Published online by Cambridge University Press: 28 November 2023

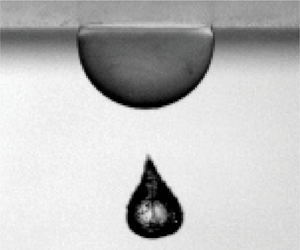

We investigate experimentally and theoretically the interactions between a cavitation bubble and a hemispherical pendant oil droplet immersed in water. In experiments, the cavitation bubble is generated by a focused laser pulse right below the pendant droplet with well-controlled bubble–wall distances and bubble–droplet size ratios. By high-speed imaging, four typical interactions are observed, namely: oil droplet rupture; water droplet entrapment; oil droplet large deformation; and oil droplet mild deformation. The bubble jetting at the end of collapse and the migration of the bubble centroid are particularly different in each bubble–droplet interaction. We propose theoretical models based on the method of images for calculating the Kelvin impulse and the anisotropy parameter which quantitatively reflects the migration of the bubble centroid at the end of the collapse. Finally, we explain that a combination of the Weber number and the anisotropy parameter determines the regimes of the bubble–droplet interactions.