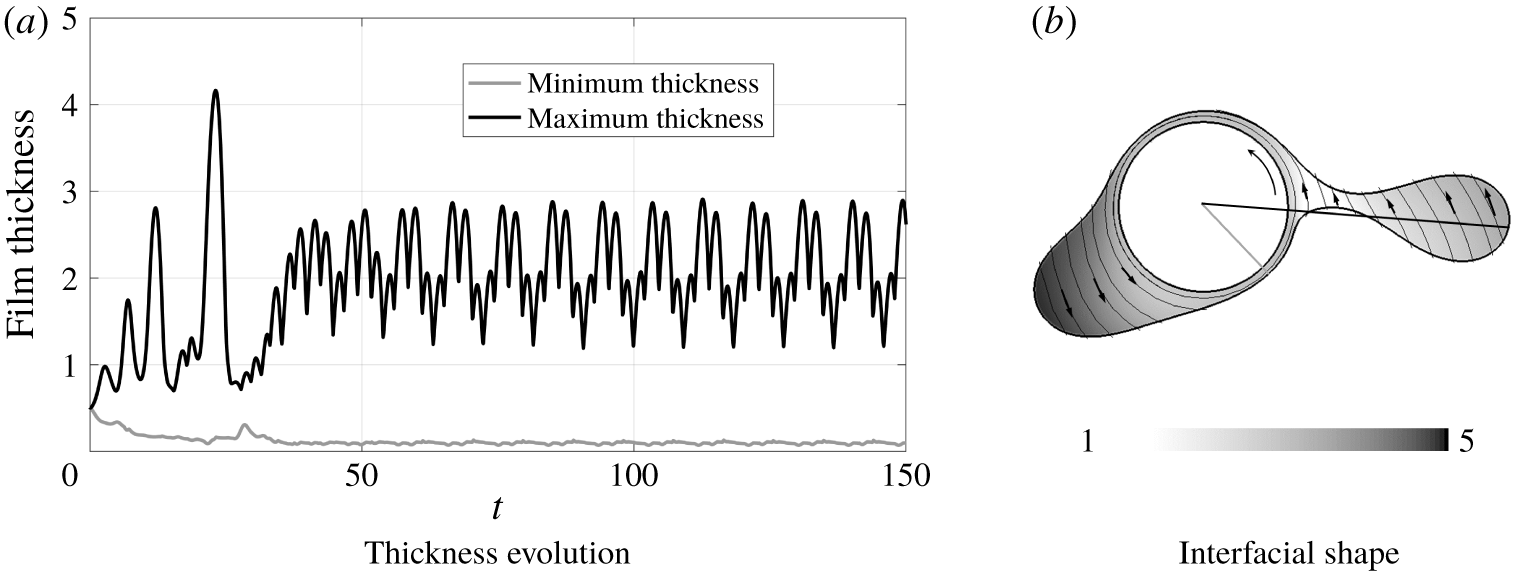

In figure 6(a) we see the behaviours of the models for  $c_{V}=0.5$,

$c_{V}=0.5$,  $c_{R}=1.5$. These parameters correspond to a relatively thick flow at a moderate rotation speed. Note that although initially the thickness of the liquid layer is only half the radius of the fibre, the accumulation of the liquid into a hanging drop rapidly results in a situation where the system is significantly thicker (the maximal radius of the long-wave model at steady state is approximately

$c_{R}=1.5$. These parameters correspond to a relatively thick flow at a moderate rotation speed. Note that although initially the thickness of the liquid layer is only half the radius of the fibre, the accumulation of the liquid into a hanging drop rapidly results in a situation where the system is significantly thicker (the maximal radius of the long-wave model at steady state is approximately  $2.53$).

$2.53$).

Figure 5. Parametric studies in  $c_{V}$ and

$c_{V}$ and  $c_{R}$ for both (a) Regime 1 and (b) Regime 2 as given in table 1. Solid black lines correspond to delineations between flow regimes as predicted by the long-wave model. Symbols correspond to DNS results, with squares representing steady states, circles representing (temporally) periodic states and diamonds representing situations where the interface becomes multivalued.

$c_{R}$ for both (a) Regime 1 and (b) Regime 2 as given in table 1. Solid black lines correspond to delineations between flow regimes as predicted by the long-wave model. Symbols correspond to DNS results, with squares representing steady states, circles representing (temporally) periodic states and diamonds representing situations where the interface becomes multivalued.