Published online by Cambridge University Press: 11 January 2024

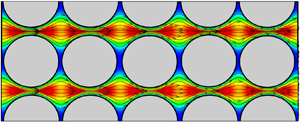

A computational study was performed of the transport of both non-adhesive and adhesive particles in a porous bed with a body-centred cubic (BCC) structure. Pore-scale simulation of the flow within the porous bed was achieved through combining the immersed boundary method and the lattice Boltzmann method. Particle transport is computed using an adhesive discrete-element method based on a multi-time-scale soft-sphere model. The fluid flow results are validated by comparison with experimental data for dimensionless permeability of flow in a porous bed of spheres. For computations with non-adhesive particles, the particles are observed to drift to the centre of ‘channels’ in the BCC array, within which most of the fluid flow occurs. The mechanism of this inward drift was found to be related to the phenomenon of oscillatory clustering, which is an inertial drift mechanism observed for particles in a corrugated channel. A measure for particle drift into these channels was developed, and the time rate of change of this measure was found to compare closely with an approximate theoretical prediction based on oscillatory clustering theory. The drift measure was observed to be limited at long time by hold-up of outlier particles caught in long-duration collisions with the fixed bed particles in regions of low fluid velocity magnitude. Simulations with adhesive particles exhibited marked increase in collision duration, as well as inhibition of the tendency to drift toward the flow channels due to adhesive hold-up.