1. Introduction

Cross-stream or lateral migration of particles in a pressure-driven flow has been an active area of research due to its relevance in many industrial (Shannon et al. Reference Shannon, Bohn, Elimelech, Georgiadis, Marinas and Mayes2008; Vidic et al. Reference Vidic, Brantley, Vandenbossche, Yoxtheimer and Abad2013) and biological (Nagrath et al. Reference Nagrath2007) applications. The phenomenon of lateral migration is specifically used for the manipulation of biological cells and particles in various microfluidic applications (Xuan, Zhu & Church Reference Xuan, Zhu and Church2010; Amini, Lee & Di Carlo Reference Amini, Lee and Di Carlo2014). The wall-normal component of force acting on the particle is responsible for its lateral migration and it is usually called the lift force. The lift force which is often relatively small in magnitude plays a central role in determining the final position of an individual particle and the particle distribution in particulate flows (Hidman et al. Reference Hidman, Ström, Sasic and Sardina2022).

The lateral motion of a particle was first investigated experimentally by Segre & Silberberg (Reference Segre and Silberberg1961) in a tube flow. Their observation was later confirmed by many experimental (Karnis & Mason Reference Karnis and Mason1966; Matas, Morris & Guazzelli Reference Matas, Morris and Guazzelli2004b) and numerical (Feng, Hu & Joseph Reference Feng, Hu and Joseph1994; Yang et al. Reference Yang, Wang, Joseph, Hu, Pan and Glowinski2005) studies. The same observation was made in rectangular channels where particles move towards or away from the channel wall in the cross-streamwise direction (Frank et al. Reference Frank, Anderson, Weeks and Morris2003; Del Giudice et al. Reference Del Giudice, Romeo, D'Avino, Greco, Netti and Maffettone2013; Wang, Yu & Lin Reference Wang, Yu and Lin2018; Yuan et al. Reference Yuan, Zhao, Yan, Tang, Alici, Zhang and Li2018). The situation becomes more involved when the ambient fluid is viscoelastic as the fluid elasticity plays its role in pushing the particle towards the centre of the channel (Seo, Kang & Lee Reference Seo, Kang and Lee2014). In the case of viscoelastic fluids, most of the existing literature is primarily focused on solid particles suspended in a viscoelastic fluid (Villone et al. Reference Villone, D'Avino, Hulsen, Greco and Maffettone2013). In the absence of inertia, the cross-stream migration of a non-deformable particle is not possible to occur in a confined Newtonian fluid flow due to the inherent reversibility of Stokes flow. However, the nonlinear characteristics of viscoelasticity provide the required irreversibility making the lateral migration possible in a complex fluid even with negligible inertia. The lateral migration of particles in complex fluids and their application in manipulating the particles in various microfluidic devices have been summarized in the review paper by D'Avino, Greco & Maffettone (Reference D'Avino, Greco and Maffettone2017).

In the presence of both inertia and viscoelasticity, several factors determine the orientation of particle migration in a pressure-driven channel flow. Some of these factors reported in numerous studies so far include shear-induced lift force (Saffman Reference Saffman1965), wall-induced lift force (Shi et al. Reference Shi, Rzehak, Lucas and Magnaudet2020), fluid elasticity (Karnis & Mason Reference Karnis and Mason1966; Raffiee, Dabiri & Ardekani Reference Raffiee, Dabiri and Ardekani2017), initial position of the particle (e.g. Villone et al. Reference Villone, D'Avino, Hulsen, Greco and Maffettone2011), geometry of the channel (Yu et al. Reference Yu, Wang, Lin and Hu2019), the shear thinning of the ambient fluid (Li, McKinley & Ardekani Reference Li, McKinley and Ardekani2015) and particle rotation rate (the Magnus effect). The effects of one or more of these factors determine the migration of a particle towards or away from the channel wall. Moreover, the deformability of an object adds further complexity to this phenomenon, and therefore, the complex dynamics of lateral migration of deformable particles in viscoelastic fluids is yet to be fully explored. As a result of this migration, some interesting secondary flow features also emerge in the vicinity of the particle. One of them is a secondary flow which is perpendicular to the primary flow (streamwise) direction and may have a velocity as large as the order of the particle migration velocity. However, this secondary flow is generated in non-circular channels only by the viscoelastic fluids having a non-zero second normal stress difference (Debbaut et al. Reference Debbaut, Avalosse, Dooley and Hughes1997).

When a spherical particle moves with a relative velocity in a shear flow, a force is exerted on the particle by the surrounding fluid in a direction perpendicular to its relative motion. This force is known as the shear-induced lift force, first calculated analytically by Saffman (Reference Saffman1965) for a solid sphere. This force pushes the particle towards the channel wall until it is balanced by the wall-induced lift force (Feng et al. Reference Feng, Hu and Joseph1994; Matas, Morris & Guazzelli Reference Matas, Morris and Guazzelli2004a). The flow field around the particle is significantly influenced by the presence of the wall. The wall decelerates the motion of the particle in the streamwise direction due to extra drag and repels it away from the wall if the characteristic length of the particle is much smaller than the channel size. If the characteristic length of the particle is comparable to the channel size, like the motion of bubbles in capillaries, the channel walls constrain the motion of the immersed object, as explained by Michaelides (Reference Michaelides2006).

The well-known Magnus effect (rotation-induced lift force) is another factor influencing the migration of an object in the channel flow. For a solid particle having the no-slip condition on its surface, the difference in the relative fluid velocity on its sides may cause it to rotate. This shear-induced rotation generates an additional transverse pressure difference and the resulting lift force is referred to as the ‘Magnus effect’ (Rubinow & Keller Reference Rubinow and Keller1961). Instead of a solid particle, if the object is deformable, the deformability induces yet another lateral migration directed towards the channel centre (Chan & Leal Reference Chan and Leal1979). Similarly, the initial position of the particle in the channel has a direct impact on its lateral migration as dictated by the gradient of velocity at that initial location. The size of the particle as compared with the channel is another important variable to be considered while analysing the lateral migration in a pressure-driven flow. It is generally characterized by the blockage ratio (Di Carlo Reference Di Carlo2009) defined as ![]() $b=d/H$, where

$b=d/H$, where ![]() $d$ is the particle size (e.g. diameter) and

$d$ is the particle size (e.g. diameter) and ![]() $H$ is the channel width. It has been observed in both experimental (Lim et al. Reference Lim, Ober, Edd, Desai, Neal, Bong, Doyle, McKinley and Toner2014) and numerical (Mortazavi & Tryggvason Reference Mortazavi and Tryggvason2000) works that a deformable object with a diameter beyond a certain limit migrates towards the channel centre due to deformation-induced lift force while a smaller one migrates towards the wall due to inertial lift force. This feature is used in many microfluidic devices for sorting particles of different sizes (Nam et al. Reference Nam, Namgung, Lim, Bae, Leo, Cho and Kim2015).

$H$ is the channel width. It has been observed in both experimental (Lim et al. Reference Lim, Ober, Edd, Desai, Neal, Bong, Doyle, McKinley and Toner2014) and numerical (Mortazavi & Tryggvason Reference Mortazavi and Tryggvason2000) works that a deformable object with a diameter beyond a certain limit migrates towards the channel centre due to deformation-induced lift force while a smaller one migrates towards the wall due to inertial lift force. This feature is used in many microfluidic devices for sorting particles of different sizes (Nam et al. Reference Nam, Namgung, Lim, Bae, Leo, Cho and Kim2015).

The Magnus effect, shear-induced lift force and wall-induced lift force may be referred to as the ‘inertial effects’ as all these forces primarily originate due to fluid inertia. If the ambient fluid is viscoelastic, the elastic effects tend to push the object towards the centre (Seo et al. Reference Seo, Kang and Lee2014) while the inertial effects tend to move it towards the channel wall. The relative strength of inertia and elasticity determines the final equilibrium position of a non-deformable particle in a channel. This interplay between inertia and elasticity is quantified by the elasticity number, defined as ![]() $El= Wi/Re$, where

$El= Wi/Re$, where ![]() $Wi$ and

$Wi$ and ![]() $Re$ are the Weissenberg number and the Reynolds number, respectively. Furthermore, if the ambient fluid exhibits a shear-thinning behaviour as well, it has been reported by Li et al. (Reference Li, McKinley and Ardekani2015) that the shear thinning amplifies inertial effects and thus promotes particle migration towards the wall. Hazra, Mitra & Sen (Reference Hazra, Mitra and Sen2020) experimentally studied the role of shear thinning on the cross-stream migration of droplets in a confined shear flow for

$Re$ are the Weissenberg number and the Reynolds number, respectively. Furthermore, if the ambient fluid exhibits a shear-thinning behaviour as well, it has been reported by Li et al. (Reference Li, McKinley and Ardekani2015) that the shear thinning amplifies inertial effects and thus promotes particle migration towards the wall. Hazra, Mitra & Sen (Reference Hazra, Mitra and Sen2020) experimentally studied the role of shear thinning on the cross-stream migration of droplets in a confined shear flow for ![]() $Re<1$. They observed that larger droplets followed their original streamlines while the smaller ones migrated towards the centre. Similarly, to predict the role of elasticity, Mukherjee & Sarkar (Reference Mukherjee and Sarkar2014) performed computational simulations of a viscoelastic drop in a Newtonian fluid for a linear shear flow with negligible inertia. They found a non-monotonic impact of elasticity on the migration velocity of the droplet.

$Re<1$. They observed that larger droplets followed their original streamlines while the smaller ones migrated towards the centre. Similarly, to predict the role of elasticity, Mukherjee & Sarkar (Reference Mukherjee and Sarkar2014) performed computational simulations of a viscoelastic drop in a Newtonian fluid for a linear shear flow with negligible inertia. They found a non-monotonic impact of elasticity on the migration velocity of the droplet.

The above-mentioned list of factors affecting the migration dynamics of a deformable object is still not exhaustive. In the presence of surfactant contamination, the surfactant-induced Marangoni stresses oppose the inertial lift force and can completely alter the migration dynamics of an object. In our earlier work (Muradoglu & Tryggvason Reference Muradoglu and Tryggvason2014; Ahmed et al. Reference Ahmed, Izbassarov, Lu, Tryggvason, Muradoglu and Tammisola2020b), it was observed that, in the pressure-driven channel flow of a Newtonian fluid, clean spherical bubbles move towards the wall while the deformable ones migrate away from it. However, even the spherical bubbles can move away from the wall in the presence of a strong enough surfactant.

Although there are a large number of experimental and numerical works devoted to solid particle migration, much less attention has been paid to the combined effects of inertia, viscoelasticity, and shear thinning on the lateral migration of a deformable fluid particle and only a few details are available in the existing literature, which motivates the present study. The main focus here is to explore the combined effects of fluid inertia, viscoelasticity and particle deformability on its lateral migration in a shear-thinning viscoelastic fluid. For this purpose, fully interface-resolved numerical simulations are performed using an Eulerian–Lagrangian method (Tryggvason et al. Reference Tryggvason, Bunner, Esmaeeli, Juric, Al-Rawahi, Tauber, Han, Nas and Jan2001) for a wide range of relevant flow parameters to explore the features of this complex flow field. In addition to the lateral migration, the particle-induced elastic instability and its impact on the onset of a path instability, the effect of shear thinning, and the resulting flow are investigated computationally. The secondary flow field developed due to the second normal stress difference in the flow is also examined and quantified.

The rest of the paper is organized as follows. The problem statement and the computational set-up are described in the next section. The governing equations and the numerical method are briefly described in § 3. The results are presented and discussed in § 4 followed by the conclusions in § 5. A grid convergence study is conducted and the results are presented in the Appendix.

2. Problem statement and computational set-up

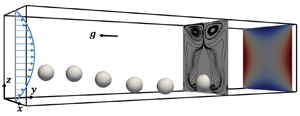

Microfluidic devices usually use channels with rectangular cross-sections due to their relative ease of fabrication. If the aspect ratio of the channel is reduced, the relative influence of channel walls on the flow field becomes more pronounced (Villone et al. Reference Villone, D'Avino, Hulsen, Greco and Maffettone2013). The limiting case is obtained for a square-shaped cross-section, which is selected in the present study. Figure 1(a) shows the computational domain which is a square channel with the dimensions of ![]() $H$,

$H$, ![]() $L$ and

$L$ and ![]() $H$ in the

$H$ in the ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ directions, respectively. Periodic boundary conditions are applied in the streamwise (

$z$ directions, respectively. Periodic boundary conditions are applied in the streamwise (![]() $y$) direction whereas the other two directions (

$y$) direction whereas the other two directions (![]() $x$ and

$x$ and ![]() $z$) have no-slip/no-penetration boundary conditions. The centroid of the particle is denoted by

$z$) have no-slip/no-penetration boundary conditions. The centroid of the particle is denoted by ![]() $(x_b,y_b,z_b)$ and a spherical fluid particle of diameter

$(x_b,y_b,z_b)$ and a spherical fluid particle of diameter ![]() $d$ is initially located at

$d$ is initially located at ![]() $(x_{bi},y_{bi},z_{bi}) = (0.5H, H, 0.25H)$ unless specified otherwise. The value of

$(x_{bi},y_{bi},z_{bi}) = (0.5H, H, 0.25H)$ unless specified otherwise. The value of ![]() $H$ is set to

$H$ is set to ![]() $4d$. After performing the simulations by gradually increasing the length of the channel in the streamwise (

$4d$. After performing the simulations by gradually increasing the length of the channel in the streamwise (![]() $y$) direction to check the effects of periodicity, the channel length is set to

$y$) direction to check the effects of periodicity, the channel length is set to ![]() $L=4H$, which is found to be sufficient to eliminate any significant effects of periodicity.

$L=4H$, which is found to be sufficient to eliminate any significant effects of periodicity.

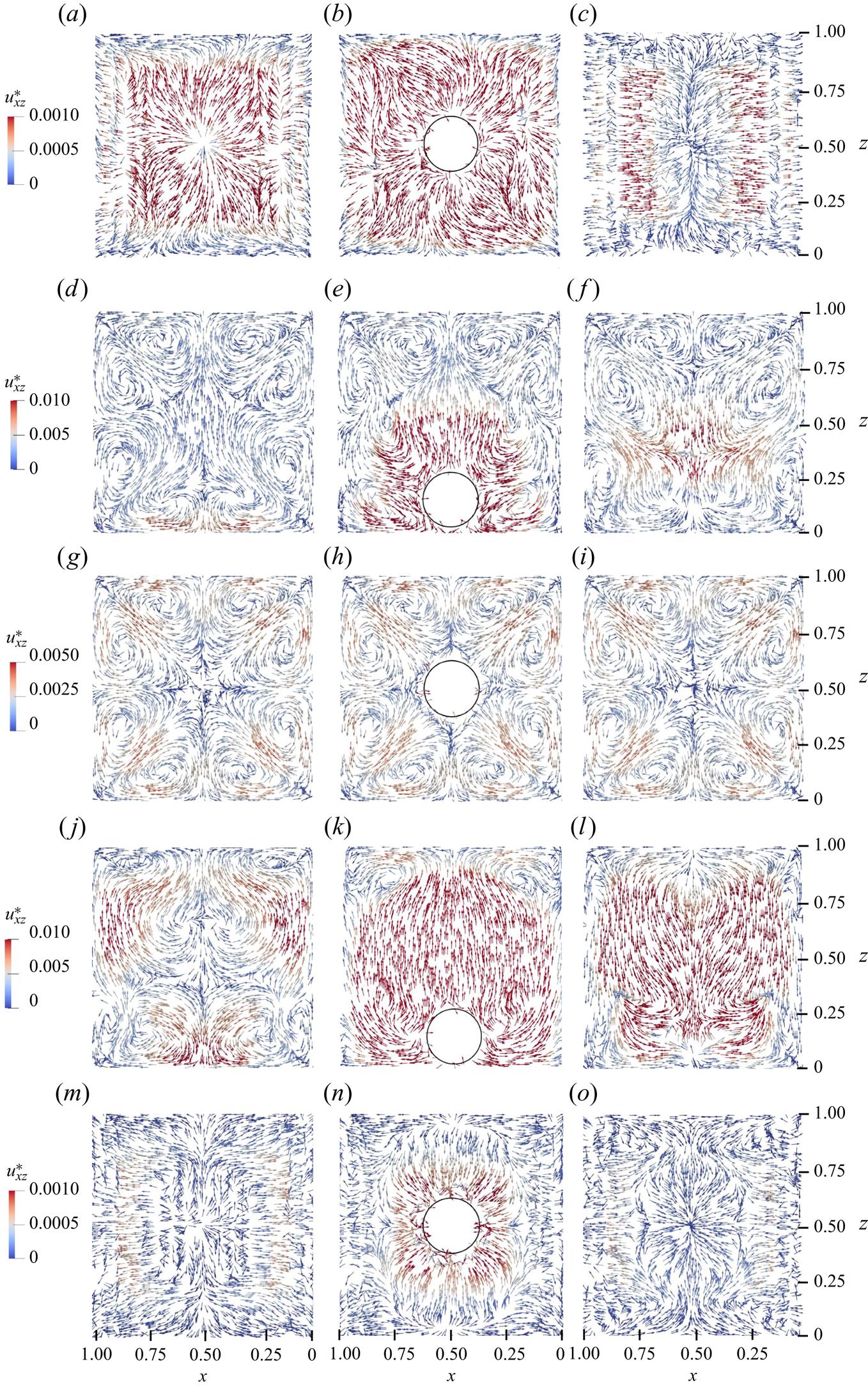

Figure 1. (a) Computational domain shown with the schematic representation of a deformable fluid particle migrating towards the wall of the channel. The streamlines of the flow are shown above the particle in the ![]() $xz$-plane once the particle reaches its equilibrium position closer to the wall. The distribution of the second normal stress difference (

$xz$-plane once the particle reaches its equilibrium position closer to the wall. The distribution of the second normal stress difference (![]() $N_2$) is shown in the

$N_2$) is shown in the ![]() $xz$-plane upstream of the particle at

$xz$-plane upstream of the particle at ![]() $y=3.95$. (b) Eight vortices showing the secondary flow field in the same

$y=3.95$. (b) Eight vortices showing the secondary flow field in the same ![]() $xz$-plane away from the particle at

$xz$-plane away from the particle at ![]() $y=3.95$ are shown. The velocity vectors are coloured by the magnitude of flow velocity in that plane. (

$y=3.95$ are shown. The velocity vectors are coloured by the magnitude of flow velocity in that plane. (![]() $Re=18.9, El=0.05, Eo=0, Ca=0.01, \alpha =0.1$.)

$Re=18.9, El=0.05, Eo=0, Ca=0.01, \alpha =0.1$.)

The deformable particle is at rest initially at ![]() $t=0$ and a constant pressure gradient

$t=0$ and a constant pressure gradient ![]() ${\rm d}p_0/{{\rm d} y} = -U_{o}\mu _{o}{\rm \pi} ^3 / 4kH^2$ is applied in the

${\rm d}p_0/{{\rm d} y} = -U_{o}\mu _{o}{\rm \pi} ^3 / 4kH^2$ is applied in the ![]() $y$-direction to drive the flow, where

$y$-direction to drive the flow, where ![]() $U_{o}$ is the flow velocity at the centreline of the channel in the case of a fully developed single-phase laminar flow and

$U_{o}$ is the flow velocity at the centreline of the channel in the case of a fully developed single-phase laminar flow and ![]() $k$ is a geometric constant. For a square channel,

$k$ is a geometric constant. For a square channel, ![]() $k\approx 0.571$ (Fetecau & Fetecau Reference Fetecau and Fetecau2005). It is important to note that

$k\approx 0.571$ (Fetecau & Fetecau Reference Fetecau and Fetecau2005). It is important to note that ![]() $U_o$ is the centreline velocity in the channel for the Newtonian and Oldroyd-B fluids. In a Giesekus fluid, the centreline velocity becomes greater than

$U_o$ is the centreline velocity in the channel for the Newtonian and Oldroyd-B fluids. In a Giesekus fluid, the centreline velocity becomes greater than ![]() $U_o$ due to the shear-thinning effect. However, throughout this paper, all the non-dimensional numbers are defined based on

$U_o$ due to the shear-thinning effect. However, throughout this paper, all the non-dimensional numbers are defined based on ![]() $U_o$ corresponding to the applied pressure gradient in the Newtonian fluid unless stated otherwise. Here,

$U_o$ corresponding to the applied pressure gradient in the Newtonian fluid unless stated otherwise. Here, ![]() $H$,

$H$, ![]() $U_{o}$ and

$U_{o}$ and ![]() $H/U_{o}$ are used as the length, velocity and time scales, respectively. The stresses are normalized by

$H/U_{o}$ are used as the length, velocity and time scales, respectively. The stresses are normalized by ![]() $\mu _{o}U_{o}/H$. The normalized non-dimensional quantities are denoted by the superscript (

$\mu _{o}U_{o}/H$. The normalized non-dimensional quantities are denoted by the superscript (![]() $^*$). The blockage ratio (

$^*$). The blockage ratio (![]() $b=d/H$) is fixed at

$b=d/H$) is fixed at ![]() $0.25$. The density (

$0.25$. The density (![]() $\rho _{o}/\rho _{i}$) and the viscosity (

$\rho _{o}/\rho _{i}$) and the viscosity (![]() $\mu _{o}/\mu _{i}$) ratios are set to

$\mu _{o}/\mu _{i}$) ratios are set to ![]() $10$ in this study where the subscripts

$10$ in this study where the subscripts ![]() $i$ and

$i$ and ![]() $o$ denote the dispersed and continuous phases, respectively. These comparatively smaller ratios are used to reduce the spatial error exacerbated by sudden jumps in material properties across the interface and enhance numerical stability, and thus relax the excessive grid resolution requirement and time step restrictions. Tasoglu et al. (Reference Tasoglu, Kaynak, Szeri, Demirci and Muradoglu2010) and Olgac, Izbassarov & Muradoglu (Reference Olgac, Izbassarov and Muradoglu2013) have demonstrated that the results are not affected significantly for these types of flows at higher ratios. In the present case of pressure-driven viscoelastic channel flow, although not shown here, simulations have been performed for the density and viscosity ratios of

$o$ denote the dispersed and continuous phases, respectively. These comparatively smaller ratios are used to reduce the spatial error exacerbated by sudden jumps in material properties across the interface and enhance numerical stability, and thus relax the excessive grid resolution requirement and time step restrictions. Tasoglu et al. (Reference Tasoglu, Kaynak, Szeri, Demirci and Muradoglu2010) and Olgac, Izbassarov & Muradoglu (Reference Olgac, Izbassarov and Muradoglu2013) have demonstrated that the results are not affected significantly for these types of flows at higher ratios. In the present case of pressure-driven viscoelastic channel flow, although not shown here, simulations have been performed for the density and viscosity ratios of ![]() $20$,

$20$, ![]() $40$ and

$40$ and ![]() $80$ as well, and the results are found to be not very sensitive to the increase in the density ratio, i.e. the difference is less than 1 % but more sensitive to the viscosity ratio due to a higher contribution of polymeric viscosity in a concentrated polymer solution. It is observed that at a higher viscosity ratio, the secondary flow velocity induced by the fluid particle once it attains its equilibrium position (as will be discussed in detail in § 4.4) is not much affected but the lateral displacement of the fluid particle is still significantly influenced by this higher viscosity ratio. As the viscosity ratio in the liquid–air system of a complex fluid flow can be as high as

$80$ as well, and the results are found to be not very sensitive to the increase in the density ratio, i.e. the difference is less than 1 % but more sensitive to the viscosity ratio due to a higher contribution of polymeric viscosity in a concentrated polymer solution. It is observed that at a higher viscosity ratio, the secondary flow velocity induced by the fluid particle once it attains its equilibrium position (as will be discussed in detail in § 4.4) is not much affected but the lateral displacement of the fluid particle is still significantly influenced by this higher viscosity ratio. As the viscosity ratio in the liquid–air system of a complex fluid flow can be as high as ![]() $10^8$ depending upon the molecular weight and concentration of the polymer molecules, the term ‘deformable fluid particle’ is used instead of a bubble in the present study.

$10^8$ depending upon the molecular weight and concentration of the polymer molecules, the term ‘deformable fluid particle’ is used instead of a bubble in the present study.

In addition to the density and viscosity ratios, the flow conditions are characterized by the following non-dimensional numbers defined as

where ![]() $Re$,

$Re$, ![]() $Wi$,

$Wi$, ![]() $Eo$,

$Eo$, ![]() $Mo$ and

$Mo$ and ![]() $Ca$ denote the Reynolds, Weissenberg, Eötvös, Morton and capillary numbers, respectively. Note that the Morton number is not an independent parameter. Additionally,

$Ca$ denote the Reynolds, Weissenberg, Eötvös, Morton and capillary numbers, respectively. Note that the Morton number is not an independent parameter. Additionally, ![]() $\beta$ is the ratio of solvent viscosity to zero shear viscosity of the viscoelastic fluid. The density difference is defined as

$\beta$ is the ratio of solvent viscosity to zero shear viscosity of the viscoelastic fluid. The density difference is defined as ![]() $\Delta \rho = \rho _o-\rho _i$. The particle deformation (

$\Delta \rho = \rho _o-\rho _i$. The particle deformation (![]() $\chi$) is quantified as

$\chi$) is quantified as

where ![]() $I_{max}$ and

$I_{max}$ and ![]() $I_{min}$ are the maximum and minimum eigenvalues of the second moment of inertia tensor defined as

$I_{min}$ are the maximum and minimum eigenvalues of the second moment of inertia tensor defined as

where ![]() $\mathcal {V}_b$ is the volume of the particle, and

$\mathcal {V}_b$ is the volume of the particle, and ![]() $x_{io}$ and

$x_{io}$ and ![]() $x_{jo}$ are the coordinates of the particle centroid in the

$x_{jo}$ are the coordinates of the particle centroid in the ![]() $i{{\rm th}}$ and

$i{{\rm th}}$ and ![]() $j{{\rm th}}$ directions, respectively. Bunner & Tryggvason (Reference Bunner and Tryggvason2003) have shown that deformation quantified by this method is approximately equal to the ratio of the shortest to the longest axis for modestly deformed ellipsoids. However, for complex particle shapes, this definition of deformation gives a more general measure for the particle deformation and eliminates uncertainty in identifying the longest and the shortest axes.

$j{{\rm th}}$ directions, respectively. Bunner & Tryggvason (Reference Bunner and Tryggvason2003) have shown that deformation quantified by this method is approximately equal to the ratio of the shortest to the longest axis for modestly deformed ellipsoids. However, for complex particle shapes, this definition of deformation gives a more general measure for the particle deformation and eliminates uncertainty in identifying the longest and the shortest axes.

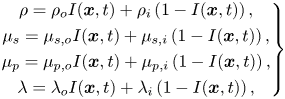

3. Governing equations and numerical method

The flow and the Giesekus model equations are described here in the context of the Eulerian–Lagrangian method that uses a one-field formulation. As discussed by Tryggvason, Scardovelli & Zaleski (Reference Tryggvason, Scardovelli and Zaleski2011), Ahmed et al. (Reference Ahmed, Izbassarov, Costa, Muradoglu and Tammisola2020a), Izbassarov et al. (Reference Izbassarov, Ahmed, Costa, Vuorinen, Tammisola and Muradoglu2021) and Izbassarov & Muradoglu (Reference Izbassarov and Muradoglu2015), one set of governing equations can be written for the entire multiphase computational domain. In this approach, the effect of surface tension is taken into account by adding a distributed body force term to the momentum equations near the interface, and the discontinuities in material properties are handled by defining an indicator function. The Navier–Stokes equations are thus written as

$$\begin{gather} \rho\frac{\partial \boldsymbol{u}}{\partial t} +{\rho} \boldsymbol{\nabla}\boldsymbol{\cdot}({\boldsymbol{u}}{\boldsymbol{u}}) =-\boldsymbol{\nabla}{p} -\frac{{\rm d}p_0}{{\rm d} y}\boldsymbol{j} +\boldsymbol{\nabla}\boldsymbol{\cdot}{\boldsymbol\tau} +\boldsymbol{\nabla}\boldsymbol{\cdot}\mu_s(\boldsymbol{\nabla}{{\boldsymbol{u}}}+\boldsymbol{\nabla}{{\boldsymbol{u}}^{\rm T}})+\boldsymbol{g}\left(\rho-\rho_{ave}\right) \nonumber\\ + \int_A \sigma\kappa\boldsymbol{n}\delta(\boldsymbol{x}-\boldsymbol{x}_f)\,{\rm d}A, \end{gather}$$

$$\begin{gather} \rho\frac{\partial \boldsymbol{u}}{\partial t} +{\rho} \boldsymbol{\nabla}\boldsymbol{\cdot}({\boldsymbol{u}}{\boldsymbol{u}}) =-\boldsymbol{\nabla}{p} -\frac{{\rm d}p_0}{{\rm d} y}\boldsymbol{j} +\boldsymbol{\nabla}\boldsymbol{\cdot}{\boldsymbol\tau} +\boldsymbol{\nabla}\boldsymbol{\cdot}\mu_s(\boldsymbol{\nabla}{{\boldsymbol{u}}}+\boldsymbol{\nabla}{{\boldsymbol{u}}^{\rm T}})+\boldsymbol{g}\left(\rho-\rho_{ave}\right) \nonumber\\ + \int_A \sigma\kappa\boldsymbol{n}\delta(\boldsymbol{x}-\boldsymbol{x}_f)\,{\rm d}A, \end{gather}$$

where ![]() ${\boldsymbol {u}}$,

${\boldsymbol {u}}$, ![]() $\boldsymbol {\tau }$,

$\boldsymbol {\tau }$, ![]() $p$,

$p$, ![]() $\rho$,

$\rho$, ![]() $\mu _s$ are the velocity vector, polymer stress tensor, pressure, discontinuous density and solvent viscosity fields, respectively. A constant pressure gradient

$\mu _s$ are the velocity vector, polymer stress tensor, pressure, discontinuous density and solvent viscosity fields, respectively. A constant pressure gradient ![]() $-({{\rm d}p_0}/{{\rm d} y})\boldsymbol {j}$ is applied to drive the flow where

$-({{\rm d}p_0}/{{\rm d} y})\boldsymbol {j}$ is applied to drive the flow where ![]() $\boldsymbol {j}$ is the unit vector in the

$\boldsymbol {j}$ is the unit vector in the ![]() $y$-direction. The buoyancy term consists of the gravitational acceleration

$y$-direction. The buoyancy term consists of the gravitational acceleration ![]() $\boldsymbol {g}$ and the density difference

$\boldsymbol {g}$ and the density difference ![]() $\rho -\rho _{ave}$, where

$\rho -\rho _{ave}$, where ![]() $\rho _{ave}$ is the average density in the computational domain. The effect of surface tension is added as a body force term on the right-hand side of the momentum equation where

$\rho _{ave}$ is the average density in the computational domain. The effect of surface tension is added as a body force term on the right-hand side of the momentum equation where ![]() $\sigma$ is the surface tension coefficient,

$\sigma$ is the surface tension coefficient, ![]() $\kappa$ is twice the mean curvature and

$\kappa$ is twice the mean curvature and ![]() $\boldsymbol {n}$ is a unit vector normal to the interface. As the surface tension acts only on the interface,

$\boldsymbol {n}$ is a unit vector normal to the interface. As the surface tension acts only on the interface, ![]() $\delta$ represents a three-dimensional Dirac delta function with the arguments

$\delta$ represents a three-dimensional Dirac delta function with the arguments ![]() $\boldsymbol {x}$ and

$\boldsymbol {x}$ and ![]() $\boldsymbol {x}_f$ being a point at which the equation is evaluated and a point at the interface, respectively. The momentum equation is supplemented by the continuity equation

$\boldsymbol {x}_f$ being a point at which the equation is evaluated and a point at the interface, respectively. The momentum equation is supplemented by the continuity equation

It is assumed that the material properties remain constant following a fluid particle, i.e.

where ![]() ${{\rm D}}/{{\rm D}t}= {\partial }/{\partial t} + \boldsymbol {u}\boldsymbol{\cdot}\nabla$ is the material derivative. For a viscoelastic fluid,

${{\rm D}}/{{\rm D}t}= {\partial }/{\partial t} + \boldsymbol {u}\boldsymbol{\cdot}\nabla$ is the material derivative. For a viscoelastic fluid, ![]() $\mu _p$ is the polymeric viscosity and

$\mu _p$ is the polymeric viscosity and ![]() $\lambda$ is the polymer relaxation time.

$\lambda$ is the polymer relaxation time.

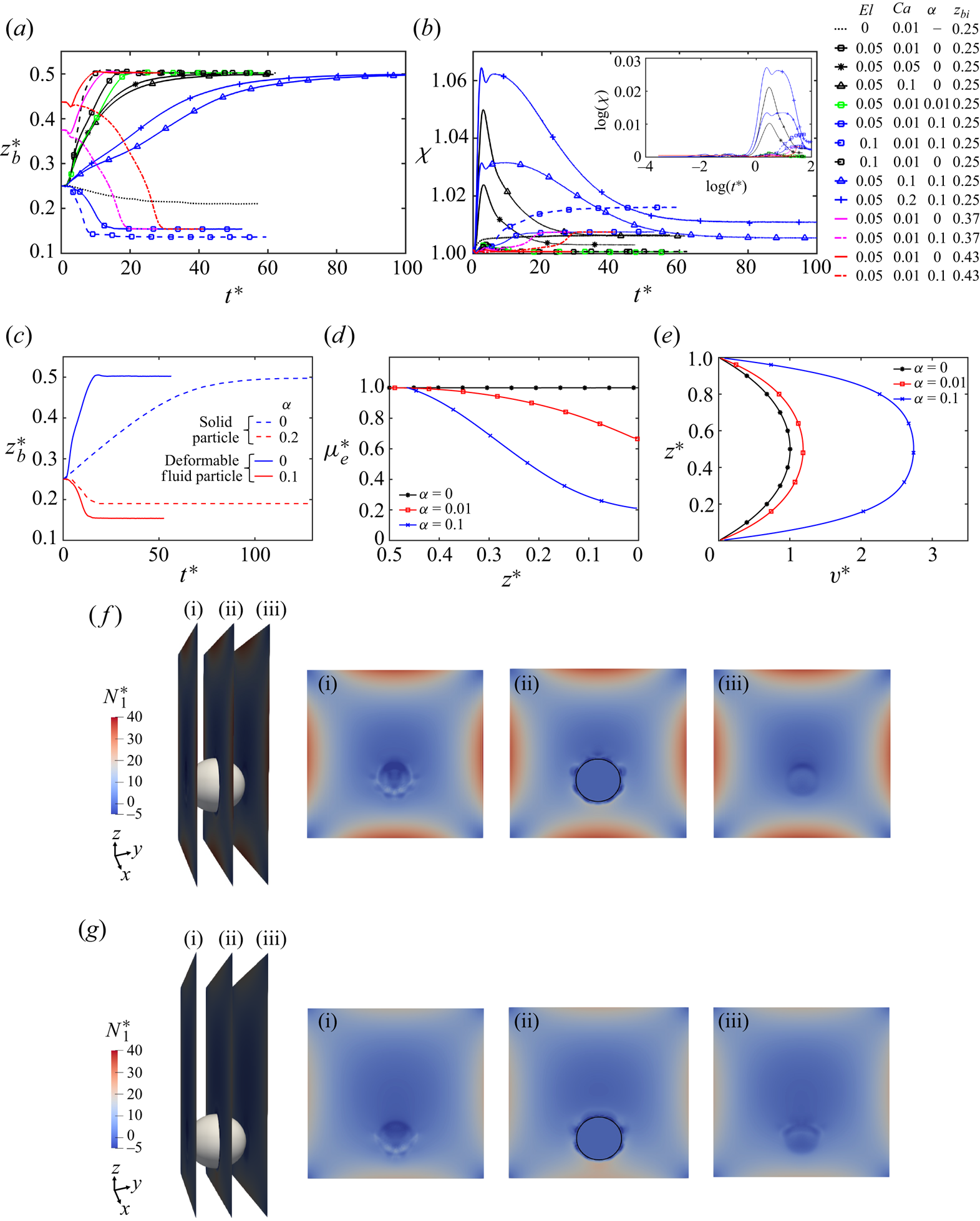

Using an indicator function (![]() $I$), the material properties are set in the entire computational domain as

$I$), the material properties are set in the entire computational domain as

\begin{equation} \left. \begin{gathered} \rho =\rho_{o}I({\boldsymbol{x}},t)+\rho_i\left(1-I({\boldsymbol{x}},t)\right),\\ \mu_s =\mu_{s,o}I({\boldsymbol{x}},t)+\mu_{s,i}\left(1-I({\boldsymbol{x}},t)\right),\\ \mu_p =\mu_{p,o}I({\boldsymbol{x}},t)+\mu_{p,i}\left(1-I({\boldsymbol{x}},t)\right),\\ \lambda =\lambda_{o}I({\boldsymbol{x}},t)+\lambda_i\left(1-I({\boldsymbol{x}},t)\right), \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \rho =\rho_{o}I({\boldsymbol{x}},t)+\rho_i\left(1-I({\boldsymbol{x}},t)\right),\\ \mu_s =\mu_{s,o}I({\boldsymbol{x}},t)+\mu_{s,i}\left(1-I({\boldsymbol{x}},t)\right),\\ \mu_p =\mu_{p,o}I({\boldsymbol{x}},t)+\mu_{p,i}\left(1-I({\boldsymbol{x}},t)\right),\\ \lambda =\lambda_{o}I({\boldsymbol{x}},t)+\lambda_i\left(1-I({\boldsymbol{x}},t)\right), \end{gathered} \right\} \end{equation}

where the subscripts ‘![]() $i$’ and ‘

$i$’ and ‘![]() $o$’ denote the properties of the particle and the bulk fluid, respectively. Since the fluid in the dispersed phase is Newtonian, the values of

$o$’ denote the properties of the particle and the bulk fluid, respectively. Since the fluid in the dispersed phase is Newtonian, the values of ![]() $\mu _{p,i}$ and

$\mu _{p,i}$ and ![]() $\lambda _i$ are set to zero. The indicator function is defined as

$\lambda _i$ are set to zero. The indicator function is defined as

Viscoelasticity of bulk liquid is modelled using the Giesekus model (Giesekus Reference Giesekus1982). This model is capable of capturing the elongation of individual polymer chains and the resulting shear-thinning behaviour of the viscoelastic fluid. In the Giesekus model, the polymer stress tensor ![]() $\boldsymbol {\tau }$ evolves by

$\boldsymbol {\tau }$ evolves by

where ![]() $\boldsymbol {B}$ and

$\boldsymbol {B}$ and ![]() $\boldsymbol {I}$ are the conformation and the identity tensors, respectively. The conformation tensor evolves by

$\boldsymbol {I}$ are the conformation and the identity tensors, respectively. The conformation tensor evolves by

where ![]() $\alpha$ is the mobility factor representing the anisotropy of the hydrodynamic drag exerted on the polymer molecules. Due to the thermodynamic considerations,

$\alpha$ is the mobility factor representing the anisotropy of the hydrodynamic drag exerted on the polymer molecules. Due to the thermodynamic considerations, ![]() $\alpha$ is restricted to

$\alpha$ is restricted to ![]() $0\le \alpha \le 0.5$ (Schleiniger & Weinacht Reference Schleiniger and Weinacht1991). When

$0\le \alpha \le 0.5$ (Schleiniger & Weinacht Reference Schleiniger and Weinacht1991). When ![]() $\alpha = 0$, the Giesekus model reduces to the Oldroyd-B model.

$\alpha = 0$, the Giesekus model reduces to the Oldroyd-B model.

At high Weissenberg numbers, these highly nonlinear viscoelastic constitutive equations become extremely stiff, which makes their numerical solution a challenging task. The problem is overcome by using the well-known log-conformation method where an eigen decomposition is employed to re-write the constitutive equation of the conformation tensor in terms of its logarithm (Izbassarov & Muradoglu Reference Izbassarov and Muradoglu2015; Izbassarov et al. Reference Izbassarov, Rosti, Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018). The interested readers are referred to Fattal & Kupferman (Reference Fattal and Kupferman2005) for the detailed procedure.

The flow equations (3.1) and (3.2) are solved fully coupled with the Giesekus model equation (3.6). The momentum, continuity and viscoelastic constitutive equations are solved on a stationary staggered Eulerian grid. A QUICK scheme is used to discretize the convective terms in the momentum equations while second-order central differences are used for the diffusive terms. For the convective terms in the viscoelastic equations, a fifth-order WENO-Z scheme (Borges, Carmona & Costa Reference Borges, Carmona, Costa and Don2008) is used. A fast Fourier transform (FFT)-based solver is used for the pressure Poisson equation. Since the pressure equation is not separable due to variable density in the present multiphase flow, the FFT-based solvers cannot be used directly. To overcome this challenge, a pressure-splitting technique presented by Dong & Shen (Reference Dong and Shen2012) and Dodd & Ferrante (Reference Dodd and Ferrante2014) is employed. The fluid–fluid interface is tracked by using the Lagrangian marker points located at the vertices of a triangular surface mesh. The marker points move with the local flow velocity interpolated from the Eulerian grid. The surface tension is computed on the Lagrangian grid and transferred to the Eulerian grid to be added to the momentum equation as a body force in a conservative manner. The Lagrangian grid is restructured at every time step to keep the surface mesh nearly uniform, smooth and comparable to the Eulerian grid. The indicator function is computed based on the location of the interface using the standard procedure as described by Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011), which requires a solution of a separable Poisson equation. The same FFT-based solver is used to compute the indicator function. Once the indicator function is computed, the material properties are set in each phase using (3.4), which results in a smooth transition of material properties across the interface. A predictor-corrector scheme is used to achieve second-order time accuracy as described by Tryggvason et al. (Reference Tryggvason, Bunner, Esmaeeli, Juric, Al-Rawahi, Tauber, Han, Nas and Jan2001). The details of this Eulerian–Lagrangian method can be found in the book by Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011) and in the review paper by Tryggvason et al. (Reference Tryggvason, Bunner, Esmaeeli, Juric, Al-Rawahi, Tauber, Han, Nas and Jan2001), and the treatment of the viscoelastic model equations in Izbassarov & Muradoglu (Reference Izbassarov and Muradoglu2015) and Izbassarov et al. (Reference Izbassarov, Rosti, Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018).

4. Results and discussions

We first examine the dynamics of a nearly spherical fluid particle under similar conditions as used by Li et al. (Reference Li, McKinley and Ardekani2015) for a solid particle, i.e. ![]() $Re=18.9, El=0.05, Ca=0.01, \alpha =0$. The main difference in the present case is the slip at the particle interface. Note that this set of parameters is also designated as the baseline case in the present study to facilitate direct comparison with the results obtained for a solid particle by Li et al. (Reference Li, McKinley and Ardekani2015).

$Re=18.9, El=0.05, Ca=0.01, \alpha =0$. The main difference in the present case is the slip at the particle interface. Note that this set of parameters is also designated as the baseline case in the present study to facilitate direct comparison with the results obtained for a solid particle by Li et al. (Reference Li, McKinley and Ardekani2015).

A peculiar feature of a viscoelastic fluid flow is the presence of normal stress differences, which are given by ![]() $N_1 = \tau _{yy} - \tau _{zz}$ and

$N_1 = \tau _{yy} - \tau _{zz}$ and ![]() $N_2 = \tau _{zz} - \tau _{xx}$ in the present scenario. In the absence of the shear-thinning effect (

$N_2 = \tau _{zz} - \tau _{xx}$ in the present scenario. In the absence of the shear-thinning effect (![]() $\alpha =0$), the Giesekus model reduces to the Oldroyd-B model and the second normal stress difference (

$\alpha =0$), the Giesekus model reduces to the Oldroyd-B model and the second normal stress difference (![]() $N_2$) becomes zero. Thus,

$N_2$) becomes zero. Thus, ![]() $\alpha >0$ is an essential condition to model a viscoelastic fluid that exhibits a non-zero second normal stress difference. The geometry of the channel also plays a significant role in the development of these stresses. Here,

$\alpha >0$ is an essential condition to model a viscoelastic fluid that exhibits a non-zero second normal stress difference. The geometry of the channel also plays a significant role in the development of these stresses. Here, ![]() $N_1$ is found to be maximum in the highest shear region near the walls, and its value becomes minimum in the corners and at the centre. Ho & Leal (Reference Ho and Leal1976) argued that this particular distribution of

$N_1$ is found to be maximum in the highest shear region near the walls, and its value becomes minimum in the corners and at the centre. Ho & Leal (Reference Ho and Leal1976) argued that this particular distribution of ![]() $N_1$ in a four-wall channel is the primary reason for the accumulation of solid particles in the corner and centreline regions. When the second normal stress difference develops in a shear-thinning viscoelastic fluid, not only does the distribution of

$N_1$ in a four-wall channel is the primary reason for the accumulation of solid particles in the corner and centreline regions. When the second normal stress difference develops in a shear-thinning viscoelastic fluid, not only does the distribution of ![]() $N_1$ in the channel change, but its magnitude is also reduced due to enhanced inertial effects (Li et al. Reference Li, McKinley and Ardekani2015). Figure 1(a) shows the distribution of

$N_1$ in the channel change, but its magnitude is also reduced due to enhanced inertial effects (Li et al. Reference Li, McKinley and Ardekani2015). Figure 1(a) shows the distribution of ![]() $N_2$ in the channel cross-section when there is a strong shear-thinning effect present in the flow, i.e.

$N_2$ in the channel cross-section when there is a strong shear-thinning effect present in the flow, i.e. ![]() $\alpha =0.1$. Eight vortices generated due to this distribution of

$\alpha =0.1$. Eight vortices generated due to this distribution of ![]() $N_2$ away from the particle are also depicted in figure 1(b). This particular distribution of

$N_2$ away from the particle are also depicted in figure 1(b). This particular distribution of ![]() $N_2$ affects the orientation of particle migration and the development of a secondary flow field around the particle. An asymmetric pattern of streamlines is shown in figure 1(a) above the particle once the particle reaches its equilibrium position near the wall. These effects on the lateral migration of a deformable particle are explored one by one in the subsequent sections.

$N_2$ affects the orientation of particle migration and the development of a secondary flow field around the particle. An asymmetric pattern of streamlines is shown in figure 1(a) above the particle once the particle reaches its equilibrium position near the wall. These effects on the lateral migration of a deformable particle are explored one by one in the subsequent sections.

4.1. Dynamics of particle migration

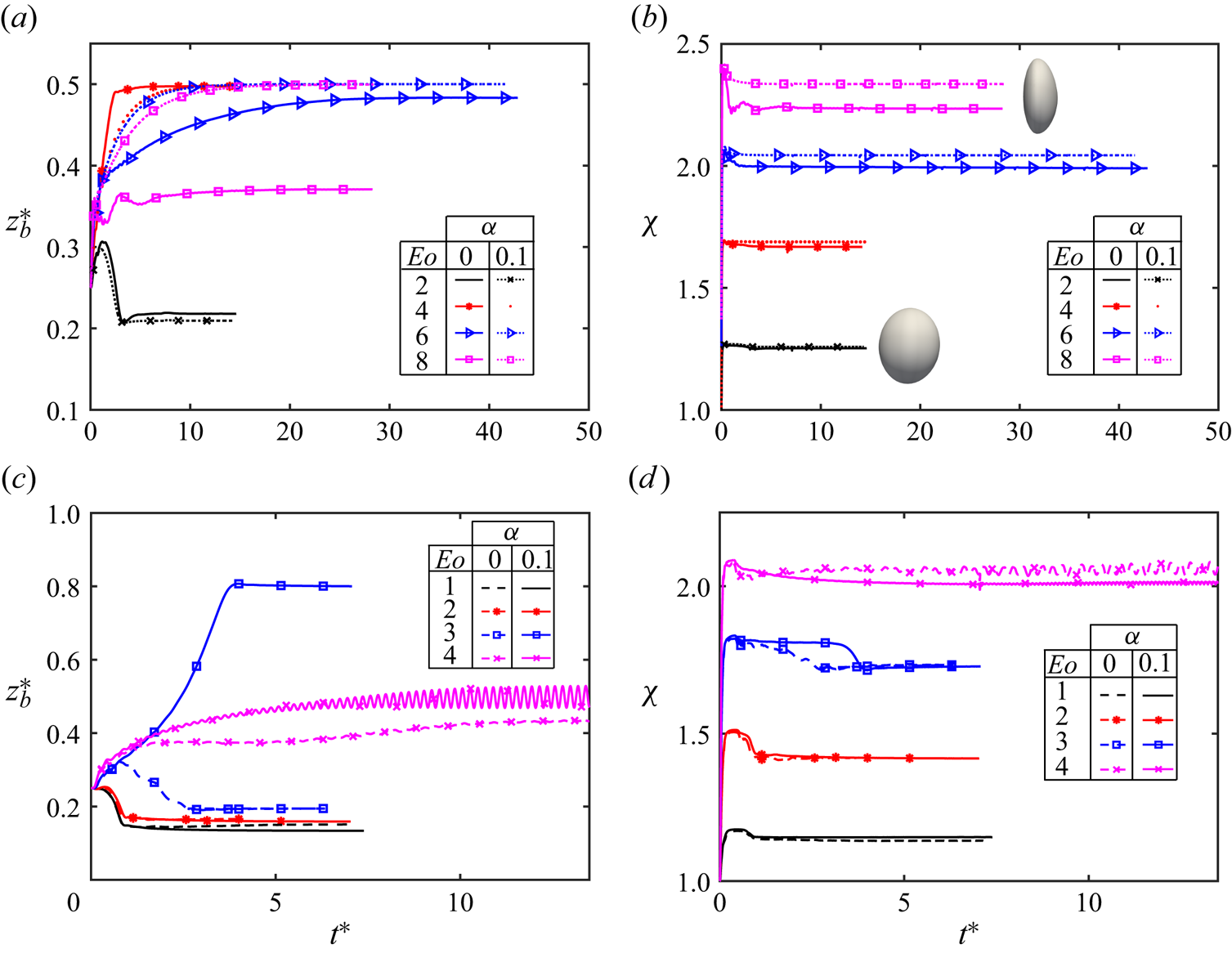

Simulations are first performed to examine the effects of the Weissenberg number, the capillary number, the initial position and the mobility factor on the lateral migration of a non-buoyant particle in the channel flow at the nominal Reynolds number ![]() $Re = 18.9$ and

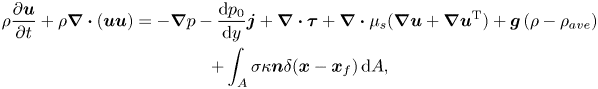

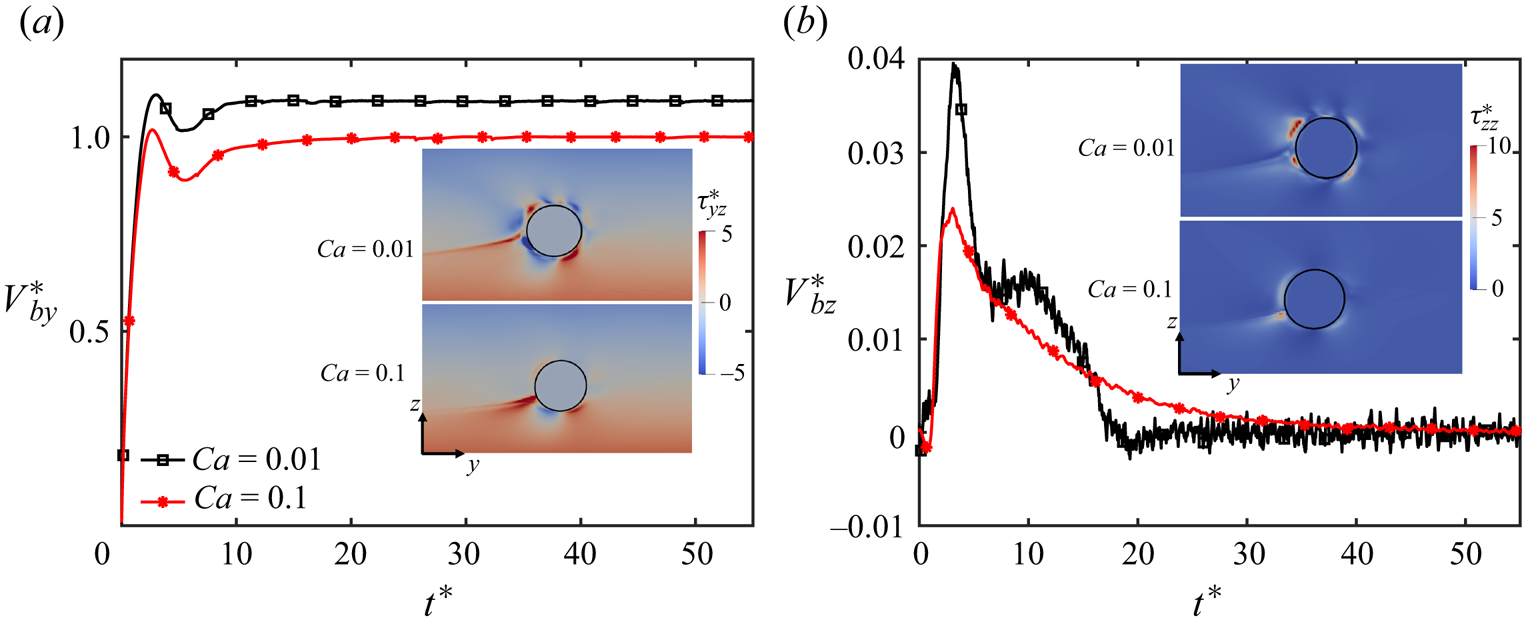

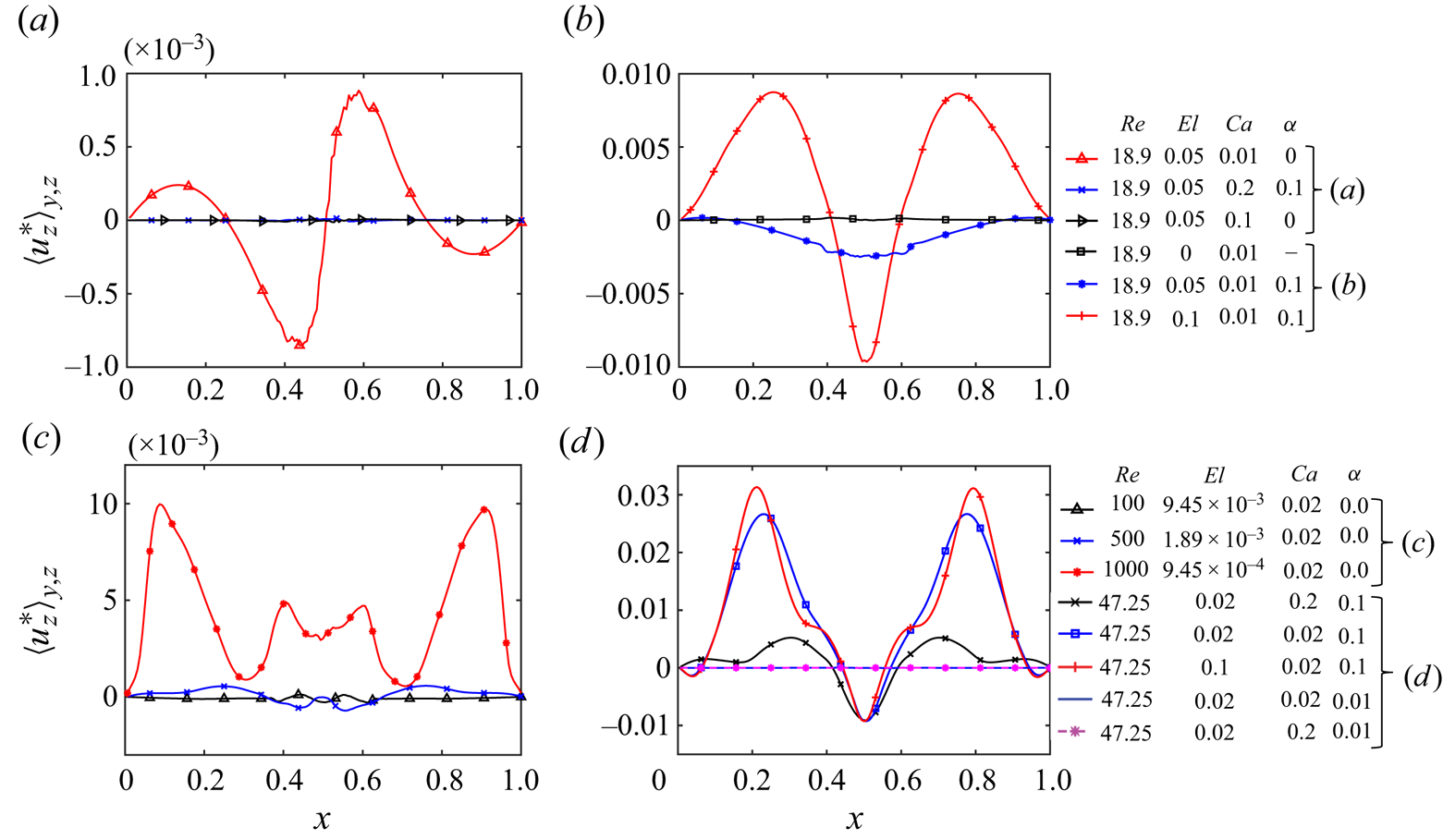

$Re = 18.9$ and ![]() $\beta =0.1$. Figures 2(a) and 2(b) show the evolution of particle displacement in the lateral (

$\beta =0.1$. Figures 2(a) and 2(b) show the evolution of particle displacement in the lateral (![]() $z$) direction and the corresponding change in the particle deformation during its migration, respectively. In a Newtonian fluid, a nearly spherical particle slightly moves towards the channel wall under the effects of inertia and stabilizes near the wall where wall-induced repulsive force balances the lift force. When the ambient fluid is viscoelastic, modelled by Oldroyd-B (

$z$) direction and the corresponding change in the particle deformation during its migration, respectively. In a Newtonian fluid, a nearly spherical particle slightly moves towards the channel wall under the effects of inertia and stabilizes near the wall where wall-induced repulsive force balances the lift force. When the ambient fluid is viscoelastic, modelled by Oldroyd-B (![]() $\alpha = 0$), the same spherical particle moves towards the centre of the channel under the elastic effects just like a solid particle (Li et al. Reference Li, McKinley and Ardekani2015). It is observed that although the overall trend of fluid particle displacement in the Oldroyd-B fluid is similar to that of a solid particle, the fluid particle moves towards the centre of the channel at a much higher rate as shown in figure 2(c). Compared with a solid particle, a fluid particle experiences a smaller drag due to slip at the interface, which makes it more sensitive to the inertial and elastic effects. When the particle deformability is increased gradually by increasing the capillary number to

$\alpha = 0$), the same spherical particle moves towards the centre of the channel under the elastic effects just like a solid particle (Li et al. Reference Li, McKinley and Ardekani2015). It is observed that although the overall trend of fluid particle displacement in the Oldroyd-B fluid is similar to that of a solid particle, the fluid particle moves towards the centre of the channel at a much higher rate as shown in figure 2(c). Compared with a solid particle, a fluid particle experiences a smaller drag due to slip at the interface, which makes it more sensitive to the inertial and elastic effects. When the particle deformability is increased gradually by increasing the capillary number to ![]() $Ca = 0.05$ and

$Ca = 0.05$ and ![]() $Ca = 0.1$ for the same Oldroyd-B fluid, the rate of particle migration towards the channel centre is slightly reduced. As the particle moves towards the low shear region (towards the centre), its deformability starts to reduce and the same effect is observed in its lateral velocity as well. The effects on particle velocity will be discussed in detail later in § 4.5. It is interesting to observe that, although the deformability-induced lift force is expected to push the particle towards the centre, it acts in the opposite direction at this Reynolds number and slows down the particle migration towards the centre of the channel. Evolution of streamwise and wall normal velocities of the spherical and the slightly deformable particle are shown in figure 3, where the constant contours of viscoelastic stress components of

$Ca = 0.1$ for the same Oldroyd-B fluid, the rate of particle migration towards the channel centre is slightly reduced. As the particle moves towards the low shear region (towards the centre), its deformability starts to reduce and the same effect is observed in its lateral velocity as well. The effects on particle velocity will be discussed in detail later in § 4.5. It is interesting to observe that, although the deformability-induced lift force is expected to push the particle towards the centre, it acts in the opposite direction at this Reynolds number and slows down the particle migration towards the centre of the channel. Evolution of streamwise and wall normal velocities of the spherical and the slightly deformable particle are shown in figure 3, where the constant contours of viscoelastic stress components of ![]() $\tau _{yz}$ and

$\tau _{yz}$ and ![]() $\tau _{zz}$ are also plotted in the insets in the

$\tau _{zz}$ are also plotted in the insets in the ![]() $yz$-cutting plane. As seen, not only the wall-normal velocity but also the streamwise velocity is reduced when the particle is made slightly deformed by increasing the capillary number to

$yz$-cutting plane. As seen, not only the wall-normal velocity but also the streamwise velocity is reduced when the particle is made slightly deformed by increasing the capillary number to ![]() $Ca=0.1$, although the deformation is still modest, i.e.

$Ca=0.1$, although the deformation is still modest, i.e. ![]() $\chi \approx 1.05$. The viscoelastic stress distribution is also markedly different in both cases. This extreme sensitivity is attributed to a similar mechanism that is responsible for a jump discontinuity in the rise velocity of a buoyancy-driven bubble (Bothe et al. Reference Bothe, Niethammer, Pilz and Brenn2022). A different manifestation of the same mechanism has also been observed in our earlier work (Naseer et al. Reference Naseer, Ahmed, Izbassarov and Muradoglu2023) as well. According to the theory proposed by Bothe et al. (Reference Bothe, Niethammer, Pilz and Brenn2022), polymer molecules are stretched by the flow as they pass over the particle and this stored elastic energy is released on its front/back hemisphere giving an additional pull/push to the particle depending on the flow conditions. The transition is expected to occur when the convective time scale is equal to the polymer relaxation time, i.e. the effective Weissenberg number is unity. In the present scenario, the effective Weissenberg number can be defined as

$\chi \approx 1.05$. The viscoelastic stress distribution is also markedly different in both cases. This extreme sensitivity is attributed to a similar mechanism that is responsible for a jump discontinuity in the rise velocity of a buoyancy-driven bubble (Bothe et al. Reference Bothe, Niethammer, Pilz and Brenn2022). A different manifestation of the same mechanism has also been observed in our earlier work (Naseer et al. Reference Naseer, Ahmed, Izbassarov and Muradoglu2023) as well. According to the theory proposed by Bothe et al. (Reference Bothe, Niethammer, Pilz and Brenn2022), polymer molecules are stretched by the flow as they pass over the particle and this stored elastic energy is released on its front/back hemisphere giving an additional pull/push to the particle depending on the flow conditions. The transition is expected to occur when the convective time scale is equal to the polymer relaxation time, i.e. the effective Weissenberg number is unity. In the present scenario, the effective Weissenberg number can be defined as ![]() $Wi_{eff}={\lambda }/{(R/u_{rel})}$, where

$Wi_{eff}={\lambda }/{(R/u_{rel})}$, where ![]() $R$ is the particle radius and

$R$ is the particle radius and ![]() $u_{rel}$ is the slip velocity. For the nearly spherical particle, the effective Weissenberg number is computed as

$u_{rel}$ is the slip velocity. For the nearly spherical particle, the effective Weissenberg number is computed as ![]() $Wi_{eff}= 0.92$ at

$Wi_{eff}= 0.92$ at ![]() $t^*=5.53$ which is close to the critical value of unity. As the particle is elongated in the streamwise direction in the deformable case, the effective radius (minor axis) becomes larger so the polymer molecules relax on the front part of the particle before reaching the equator, which thus increases the drag and slows down the particle migration velocity.

$t^*=5.53$ which is close to the critical value of unity. As the particle is elongated in the streamwise direction in the deformable case, the effective radius (minor axis) becomes larger so the polymer molecules relax on the front part of the particle before reaching the equator, which thus increases the drag and slows down the particle migration velocity.

Figure 2. (a) Evolution of fluid particle displacement in the wall-normal (![]() $z$) direction under non-buoyant conditions for different initial positions and flow conditions. (b) Corresponding change in the particle deformation shown as the particle moves towards or away from the wall. The same plot is shown in the inset on a log-scale. (c) Evolution of the fluid particle displacement compared with a solid particle studied by Li et al. (Reference Li, McKinley and Ardekani2015) under similar flow conditions. (d) Reduction in the effective viscosity of the fluid due to shear thinning quantified in a vertical cutting

$z$) direction under non-buoyant conditions for different initial positions and flow conditions. (b) Corresponding change in the particle deformation shown as the particle moves towards or away from the wall. The same plot is shown in the inset on a log-scale. (c) Evolution of the fluid particle displacement compared with a solid particle studied by Li et al. (Reference Li, McKinley and Ardekani2015) under similar flow conditions. (d) Reduction in the effective viscosity of the fluid due to shear thinning quantified in a vertical cutting ![]() $xz$-plane away from the particle. (e) Flow velocity profiles in the same

$xz$-plane away from the particle. (e) Flow velocity profiles in the same ![]() $xz$-plane shown for different values of

$xz$-plane shown for different values of ![]() $\alpha$. The distributions of the first normal stress difference (

$\alpha$. The distributions of the first normal stress difference (![]() $N_1$) around the particle are shown in vertical cutting planes of (i), (ii) and (iii) as indicated on the left for (f)

$N_1$) around the particle are shown in vertical cutting planes of (i), (ii) and (iii) as indicated on the left for (f) ![]() $\alpha =0.01$ and for (g)

$\alpha =0.01$ and for (g) ![]() $\alpha =0.1$. For panels (c–g),

$\alpha =0.1$. For panels (c–g), ![]() $El=0.05, Ca=0.01$. Additionally,

$El=0.05, Ca=0.01$. Additionally, ![]() $Re=18.9$ for all the cases presented in this figure.

$Re=18.9$ for all the cases presented in this figure.

Figure 3. Evolution of migration velocity of a nearly spherical (![]() $Ca=0.01$) and a slightly deformed (

$Ca=0.01$) and a slightly deformed (![]() $Ca=0.1$) fluid particle (a) in the streamwise and (b) in the wall-normal directions. The contours of viscoelastic stress components

$Ca=0.1$) fluid particle (a) in the streamwise and (b) in the wall-normal directions. The contours of viscoelastic stress components ![]() $\tau _{yz}$ and

$\tau _{yz}$ and ![]() $\tau _{zz}$ are shown in the insets around the particles in the

$\tau _{zz}$ are shown in the insets around the particles in the ![]() $yz$-cutting plane at

$yz$-cutting plane at ![]() $t^*=5.53$ (

$t^*=5.53$ (![]() $Re=18.9, El=0.05, \alpha =0$).

$Re=18.9, El=0.05, \alpha =0$).

When the shear-thinning effects are enhanced by increasing the mobility parameter (![]() $\alpha$) in the Giesekus model, the orientation of particle migration changes due to an increase in the relative importance of the fluid inertia. At a very small value of

$\alpha$) in the Giesekus model, the orientation of particle migration changes due to an increase in the relative importance of the fluid inertia. At a very small value of ![]() $\alpha =0.01$, a spherical particle still moves towards the centre but it takes a comparatively longer time than that in the Oldroyd-B fluid to reach its equilibrium position. Once

$\alpha =0.01$, a spherical particle still moves towards the centre but it takes a comparatively longer time than that in the Oldroyd-B fluid to reach its equilibrium position. Once ![]() $\alpha$ is increased further to

$\alpha$ is increased further to ![]() $0.1$, the orientation of particle migration changes completely, i.e. instead of moving towards the centre, it starts moving towards the wall. Again, although the trend is similar to that of a solid particle in a shear-thinning fluid under the same parametric settings, the migration of a fluid particle is significantly more sensitive to the shear-thinning parameter than the corresponding solid particle. For example, while

$0.1$, the orientation of particle migration changes completely, i.e. instead of moving towards the centre, it starts moving towards the wall. Again, although the trend is similar to that of a solid particle in a shear-thinning fluid under the same parametric settings, the migration of a fluid particle is significantly more sensitive to the shear-thinning parameter than the corresponding solid particle. For example, while ![]() $\alpha = 0.2$ is required by the solid particle to reverse its orientation from the channel centre towards the wall (Li et al. Reference Li, McKinley and Ardekani2015),

$\alpha = 0.2$ is required by the solid particle to reverse its orientation from the channel centre towards the wall (Li et al. Reference Li, McKinley and Ardekani2015), ![]() $\alpha =0.1$ is sufficient for the fluid particle to reverse its orientation. The shear-thinning effect is quantified by the reduction in the effective viscosity (

$\alpha =0.1$ is sufficient for the fluid particle to reverse its orientation. The shear-thinning effect is quantified by the reduction in the effective viscosity (![]() $\mu _{e}$) of the fluid defined as

$\mu _{e}$) of the fluid defined as

\begin{equation} \mu_e/\mu_o = \frac{\mu_s\left(\dfrac{\partial v}{\partial z}+\dfrac{\partial w}{\partial y}\right)+\tau_{yz}}{\mu_o\left(\dfrac{\partial v}{\partial z}+\dfrac{\partial w}{\partial y}\right)}. \end{equation}

\begin{equation} \mu_e/\mu_o = \frac{\mu_s\left(\dfrac{\partial v}{\partial z}+\dfrac{\partial w}{\partial y}\right)+\tau_{yz}}{\mu_o\left(\dfrac{\partial v}{\partial z}+\dfrac{\partial w}{\partial y}\right)}. \end{equation}

The variation of the effective viscosity and the corresponding flow velocity profiles are shown in figures 2(d) and 2(e), respectively, for ![]() $\alpha =0$, 0.01 and 0.1. As seen, for

$\alpha =0$, 0.01 and 0.1. As seen, for ![]() $\alpha = 0$, the effective viscosity remains constant in the channel as expected. In a shear-thinning fluid (

$\alpha = 0$, the effective viscosity remains constant in the channel as expected. In a shear-thinning fluid (![]() $\alpha >0$), the viscosity of the fluid decreases significantly in the high shear region near the wall and becomes as low as

$\alpha >0$), the viscosity of the fluid decreases significantly in the high shear region near the wall and becomes as low as ![]() $20\,\%$ of its value in the channel centre for

$20\,\%$ of its value in the channel centre for ![]() $\alpha =0.1$. As a result, the centreline flow velocity becomes approximately

$\alpha =0.1$. As a result, the centreline flow velocity becomes approximately ![]() $2.8$ times larger than that of the non-shear-thinning fluid (figure 2e). This enhanced inertia helps the quick migration of the particle towards the wall as seen in figure 2(a). It is observed that this shear-thinning effect is strong enough to reverse the migration of fluid particle from the centre towards the wall even when the initial position of the particle is shifted gradually towards the channel centre, i.e. a low shear region (figure 2a). The shear thinning also changes the distribution of the first normal stress difference (

$2.8$ times larger than that of the non-shear-thinning fluid (figure 2e). This enhanced inertia helps the quick migration of the particle towards the wall as seen in figure 2(a). It is observed that this shear-thinning effect is strong enough to reverse the migration of fluid particle from the centre towards the wall even when the initial position of the particle is shifted gradually towards the channel centre, i.e. a low shear region (figure 2a). The shear thinning also changes the distribution of the first normal stress difference (![]() $N_1$) in the channel. The distribution of

$N_1$) in the channel. The distribution of ![]() $N_1$ is shown in three vertical cutting planes in the vicinity of the particle for

$N_1$ is shown in three vertical cutting planes in the vicinity of the particle for ![]() $\alpha =0.01$ and

$\alpha =0.01$ and ![]() $\alpha =0.1$ in figures 2(f) and 2(g), respectively, at the same time instant

$\alpha =0.1$ in figures 2(f) and 2(g), respectively, at the same time instant ![]() $t^*=5.71$. The higher magnitude of

$t^*=5.71$. The higher magnitude of ![]() $N_1$ for

$N_1$ for ![]() $\alpha =0.01$ explains why the particle is pushed towards the channel centre. It is important to note that in the present study, as the channel aspect ratio is fixed (square duct only) and the initial position of the fluid particle is varied along one wall-normal direction (

$\alpha =0.01$ explains why the particle is pushed towards the channel centre. It is important to note that in the present study, as the channel aspect ratio is fixed (square duct only) and the initial position of the fluid particle is varied along one wall-normal direction (![]() $z$) only while the initial position of the particle is fixed at

$z$) only while the initial position of the particle is fixed at ![]() $x=0.5H$ in the second wall-normal direction, the equilibrium positions of the fluid particle along the channel diagonals or in the corner regions are not observed (Yu et al. Reference Yu, Wang, Lin and Hu2019).

$x=0.5H$ in the second wall-normal direction, the equilibrium positions of the fluid particle along the channel diagonals or in the corner regions are not observed (Yu et al. Reference Yu, Wang, Lin and Hu2019).

When the elasticity number is increased to ![]() $El = 0.1$ by increasing the Weissenberg number in the presence of a strong shear-thinning effect (

$El = 0.1$ by increasing the Weissenberg number in the presence of a strong shear-thinning effect (![]() $\alpha =0.1$) for a spherical particle (

$\alpha =0.1$) for a spherical particle (![]() $Ca = 0.01$), the viscoelastic stresses take more time to develop due to a higher relaxation time (

$Ca = 0.01$), the viscoelastic stresses take more time to develop due to a higher relaxation time (![]() $\lambda$) of polymer molecules. Therefore, the enhanced inertia due to the shear thinning quickly moves the particle towards the wall while the viscoelastic stresses are not yet fully developed in the flow. The particle reaches its equilibrium position closer to the wall and its deformation also increases due to a higher shear region there. However, this higher deformability and higher elasticity are not strong enough to reverse the particle migration back towards the channel centre. In the absence of the shear thinning (

$\lambda$) of polymer molecules. Therefore, the enhanced inertia due to the shear thinning quickly moves the particle towards the wall while the viscoelastic stresses are not yet fully developed in the flow. The particle reaches its equilibrium position closer to the wall and its deformation also increases due to a higher shear region there. However, this higher deformability and higher elasticity are not strong enough to reverse the particle migration back towards the channel centre. In the absence of the shear thinning (![]() $\alpha =0$) with the same high elasticity number, the particle quickly moves towards the centre due to relatively lower inertia.

$\alpha =0$) with the same high elasticity number, the particle quickly moves towards the centre due to relatively lower inertia.

When the fluid particle is made more deformable by increasing the capillary number to ![]() $Ca=0.1$ (figure 2b) in this shear-thinning fluid (

$Ca=0.1$ (figure 2b) in this shear-thinning fluid (![]() $\alpha =0.1$), the deformability-induced lift force resists the pronounced effects of shear thinning on the fluid inertia. This higher particle deformation is sufficient enough to push the particle back towards the channel centre. However, due to the resistance by the higher inertial force, the rate of particle migration is much slower in this fluid than in the non-shear-thinning fluid. When the capillary number is increased even further to

$\alpha =0.1$), the deformability-induced lift force resists the pronounced effects of shear thinning on the fluid inertia. This higher particle deformation is sufficient enough to push the particle back towards the channel centre. However, due to the resistance by the higher inertial force, the rate of particle migration is much slower in this fluid than in the non-shear-thinning fluid. When the capillary number is increased even further to ![]() $Ca=0.2$, the effect is found to be more pronounced and the rate of particle migration towards the centre of the channel is slightly increased. The enhanced fluid inertia due to the shear-thinning effect also makes the particle more deformable in a shear-thinning fluid due to an effective high capillary number.

$Ca=0.2$, the effect is found to be more pronounced and the rate of particle migration towards the centre of the channel is slightly increased. The enhanced fluid inertia due to the shear-thinning effect also makes the particle more deformable in a shear-thinning fluid due to an effective high capillary number.

For all the simulations shown in figure 2, the nominal Reynolds number is kept constant. It can be observed that in this non-buoyant situation, the orientation of particle migration can be controlled with the shear-thinning effect of the viscoelastic fluid. With a strong shear-thinning effect (![]() $\alpha =0.1$), the particle moves towards the wall and higher elasticity (e.g.

$\alpha =0.1$), the particle moves towards the wall and higher elasticity (e.g. ![]() $El=0.1$) is not able to reverse its orientation. The higher particle deformability, however, resists this shear-thinning effect on particle migration and moves it back towards the centre. Interestingly, the particle deformation increases only by

$El=0.1$) is not able to reverse its orientation. The higher particle deformability, however, resists this shear-thinning effect on particle migration and moves it back towards the centre. Interestingly, the particle deformation increases only by ![]() $6\,\%$ in the case of the maximum capillary number of

$6\,\%$ in the case of the maximum capillary number of ![]() $Ca=0.2$ in this viscoelastic fluid. However, even this modest deformation makes a significant impact on the dynamics of particle migration and reverses its orientation towards the centre. In the absence of shear thinning, the particle migrates towards the centre even with a weak elastic effect or with a little deformability.

$Ca=0.2$ in this viscoelastic fluid. However, even this modest deformation makes a significant impact on the dynamics of particle migration and reverses its orientation towards the centre. In the absence of shear thinning, the particle migrates towards the centre even with a weak elastic effect or with a little deformability.

4.2. Path instability

Path instability of a freely rising bubble in a Newtonian fluid has been thoroughly studied and well documented in the existing literature. For instance, Zenit & Magnaudet (Reference Zenit and Magnaudet2008) experimentally observed that the path instability of a bubble does not depend on the Reynolds number and it is rather governed by the aspect ratio of bubble shape, i.e. its deformation. When the aspect ratio increases beyond ![]() $\chi > 2$, vortices generated on the free-slip surface of the bubble give rise to a wake instability behind the trailing edge, forcing its path to become unstable. In the case of a viscoelastic ambient fluid, Shew & Pinton (Reference Shew and Pinton2006) observed that the flow structure in the wake region becomes more intense leading to path instability even at a much lower deformability.

$\chi > 2$, vortices generated on the free-slip surface of the bubble give rise to a wake instability behind the trailing edge, forcing its path to become unstable. In the case of a viscoelastic ambient fluid, Shew & Pinton (Reference Shew and Pinton2006) observed that the flow structure in the wake region becomes more intense leading to path instability even at a much lower deformability.

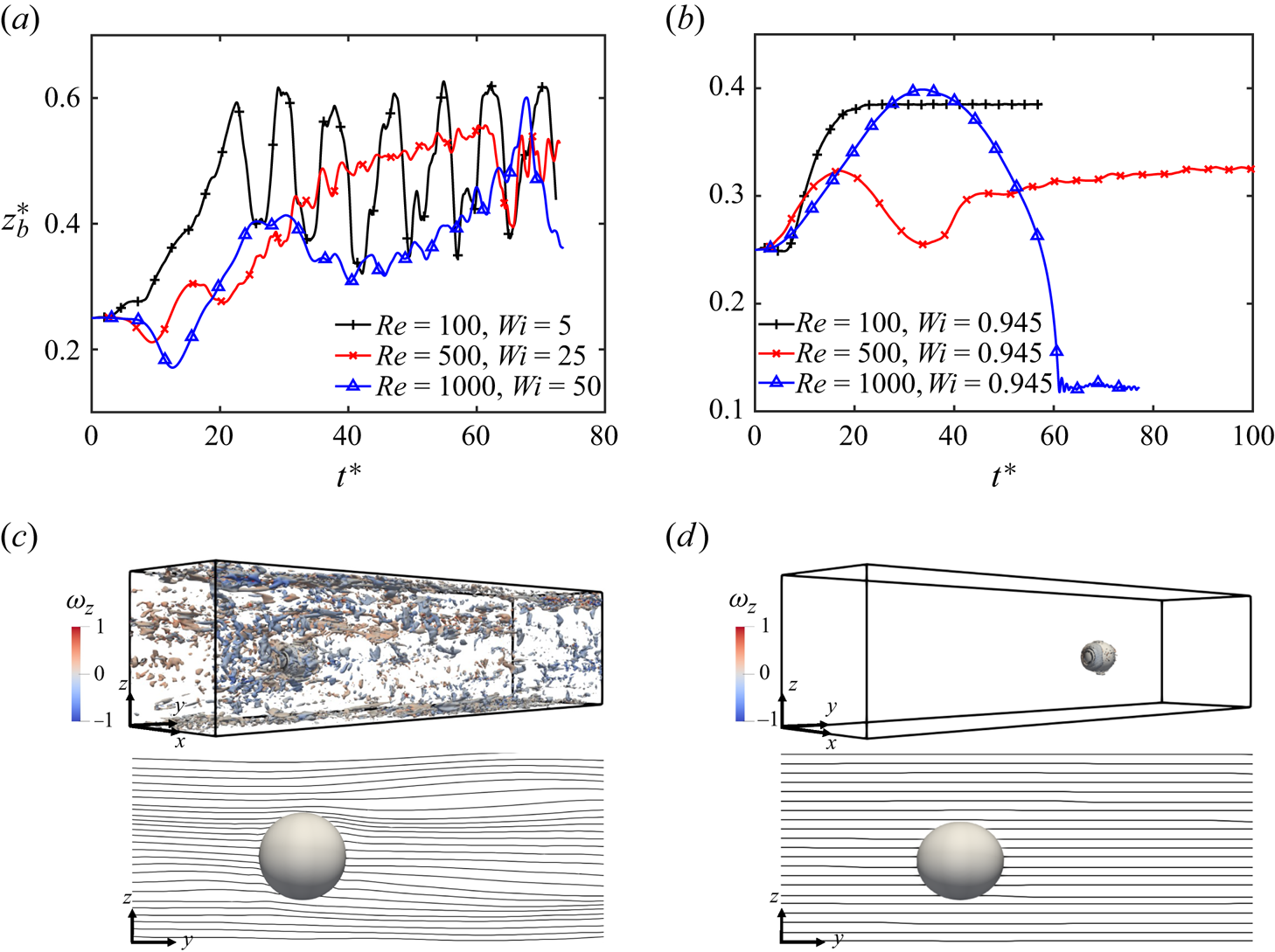

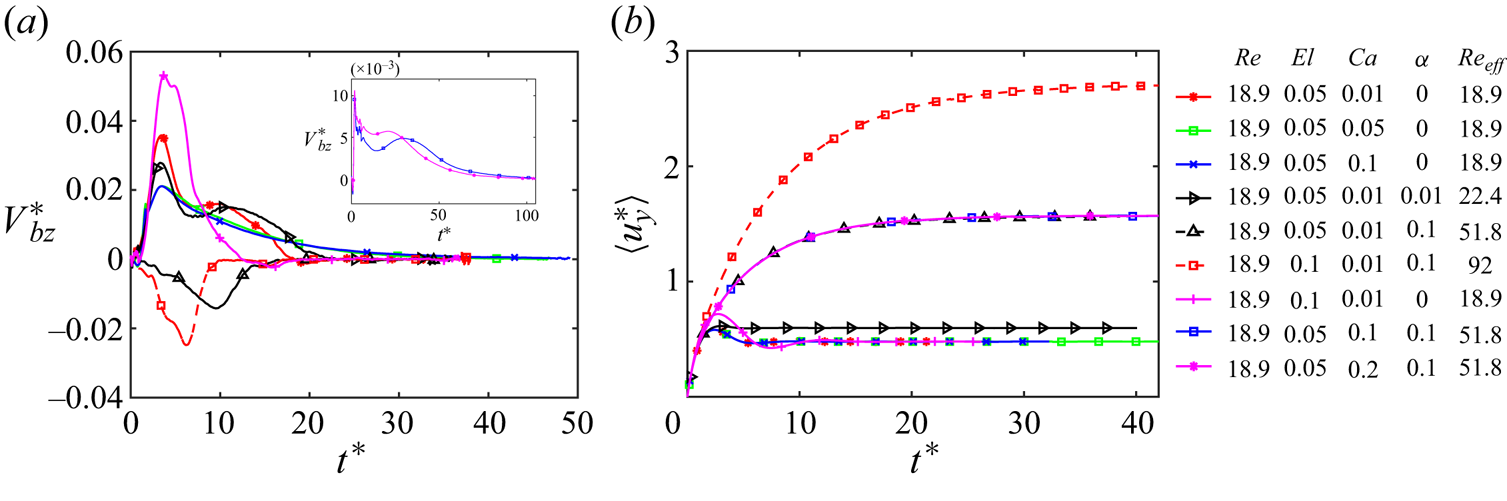

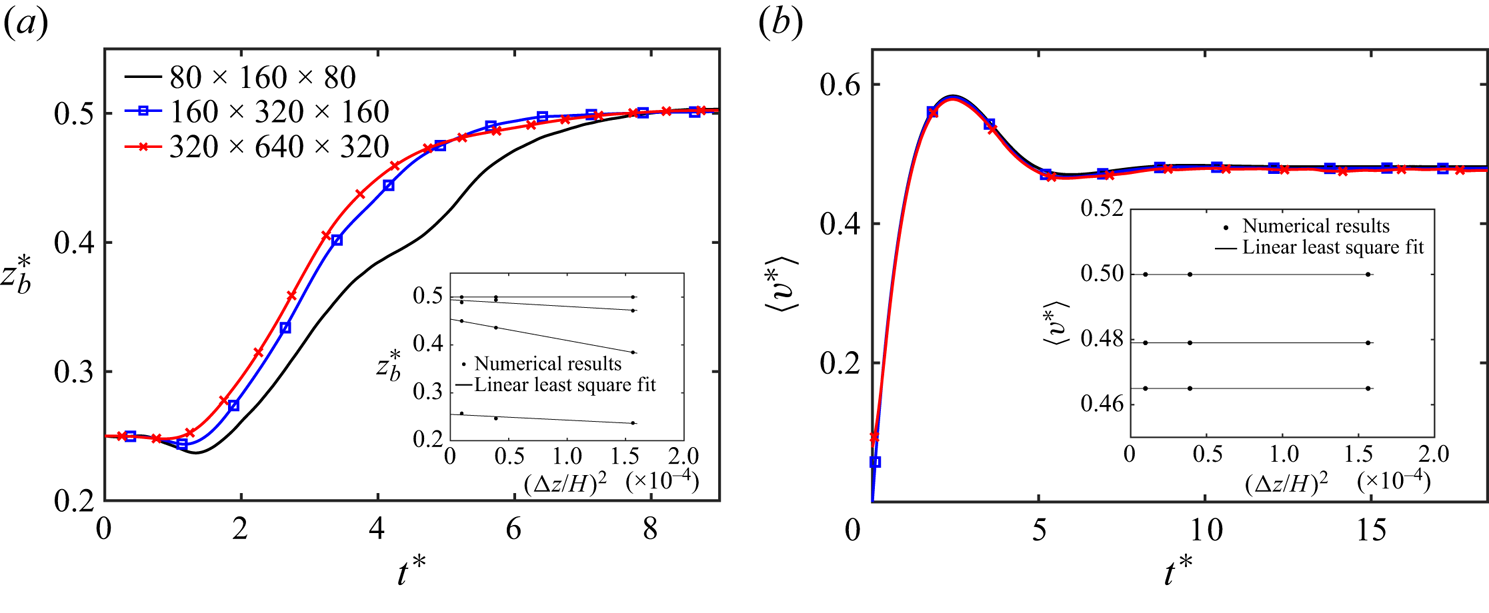

Simulations are first performed for ![]() $Re=100$,

$Re=100$, ![]() $500$ and

$500$ and ![]() $1000$ to examine the effects of the Reynolds number on the path instability of the deformable fluid particle in the present pressure-driven viscoelastic flow in the absence of buoyancy. To isolate the effects of the Reynolds number, the shear-thinning effect is eliminated by setting

$1000$ to examine the effects of the Reynolds number on the path instability of the deformable fluid particle in the present pressure-driven viscoelastic flow in the absence of buoyancy. To isolate the effects of the Reynolds number, the shear-thinning effect is eliminated by setting ![]() $\alpha =0$, and the capillary number is fixed at

$\alpha =0$, and the capillary number is fixed at ![]() $Ca=0.01$ to keep the particle nearly spherical. Simulations are repeated by keeping either the elasticity number or the Weissenberg number constant as the Reynolds number is increased. The results are summarized in figures 4(a,c) and 4(b,d) for the fixed elasticity number and the fixed Weissenberg number cases, respectively. When the elasticity number is kept constant at

$Ca=0.01$ to keep the particle nearly spherical. Simulations are repeated by keeping either the elasticity number or the Weissenberg number constant as the Reynolds number is increased. The results are summarized in figures 4(a,c) and 4(b,d) for the fixed elasticity number and the fixed Weissenberg number cases, respectively. When the elasticity number is kept constant at ![]() $El=0.05$ (figure 4a), the Weissenberg number increases as the Reynolds number is increased. The particle path becomes unstable at

$El=0.05$ (figure 4a), the Weissenberg number increases as the Reynolds number is increased. The particle path becomes unstable at ![]() $Re=100$ (the corresponding

$Re=100$ (the corresponding ![]() $Wi=5$). However, the particle deformation remains negligible due to a low value of the capillary number. The path instability observed in this case of a nearly spherical particle at

$Wi=5$). However, the particle deformation remains negligible due to a low value of the capillary number. The path instability observed in this case of a nearly spherical particle at ![]() $Re=100$ occurs mainly due to the onset of an elastic flow instability caused by the curved streamlines along the particle interface. McKinley, Pakdel & Öztekin (Reference McKinley, Pakdel and Öztekin1996) determined a critical parameter for the onset of an elastic instability as

$Re=100$ occurs mainly due to the onset of an elastic flow instability caused by the curved streamlines along the particle interface. McKinley, Pakdel & Öztekin (Reference McKinley, Pakdel and Öztekin1996) determined a critical parameter for the onset of an elastic instability as

where ![]() $U$ is the flow velocity along the streamline,

$U$ is the flow velocity along the streamline, ![]() $N_1$ is the first normal stress difference,

$N_1$ is the first normal stress difference, ![]() $R$ is the radius of curvature of the streamline and

$R$ is the radius of curvature of the streamline and ![]() $\tau _t$ is the total shear stress. McKinley et al. (Reference McKinley, Pakdel and Öztekin1996) calculated the critical value for a two-dimensional cylinder as

$\tau _t$ is the total shear stress. McKinley et al. (Reference McKinley, Pakdel and Öztekin1996) calculated the critical value for a two-dimensional cylinder as ![]() $M_{crit}\approx 6.08$. In the present scenario of a spherical fluid particle, the critical value turns out to be

$M_{crit}\approx 6.08$. In the present scenario of a spherical fluid particle, the critical value turns out to be ![]() $M_{crit}\approx 5.59$ at

$M_{crit}\approx 5.59$ at ![]() $Re=100$. The constant contours of the Q-criterion (second invariant of velocity gradient tensor) at

$Re=100$. The constant contours of the Q-criterion (second invariant of velocity gradient tensor) at ![]() $0.001$ and the streamlines are also plotted around the particle in figure 4(c) for

$0.001$ and the streamlines are also plotted around the particle in figure 4(c) for ![]() $Re=500$ to show the overall flow structure. The contours are coloured by the magnitude of vorticity in the

$Re=500$ to show the overall flow structure. The contours are coloured by the magnitude of vorticity in the ![]() $z$-direction. The curvature of streamlines across the particle and the contours of the Q-criterion confirm that the flow is no longer stable. As a result, the particle path shows an oscillatory pattern around the channel centre for

$z$-direction. The curvature of streamlines across the particle and the contours of the Q-criterion confirm that the flow is no longer stable. As a result, the particle path shows an oscillatory pattern around the channel centre for ![]() $Re=100$. When the Weissenberg number is increased further by increasing the Reynolds number at the fixed value of

$Re=100$. When the Weissenberg number is increased further by increasing the Reynolds number at the fixed value of ![]() $El=0.05$, figure 4(a) shows that the particle path becomes more irregular and unpredictable as the flow gets closer to the onset of elastic turbulence stemming from the elastic instability. The exact mechanism behind this probable transition is still elusive (Datta et al. Reference Datta2022).

$El=0.05$, figure 4(a) shows that the particle path becomes more irregular and unpredictable as the flow gets closer to the onset of elastic turbulence stemming from the elastic instability. The exact mechanism behind this probable transition is still elusive (Datta et al. Reference Datta2022).

Figure 4. Evolution of lateral migration of the fluid particle (a) at constant ![]() $El=0.05$ and (b) at constant

$El=0.05$ and (b) at constant ![]() $Wi=0.945$ are shown for different values of Reynolds number. (c) Constant contours of Q-criterion at

$Wi=0.945$ are shown for different values of Reynolds number. (c) Constant contours of Q-criterion at ![]() $0.001$ coloured by the vorticity component (

$0.001$ coloured by the vorticity component (![]() $\omega _z$) shown for

$\omega _z$) shown for ![]() $Re=500, Wi=25$ as the flow becomes elastically unstable due to the curvature of streamlines across the particle. (d) Contours of Q-criterion plotted at the same value of

$Re=500, Wi=25$ as the flow becomes elastically unstable due to the curvature of streamlines across the particle. (d) Contours of Q-criterion plotted at the same value of ![]() $0.001$ for

$0.001$ for ![]() $Re=500, Wi=0.945$ showing a negligible presence, confirming a stable flow. This is also confirmed by the straight streamlines across the fluid particle.

$Re=500, Wi=0.945$ showing a negligible presence, confirming a stable flow. This is also confirmed by the straight streamlines across the fluid particle.

However, when the Weissenberg number is kept constant at ![]() $Wi=0.945$ as

$Wi=0.945$ as ![]() $Re$ is increased, the particle path remains stable even for the Reynolds number as high as

$Re$ is increased, the particle path remains stable even for the Reynolds number as high as ![]() $Re=1000$. As shown in figure 4(d), the streamlines remain straight across the particle and no significant contours of Q-criterion are observed in the flow, unlike the fixed elasticity number case. It is interesting to observe that the particle initially moves towards the channel centreline and then reverses its direction towards the channel wall at higher Reynolds numbers. The final position is determined by the interplay of inertial and viscoelastic effects. The equilibrium position of the particle shifts from the channel centre towards the wall as the Reynolds number is increased (figure 4b). At

$Re=1000$. As shown in figure 4(d), the streamlines remain straight across the particle and no significant contours of Q-criterion are observed in the flow, unlike the fixed elasticity number case. It is interesting to observe that the particle initially moves towards the channel centreline and then reverses its direction towards the channel wall at higher Reynolds numbers. The final position is determined by the interplay of inertial and viscoelastic effects. The equilibrium position of the particle shifts from the channel centre towards the wall as the Reynolds number is increased (figure 4b). At ![]() $Re=1000$, the particle reaches the wall under the influence of strong inertia, which results in an increase in its deformation as well due to the high-shear region near the wall.

$Re=1000$, the particle reaches the wall under the influence of strong inertia, which results in an increase in its deformation as well due to the high-shear region near the wall.

4.3. Effect of buoyancy

The buoyancy is significant in many natural processes and practical applications. A commonly encountered situation is an upward flow where the gravity acts in the opposite direction of the fluid flow such as in bubble column reactors and in crude oil extraction. Simulations are next performed for a range of Eötvös numbers to examine the effects of buoyancy in an upward flow while keeping the other parameters fixed at their baseline values of ![]() $Re=18.9$,

$Re=18.9$, ![]() $Ca=0.01$ and

$Ca=0.01$ and ![]() $El=0.05$. Note that the Morton number is

$El=0.05$. Note that the Morton number is ![]() $M=4.97 \times 10^{-6}$ for

$M=4.97 \times 10^{-6}$ for ![]() $Eo = 1$ in this viscoelastic fluid. For reference, this value is much higher than the Morton number of

$Eo = 1$ in this viscoelastic fluid. For reference, this value is much higher than the Morton number of ![]() $2.52 \times 10^{-11}$ for an air particle in water at

$2.52 \times 10^{-11}$ for an air particle in water at ![]() $20\,^\circ$C but can be matched by using a water–glycerin solution (Legendre, Zenit & Velez-Cordero Reference Legendre, Zenit and Velez-Cordero2012).

$20\,^\circ$C but can be matched by using a water–glycerin solution (Legendre, Zenit & Velez-Cordero Reference Legendre, Zenit and Velez-Cordero2012).

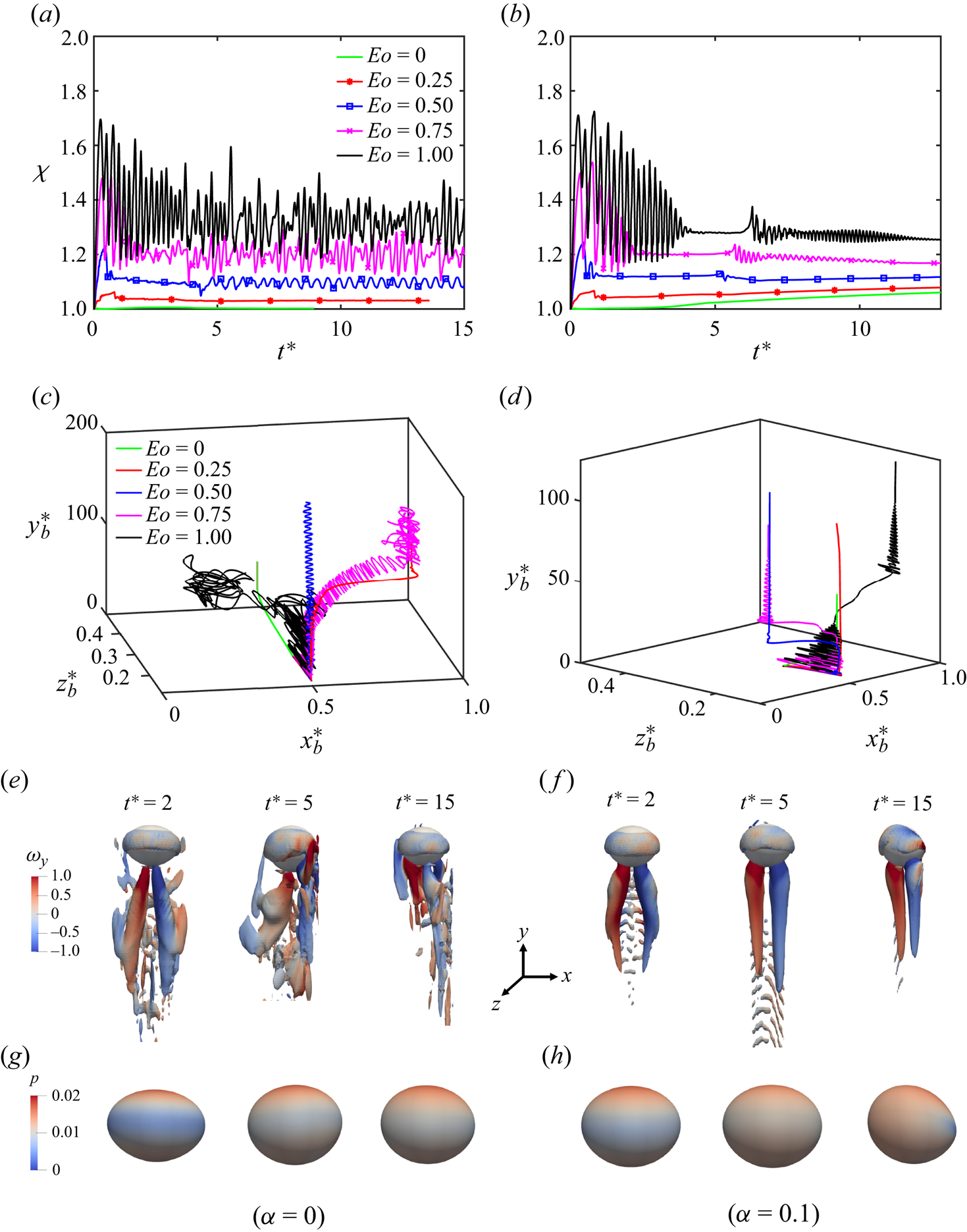

Simulations are performed by gradually increasing the Eötvös number from ![]() $Eo=0$ (neutrally buoyant) to

$Eo=0$ (neutrally buoyant) to ![]() $Eo=1$ without and with the shear-thinning effect. The case of

$Eo=1$ without and with the shear-thinning effect. The case of ![]() $Eo=0$ is simulated by setting

$Eo=0$ is simulated by setting ![]() ${\boldsymbol g}=0$, which can be realistic only in a microgravity environment. This condition is used here to isolate the sole effects of the other parameters from buoyancy. The results are shown in figures 5(a,c,e,g) and 5(b,d,f,h) in terms of the evolution of particle deformation, its three-dimensional displacement, the wake structure behind the particle, and the pressure distribution on the particle surface for an Oldroyd-B (

${\boldsymbol g}=0$, which can be realistic only in a microgravity environment. This condition is used here to isolate the sole effects of the other parameters from buoyancy. The results are shown in figures 5(a,c,e,g) and 5(b,d,f,h) in terms of the evolution of particle deformation, its three-dimensional displacement, the wake structure behind the particle, and the pressure distribution on the particle surface for an Oldroyd-B (![]() $\alpha =0$) and a Giesekus (

$\alpha =0$) and a Giesekus (![]() $\alpha =0.1$) fluid case, respectively. In the Oldroyd-B fluid, the particle moves towards the channel wall without any sign of path instability at

$\alpha =0.1$) fluid case, respectively. In the Oldroyd-B fluid, the particle moves towards the channel wall without any sign of path instability at ![]() $Eo=0.25$. We note that the same particle moves towards the channel centre in the absence of buoyancy. This change in the orientation occurs due to the additional buoyancy-induced lift force (Lu, Biswas & Tryggvason Reference Lu, Biswas and Tryggvason2006). At

$Eo=0.25$. We note that the same particle moves towards the channel centre in the absence of buoyancy. This change in the orientation occurs due to the additional buoyancy-induced lift force (Lu, Biswas & Tryggvason Reference Lu, Biswas and Tryggvason2006). At ![]() $Eo=0.5$, the particle still migrates towards a channel wall (interestingly not to the same wall as in the

$Eo=0.5$, the particle still migrates towards a channel wall (interestingly not to the same wall as in the ![]() $Eo=0.25$ case) but small oscillations start to appear in its path with a regular zigzag pattern indicating the onset of a path instability. A similar oscillatory pattern is also visible in the particle deformation (

$Eo=0.25$ case) but small oscillations start to appear in its path with a regular zigzag pattern indicating the onset of a path instability. A similar oscillatory pattern is also visible in the particle deformation (![]() $\chi$) as seen in figure 5(a). When